Opportunities within the state encompass roles focused on designing, developing, testing, and manufacturing aircraft, spacecraft, and related systems. These positions support various aspects of aerospace, from research and development to production and maintenance, often within government agencies, private companies, and academic institutions. The work requires a strong foundation in mathematics, physics, and engineering principles and may involve specializations such as aerodynamics, propulsion, or structural analysis.

The availability of technical talent within the region and strategic geographic location can foster innovation and economic growth. This sector contributes to the advancement of technology, national security, and space exploration. Investment in this field can lead to the creation of highly skilled jobs, attracting top talent and fostering a knowledge-based economy. The concentration of relevant industries can also support research collaborations and the development of cutting-edge technologies.

The following sections will delve into the specific companies offering such positions within Tennessee, the required qualifications and experience, and the potential career paths available. Furthermore, resources for job seekers and insights into the local industry landscape will be presented.

Securing a role in the aerospace sector within Tennessee requires a strategic approach and a clear understanding of the industry landscape. The following tips are designed to provide guidance to aspiring professionals.

Tip 1: Target Key Employers: Research companies with a significant presence in Tennessee’s aerospace industry, such as those involved in aviation manufacturing, propulsion systems, or materials research. Identifying these key players can focus job search efforts effectively.

Tip 2: Emphasize Relevant Skills: Highlight expertise in areas such as computational fluid dynamics (CFD), finite element analysis (FEA), CAD software (e.g., CATIA, SolidWorks), and systems engineering. Demonstrating proficiency in these areas is crucial.

Tip 3: Network Strategically: Attend industry events, join professional organizations like the American Institute of Aeronautics and Astronautics (AIAA), and connect with professionals on platforms like LinkedIn. Networking can provide valuable insights and opportunities.

Tip 4: Obtain Relevant Certifications: Consider pursuing certifications that demonstrate expertise in specific areas, such as project management or quality assurance. Certifications can enhance credibility and marketability.

Tip 5: Tailor Resumes and Cover Letters: Customize each application to align with the specific requirements of the position and the values of the company. Generic applications are less likely to be successful.

Tip 6: Consider Advanced Education: Pursue a master’s degree or doctorate in aerospace engineering or a related field. Advanced education can open doors to research-oriented roles and leadership positions.

Tip 7: Explore Government Opportunities: Investigate positions with government agencies, such as NASA facilities or Department of Defense contractors, that may have a presence or projects within the state.

Applying these guidelines can significantly improve the chances of securing a position within this competitive sector. A proactive approach and a focus on developing in-demand skills are essential for success.

The next section will cover specific resources that can aid in your job search and career development within the aerospace sector.

1. Manufacturing Facilities

The presence of manufacturing facilities within Tennessee directly influences the availability and nature of aerospace engineering positions. These facilities serve as hubs for design, production, and testing, requiring a diverse range of engineering expertise.

- Design and Development

Manufacturing facilities often house design and development teams responsible for creating new aircraft components or systems. Aerospace engineers in these roles use CAD software and simulation tools to optimize designs for performance, safety, and manufacturability. For instance, engineers may design lightweight structures to improve fuel efficiency or develop new materials that can withstand extreme temperatures.

- Production Engineering

Production engineers focus on optimizing the manufacturing process to ensure efficiency and quality. This includes designing tooling, developing assembly procedures, and implementing quality control measures. Aerospace engineers in this area may work on automating manufacturing processes or implementing lean manufacturing principles to reduce costs and improve throughput. Examples include optimizing the assembly line for aircraft wings or developing automated inspection systems for critical components.

- Testing and Validation

Manufacturing facilities require engineers to test and validate the performance of aircraft components and systems. This may involve conducting static and dynamic tests to ensure structural integrity or performing wind tunnel tests to evaluate aerodynamic performance. Aerospace engineers in testing roles analyze data, identify potential issues, and recommend design improvements to ensure compliance with industry standards and regulations.

- Materials Science and Engineering

Many aerospace manufacturing facilities have materials science and engineering departments that focus on developing and testing new materials for use in aircraft construction. Aerospace engineers in these roles work with composites, alloys, and other advanced materials to improve strength, reduce weight, and enhance durability. Examples include developing heat-resistant coatings for engine components or designing lightweight composite structures for aircraft fuselages.

