Compensation for professionals engaged in the manufacturing and assembly of components for aircraft and spacecraft represents a critical aspect of the aerospace industry. This remuneration reflects the skill, experience, and responsibility associated with producing parts that meet stringent safety and performance requirements. For example, a technician welding intricate aluminum structures for a commercial airliner receives payment commensurate with the precision and quality demanded by the role.

Adequate earnings are essential for attracting and retaining qualified personnel within this specialized sector. Competitive pay scales ensure a workforce motivated to uphold high standards in production, contributing directly to the reliability and safety of flight. Historically, these earnings have been influenced by factors such as economic conditions, union representation, and advancements in manufacturing technology, impacting both overall industry growth and the livelihood of skilled workers.

The subsequent discussion delves into the key factors that influence earnings within the aerospace manufacturing environment, exploring regional variations, experience levels, and the impact of specialized skills on compensation packages. Further analysis will examine the projected trends and future outlook for career advancement within this vital segment of the aerospace sector.

Understanding the factors that influence earnings is crucial for individuals entering or advancing within the aerospace manufacturing sector. The following tips offer insight into maximizing potential income and career progression.

Tip 1: Acquire Specialized Skills: Mastery of niche skills, such as advanced welding techniques, precision machining, or composite material fabrication, significantly increases earning potential. For example, certified welders with experience in titanium alloys command higher compensation.

Tip 2: Pursue Relevant Certifications: Industry-recognized certifications, such as those offered by the FAA or professional engineering organizations, demonstrate competency and commitment to quality. These credentials can lead to salary increases and enhanced job opportunities.

Tip 3: Gain Experience with Advanced Technologies: Familiarity with computer-aided design (CAD) software, numerical control (NC) programming, and robotic automation systems is highly valued. Demonstrating proficiency in these technologies can translate to higher earnings in modern fabrication environments.

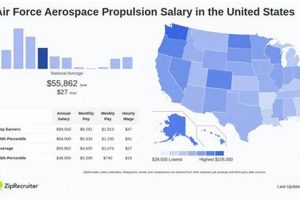

Tip 4: Consider Geographic Location: Earnings can vary significantly based on location, with regions boasting a high concentration of aerospace companies often offering more competitive compensation packages. Researching regional pay scales before accepting a position is advisable.

Tip 5: Negotiate Effectively: Thoroughly research industry standards and understand the market value of one’s skills before engaging in salary negotiations. Presenting a well-prepared case based on experience, certifications, and demonstrated abilities can result in a more favorable offer.

Tip 6: Stay Updated on Industry Trends: Continuously monitor advancements in aerospace manufacturing processes and technologies. Adapting to new methods and acquiring relevant knowledge ensures continued relevance and increases long-term earning potential.

Tip 7: Seek Opportunities for Advancement: Proactively pursue opportunities to take on leadership roles or expand responsibilities within the organization. Demonstrating a commitment to continuous improvement and taking initiative can pave the way for promotions and salary increases.

By focusing on skills development, acquiring relevant certifications, and understanding market dynamics, professionals can effectively navigate the complexities of compensation in aerospace manufacturing.

The subsequent sections will provide detailed information regarding salary ranges and benefits packages that are commonly found within this industry.

1. Experience Level

Experience level exerts a direct and substantial influence on earnings within aerospace fabrication. The correlation operates on a principle of increasing competence and diminishing risk; as an individual accumulates years of practical application, their value to the organization rises proportionally. Entry-level positions, such as trainee fabricators or junior assemblers, command relatively lower salaries, reflecting the initial learning curve and the need for close supervision. As employees progress, mastering core skills and demonstrating consistent performance, their earnings potential steadily increases.

Consider, for instance, a newly graduated machinist entering an aerospace manufacturing facility. Their initial compensation will likely be significantly lower than that of a master machinist with fifteen years of experience. The seasoned professional possesses an extensive understanding of materials, processes, and troubleshooting techniques, enabling them to execute complex tasks with minimal supervision and a reduced probability of error. This expertise is crucial for maintaining quality control and minimizing costly production delays, thereby justifying higher compensation. Similarly, a lead technician with decades of experience in composite layup for aircraft wings brings invaluable knowledge to the table, impacting efficiency, material usage, and ultimately, the structural integrity of the final product.

The impact of experience level is further amplified by the specialized nature of aerospace fabrication. Mastery of specific techniques, such as advanced welding, precision machining, or non-destructive testing, requires years of dedicated practice. Consequently, individuals possessing these skills and a proven track record command a premium in the labor market. Understanding this relationship between experience and earnings is essential for both employers and employees. It allows companies to structure compensation packages that attract and retain skilled personnel, while also providing individuals with a clear path for career advancement and increased financial reward.

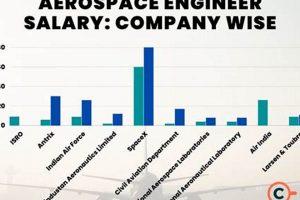

2. Geographic Location

Geographic location constitutes a significant determinant in the compensation structures within the aerospace fabrication sector. Regional economic conditions, the concentration of aerospace manufacturing facilities, and the local cost of living collectively shape the salary landscape for professionals in this field.

- Cost of Living Adjustments

The prevailing cost of living within a specific geographic area directly impacts earning expectations. Regions with higher living expenses, such as major metropolitan areas or states with stringent environmental regulations, typically offer elevated compensation to offset these costs. For instance, the expense of housing, transportation, and daily necessities in Southern California, a hub for aerospace activity, necessitate higher wages compared to areas with a lower cost of living. This adjustment aims to maintain a comparable standard of living for employees.

- Regional Demand and Industry Concentration

The density of aerospace manufacturing facilities within a region influences the demand for skilled labor. Areas with a high concentration of aerospace companies, research institutions, and supporting industries create a competitive job market, driving up compensation levels. States like Washington, home to major aircraft manufacturers, and Florida, with its significant space industry presence, exemplify this phenomenon. The increased competition for talent incentivizes employers to offer more attractive salaries and benefits packages to attract and retain qualified professionals.

- Union Representation and Collective Bargaining

The presence and strength of labor unions vary significantly across geographic regions. In areas with strong union representation, collective bargaining agreements often establish standardized wage scales and benefits packages for aerospace fabrication workers. These agreements typically result in higher wages and improved working conditions compared to non-unionized facilities. The influence of unions can therefore contribute to regional variations in compensation, particularly in states with a history of strong labor movements.

- State and Local Economic Incentives

State and local governments may offer economic incentives, such as tax breaks or training grants, to attract aerospace companies to their region. These incentives can indirectly impact compensation by encouraging companies to invest in workforce development and offer competitive salaries. Conversely, regions with less favorable business climates may experience lower wage growth and fewer job opportunities within the aerospace fabrication sector.

The interplay of cost of living, industry concentration, union influence, and economic incentives creates a complex mosaic of compensation levels across different geographic locations. Professionals seeking to maximize their earning potential within aerospace fabrication should carefully consider these regional variations when evaluating career opportunities.

3. Skill Specialization

Skill specialization is a primary driver of compensation within aerospace fabrication. Possessing expertise in niche areas of manufacturing directly correlates with increased earning potential. This relationship stems from the critical need for precision, reliability, and adherence to stringent quality standards inherent in aerospace component production. The more specialized and difficult a skill to acquire, the greater its value in the labor market.

Examples of high-value skill specializations include advanced composite layup techniques, proficiency in non-destructive testing (NDT) methods like ultrasonic or radiographic inspection, expertise in electron beam welding of exotic alloys, and mastery of complex computer-aided design (CAD) and manufacturing (CAM) software. A technician certified in a specific NDT method, for example, ensures the structural integrity of critical airframe components, preventing potential catastrophic failures. This specialized knowledge directly translates into a higher salary due to the inherent risk mitigation and quality assurance capabilities it provides. Similarly, a CNC programmer capable of optimizing machining processes for complex geometries can significantly reduce material waste and production time, justifying increased compensation.

The practical significance of understanding the link between skill specialization and earnings lies in its ability to guide career development. Professionals can strategically invest in acquiring skills that are in high demand within the aerospace industry, thereby maximizing their future earning potential. This targeted approach, focusing on areas with limited skilled personnel, allows individuals to differentiate themselves in the competitive job market and command higher salaries. Furthermore, employers can leverage this understanding to prioritize training programs that address critical skill gaps, ensuring a workforce equipped to meet the evolving demands of aerospace manufacturing.

4. Company Size

The size of an aerospace fabrication company correlates significantly with compensation levels. Larger organizations typically offer higher salaries due to several factors, including greater revenue streams, more complex projects, and a hierarchical management structure that supports higher pay grades. These firms often possess the financial resources to invest in advanced technologies and attract top talent, translating to more competitive compensation packages. For example, a multinational aerospace corporation engaged in the production of commercial aircraft will likely provide higher earnings than a smaller, privately owned shop specializing in custom aircraft components. This difference reflects the scale of operations, the technical demands of the projects, and the company’s overall financial capacity.

The complexity of projects handled by larger firms also contributes to the higher salary scales. These companies often undertake large-scale manufacturing operations that require specialized expertise and advanced equipment. Consequently, they are willing to pay a premium for skilled professionals who can manage and execute these complex tasks. In contrast, smaller fabrication shops may focus on less intricate projects, requiring a smaller range of skills and offering correspondingly lower compensation. Furthermore, larger companies typically offer more comprehensive benefits packages, including health insurance, retirement plans, and paid time off, which collectively enhance the overall value of employment beyond just the base salary.

In summary, company size functions as a critical determinant in aerospace fabrication earnings. Larger organizations, with their greater financial resources and more complex projects, generally provide higher compensation and more comprehensive benefits compared to smaller entities. Understanding this relationship is essential for individuals seeking to maximize their earning potential within the aerospace manufacturing sector, allowing them to strategically target employment opportunities based on company size and associated compensation expectations.

5. Union Membership

Union membership represents a significant factor influencing compensation within the aerospace fabrication sector. Collective bargaining agreements negotiated by labor unions often establish standardized wage scales and benefits packages, impacting the overall earnings of unionized employees.

- Collective Bargaining Agreements

Labor unions negotiate contracts with aerospace manufacturing companies that stipulate minimum wage rates, cost-of-living adjustments, and other compensation provisions. These agreements provide a baseline for earnings and often result in higher wages compared to non-unionized positions with similar skill requirements. For example, the United Aerospace Workers (UAW) negotiates contracts that determine pay scales and benefits for numerous aerospace manufacturing facilities.

- Wage Standardization and Transparency

Union contracts promote wage standardization, ensuring that employees with similar skills and experience receive comparable compensation, regardless of individual negotiation skills. This transparency reduces pay disparities and provides a predictable framework for earnings. The International Association of Machinists and Aerospace Workers (IAM) advocates for clear and equitable wage structures, minimizing potential for discriminatory pay practices.

- Benefits and Retirement Packages

In addition to wages, union membership often includes access to more comprehensive benefits packages, such as health insurance, retirement plans, and paid time off. These benefits contribute significantly to the overall value of employment and can improve the financial security of unionized workers. Union-negotiated retirement plans, for instance, typically offer guaranteed benefits and employer contributions, enhancing long-term financial stability.

- Job Security and Advocacy

Union membership can provide increased job security through contractual protections against arbitrary termination or layoffs. Unions also advocate for their members’ interests, addressing workplace issues and ensuring fair treatment. This added security and advocacy can reduce stress and improve overall job satisfaction, indirectly impacting productivity and potential for advancement.

The influence of union membership on earnings within aerospace fabrication is substantial. Collective bargaining agreements, wage standardization, comprehensive benefits packages, and job security provisions collectively contribute to improved financial outcomes for unionized employees compared to their non-union counterparts. Understanding this correlation is crucial for individuals seeking employment within this sector, as union membership can significantly impact long-term earning potential and overall job satisfaction.

