This type of enterprise concentrates on designing, developing, and manufacturing aircraft, spacecraft, satellites, and related systems. Such organizations often encompass a wide range of activities, from initial concept and prototyping to full-scale production and testing of complex aerospace technologies. As an illustration, a firm might be responsible for the entire lifecycle of a commercial airliner, from initial design specifications to final assembly and ongoing maintenance support.

The significance of these entities stems from their contributions to advancements in air travel, space exploration, national defense, and scientific research. They facilitate global connectivity, enable the study of our universe, and contribute to economic growth through job creation and technological innovation. Historically, these organizations have played a pivotal role in shaping the course of aviation and spaceflight, leading to breakthroughs in materials science, propulsion systems, and avionics.

The core functions these companies undertake have far-reaching impact. The following sections will delve into specific aspects, including design processes, manufacturing techniques, regulatory compliance, and future trends within the industry.

The following guidelines offer insights into choosing an aerospace engineering entity, emphasizing factors critical to project success and long-term partnerships.

Tip 1: Evaluate Core Competencies: A thorough assessment of technical expertise within specialized areas is crucial. Examine past projects and demonstrated capabilities in areas such as aerodynamics, propulsion, structural analysis, and systems engineering to ensure alignment with project requirements.

Tip 2: Assess Regulatory Compliance: Confirm adherence to stringent aerospace industry standards and certifications. Verifying compliance with regulations from organizations like the FAA, EASA, or relevant national authorities is non-negotiable for safe and legal operation.

Tip 3: Review Project Management Methodologies: Effective project management is vital for timely and cost-efficient project completion. Understanding the firm’s processes for planning, execution, monitoring, and risk mitigation is critical.

Tip 4: Analyze Quality Assurance Protocols: Rigorous quality control measures are essential for producing reliable and safe aerospace components and systems. Scrutinize the firm’s quality assurance processes, testing procedures, and defect resolution protocols.

Tip 5: Investigate Research and Development Capabilities: The ability to innovate and adapt to evolving technological landscapes is a key indicator of long-term viability. Consider the entity’s investments in research, development, and its track record of implementing new technologies.

Tip 6: Examine Facilities and Resources: The availability of modern facilities, specialized equipment, and skilled personnel is essential for successful project execution. Assess the entity’s infrastructure and its ability to handle complex manufacturing and testing requirements.

Tip 7: Consider Communication and Collaboration: Open and transparent communication channels are vital for effective collaboration. Evaluate the firm’s responsiveness, communication protocols, and ability to integrate with existing teams.

Careful consideration of these factors enables informed decision-making and fosters successful collaborations, contributing to the advancement of aerospace technology and capabilities.

The subsequent sections will address the future challenges and opportunities facing the aerospace industry, emphasizing the role of innovative partnerships in navigating these complexities.

1. Design and Innovation

Design and innovation are foundational elements of any successful aerospace engineering entity. These functions drive the creation of new technologies, improve existing systems, and enable the advancement of aerospace capabilities. The capacity for innovation directly influences an organization’s competitiveness and its ability to address evolving industry challenges.

- Conceptual Design and Feasibility Studies

This phase involves the generation of initial concepts for aircraft, spacecraft, or related systems. Feasibility studies assess the technical and economic viability of these concepts, considering factors such as performance requirements, cost constraints, and regulatory limitations. Successful outcomes at this stage dictate whether a project progresses to detailed design and development.

- Advanced Materials Research

The utilization of advanced materials, such as composites, alloys, and ceramics, is critical for enhancing the performance and reducing the weight of aerospace structures. Research in this area focuses on developing materials with improved strength-to-weight ratios, temperature resistance, and corrosion resistance. These advancements directly impact fuel efficiency, payload capacity, and operational lifespan.

- Propulsion System Innovation

Propulsion systems are a primary area of innovation within the aerospace sector. Development efforts concentrate on improving the efficiency, thrust-to-weight ratio, and environmental impact of engines and rocket motors. Innovations in this field encompass advanced combustion techniques, alternative fuels, and electric propulsion systems, each contributing to enhanced performance and reduced emissions.

