These distinct yet related fields involve the application of physics, mathematics, and engineering principles to design, develop, and manufacture systems and products. One focuses on vehicles and technology operating within and beyond Earth’s atmosphere, exemplified by aircraft and spacecraft design. The other encompasses a broader spectrum, covering machinery, power systems, robotics, manufacturing processes, and thermal systems, evident in automotive engineering and industrial automation.

The study and practice of these disciplines are crucial for technological advancement, economic growth, and societal well-being. They drive innovation in diverse sectors such as transportation, energy, manufacturing, and defense. Historically, both have evolved significantly, influenced by scientific discoveries, technological breakthroughs, and global demands, leading to increased efficiency, sustainability, and performance in various applications. This progression continues to impact the world.

The following sections delve into core principles, specialization areas, career pathways, and future trends associated with these engineering domains, providing a comprehensive overview for prospective students, industry professionals, and those seeking a deeper understanding of these vital disciplines.

Guidance for Aspiring Professionals

The following suggestions aim to provide insights and strategies for individuals interested in pursuing a career in either of these demanding fields. Diligence, commitment, and continuous learning are essential for success.

Tip 1: Cultivate a Strong Foundation in Mathematics and Physics. These subjects form the bedrock of both disciplines. Develop a thorough understanding of calculus, differential equations, linear algebra, mechanics, thermodynamics, and fluid dynamics. Utilize online resources, textbooks, and academic support to strengthen these foundational skills.

Tip 2: Seek Relevant Hands-On Experience. Participate in internships, co-op programs, or research opportunities. Practical experience allows for the application of theoretical knowledge and provides valuable insight into real-world engineering challenges. Actively engage in projects involving design, analysis, and testing.

Tip 3: Specialize Strategically. While a broad understanding is beneficial, specialization allows for focused expertise. Identify areas of interest such as propulsion systems, structural analysis, robotics, or thermal engineering. Tailor coursework, projects, and research activities to develop in-depth knowledge within the chosen specialization.

Tip 4: Develop Proficiency in Computer-Aided Design (CAD) and Simulation Software. Mastery of software packages such as SolidWorks, ANSYS, or MATLAB is crucial. These tools are used extensively for design, analysis, and simulation purposes. Practice using these programs to create models, analyze performance, and optimize designs.

Tip 5: Engage in Professional Development. Join professional organizations such as the American Society of Mechanical Engineers (ASME) or the American Institute of Aeronautics and Astronautics (AIAA). Attend conferences, workshops, and seminars to stay abreast of the latest advancements and network with industry professionals. Seek mentorship from experienced engineers.

Tip 6: Hone Problem-Solving and Analytical Skills. Engineering involves identifying, analyzing, and solving complex problems. Develop critical thinking skills by tackling challenging problems and seeking creative solutions. Participate in problem-solving competitions and collaborate with others to enhance these skills.

Tip 7: Cultivate Effective Communication Skills. The ability to communicate technical information clearly and concisely is essential. Develop strong written and oral communication skills through coursework, presentations, and technical report writing. Practice communicating complex concepts to both technical and non-technical audiences.

Adherence to these suggestions enhances the prospect of a successful and fulfilling career within these challenging and rewarding professions.

The concluding sections will explore the diverse career paths and future outlook associated with the chosen field, offering further insight for career planning and professional growth.

1. Thermodynamics

Thermodynamics is a foundational science deeply intertwined with both aerospace and mechanical engineering. Its principles govern energy conversion, heat transfer, and system efficiency, all of which are critical considerations in the design and analysis of various engineering systems.

- Engine Design and Performance

Thermodynamics is fundamental to the design and optimization of internal combustion engines, gas turbines, and rocket engines. Understanding thermodynamic cycles such as the Otto, Diesel, and Brayton cycles is essential for maximizing efficiency and power output. For instance, the design of a jet engine in aerospace engineering relies heavily on thermodynamic principles to optimize fuel consumption and thrust.

- Heat Transfer in Aerospace Vehicles

Aerospace vehicles experience extreme temperature variations due to atmospheric friction during flight and solar radiation in space. Thermodynamics dictates the principles of heat transfer conduction, convection, and radiation that govern thermal management systems. Efficient heat dissipation is crucial for maintaining optimal operating temperatures of critical components, preventing overheating, and ensuring mission success.