These diverse engineering roles within manufacturing facilities are critical to the aerospace sector and directly contribute to the availability of aerospace engineering opportunities in Tennessee. The presence of these facilities drives demand for skilled engineers and fosters innovation within the industry.

2. Research Institutions

Research institutions within Tennessee play a vital role in fostering opportunities in aerospace engineering. Their activities drive innovation, attract funding, and educate future professionals, directly influencing the job market.

- Basic and Applied Research

Universities and research centers conduct fundamental and applied research in areas crucial to aerospace, such as aerodynamics, propulsion, and materials science. This research generates new knowledge and technologies, leading to demand for researchers, engineers, and technicians. For instance, a university project focused on developing more efficient jet engines may create positions for aerospace engineers specializing in thermodynamics and fluid dynamics. Such projects contribute to the state’s reputation as a hub for aerospace innovation.

- Technology Transfer and Commercialization

Research institutions often collaborate with industry partners to transfer new technologies from the laboratory to practical applications. This process of technology transfer generates opportunities for engineers to work on the development and commercialization of cutting-edge aerospace technologies. A university developing a new composite material, for example, might partner with an aerospace manufacturer to integrate it into aircraft design, creating positions focused on materials engineering and structural analysis. This collaboration enhances the competitiveness of the local aerospace industry.

- Workforce Development and Education

Universities and colleges offer aerospace engineering programs that educate and train the next generation of engineers. These programs provide students with the theoretical knowledge and practical skills needed to succeed in the aerospace industry. Additionally, some research institutions offer specialized training programs and workshops for aerospace professionals, enhancing their skills and keeping them abreast of the latest technological advancements. This emphasis on education contributes to a highly skilled workforce, attracting aerospace companies to the state.

- Funding and Investment

Research institutions attract funding from government agencies, private companies, and philanthropic organizations. This funding supports research projects, infrastructure development, and workforce training programs, all of which contribute to the growth of the aerospace industry in Tennessee. A successful research grant focused on developing new space technologies, for example, can lead to the creation of new jobs and attract further investment in the state’s aerospace sector. Securing funding is vital for sustaining research activities and expanding job opportunities.

The multifaceted involvement of research institutionsfrom basic research to workforce developmentcollectively strengthens Tennessee’s aerospace sector. These institutions serve as a catalyst for innovation, attracting both talent and investment, which in turn amplifies the availability and diversity of opportunities in this specialized engineering domain.

3. Government Contracts

Government contracts exert a substantial influence on the availability and nature of opportunities within the aerospace engineering sector in Tennessee. These contracts, typically awarded by federal agencies such as the Department of Defense and NASA, directly fund projects related to aircraft design, development, testing, and maintenance. Consequently, they stimulate job creation and foster technological advancement within the state.

- Funding for Research and Development

Government contracts frequently allocate significant resources to research and development initiatives. These projects, conducted by private companies and academic institutions, necessitate the expertise of aerospace engineers in areas such as aerodynamics, propulsion systems, and advanced materials. For example, a contract to develop a next-generation hypersonic vehicle could require engineers specializing in computational fluid dynamics and heat transfer. This funding drives innovation and provides engineers with opportunities to work on cutting-edge technologies.

- Manufacturing and Production

Government contracts support the manufacturing and production of aircraft, spacecraft, and related components. These activities create jobs for aerospace engineers in areas such as design, manufacturing, quality control, and testing. A contract to produce military aircraft, for instance, would require engineers to oversee the manufacturing process, ensure compliance with stringent quality standards, and conduct rigorous testing to validate performance. These opportunities provide engineers with hands-on experience in the production of critical aerospace systems.

- Maintenance and Sustainment

Government contracts also fund the maintenance and sustainment of existing aircraft and spacecraft. This work requires aerospace engineers to perform inspections, repairs, and upgrades to ensure the continued operational readiness of these systems. A contract to maintain a fleet of military helicopters, for example, would require engineers to develop maintenance procedures, troubleshoot technical issues, and implement upgrades to enhance performance and reliability. These contracts provide engineers with stable employment opportunities and the chance to contribute to national security.