- Avionics and Control Systems Development

The design and development of sophisticated avionics and control systems are essential for safe and efficient aircraft operation. This area includes innovations in flight control algorithms, navigation systems, sensor technologies, and human-machine interfaces. These advancements enhance pilot situational awareness, reduce workload, and improve overall flight safety.

These facets of design and innovation collectively determine the technological capabilities of an aerospace engineering entity. Investments in research and development, coupled with a culture of innovation, are crucial for maintaining a competitive edge and addressing the future challenges of the aerospace industry. The translation of innovative concepts into tangible products and systems ultimately drives progress and economic growth within the sector.

2. Manufacturing Expertise

Manufacturing expertise forms a critical component within aerospace engineering entities. It bridges the gap between conceptual designs and tangible aerospace products. The capabilities in this domain dictate the quality, reliability, and performance of aircraft, spacecraft, and related systems.

- Precision Machining and Fabrication

Aerospace components often demand exacting tolerances and intricate geometries. Manufacturing expertise encompasses advanced machining techniques, such as CNC milling and turning, as well as specialized fabrication processes for lightweight and high-strength materials. The ability to consistently produce parts within specified parameters directly impacts the structural integrity and operational effectiveness of aerospace vehicles. For example, the precise machining of turbine blades in jet engines is crucial for maintaining optimal performance and preventing catastrophic failures.

- Composite Manufacturing

Composite materials, such as carbon fiber reinforced polymers, are increasingly prevalent in aerospace applications due to their high strength-to-weight ratios. Expertise in composite manufacturing includes layup techniques, curing processes, and non-destructive testing methods to ensure structural integrity. The manufacturing of aircraft wings and fuselage sections often relies heavily on composite materials to reduce weight and improve fuel efficiency.

- Additive Manufacturing (3D Printing)

Additive manufacturing offers the potential to create complex aerospace components with reduced material waste and lead times. Expertise in this area includes selecting appropriate materials and printing parameters, as well as post-processing techniques to achieve desired mechanical properties. Examples include the 3D printing of engine nozzles and lightweight structural components.

- Quality Control and Inspection

Stringent quality control measures are essential for ensuring the safety and reliability of aerospace products. Manufacturing expertise encompasses the implementation of rigorous inspection procedures, including non-destructive testing, dimensional verification, and material analysis. These processes are critical for detecting defects and preventing failures throughout the product lifecycle.

These facets of manufacturing expertise are integral to the success of any aerospace engineering organization. The ability to translate designs into high-quality, reliable products directly impacts the performance, safety, and economic viability of aerospace systems. Continuous improvement in manufacturing processes, coupled with investments in advanced technologies, is essential for maintaining a competitive edge in the industry.

3. Regulatory Compliance

For an aerospace engineering entity, adherence to regulatory compliance represents a non-negotiable operational imperative. Stringent regulations, dictated by international bodies and national aviation authorities, govern every stage of the aerospace product lifecycle, from initial design to manufacturing, testing, and in-service maintenance. Non-compliance can trigger severe consequences, ranging from project delays and financial penalties to operational grounding and reputational damage. For example, a failure to meet FAA standards in the design of a commercial aircraft’s wing could result in a denial of certification, effectively halting production and jeopardizing the company’s financial stability.

The intricacies of regulatory compliance extend to diverse areas, including airworthiness directives, environmental regulations, and safety management systems. These regulations aim to ensure the safety of passengers and crew, protect the environment, and maintain the integrity of the aerospace system. Aerospace firms must therefore invest significantly in resources and expertise to navigate this complex regulatory landscape. This includes establishing robust quality assurance programs, maintaining detailed documentation, and conducting regular audits to ensure ongoing compliance. An example would be the detailed record-keeping required for every component used in an aircraft, tracing its origin, manufacturing process, and testing history to ensure traceability and accountability.