- Power Generation Systems

Mechanical engineers design and analyze power generation systems that rely heavily on thermodynamics. These include power plants, renewable energy systems (solar thermal, geothermal), and waste heat recovery systems. The efficiency of these systems is directly determined by adherence to the laws of thermodynamics, with the goal of maximizing energy conversion and minimizing waste.

- HVAC Systems and Thermal Comfort

Mechanical engineers also design heating, ventilation, and air conditioning (HVAC) systems to maintain thermal comfort in buildings and vehicles. These systems utilize thermodynamic principles to control temperature, humidity, and air quality. Optimizing HVAC systems for energy efficiency and occupant comfort requires a thorough understanding of thermodynamic processes and heat transfer mechanisms.

The application of thermodynamic principles is essential across numerous engineering disciplines. Effective utilization of energy, thermal management, and cycle analysis are fundamental to both aerospace and mechanical engineering to ensure the performance, safety, and efficiency of engineering systems and products.

2. Fluid Dynamics

Fluid dynamics, the study of fluids (liquids and gases) in motion, is a cornerstone of both aerospace and mechanical engineering. The principles governing fluid behavior are directly applicable to the design, analysis, and optimization of systems operating within or interacting with fluids. Consequently, a thorough understanding of fluid dynamics is indispensable for engineers in these fields.

In aerospace engineering, fluid dynamics dictates aircraft and spacecraft aerodynamics. The shape of an airfoil, for instance, is carefully designed using fluid dynamics principles to generate lift efficiently and minimize drag. Computational Fluid Dynamics (CFD) simulations are routinely employed to predict airflow patterns around aircraft, enabling engineers to refine designs for improved performance and fuel efficiency. Furthermore, understanding fluid dynamics is critical for designing efficient propulsion systems, such as jet engines and rockets, where the flow of gases through nozzles and turbines determines thrust and overall performance. Examples include optimizing the shape of a rocket nozzle for maximum exhaust velocity or predicting the aerodynamic forces on a hypersonic vehicle during atmospheric reentry. In mechanical engineering, fluid dynamics plays a crucial role in designing pumps, turbines, pipelines, and HVAC systems. The efficiency and performance of these systems depend on the proper management of fluid flow. For instance, the design of a centrifugal pump requires a detailed understanding of fluid flow patterns to maximize its volumetric flow rate and minimize energy losses. Similarly, the design of a wind turbine requires precise understanding of aerodynamics to maximize energy capture. These principles guide the development of efficient and reliable machines.

Challenges remain in accurately modeling complex fluid flows, particularly turbulent flows, which are prevalent in many engineering applications. The development of more accurate and computationally efficient CFD models is an ongoing area of research. The integration of fluid dynamics principles continues to be essential for advancing engineering technologies and achieving more efficient and sustainable designs, which is vital for addressing issues of energy efficiency, environmental impact, and overall system performance.

3. Stress Analysis

Stress analysis, a critical component of engineering design, rigorously evaluates the internal forces and stresses within a material or structure subjected to external loads or thermal gradients. Its application is indispensable in both aerospace and mechanical engineering, ensuring structural integrity and preventing failure under operational conditions.

- Component Lifespan Prediction

Stress analysis predicts the lifespan of components under cyclic loading, identifying fatigue-prone areas. In aerospace, this is vital for wing structures enduring repeated stress cycles during flight. Mechanical engineering applies these methods to rotating machinery parts, guaranteeing functionality over prescribed service intervals.

- Material Selection Optimization

The process informs material selection, matching materials to specific stress conditions. In aerospace, lightweight, high-strength alloys are favored to minimize weight without compromising structural integrity. Mechanical engineering employs stress analysis to select materials suitable for high-pressure vessels or engine components.

- Failure Mode Evaluation

Stress analysis identifies potential failure modes, predicting crack initiation and propagation pathways. Aerospace applications use fracture mechanics to assess the impact of pre-existing flaws on structural performance. Mechanical engineering utilizes similar methods to prevent failures in critical machinery.

- Design Optimization for Weight and Strength

The process allows engineers to optimize designs for weight and strength, minimizing material usage without compromising safety. Aerospace designs strive for minimal weight to maximize payload capacity and fuel efficiency. Mechanical engineering employs stress analysis to refine designs of automotive components, reducing weight while maintaining safety standards.