6. Education Attainment

Education attainment serves as a noteworthy factor influencing compensation within the aerospace fabrication sector. Higher levels of education typically translate to greater technical proficiency, problem-solving capabilities, and the capacity to adapt to technological advancements, attributes highly valued by employers. Consequently, individuals with advanced degrees or specialized certifications often command higher salaries.

- Formal Degrees (Associate’s and Bachelor’s)

An Associate’s or Bachelor’s degree in fields such as aerospace engineering technology, manufacturing engineering, or materials science can provide a foundational understanding of aerospace fabrication processes. These degrees equip individuals with the theoretical knowledge and practical skills necessary to perform complex tasks, such as designing tooling, optimizing manufacturing processes, and troubleshooting technical issues. For example, a manufacturing engineer with a Bachelor’s degree may be responsible for implementing lean manufacturing principles to improve efficiency, leading to cost savings and justifying a higher salary.

- Vocational Certifications and Training Programs

Vocational certifications from accredited institutions or industry associations demonstrate mastery of specific skills, such as welding, machining, or composite fabrication. These certifications validate competence and signal to employers that the individual possesses the necessary expertise to perform critical tasks safely and effectively. For example, a certified welder with expertise in aerospace-grade alloys commands higher compensation due to the stringent quality requirements and the potential consequences of weld failures.

- Advanced Degrees (Master’s and Doctorate)

A Master’s or Doctorate degree in a relevant field can significantly enhance earning potential, particularly in research and development or management roles. These advanced degrees signify a deeper understanding of engineering principles and research methodologies, enabling individuals to contribute to innovation and process improvement. For example, a materials scientist with a Ph.D. may lead research efforts to develop new lightweight materials for aircraft structures, contributing to improved fuel efficiency and performance, thus justifying a premium salary.

- Continuing Education and Professional Development

Continuing education and professional development activities, such as attending industry conferences, completing online courses, or pursuing advanced certifications, demonstrate a commitment to lifelong learning and staying current with technological advancements. Employers value individuals who proactively seek to expand their knowledge and skills, as this enhances their ability to contribute to the organization’s success. For instance, a technician who completes training in the latest CNC programming techniques becomes more valuable to the company, as they can improve machining efficiency and reduce errors.

In conclusion, education attainment significantly impacts compensation within aerospace fabrication. Formal degrees, vocational certifications, advanced degrees, and ongoing professional development all contribute to enhanced skills and knowledge, ultimately leading to higher salaries and greater career opportunities. Professionals seeking to maximize their earning potential should strategically invest in education and training that aligns with industry demands and technological advancements.

7. Security Clearance

The attainment and maintenance of a security clearance represent a critical factor influencing compensation levels within specific segments of the aerospace fabrication sector. This requirement, often mandated by government agencies or prime contractors, signifies an individual’s trustworthiness and suitability to access classified information, materials, or facilities, directly impacting potential earnings.

- Access to Classified Projects

Positions requiring a security clearance are frequently associated with projects involving sensitive national security information or advanced technology. The limited pool of qualified personnel with the necessary clearances creates a supply-demand dynamic that drives up compensation. For example, a skilled machinist fabricating components for a classified military aircraft will likely receive a higher salary than a counterpart working on commercial aircraft parts, even with similar skills and experience.

- Enhanced Background Checks and Vetting

The process of obtaining a security clearance involves rigorous background checks, security interviews, and potential polygraph examinations. This extensive vetting process assures employers of an individual’s reliability and trustworthiness, reducing potential risks associated with handling sensitive information. The investment of time and resources required for clearance processing further justifies higher compensation for cleared personnel.

- Increased Responsibility and Accountability

Individuals with security clearances assume a higher level of responsibility and accountability for safeguarding classified information and adhering to strict security protocols. Any breach of security can result in severe penalties, including legal prosecution and loss of clearance. This heightened responsibility warrants additional compensation to reflect the increased demands and potential risks associated with the role.