Ultimately, regulatory compliance forms an integral part of the core business strategy for any aerospace engineering organization. It is not merely a legal obligation but rather a fundamental element of responsible engineering practice. Companies that prioritize compliance not only mitigate risks but also enhance their credibility and build trust with customers, regulators, and the public. As the aerospace industry continues to evolve, proactive engagement with regulatory bodies and a commitment to continuous improvement in compliance practices will be essential for long-term success.

4. Systems Integration

Systems integration is a core function within any successful aerospace engineering enterprise. It represents the process of combining individual components and subsystems into a cohesive, functional aerospace system. The ability to effectively integrate diverse elements, such as avionics, propulsion, structures, and control systems, is paramount for achieving desired performance characteristics and ensuring mission success. Consider the development of a modern commercial aircraft; an aerospace engineering organization must orchestrate the integration of thousands of individual components, ensuring seamless interaction between the flight control system, navigation system, engine management system, and passenger comfort systems. This integration process demands meticulous planning, rigorous testing, and adherence to stringent safety standards. Failure in systems integration can manifest as performance degradation, system malfunctions, or, in extreme cases, catastrophic failures.

Aerospace engineering firms employ a range of methodologies to ensure effective systems integration. Model-based systems engineering (MBSE) is increasingly utilized to create digital models of the system architecture, enabling early detection of potential integration issues. Hardware-in-the-loop (HIL) simulation allows for real-time testing of embedded systems within a simulated operating environment. Flight testing represents the ultimate validation of systems integration, providing critical data on system performance under real-world conditions. The development of the James Webb Space Telescope provides a relevant example. This complex system required the integration of advanced optics, cryogenic cooling systems, and intricate deployment mechanisms. The success of the mission hinges on the flawless integration of these disparate elements, which was achieved through extensive testing and simulation.

Effective systems integration not only enhances the performance and reliability of aerospace systems but also reduces development costs and shortens time-to-market. By identifying and resolving integration issues early in the development cycle, aerospace engineering companies can avoid costly redesigns and delays. The ability to deliver integrated solutions that meet customer requirements and regulatory standards is a key differentiator in the competitive aerospace market. The integration of autonomous flight control systems into unmanned aerial vehicles (UAVs) provides a final example. This integration requires the seamless interaction of sensors, algorithms, and actuators, enabling UAVs to perform complex missions without human intervention. The successful integration of these systems demonstrates the capabilities of an aerospace engineering company to deliver cutting-edge technological solutions.

5. Project Management

Project management constitutes a pivotal function within aerospace engineering organizations. It encompasses the structured planning, execution, monitoring, and control of complex projects aimed at developing and delivering aerospace products and services. Effective project management ensures that these projects are completed on time, within budget, and in accordance with stringent quality and safety requirements.

- Requirements Definition and Scope Management

This phase involves the detailed specification of project objectives, deliverables, and constraints. Within an aerospace engineering context, it necessitates a thorough understanding of customer needs, regulatory requirements, and technological limitations. For instance, defining the requirements for a new satellite launch vehicle includes specifying payload capacity, orbital parameters, reliability targets, and budget constraints. A well-defined scope minimizes the risk of scope creep, ensuring that resources are focused on delivering the core objectives of the project.

- Schedule Development and Resource Allocation

Creating a realistic project schedule and allocating resources effectively are essential for meeting project deadlines. Aerospace projects often involve numerous interdependent tasks and require specialized expertise and equipment. Developing a schedule for the design and manufacture of a new aircraft engine necessitates coordinating the activities of design engineers, manufacturing specialists, testing personnel, and supply chain partners. Efficient resource allocation minimizes delays and cost overruns, ensuring that the project remains on track.

- Risk Management and Mitigation

Aerospace projects are inherently complex and subject to various risks, including technical challenges, supply chain disruptions, and regulatory changes. Identifying and mitigating these risks proactively is crucial for project success. Developing contingency plans for potential engine failures during flight testing or addressing potential delays in the delivery of critical components requires a systematic approach to risk assessment and mitigation. Effective risk management minimizes the impact of unforeseen events and ensures project continuity.