These facets demonstrate the broad utility of stress analysis across both engineering domains. By allowing accurate prediction of material behavior under load, engineers can design safer, more efficient, and more durable systems and components, crucial for innovation and reliability in the fields.

4. Control Systems

Control systems engineering is pivotal in aerospace and mechanical engineering, focusing on the design and implementation of automated systems that regulate the behavior of dynamic processes. These systems ensure precision, stability, and efficiency across diverse applications, demanding expertise in feedback mechanisms, system modeling, and advanced control algorithms.

- Flight Control Systems

In aerospace engineering, flight control systems govern aircraft stability and maneuverability. Autopilots, stability augmentation systems, and fly-by-wire technologies rely on intricate control algorithms to maintain desired flight paths and attitudes. These systems utilize sensors to measure parameters like airspeed, altitude, and orientation, adjusting control surfaces (e.g., ailerons, elevators, rudders) to achieve optimal performance and safety. An example is the use of model predictive control (MPC) in modern aircraft to optimize fuel consumption while adhering to flight path constraints.

- Robotics and Automation

Mechanical engineering heavily utilizes control systems in robotics and automation. Industrial robots, automated assembly lines, and computer numerical control (CNC) machines depend on precise control algorithms to execute complex tasks with accuracy and repeatability. Feedback loops, incorporating sensors and actuators, enable these systems to adapt to changing conditions and maintain desired performance. The design of a robotic arm for welding, for instance, requires careful consideration of motor control, trajectory planning, and force feedback to ensure precise and consistent welds.

- Engine Management Systems

Both aerospace and mechanical engineering employ control systems in engine management. Electronic control units (ECUs) in automotive engines and full authority digital engine controls (FADECs) in aircraft engines regulate fuel injection, ignition timing, and air-fuel ratios to optimize performance, fuel efficiency, and emissions. These systems incorporate sophisticated algorithms that adapt to varying operating conditions and driver/pilot demands. The optimization of combustion in a jet engine, for example, relies on feedback control to maintain stable and efficient operation across a wide range of altitudes and speeds.

- Thermal Management Systems

Control systems are essential in thermal management applications. Heating, ventilation, and air conditioning (HVAC) systems, spacecraft thermal control systems, and industrial cooling processes utilize feedback control to maintain desired temperature levels. These systems incorporate sensors to measure temperature, flow rates, and pressure, adjusting actuators (e.g., valves, fans, pumps) to achieve optimal thermal performance. In spacecraft, precise thermal control is critical for maintaining the operating temperature of sensitive electronic components and scientific instruments in the harsh environment of space.

These facets highlight the significance of control systems in optimizing system performance, ensuring stability, and enhancing safety across diverse applications in both aerospace and mechanical engineering. Advanced control strategies and technological innovation continue to drive the evolution of these systems, enabling enhanced automation and efficiency in complex engineering processes.

5. Material Science

Material science is integral to both aerospace and mechanical engineering, serving as the foundation upon which designs are realized. It dictates the selection, processing, and characterization of materials to meet specific performance requirements and ensure structural integrity in diverse applications.

- High-Strength, Lightweight Materials for Aerospace Structures

The aerospace industry demands materials that offer exceptional strength-to-weight ratios to maximize payload capacity and fuel efficiency. Aluminum alloys, titanium alloys, and carbon fiber composites are extensively used in aircraft fuselages, wings, and engine components. These materials provide the necessary strength to withstand aerodynamic loads while minimizing weight, thus improving overall aircraft performance. The choice of material impacts fuel consumption, range, and maneuverability, influencing mission success and operational costs.

- High-Temperature Alloys for Turbine Engines

Turbine engines in both aerospace and mechanical applications require materials capable of withstanding extreme temperatures and stresses. Nickel-based superalloys are commonly used in turbine blades and combustion chambers due to their high melting points, creep resistance, and oxidation resistance. These materials enable engines to operate at higher temperatures, increasing thermal efficiency and power output. The performance and longevity of turbine engines are directly dependent on the properties of these high-temperature alloys.

- Wear-Resistant Materials for Mechanical Components

Mechanical systems often involve components subjected to friction, wear, and abrasion. Material science provides solutions through the selection of wear-resistant materials such as hardened steels, ceramics, and surface coatings. These materials are used in gears, bearings, and cutting tools to prolong component life and reduce maintenance requirements. The durability and reliability of mechanical systems hinge on the wear resistance of their constituent materials.

- Corrosion-Resistant Materials for Harsh Environments

Engineering applications in marine, chemical, and offshore environments require materials that resist corrosion and degradation. Stainless steels, specialty alloys, and polymer coatings are employed to protect structures and components from the damaging effects of corrosion. These materials ensure the long-term integrity and reliability of systems exposed to corrosive substances or harsh weather conditions. Material selection is critical for extending the service life and minimizing the risk of catastrophic failures.

These examples illustrate the profound influence of material science on both aerospace and mechanical engineering. The continuous development of new materials and processing techniques is essential for pushing the boundaries of engineering design and achieving advancements in performance, efficiency, and sustainability.

6. Design Principles

Design principles serve as the foundational guidelines within both aerospace and mechanical engineering, dictating the systematic process by which ideas are translated into tangible and functional systems. The application of these principles is not merely aesthetic; it directly affects performance, reliability, safety, and cost-effectiveness. Ineffective application of design principles can lead to structural failures, inefficient energy consumption, or increased manufacturing expenses, thus impacting project viability. Consider the design of an aircraft wing: principles of aerodynamics, structural integrity, and material science must be integrated to achieve lift, minimize drag, and withstand flight stresses. Any deviation from established design practices could result in catastrophic failure during operation.

The practical significance of understanding design principles is evident in several areas. For instance, the design of a mechanical system, such as a power transmission, must consider factors like load distribution, stress concentration, and lubrication to prevent premature wear and failure. Similarly, in the aerospace sector, designing a spacecraft requires adherence to principles of thermal management, radiation shielding, and orbital mechanics to ensure mission success. Modern Computer-Aided Design (CAD) and simulation tools allow engineers to model and analyze designs according to these principles, optimizing performance and identifying potential weaknesses before physical prototypes are built. These tools, however, are only as effective as the underlying design knowledge applied by the engineer.

In summary, design principles are not abstract concepts but rather essential components of the engineering process that influence every stage from conceptualization to manufacturing and operation. Challenges remain in applying these principles to increasingly complex systems, requiring engineers to stay abreast of new materials, manufacturing techniques, and analytical methods. A solid grasp of design principles is therefore crucial for engineers to innovate and create solutions that meet evolving technological demands.

7. Manufacturing

Manufacturing processes are inextricably linked to both aerospace and mechanical engineering, representing the practical realization of engineering designs. The selection and execution of manufacturing techniques directly impact the cost, performance, and reliability of engineered systems, necessitating a thorough understanding of these processes within both disciplines.

- Advanced Materials Processing

The aerospace industry increasingly relies on advanced materials like composites, titanium alloys, and nickel-based superalloys, which demand specialized manufacturing techniques. Processes such as automated fiber placement, vacuum bag molding, and hot isostatic pressing are essential for creating lightweight, high-strength components for aircraft and spacecraft. These methods require precise control of temperature, pressure, and material deposition to achieve desired mechanical properties and dimensional accuracy. For instance, fabricating a carbon fiber composite wing spar involves layering pre-impregnated carbon fiber sheets onto a mold, followed by curing in an autoclave to achieve the final shape and strength.

- Precision Machining and Fabrication

Mechanical engineering often involves the design and manufacturing of intricate mechanical components requiring high precision. Machining processes like CNC milling, turning, and grinding are critical for creating gears, shafts, and housings with tight tolerances. Fabrication techniques such as welding, casting, and forging are also employed to assemble larger structures and systems. The selection of appropriate machining parameters, cutting tools, and process controls is essential for achieving desired surface finishes, dimensional accuracy, and material integrity. Manufacturing a complex engine block, for example, requires multiple machining operations to achieve precise cylinder bores, coolant passages, and mounting surfaces.