- Career Advancement Opportunities

Holding a security clearance can unlock career advancement opportunities within organizations involved in classified work. As individuals gain experience and expertise, their value to the company increases, leading to promotions and higher salaries. Furthermore, the clearance itself becomes a valuable asset, making the individual more marketable to other companies engaged in classified projects.

The influence of security clearance on aerospace fabrication earnings extends beyond the immediate salary. It encompasses increased job security, enhanced career prospects, and access to specialized training and development programs. For professionals seeking to maximize their earning potential within this sector, pursuing and maintaining a security clearance can prove to be a strategic career move, leading to significant financial rewards and professional growth.

Frequently Asked Questions

The following addresses common inquiries regarding financial remuneration in aerospace fabrication, providing clarity on factors influencing earnings.

Question 1: What is the typical entry-level compensation for an aerospace fabricator?

Entry-level pay scales are influenced by geographic location, company size, and educational background. Typically, candidates with vocational training can expect an initial annual income ranging from \$35,000 to \$45,000. Positions requiring a bachelor’s degree may command a higher starting salary.

Question 2: How does experience level affect earnings in this field?

Years of experience directly correlate with increased compensation. Seasoned professionals with ten or more years in aerospace fabrication often earn significantly more than their entry-level counterparts, potentially exceeding \$75,000 annually, dependent on skill specialization and responsibilities.

Question 3: What role do certifications play in determining earnings?

Industry-recognized certifications, such as those from the FAA or AWS, can enhance earning potential. Specialized certifications demonstrate competency and proficiency in specific fabrication processes, making candidates more attractive to employers and justifying higher pay scales.

Question 4: How does geographic location impact compensation for aerospace fabricators?

Geographic location is a crucial factor. Regions with a high concentration of aerospace companies and a higher cost of living, such as California and Washington, typically offer more competitive salaries to attract skilled workers.

Question 5: Do unionized aerospace fabrication positions offer higher pay compared to non-unionized roles?

Union membership often results in higher wages and more comprehensive benefits packages due to collective bargaining agreements. These agreements establish standardized wage scales and protect workers’ rights, potentially leading to improved financial outcomes.

Question 6: What is the long-term career outlook for aerospace fabricators, and how might earnings progress over time?

The long-term career outlook is generally positive, with projected growth in the aerospace industry. By acquiring new skills, pursuing advanced training, and demonstrating leadership abilities, professionals can advance to higher-paying roles, such as manufacturing engineers, supervisors, or project managers, significantly increasing their earning potential.

These frequently asked questions offer insight into the dynamics of financial compensation in aerospace fabrication. Understanding these factors is essential for individuals navigating career paths within this sector.

The subsequent section addresses emerging trends and future opportunities within aerospace fabrication.

Aerospace Fabrication Salary

The exploration of aerospace fabrication salary has revealed a complex interplay of factors influencing remuneration within this specialized field. Experience, geographic location, skill specialization, company size, union membership, education, and security clearance each contribute to the overall compensation structure. Understanding these elements is crucial for both employers seeking to attract and retain qualified personnel and for individuals pursuing careers within aerospace manufacturing.

Continued vigilance regarding industry trends, technological advancements, and evolving skill requirements remains paramount. A proactive approach to professional development, coupled with a strategic awareness of market dynamics, will position individuals for optimal career progression and financial reward within the dynamic aerospace fabrication landscape. The ongoing pursuit of excellence and adaptability are essential for sustained success in this technically demanding and economically significant sector.

![Aerospace Engineer Salary: CS vs Aero Eng? [2024] Innovating the Future of Flight with Reliable Aviation Solutions Aerospace Engineer Salary: CS vs Aero Eng? [2024] | Innovating the Future of Flight with Reliable Aviation Solutions](https://mixaerospace.com/wp-content/uploads/2026/02/th-71-300x200.jpg)

![[Guide] Bennett Aerospace Salaries: What to Expect (2024) Innovating the Future of Flight with Reliable Aviation Solutions [Guide] Bennett Aerospace Salaries: What to Expect (2024) | Innovating the Future of Flight with Reliable Aviation Solutions](https://mixaerospace.com/wp-content/uploads/2026/02/th-52-300x200.jpg)