- Regulatory Compliance and Safety

Government contracts mandate strict adherence to regulatory requirements and safety standards. Aerospace engineers play a crucial role in ensuring compliance with these standards throughout the design, manufacturing, and operation of aircraft and spacecraft. For example, engineers must conduct safety analyses, develop risk mitigation strategies, and implement quality control procedures to ensure that aerospace systems meet or exceed all applicable regulations. This focus on safety and compliance creates opportunities for engineers with expertise in these areas.

In summation, government contracts serve as a major catalyst for aerospace engineering employment in Tennessee. The funding provided by these contracts supports a wide range of activities, from basic research to manufacturing and maintenance, creating diverse opportunities for engineers with specialized skills and expertise. The reliance on government contracts reinforces the importance of understanding federal procurement processes and maintaining compliance with regulatory requirements for those seeking careers in this sector within the state.

4. Technical Skillsets

Technical competence serves as a foundational element for securing and excelling in opportunities within the aerospace engineering sector in Tennessee. The requisite skills extend beyond theoretical knowledge, encompassing practical application and specialized expertise directly applicable to the demands of the industry. Demonstrable proficiency in specific technical domains is often a prerequisite for employment.

- Computational Fluid Dynamics (CFD)

Proficiency in CFD is essential for simulating airflow around aircraft and spacecraft. Engineers employ CFD software to analyze aerodynamic performance, optimize designs for lift and drag, and assess thermal characteristics. For instance, CFD can model airflow over a wing to predict stall behavior, or it can simulate heat transfer within a rocket engine nozzle. Mastering CFD enables engineers to improve vehicle efficiency, stability, and safety, making it a highly valued skill in the field. OpenFoam, ANSYS Fluent, and STAR-CCM+ are commonly used CFD tools.

- Finite Element Analysis (FEA)

FEA is critical for analyzing the structural integrity of aerospace components under various loads and environmental conditions. Engineers utilize FEA software to predict stress, strain, and deformation in structures such as aircraft fuselages, wings, and engine components. For example, FEA can determine how a wing will respond to aerodynamic forces during flight or assess the impact of temperature variations on structural integrity. This skill allows engineers to ensure structural safety and optimize designs for weight and strength. Abaqus, ANSYS Mechanical, and NASTRAN are examples of FEA software.

- Systems Engineering

Systems engineering encompasses a holistic approach to designing, developing, and integrating complex aerospace systems. It involves defining system requirements, managing interfaces, and ensuring that all components function together seamlessly. For example, systems engineers might oversee the integration of avionics, propulsion, and control systems in an aircraft, or they might manage the development of a satellite communication system. Expertise in systems engineering is essential for managing complex projects and ensuring that aerospace systems meet performance, reliability, and safety requirements.

- Materials Science and Engineering

Knowledge of materials science is vital for selecting and utilizing appropriate materials in aerospace applications. Engineers need to understand the properties of various materials, such as aluminum alloys, composites, and titanium, and how they behave under different conditions. For example, materials engineers might select a specific composite material for an aircraft fuselage based on its strength-to-weight ratio and resistance to corrosion. Or, they might develop new materials with enhanced properties for use in high-temperature engine components. This skill is crucial for optimizing performance, reducing weight, and ensuring the durability of aerospace systems.

These technical capabilities collectively enhance an individual’s competitiveness within the job market in Tennessee. The acquisition and demonstration of these competencies translate into increased opportunities for professional advancement and contribute to the overall growth and innovation of the aerospace engineering sector within the state. Continuous learning and adaptation to evolving technologies remain paramount for sustained success.

5. Economic Impact

The aerospace engineering sector’s economic influence within Tennessee extends significantly beyond the direct employment it generates. The presence of this industry acts as a catalyst for economic growth, attracting investment, fostering innovation, and supporting a diverse ecosystem of related businesses. These effects collectively enhance the state’s economic stability and competitiveness.

