Positions focused on the meticulous calculation of costs associated with aerospace projects constitute a vital aspect of the industry. These roles involve analyzing technical specifications, material requirements, labor costs, and other pertinent factors to formulate accurate budget projections. For example, an individual in such a position might assess the expenses linked to developing a new aircraft component or overhauling an existing satellite system.

The significance of these cost-assessment roles lies in their contribution to informed decision-making, risk mitigation, and efficient resource allocation. Accurate projections are essential for securing funding, managing project budgets effectively, and ensuring profitability. Historically, these calculations were often performed manually, but contemporary methods utilize specialized software and data analytics to enhance precision and efficiency.

The following sections will delve into the core responsibilities, required qualifications, essential skills, typical career paths, and compensation expectations related to these vital cost-projection roles within the aerospace sector.

This section provides guidance for those seeking or currently holding positions focused on aerospace cost assessment. Adherence to these points can contribute to career advancement and professional excellence.

Tip 1: Prioritize Continuous Learning: The aerospace industry is subject to technological advancements and fluctuating market conditions. Individuals involved in cost assessment should proactively pursue ongoing education and training to remain abreast of the latest developments in materials, manufacturing processes, and estimation methodologies.

Tip 2: Cultivate Strong Analytical Skills: Proficiency in data analysis is paramount. Successful cost assessors must possess the ability to interpret complex technical specifications, identify cost drivers, and develop accurate projections based on empirical evidence. Familiarity with statistical modeling and risk assessment techniques is highly beneficial.

Tip 3: Master Relevant Software: Contemporary cost projection relies heavily on specialized software tools. Acquiring expertise in programs such as Costimator, SEER-SEM, or similar platforms is essential for efficient and accurate estimation. Hands-on experience and certifications can significantly enhance professional credibility.

Tip 4: Develop Effective Communication Skills: The ability to articulate cost projections clearly and concisely to both technical and non-technical audiences is crucial. Cost assessors must be able to present their findings persuasively, justify assumptions, and respond effectively to inquiries from stakeholders.

Tip 5: Emphasize Accuracy and Attention to Detail: Errors in cost assessment can have significant financial implications for aerospace projects. A meticulous approach to data collection, analysis, and reporting is essential to minimize the risk of inaccuracies and ensure the reliability of projections.

Tip 6: Build a Robust Network: Establishing connections with engineers, project managers, and procurement specialists within the aerospace industry can provide valuable insights and opportunities for collaboration. Networking events, industry conferences, and professional organizations offer avenues for building and maintaining these relationships.

Tip 7: Understand Regulatory Requirements: Aerospace projects are often subject to stringent regulatory requirements and compliance standards. Individuals involved in cost assessment should possess a thorough understanding of these regulations and ensure that their projections align with applicable guidelines.

By prioritizing continuous learning, cultivating strong analytical skills, mastering relevant software, developing effective communication skills, emphasizing accuracy, building a robust network, and understanding regulatory requirements, individuals can enhance their prospects and excel in the field of aerospace cost assessment.

The succeeding portion will offer a summation, underscoring the primary aspects explored.

1. Accuracy

Accuracy is a non-negotiable cornerstone of roles involving cost projection in the aerospace domain. It directly impacts project viability, budget adherence, and ultimately, the success of aerospace endeavors. Precise assessments are crucial for effective resource allocation and risk management.

- Material Cost Projection Fidelity

The accurate estimation of material costs is fundamental. This encompasses raw materials, specialized components, and any outsourced parts required for manufacturing or assembly. Even minor inaccuracies in material cost projections can accumulate significantly, leading to substantial budget overruns in large-scale aerospace projects. A real-world example is the underestimation of titanium alloy costs, which can escalate overall expenses due to its specialized processing and limited availability.

- Labor Hour Estimation Precision

Labor costs represent a significant portion of overall project expenditures. Precise estimation of labor hours required for design, manufacturing, testing, and assembly is essential. This necessitates a thorough understanding of the complexity of each task and the skill sets required. An overestimation of labor hours can render a project uncompetitive, while underestimation can lead to schedule delays and compromised quality. For instance, miscalculating the man-hours needed for intricate wiring harnesses can directly impact launch dates and system reliability.

- Overhead Allocation Appropriateness

Overhead costs, including facility maintenance, utilities, and administrative expenses, must be accurately allocated to each project. Incorrect allocation can distort the true cost picture and lead to flawed decision-making. For example, failing to properly account for the energy consumption of specialized manufacturing equipment can skew cost-benefit analyses and impact pricing strategies.

- Contingency Buffer Calculation

Accurate calculation of contingency buffers is crucial for mitigating unforeseen risks and uncertainties. These buffers account for potential cost overruns due to unexpected delays, technical challenges, or changes in market conditions. Insufficient contingency planning can leave projects vulnerable to financial setbacks, while excessive buffers can tie up resources unnecessarily. A relevant example is the inclusion of contingency funds to address potential supply chain disruptions or unexpected testing failures.

The collective impact of these accuracy-driven facets underscores the indispensable role that those involved in aerospace cost projection play in ensuring the fiscal responsibility and ultimate triumph of projects within this demanding and highly regulated field. The interconnectedness of these factors requires a holistic and detail-oriented approach to cost assessment.

2. Regulations

The aerospace industry operates under a stringent regulatory framework, and compliance profoundly affects positions focused on cost assessment. These roles are not simply about calculating expenses; they are also about ensuring projects adhere to a multitude of standards set by governmental and international bodies. Non-compliance can result in substantial financial penalties, project delays, and reputational damage, directly impacting the viability and profitability of aerospace ventures.

Consider, for example, the International Traffic in Arms Regulations (ITAR) in the United States. These regulations govern the export and import of defense-related articles and services. Estimators must factor in the costs associated with compliance, such as licensing fees, security protocols, and documentation requirements. Similarly, environmental regulations concerning the use of hazardous materials or the disposal of waste products generated during manufacturing necessitate meticulous cost accounting. Failure to incorporate these regulatory-driven costs can lead to inaccurate budget projections and potential legal ramifications. The European Aviation Safety Agency (EASA) and similar bodies worldwide also impose standards impacting manufacturing processes and material usage, influencing cost estimates.

In summary, a thorough understanding of the regulatory landscape is an indispensable skill for those involved in cost assessment within the aerospace sector. Regulations are not merely external constraints; they are integral components of the cost equation. Ignoring these factors can lead to flawed financial projections and significant repercussions, underscoring the critical interplay between compliance and accurate cost estimation. This knowledge is crucial for any professional pursuing this field.

3. Technology

The intersection of technology and aerospace cost projection is defined by increasing reliance on sophisticated software tools, advanced data analytics, and digital modeling techniques. Technological advancements directly influence the accuracy, efficiency, and comprehensiveness of cost assessments within the aerospace domain. The adoption of specialized software for parametric cost estimation, for example, enables the rapid generation of detailed cost breakdowns based on technical specifications and historical data. This capability minimizes the potential for human error and facilitates the exploration of various design and manufacturing scenarios to optimize cost-effectiveness. The emergence of Building Information Modeling (BIM) in aerospace, while not as prevalent as in civil engineering, also allows for a more integrated view of project costs throughout the lifecycle.

Further, data analytics plays a crucial role in identifying cost drivers and predicting future expenses. By analyzing historical project data, market trends, and economic indicators, cost assessors can develop more informed and reliable projections. The integration of machine learning algorithms allows for continuous refinement of cost models, enhancing their predictive accuracy over time. Consider the use of predictive analytics to forecast the impact of raw material price fluctuations on project budgets, allowing for proactive risk management strategies. Additionally, additive manufacturing (3D printing), a rapidly evolving technology, presents both opportunities and challenges for cost assessment. While it can reduce manufacturing lead times and material waste, accurate cost modeling requires a thorough understanding of the specific parameters and limitations of the technology.

In conclusion, technological proficiency is no longer an optional skill but a fundamental requirement for professionals involved in aerospace cost assessment. Embracing advanced software, leveraging data analytics, and adapting to emerging manufacturing technologies are essential for maintaining competitiveness and ensuring the financial viability of aerospace projects. Challenges remain in accurately modeling the costs associated with novel technologies and rapidly evolving market dynamics, requiring continuous learning and adaptation. This convergence of technology and cost projection is critical for navigating the complexities and uncertainties inherent in the aerospace industry.