- Additive Manufacturing (3D Printing)

Additive manufacturing techniques, such as selective laser melting and fused deposition modeling, are increasingly utilized in both aerospace and mechanical engineering to create complex geometries and customized components. These processes allow for the fabrication of parts with intricate internal structures, optimized for weight reduction and improved performance. Additive manufacturing also enables rapid prototyping and on-demand production of spare parts, reducing lead times and inventory costs. For instance, aerospace engineers use 3D printing to create lightweight brackets and ducting for aircraft interiors, while mechanical engineers use it to produce custom tooling and fixtures for manufacturing processes.

- Quality Control and Inspection

Ensuring the quality and reliability of manufactured components is paramount in both aerospace and mechanical engineering. Non-destructive testing (NDT) methods such as ultrasonic testing, radiography, and eddy current testing are used to detect internal flaws and surface defects without damaging the component. Coordinate measuring machines (CMMs) are employed to verify dimensional accuracy and conformance to design specifications. Statistical process control (SPC) techniques are used to monitor and control manufacturing processes, ensuring consistent product quality and minimizing variations. For example, aerospace manufacturers use NDT to inspect welds in aircraft fuselages, while mechanical engineers use CMMs to verify the dimensions of precision gears.

In conclusion, manufacturing processes form a critical bridge between engineering design and the physical realization of aerospace and mechanical systems. A comprehensive understanding of manufacturing techniques, materials processing, and quality control is essential for engineers to create innovative, reliable, and cost-effective solutions that meet the demands of modern technology.

Frequently Asked Questions

The following questions address common inquiries regarding the nature, scope, and career prospects within these distinct yet related engineering disciplines.

Question 1: What constitutes the fundamental difference between these disciplines?

One focuses on the design, development, and testing of aircraft, spacecraft, and related systems operating within and beyond Earth’s atmosphere. The other encompasses a broader scope, addressing the design, manufacturing, and analysis of mechanical systems, including machinery, power generation equipment, and thermal systems.

Question 2: Which academic background is most suitable for pursuing studies in this field?

A strong foundation in mathematics, physics, and computer science is highly beneficial. Coursework in calculus, differential equations, linear algebra, mechanics, thermodynamics, and programming is essential for success in both fields. Prior experience with CAD software or hands-on engineering projects is advantageous.

Question 3: What are the primary specializations within each of these fields?

Specializations may include aerodynamics, propulsion, structural analysis, control systems, robotics, manufacturing, thermal engineering, and materials science. Selection of a specialization should align with individual interests and career aspirations.

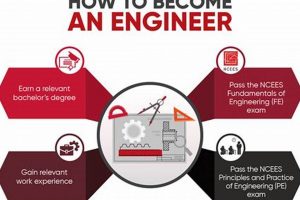

Question 4: What are the typical career paths available upon graduation?

Graduates can pursue careers in aerospace companies, automotive manufacturers, energy companies, government agencies, research institutions, and consulting firms. Roles may include design engineer, research scientist, project manager, test engineer, or manufacturing engineer.

Question 5: What are the projected future trends impacting these engineering sectors?

Emerging trends include the development of sustainable energy technologies, autonomous systems, advanced materials, and space exploration. Expertise in these areas will be highly sought after in the coming years.

Question 6: Are advanced degrees (Master’s or Ph.D.) necessary for career advancement?

While not always mandatory, advanced degrees can significantly enhance career prospects, particularly in research-intensive roles. Master’s programs provide specialized knowledge and skills, while Ph.D. programs focus on independent research and scholarly contributions.

In summary, these distinct disciplines offer diverse and rewarding career paths for individuals with a strong aptitude for mathematics, science, and problem-solving. Continuous learning and adaptation are essential for navigating the evolving technological landscape.

The subsequent section provides a comparative analysis of career paths, salary expectations, and future outlook for graduates of the related programs.

Conclusion

This exploration has delineated the fundamental characteristics and applications of both disciplines, outlining the core principles, specialization areas, and potential career paths. The distinctions between designing aircraft and spacecraft versus addressing broader mechanical systems are significant, impacting educational focus and professional roles. Both fields demand a rigorous understanding of mathematics, physics, and engineering principles, with continuous learning essential for navigating technological advancements.

Prospective engineers should carefully consider individual interests and aptitudes to determine the most suitable path. The societal impact and continuing evolution of these domains emphasize their importance in driving technological progress. Individuals are encouraged to seek further knowledge and practical experiences to contribute meaningfully to either field.