The creation of high-paying jobs within the aerospace sector has a ripple effect throughout the economy. These positions, often requiring advanced education and specialized skills, contribute to increased consumer spending, supporting local businesses and driving demand for goods and services. Furthermore, aerospace companies often collaborate with local suppliers and vendors, creating additional employment opportunities in supporting industries such as manufacturing, logistics, and technology. For example, the establishment of an aerospace manufacturing facility in a Tennessee community can lead to the creation of hundreds of new jobs, both directly and indirectly, stimulating economic activity throughout the region. Tax revenues generated by the aerospace sector contribute to funding public services and infrastructure improvements, further enhancing the quality of life for residents.

Understanding the significant economic impact of aerospace engineering is crucial for policymakers and business leaders seeking to promote economic development in Tennessee. By investing in education, infrastructure, and incentives that support the growth of the aerospace sector, the state can attract new companies, create high-paying jobs, and strengthen its overall economic position. Challenges remain in maintaining competitiveness in the global aerospace market and addressing the need for a skilled workforce. However, by prioritizing strategic investments and fostering a supportive business environment, Tennessee can continue to reap the substantial economic benefits of its vibrant aerospace engineering industry.

Frequently Asked Questions Regarding Aerospace Engineering Opportunities in Tennessee

The following addresses prevalent inquiries concerning employment in this sector within the state, providing clarity and detailed responses.

Question 1: What are the primary employers of aerospace engineers in Tennessee?

Principal employers encompass companies involved in aviation manufacturing, defense contracting, space exploration, and related research and development. Specific examples include facilities specializing in aircraft component production and firms engaged in government-funded aerospace projects.

Question 2: What educational qualifications are typically required for aerospace engineering positions?

A minimum of a bachelor’s degree in aerospace engineering or a closely related field, such as mechanical engineering with a specialization in aerospace, is generally required. Advanced degrees (Master’s or Ph.D.) may be necessary for research-oriented or leadership roles.

Question 3: What specific technical skills are most valued by aerospace employers in Tennessee?

Highly valued skills include proficiency in computational fluid dynamics (CFD), finite element analysis (FEA), CAD software (e.g., CATIA, SolidWorks), systems engineering principles, and a thorough understanding of materials science as it relates to aerospace applications.

Question 4: Are there any particular certifications or licenses that can enhance a candidate’s prospects?

While not always mandatory, certifications such as Project Management Professional (PMP) or certifications related to specific software packages (e.g., ANSYS) can demonstrate expertise and enhance a candidate’s competitiveness.

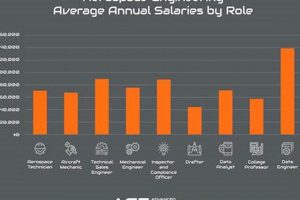

Question 5: What is the typical salary range for aerospace engineers in Tennessee?

Salary ranges vary depending on experience, education, and the specific role. However, entry-level positions generally start around \$70,000 annually, with more experienced engineers earning significantly higher salaries, potentially exceeding \$120,000 or more.

Question 6: What are the prospects for future growth in aerospace engineering employment within Tennessee?

The outlook for aerospace engineering employment in Tennessee remains positive, driven by ongoing investments in aviation manufacturing, defense, and space exploration. The state’s strategic location, skilled workforce, and supportive business environment contribute to a favorable growth trajectory.

These responses offer a foundational understanding of the landscape for aerospace engineering professionals in Tennessee. Further research into specific companies and roles is recommended for detailed information.

The following section will provide a listing of relevant resources for those pursuing aerospace engineering careers.

Conclusion

This exposition has detailed the multifaceted nature of aerospace engineering employment within Tennessee. Key factors examined encompass the influence of manufacturing facilities, research institutions, government contracts, requisite technical skillsets, and the overall economic impact of the sector. A comprehension of these elements is critical for individuals seeking entry or advancement within this domain.

Prospective candidates are encouraged to engage proactively with industry resources, cultivate pertinent technical expertise, and diligently pursue opportunities aligned with their professional aspirations. The continued advancement of aerospace technologies and sustained investment in related industries suggest a promising trajectory for engineering careers within the state.

![Top Countries: Best Aerospace Engineering Jobs [2024] Innovating the Future of Flight with Reliable Aviation Solutions Top Countries: Best Aerospace Engineering Jobs [2024] | Innovating the Future of Flight with Reliable Aviation Solutions](https://mixaerospace.com/wp-content/uploads/2026/03/th-91-300x200.jpg)