Opportunities within the aircraft and spacecraft industry located in British Columbia encompass a variety of roles, from engineering and design to manufacturing and maintenance. These positions are found in companies that build aircraft components, provide maintenance services for existing fleets, and develop new aerospace technologies.

The presence of these roles contributes significantly to the provincial economy, fostering innovation and providing skilled employment. The sector’s growth has historically been driven by British Columbia’s strategic location, a skilled workforce, and government initiatives that support aerospace development. This industry provides benefits through attracting investment and contributing to a high-technology economic environment.

Further examination will detail the specific roles available, the necessary qualifications for entry, and a review of prominent companies and organizations involved in this field within British Columbia.

The following suggestions are provided to aid individuals seeking opportunities in the aircraft and spacecraft industry within the province.

Tip 1: Educational Foundation: A strong background in engineering (aerospace, mechanical, electrical), computer science, or a related technical discipline is fundamental. Relevant degrees and certifications significantly enhance candidacy.

Tip 2: Skills Development: Acquire specific skills that are highly valued, such as CAD/CAM software proficiency, knowledge of aerospace materials, and experience with quality control standards (e.g., AS9100). Technical institutions and colleges often offer specialized training programs.

Tip 3: Targeted Networking: Actively participate in industry events, conferences, and workshops. Networking provides opportunities to connect with professionals and learn about unadvertised positions.

Tip 4: Internship Programs: Seek internship opportunities with aerospace companies in British Columbia. Internships offer practical experience and can lead to full-time employment.

Tip 5: Company Research: Conduct thorough research on aerospace companies operating in British Columbia. Understanding their specific areas of specialization and technological focus will allow for tailoring applications effectively.

Tip 6: Online Job Boards: Monitor relevant online job boards and company websites frequently for advertised openings. Customize resumes and cover letters to align with the specific requirements of each position.

Tip 7: Continuous Learning: The aerospace industry is constantly evolving. Commit to continuous learning to stay abreast of new technologies and advancements. This includes attending workshops, reading industry publications, and pursuing advanced certifications.

The suggestions emphasize the importance of a relevant educational background, skills in specific areas, active networking, and industry experience. These elements are critical for success in the aerospace job market.

The next section will consider common qualifications and requirements sought by employers when hiring for aerospace-related roles.

1. Engineering and Design

Engineering and Design serve as the foundational element for many opportunities within the British Columbia aerospace sector. A constant demand exists for skilled professionals capable of innovating, developing, and refining aircraft and spacecraft components. This demand stems directly from the industry’s need to maintain a competitive edge through technological advancement and efficiency improvements. Companies operating within the province, such as Viking Air and MDA, invest heavily in research and development, creating a consistent need for engineers and designers specializing in areas like aerodynamics, structural analysis, avionics, and propulsion systems. These roles directly impact the performance, safety, and operational costs of aerospace products and services.

The practical significance of understanding this connection lies in recognizing the specific skills and qualifications sought by employers. Positions frequently require a strong academic background in aerospace, mechanical, or electrical engineering, coupled with proficiency in software such as CAD/CAM and finite element analysis (FEA) tools. Familiarity with aerospace materials, manufacturing processes, and regulatory standards (e.g., Transport Canada regulations) is also highly valued. For example, a design engineer working on a new landing gear system for a regional aircraft would need to apply principles of stress analysis, material science, and hydraulics to ensure structural integrity and compliance with safety regulations. These engineering capabilities become essential for ensuring safety and reliability of aircraft and spacecraft.

In summary, Engineering and Design are integral to the aerospace sector in British Columbia, with a clear cause-and-effect relationship between industry innovation and the demand for qualified professionals. Recognizing the specific skills and qualifications required, and understanding the practical applications of engineering principles within the industry, is crucial for individuals seeking these opportunities. The ongoing development of new technologies and materials within the aerospace field ensures that this area will remain a key driver for employment within British Columbia’s aerospace industry.

2. Manufacturing Processes

Manufacturing processes form a critical pillar supporting opportunities within British Columbias aerospace sector. These processes, encompassing fabrication, assembly, and finishing of aircraft components, are directly linked to the creation and sustenance of specialized roles within the industry.

- