This specialized field integrates principles of aeronautical and astronautical disciplines with business administration and leadership strategies. Professionals in this domain are equipped to oversee complex projects, manage resources effectively, and make strategic decisions within the aviation and space sectors. For example, these specialists might lead a team developing a new satellite system, coordinating the efforts of engineers, scientists, and technicians while ensuring adherence to budget constraints and project timelines.

Effective oversight of technical endeavors within aerospace is vital for ensuring safety, efficiency, and innovation. A focus on streamlined processes, risk mitigation, and strategic planning contributes significantly to the successful development and deployment of advanced aerospace technologies. Historically, the growing complexity of aviation and space programs has necessitated the development of a cadre of leaders with expertise in both technical and managerial areas.

The subsequent sections will delve into crucial aspects of this interdisciplinary area, encompassing project lifecycle management, quality assurance protocols, regulatory compliance considerations, and the evolving role of technology in shaping the future of aerospace ventures.

Essential Guidance for Aerospace Project Leadership

Effective leadership in aerospace initiatives demands a blend of technical proficiency and administrative acumen. The following guidelines emphasize strategies for optimizing project outcomes and mitigating potential challenges.

Tip 1: Implement Robust Risk Management Protocols. Identify potential risks early in the project lifecycle and develop mitigation strategies. This proactive approach minimizes disruptions and ensures project stability. Example: Conducting Failure Modes and Effects Analysis (FMEA) to identify potential system weaknesses.

Tip 2: Foster Cross-Functional Collaboration. Encourage communication and collaboration between engineering, manufacturing, and business teams. This holistic approach streamlines workflows and reduces misunderstandings. Example: Establishing regular cross-departmental meetings to facilitate information sharing and problem-solving.

Tip 3: Prioritize Systems Engineering Methodologies. Employ systems thinking to understand the interdependencies of various project components. This comprehensive approach ensures seamless integration and optimal performance. Example: Utilizing Model-Based Systems Engineering (MBSE) to visualize and manage system complexity.

Tip 4: Maintain Strict Adherence to Regulatory Standards. Aerospace projects are subject to rigorous regulatory requirements. Implement quality control measures to ensure compliance and avoid costly penalties. Example: Regularly auditing processes against FAA or EASA regulations.

Tip 5: Invest in Employee Training and Development. Provide ongoing training to enhance employee skills and knowledge. This investment improves productivity and fosters a culture of continuous improvement. Example: Sponsoring employees to attend workshops on advanced materials or project management techniques.

Tip 6: Leverage Data-Driven Decision Making. Collect and analyze project data to identify trends and inform decisions. This evidence-based approach ensures objective evaluations and optimal resource allocation. Example: Implementing Key Performance Indicators (KPIs) to track progress and identify areas for improvement.

Tip 7: Emphasize Clear and Consistent Communication. Establish clear communication channels and ensure that all stakeholders are informed of project progress. This transparency fosters trust and promotes accountability. Example: Using project management software to track tasks, deadlines, and communication logs.

Adherence to these principles enhances the likelihood of project success, reduces operational risks, and maximizes the return on investment in aerospace ventures.

The subsequent discourse will address contemporary challenges and future trends impacting the field of aerospace development and deployment.

1. Strategic Planning

Strategic planning is integral to the success of aerospace ventures. Its effective execution provides a framework for aligning resources and efforts towards achieving defined objectives within a complex and highly regulated environment.

- Defining Project Scope and Objectives

Strategic planning begins with clearly defining the project’s scope, objectives, and deliverables. In an aerospace context, this might involve determining the mission parameters for a new satellite, specifying the performance requirements for an aircraft engine, or outlining the goals of a space exploration program. Without a well-defined scope, projects can become unfocused, leading to wasted resources and missed deadlines. For instance, a vague objective to “improve aircraft fuel efficiency” requires refinement into measurable targets, such as “reduce fuel consumption by 15% over the next five years.”

- Resource Allocation and Budgeting

Strategic plans dictate how resources including personnel, equipment, and funding will be allocated throughout the project lifecycle. Aerospace projects are often characterized by high costs and specialized resource requirements. Strategic allocation involves prioritizing essential activities, optimizing resource utilization, and establishing contingency plans for unforeseen expenses. An example includes strategically phasing the procurement of specialized materials for aircraft construction to align with the production schedule and minimize storage costs.

- Risk Assessment and Mitigation

Aerospace projects inherently involve significant risks, ranging from technical challenges to regulatory hurdles and market uncertainties. Strategic planning includes identifying potential risks, assessing their impact and probability, and developing mitigation strategies. This might involve implementing redundant systems to address potential equipment failures or securing necessary certifications well in advance to avoid delays. For example, during the development of a new spacecraft, strategic planning may involve simulating potential radiation exposure to critical electronic components and implementing shielding measures accordingly.

- Market Analysis and Competitive Positioning

For commercial aerospace ventures, strategic planning encompasses a thorough analysis of the market landscape, including customer needs, competitive pressures, and emerging trends. This analysis informs decisions about product development, pricing strategies, and marketing campaigns. For example, a company developing a new commercial aircraft would conduct market research to identify potential customers, assess the demand for different aircraft configurations, and analyze the competitive offerings of existing manufacturers. This informs decisions around aircraft size, range, and fuel efficiency.

These facets of strategic planning are interwoven and mutually reinforcing, contributing to the overall success of aerospace projects. By establishing clear objectives, allocating resources effectively, mitigating risks, and adapting to market dynamics, professionals in this domain can effectively navigate the complexities of this highly demanding sector.

2. Resource Optimization

Within the realm of aerospace engineering administration, the efficient allocation and utilization of resources are paramount for project success. Resource optimization strategies directly impact project timelines, budgetary constraints, and overall operational effectiveness. The implementation of effective techniques ensures that projects are completed on time, within budget, and to the required performance specifications.

- Materials Management

Efficient materials management is vital due to the high cost and stringent requirements of aerospace materials. This involves forecasting material needs, streamlining procurement processes, minimizing waste, and implementing inventory control measures. Example: Employing just-in-time (JIT) inventory systems to reduce storage costs and prevent material obsolescence, and implementing advanced analytics to predict demand fluctuations for raw materials such as titanium and carbon fiber composites. Accurate forecasting prevents delays and cost overruns related to material shortages.

- Personnel Allocation

Aerospace projects require specialized expertise. Effective allocation of personnel involves assigning the right individuals to the right tasks, optimizing team structures, and providing adequate training and development. Example: Utilizing skills matrices to identify personnel competencies and ensure optimal team composition for specific project phases. Allocating experienced engineers to critical design tasks and less experienced personnel to supporting roles maximizes productivity and minimizes errors. Further, workforce planning allows for strategically onboarding staff with critical skills to match emerging technology demands.

- Equipment Utilization

Maximizing the utilization of specialized equipment, such as wind tunnels, testing facilities, and manufacturing machinery, is crucial. This involves scheduling equipment usage, minimizing downtime, and implementing maintenance programs. Example: Employing predictive maintenance techniques to anticipate equipment failures and schedule maintenance activities proactively. By strategically optimizing equipment usage, downtime is reduced, thereby maximizing efficiency and minimizing costs. For instance, optimizing the scheduling of wind tunnel tests to minimize setup changes and transition times, or coordinating the use of specialized robotic assembly systems across multiple projects.

- Financial Resource Management

Effective financial resource management includes budgeting, cost control, and financial forecasting. It ensures that projects remain within budget and that resources are allocated efficiently. Example: Implementing earned value management (EVM) techniques to track project performance against planned costs and schedules. By monitoring spending against milestones, potential cost overruns can be identified early and corrective actions taken. Financial forecasting tools help in predicting future resource requirements, allowing for proactive budgetary adjustments, and ensuring the continuity of funding during critical project phases.

Resource optimization is not merely a cost-cutting exercise, but rather a strategic imperative for ensuring the successful execution of aerospace projects. By focusing on efficient materials management, personnel allocation, equipment utilization, and financial resource management, professionals in aerospace engineering oversight can maximize project value and achieve organizational objectives effectively. Efficient resource utilization can provide a competitive edge in the challenging aerospace industry.

3. Risk Mitigation

Within the complex and technologically demanding domain of aerospace engineering administration, risk mitigation is not merely a procedural element but a foundational principle. Its effective implementation safeguards projects against potential failures, financial losses, and, most critically, safety compromises. Rigorous risk assessment and proactive mitigation strategies are essential for ensuring the successful execution and operation of aerospace endeavors.

- System Failure Analysis and Redundancy

A cornerstone of risk mitigation involves the systematic analysis of potential system failures and the incorporation of redundant components or systems to maintain functionality in the event of a failure. In aerospace, the consequences of even minor component failures can be catastrophic. For instance, aircraft flight control systems invariably employ multiple redundant sensors and actuators. If one sensor fails, the system seamlessly switches to another, preventing loss of control. This proactive approach, embedded in the design and verified through rigorous testing, minimizes the risk of system-wide failures and enhances overall safety. The role of oversight in this area includes ensuring compliance with rigorous testing and validation protocols and providing oversight on redundancy and fault tolerance planning.

- Regulatory Compliance and Certification

Aerospace activities are heavily regulated by national and international authorities, such as the FAA and EASA. Adherence to these regulations is not only a legal requirement but also a critical element of risk mitigation. Non-compliance can lead to project delays, costly rework, and even grounding of aircraft or spacecraft. Rigorous monitoring of compliance, thorough documentation, and proactive engagement with regulatory bodies are necessary to minimize the risk of regulatory violations. For example, meticulous tracking of materials used in aircraft construction to ensure they meet required flammability and strength standards, coupled with regular audits to verify compliance with manufacturing processes.

- Security Protocols and Cybersecurity

With the increasing reliance on digital systems and interconnected networks, cybersecurity has become a paramount concern in aerospace. Vulnerabilities in aircraft control systems, satellite communication networks, or air traffic management systems can be exploited for malicious purposes, potentially leading to safety breaches or operational disruptions. Robust security protocols, including encryption, firewalls, and intrusion detection systems, are essential to mitigate the risk of cyberattacks. Frequent security audits and vulnerability assessments help identify and address potential weaknesses in the system. For instance, implementing multi-factor authentication for access to critical systems and regularly updating software to patch security vulnerabilities are essential to mitigate the risk of cyberattacks, along with detailed incident response plans.

- Supply Chain Management and Contingency Planning

Aerospace projects often rely on complex and global supply chains. Disruptions in the supply chain, whether due to natural disasters, political instability, or supplier bankruptcies, can lead to project delays and cost overruns. Effective supply chain management involves diversifying suppliers, establishing backup sources, and implementing contingency plans to address potential disruptions. For instance, maintaining strategic reserves of critical components or establishing long-term contracts with multiple suppliers can help mitigate the risk of supply chain disruptions. Regularly assessing the financial health and operational capabilities of key suppliers is critical to identifying and addressing potential risks proactively.

These components of risk mitigation are integral to the comprehensive oversight required in the aerospace sector. By meticulously addressing these potential pitfalls and implementing robust preventive measures, engineers and project leaders can significantly enhance the safety, reliability, and overall success of aerospace projects. Ignoring these facets can lead to consequences with significant impacts on safety and financials.

4. Regulatory Compliance

Adherence to stringent regulations is a critical facet of aerospace engineering administration. The aerospace sector is subject to rigorous oversight by national and international bodies to ensure safety, security, and environmental protection. The effective navigation and implementation of these regulations are essential for the success and viability of any aerospace project.

- Design and Manufacturing Standards

Aerospace components and systems must adhere to specific design and manufacturing standards established by regulatory agencies. These standards dictate material properties, manufacturing processes, testing protocols, and performance criteria. For example, aircraft structures must meet stringent strength and fatigue resistance requirements outlined in FAA regulations. Aerospace engineering administration ensures that these standards are integrated into the design and manufacturing processes, with rigorous verification and validation testing to confirm compliance. Failure to comply with these standards can result in grounding of aircraft, costly recalls, and severe legal ramifications. Proper planning includes meticulous documentation, materials traceability, and process control throughout the lifecycle.

- Airworthiness Certification

Before an aircraft or spacecraft can be put into service, it must undergo airworthiness certification by the relevant regulatory authority. This process involves comprehensive testing and evaluation to ensure that the design and performance meet applicable safety standards. Aerospace engineering administration plays a crucial role in preparing the necessary documentation, coordinating testing activities, and demonstrating compliance to the certifying agency. An example is the rigorous flight testing of a new aircraft model to demonstrate its stability, control, and performance characteristics. Airworthiness certification also includes ongoing maintenance and inspection requirements to ensure continued compliance throughout the operational life of the vehicle. Managing this ongoing compliance is a key administrative function.

- Environmental Regulations

Aerospace activities can have significant environmental impacts, including air pollution, noise pollution, and greenhouse gas emissions. Regulatory agencies impose strict environmental regulations to minimize these impacts. Aerospace engineering administration is responsible for ensuring compliance with these regulations, including implementing technologies and practices to reduce emissions and noise levels. For example, the development and deployment of more fuel-efficient aircraft engines and the implementation of noise abatement procedures at airports. Adherence to environmental regulations is not only a legal requirement but also a matter of corporate social responsibility.

- Safety Management Systems (SMS)

Regulatory agencies increasingly require aerospace organizations to implement comprehensive Safety Management Systems (SMS). An SMS is a structured approach to managing safety risks, including hazard identification, risk assessment, and mitigation strategies. Aerospace engineering administration is responsible for developing, implementing, and maintaining an effective SMS. This involves establishing clear lines of accountability, promoting a safety culture, and continuously monitoring and improving safety performance. An example is the implementation of procedures for reporting and investigating safety incidents, analyzing root causes, and implementing corrective actions to prevent recurrence. The SMS framework promotes proactive risk mitigation rather than reactive responses to accidents.

These elements of regulatory compliance underscore the critical intersection between regulatory requirements and the administrative oversight of aerospace projects. By integrating compliance considerations into every stage of the project lifecycle, from design and manufacturing to operations and maintenance, professionals in aerospace engineering administration can ensure the safety, reliability, and sustainability of aerospace activities. An effective approach to regulatory compliance strengthens an organization’s reputation and its long-term viability in the global aerospace market.

5. Technological Integration

The effective adoption and management of advanced technologies are integral to success in the contemporary aerospace sector. Aerospace engineering administration is fundamentally concerned with overseeing the seamless integration of these technologies into all phases of the project lifecycle, from initial design and development to manufacturing, testing, and ongoing operations.

- Advanced Materials and Manufacturing Processes

The integration of advanced materials, such as composites and alloys with enhanced strength-to-weight ratios, alongside sophisticated manufacturing processes like additive manufacturing (3D printing), directly impacts the performance, efficiency, and cost-effectiveness of aerospace systems. For example, the use of carbon fiber reinforced polymers in aircraft structures reduces weight, improving fuel efficiency and extending range. Aerospace engineering administration must manage the adoption of these materials and processes, ensuring appropriate quality control, risk assessment, and regulatory compliance are maintained. This necessitates expertise in materials science, manufacturing engineering, and quality assurance.

- Digital Engineering and Modeling

The implementation of digital engineering tools, including Model-Based Systems Engineering (MBSE) and advanced simulation software, revolutionizes the design and development process. These tools enable engineers to create virtual prototypes, simulate system behavior under various conditions, and identify potential design flaws early in the development cycle. Aerospace engineering administration leverages these tools to improve design accuracy, reduce development time, and minimize costly physical testing. Effective management requires overseeing the implementation of digital workflows, ensuring data integrity and security, and training personnel on the use of these advanced tools. Managing the complexities of large-scale digital engineering projects is a core administrative challenge.

- Autonomous Systems and Robotics

The integration of autonomous systems and robotics is transforming various aspects of aerospace operations, from automated manufacturing processes to unmanned aerial vehicles (UAVs) for surveillance and inspection. Aerospace engineering administration is responsible for managing the development and deployment of these systems, ensuring their safe and reliable operation. For instance, the use of robotic systems for aircraft assembly improves precision and reduces labor costs. Management involves addressing ethical considerations, regulatory requirements, and cybersecurity risks associated with autonomous systems. This requires a multi-disciplinary approach involving engineers, ethicists, and legal experts.

- Data Analytics and Artificial Intelligence

The aerospace sector generates vast amounts of data from sensors, simulations, and operational systems. The application of data analytics and artificial intelligence (AI) enables engineers to extract valuable insights from this data, improving decision-making and optimizing system performance. For example, AI-powered predictive maintenance systems can analyze sensor data to identify potential equipment failures before they occur, minimizing downtime and reducing maintenance costs. Aerospace engineering administration oversees the implementation of these technologies, ensuring data privacy, security, and ethical use. This necessitates expertise in data science, machine learning, and cybersecurity.

These facets of technological integration highlight the critical role of aerospace engineering administration in managing the complexities of innovation. By effectively overseeing the adoption and implementation of advanced technologies, aerospace organizations can enhance their competitiveness, improve safety, and drive innovation across the sector.

6. Quality Assurance

Quality assurance (QA) is an indispensable element within aerospace engineering administration, impacting every stage of a project’s lifecycle, from initial design to final delivery and maintenance. QA provides a structured framework for ensuring that all products, processes, and services meet predefined standards and regulatory requirements. The absence of robust QA protocols can lead to catastrophic failures, financial losses, and reputational damage. For example, improper welding during aircraft construction, undetected by quality control measures, can result in structural failure during flight, leading to fatal consequences. Therefore, QA is not merely a procedural formality but a critical safeguard for ensuring the integrity and safety of aerospace systems.

The effective implementation of QA involves a multi-faceted approach, encompassing stringent inspection protocols, rigorous testing procedures, and continuous monitoring of manufacturing processes. Furthermore, robust documentation and traceability systems are essential for tracking components and materials throughout the supply chain. For example, QA protocols might mandate non-destructive testing (NDT) of critical aircraft components to detect hidden flaws or fatigue cracks. The results of these tests are meticulously documented and compared against pre-defined acceptance criteria. Furthermore, statistical process control (SPC) techniques are employed to monitor manufacturing processes and identify any deviations from established standards. Effective oversight involves managing these processes, ensuring adherence to standards, and implementing corrective actions when necessary.

In conclusion, QA is intrinsically linked to the success of aerospace engineering administration. By prioritizing QA, organizations can minimize risks, ensure compliance, and enhance the overall reliability and performance of aerospace systems. The challenges of maintaining high-quality standards in a rapidly evolving technological landscape require continuous improvement, adaptation, and a commitment to excellence. Effective management in this field necessitates a comprehensive understanding of QA principles and the ability to integrate them seamlessly into all aspects of project execution.

Frequently Asked Questions

This section addresses common queries regarding the specialized discipline encompassing the administration of complex projects within the aviation and space sectors. The objective is to provide clarity on scope, requirements, and career prospects within this field.

Question 1: What distinguishes the administrative aspects of aerospace endeavors from general engineering management?

Aerospace administration necessitates a deep understanding of specialized technical complexities, stringent regulatory frameworks, and critical safety considerations inherent to the aviation and space domains. General engineering oversight may lack this sector-specific knowledge.

Question 2: What educational background is typically required to pursue a career in this domain?

A combination of engineering education (preferably in aerospace, mechanical, or a related field) and administrative training (such as an MBA or a master’s degree in management) is highly desirable. Specific certifications in project leadership are also valued.

Question 3: What are the core responsibilities of professionals in this field?

Core responsibilities include project lifecycle management, resource allocation, risk mitigation, regulatory compliance, strategic planning, team leadership, and financial oversight, all within the context of aerospace-specific challenges and opportunities.

Question 4: How critical is knowledge of regulatory frameworks (e.g., FAA, EASA) for professionals in this role?

A comprehensive understanding of regulatory frameworks is paramount. Non-compliance can result in project delays, financial penalties, and potentially compromise safety, leading to severe legal and operational consequences.

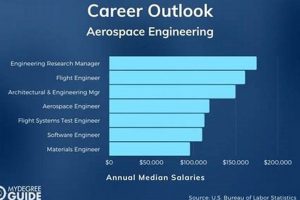

Question 5: What are the common career paths available within this specialized area?

Potential career paths include project leader, program administrator, systems engineering manager, quality assurance manager, and leadership positions within aerospace manufacturing or research and development organizations.

Question 6: How does technological advancement impact the role of administrators in this field?

Technological advancements require continuous learning and adaptation. Professionals must stay abreast of emerging technologies, such as advanced materials, digital engineering tools, and autonomous systems, and effectively integrate them into project strategies.

In summary, effective management of aerospace projects requires a unique blend of technical expertise, administrative acumen, and unwavering commitment to safety and regulatory compliance.

The subsequent section will delve into the ethical considerations relevant to leadership within the aerospace field.

Conclusion

This examination of aerospace engineering management has underscored its critical role in ensuring the successful development, deployment, and operation of complex aerospace systems. It has highlighted the essential elements of strategic planning, resource optimization, risk mitigation, regulatory compliance, technological integration, and quality assurance that define this field.

The future of aerospace endeavors hinges on the continued cultivation of leadership equipped with both technical expertise and administrative proficiency. A sustained commitment to rigorous standards and ethical practices is paramount to navigate the evolving landscape and ensure the continued advancement of this vital sector. The pursuit of innovation and excellence must remain at the forefront of all aerospace initiatives.