4. Materials

The selection, procurement, and management of materials constitute a substantial aspect of responsibilities focused on aerospace cost assessment. An individual in such a position must possess a comprehensive understanding of material properties, market dynamics, and supply chain logistics to develop accurate and reliable cost projections. The choice of materials directly impacts manufacturing processes, performance characteristics, and ultimately, the total cost of aerospace projects. For instance, opting for a lightweight composite material over traditional aluminum alloys can reduce fuel consumption and improve payload capacity, but it also necessitates specialized manufacturing techniques and higher upfront material costs. These factors must be meticulously evaluated and incorporated into the overall cost model.

Furthermore, variations in material prices due to market fluctuations, geopolitical events, or supply chain disruptions can significantly impact project budgets. Effective material cost estimation requires continuous monitoring of market trends, building strong relationships with suppliers, and implementing risk mitigation strategies to address potential price volatility. Consider the impact of rare earth element scarcity on the cost of electronic components used in aerospace systems. A proactive approach to material sourcing and procurement is essential for minimizing cost overruns and ensuring project success. Software tools often include databases of material costs, allowing for better calculations.

In conclusion, a deep understanding of materials and their associated costs is indispensable for professionals involved in aerospace cost assessment. The relationship between material selection and cost is complex and multifaceted, requiring a combination of technical knowledge, market awareness, and strategic planning. The ability to accurately estimate material costs is critical for maintaining budget adherence, optimizing project performance, and ensuring the long-term viability of aerospace endeavors. Failure to accurately estimate material costs can be catastrophic to projects.

5. Analysis

Analysis is central to the effectiveness of cost projection within the aerospace sector. These roles demand the rigorous examination of technical specifications, market data, and historical performance to develop accurate and reliable cost models. The capacity to dissect complex information and identify critical cost drivers is paramount for sound financial decision-making.

- Technical Specification Deconstruction

Effective cost projection necessitates a thorough deconstruction of technical specifications. This involves identifying all components, materials, processes, and performance requirements associated with a given aerospace project. For example, an estimator must meticulously analyze the drawings and specifications for a new satellite antenna to determine the quantity and type of materials required, the complexity of the manufacturing process, and the testing procedures needed. The ability to translate technical details into quantifiable cost elements is essential.

- Market Data Interpretation

Understanding market trends and economic indicators is crucial for accurate cost assessment. This involves analyzing commodity prices, labor rates, exchange rates, and other relevant market data to forecast future cost fluctuations. For example, an estimator might analyze historical trends in titanium prices to project the cost of this material for an upcoming aircraft component manufacturing project. The ability to interpret market data and assess its impact on project costs is a critical skill.

- Historical Data Evaluation

Historical project data provides valuable insights into past performance and potential cost drivers. Estimators analyze historical data to identify trends, patterns, and anomalies that can inform future cost projections. For example, an estimator might review the cost history of similar satellite projects to identify common sources of cost overruns and develop mitigation strategies. The ability to learn from past experiences and apply that knowledge to future projects is essential.

- Risk Assessment Identification

Aerospace projects are inherently complex and subject to numerous risks, including technical challenges, supply chain disruptions, and regulatory changes. Estimators must identify and assess these risks and incorporate them into the cost model. For example, an estimator might assess the risk of delays in obtaining regulatory approvals and include a contingency buffer in the budget to account for potential cost increases. The ability to anticipate and quantify potential risks is critical for ensuring the financial viability of aerospace projects.

These analytical facets highlight the vital role these professionals fulfill in the aerospace industry. Each element demonstrates how in-depth analysis and market insights are essential to the accuracy of project cost projections. Such precision ensures projects remain financially sustainable, adhering to necessary regulations, and technologically advanced.

6. Negotiation

Negotiation is inextricably linked to roles focused on aerospace cost assessment, serving as a crucial mechanism for securing favorable pricing and contractual terms with suppliers, subcontractors, and other external stakeholders. While accurate cost estimation provides a baseline, effective negotiation translates these estimates into tangible cost savings and risk mitigation. The capacity to skillfully negotiate pricing, delivery schedules, and contract terms directly impacts project profitability and adherence to budgetary constraints. For example, an aerospace estimator tasked with projecting the cost of a complex electronic system will often negotiate with multiple suppliers to obtain competitive quotes for components, manufacturing services, and testing. These negotiations extend beyond price, encompassing payment terms, warranty provisions, and potential volume discounts.

The practical significance of negotiation skills extends to managing change orders and resolving disputes. During the course of an aerospace project, unforeseen technical challenges or modifications to requirements often necessitate contract revisions and price adjustments. A proficient negotiator can effectively advocate for the project’s interests while maintaining positive relationships with external partners. For example, if a critical component requires redesign due to performance issues, the estimator will engage in negotiations with the supplier to determine the cost implications and minimize any potential delays. Furthermore, negotiation plays a vital role in mitigating the impact of supply chain disruptions, securing alternative sources of materials, and managing price escalations.

In conclusion, proficiency in negotiation is a critical competency for those involved in aerospace cost assessment. It serves as a vital tool for translating accurate cost estimates into concrete financial benefits, managing risks, and resolving disputes. The integration of strong negotiation skills with technical expertise is essential for ensuring the economic viability and successful execution of aerospace projects, enabling compliance with budgetary goals while maintaining the desired performance and reliability.

Frequently Asked Questions

The following addresses prevalent inquiries related to positions focusing on cost projection within the aerospace sector, offering clarification and comprehensive insights.

Question 1: What are the primary responsibilities associated with roles focused on aerospace cost projection?

Primary responsibilities encompass the analysis of technical specifications, the estimation of material and labor costs, the development of cost models, and the negotiation of pricing with suppliers. These roles also involve the preparation of budget proposals, the monitoring of project expenses, and the identification of potential cost-saving opportunities.

Question 2: What qualifications are typically required to secure roles focused on aerospace cost projection?

Common qualifications include a bachelor’s degree in engineering, finance, or a related field, along with relevant experience in cost estimation or project management. Employers often seek candidates with strong analytical skills, proficiency in cost estimation software, and a thorough understanding of aerospace manufacturing processes and regulatory requirements.

Question 3: What essential skills are necessary for success in roles focused on aerospace cost projection?

Essential skills include proficiency in data analysis, expertise in cost estimation techniques, strong communication and presentation skills, negotiation abilities, and a detailed understanding of aerospace engineering principles. Familiarity with statistical modeling and risk assessment methodologies is also highly advantageous.

Question 4: What are the typical career paths available to individuals in roles focused on aerospace cost projection?

Typical career paths may involve advancement to senior estimator positions, project management roles, or leadership positions within finance or procurement departments. Some individuals may also pursue consulting opportunities, providing expert cost estimation services to aerospace companies.

Question 5: What are the common challenges encountered in roles focused on aerospace cost projection?

Common challenges include managing uncertainty and risk, dealing with incomplete or ambiguous technical data, adapting to changing market conditions, and navigating complex regulatory requirements. Balancing cost optimization with performance requirements and ensuring project adherence to budgetary constraints can also be demanding.

Question 6: How does technology influence the evolution of roles focused on aerospace cost projection?

Technology plays a pivotal role in transforming cost estimation processes. Specialized software, data analytics, and digital modeling techniques enhance the accuracy, efficiency, and comprehensiveness of cost assessments. The integration of machine learning algorithms allows for continuous refinement of cost models, improving predictive capabilities over time.

Accurate cost projection is paramount for effective decision-making, risk mitigation, and resource allocation in aerospace endeavors. The roles discussed are vital to the fiscal soundness of this critical industry.

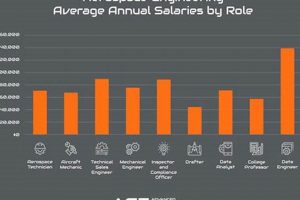

The next section will provide key insights related to compensation within the field.

Aerospace Estimator Jobs

This exposition has detailed the multifaceted responsibilities, essential qualifications, and prevalent challenges associated with aerospace estimator jobs. These roles require a unique blend of technical acumen, analytical prowess, and negotiation skills to ensure projects adhere to budgetary constraints and regulatory mandates. Accurate cost projections are critical for informed decision-making, effective risk management, and the overall financial health of aerospace ventures.

The future of aerospace estimator jobs hinges on adapting to evolving technologies, mastering advanced data analytics, and navigating an increasingly complex regulatory landscape. Professionals in this field must embrace continuous learning and cultivate strong communication skills to effectively convey cost projections to stakeholders. The enduring significance of this role lies in its contribution to the sustainability and advancement of the aerospace industry, ensuring the responsible allocation of resources in this critical sector. Continued professional development is essential for success.