- Quality Assurance and Configuration Management

Maintaining stringent quality standards and managing project configurations are critical for ensuring the safety and reliability of aerospace products. Implementing robust quality control procedures and managing changes to design specifications require a comprehensive approach to quality assurance and configuration management. Traceability of components, rigorous testing protocols, and adherence to industry standards are essential for delivering aerospace systems that meet or exceed customer expectations.

These facets underscore the integral role of project management in aerospace engineering. By effectively managing project scope, schedules, risks, and quality, aerospace engineering organizations can deliver innovative solutions while adhering to stringent safety and regulatory requirements. The convergence of these project management components directly influences the capacity to propel projects to successful completion, while maintaining the highest standards of the aerospace industry.

Frequently Asked Questions About Aerospace Engineering Entities

The following addresses common queries concerning the operation, scope, and impact of organizations specializing in aerospace engineering.

Question 1: What distinguishes an aerospace engineering entity from other engineering firms?

Aerospace engineering organizations focus primarily on the design, development, and manufacturing of aircraft, spacecraft, and related systems. Their work necessitates specialized expertise in areas such as aerodynamics, propulsion, materials science, and avionics, often involving strict adherence to regulatory standards specific to the aerospace sector.

Question 2: How does an aerospace engineering organization contribute to advancements in air travel?

These entities contribute through the design of more fuel-efficient aircraft, the development of advanced navigation systems, and the implementation of innovative safety features. These advancements lead to reduced operating costs, enhanced passenger comfort, and improved overall safety in air transportation.

Question 3: What role does an aerospace engineering entity play in space exploration?

They are instrumental in designing and building spacecraft, satellites, and launch vehicles essential for space exploration missions. This includes developing propulsion systems, life support systems, and communication systems that enable the exploration of other planets and the study of the universe.

Question 4: How do these enterprises approach ensuring safety and reliability in their products?

Safety and reliability are paramount. Organizations employ rigorous testing protocols, adhere to strict quality control measures, and implement redundancy in critical systems. Compliance with industry regulations and standards is also essential to minimizing risk and ensuring the safe operation of aerospace vehicles.

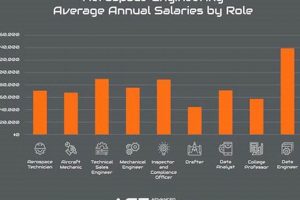

Question 5: What types of career opportunities exist within an aerospace engineering enterprise?

Opportunities span a wide range of disciplines, including design engineering, manufacturing engineering, research and development, project management, and quality assurance. These organizations also require professionals in supporting roles such as finance, marketing, and human resources.

Question 6: What are some of the major challenges currently facing the aerospace engineering sector?

Significant challenges include reducing the environmental impact of air travel, developing more sustainable propulsion systems, managing increasing air traffic congestion, and addressing cybersecurity threats to aerospace systems. Moreover, the need for skilled engineers and technicians remains a critical concern.

In summary, aerospace engineering organizations are pivotal drivers of innovation, safety, and progress within the aerospace industry. Their activities profoundly impact global connectivity, scientific discovery, and economic development.

The following section will delve into the future outlook for aerospace engineering, focusing on emerging technologies and evolving market trends.

Conclusion

The preceding analysis underscores the critical role of aerospace engineering companies in driving innovation and progress within the aerospace sector. Core competencies in design, manufacturing, regulatory compliance, systems integration, and project management collectively define an organization’s capacity to deliver complex and reliable aerospace solutions. Further considerations, such as environmental responsibility and emerging technologies, further shape the strategic direction of these organizations.

The continued advancement of aviation and space exploration depends on the sustained excellence and adaptability of entities operating within this field. By embracing innovation, prioritizing safety, and navigating the evolving regulatory landscape, aerospace engineering companies will remain pivotal in shaping the future of flight and spacefaring endeavors. The challenges and opportunities facing this sector demand ongoing commitment to engineering excellence and a relentless pursuit of technological advancement.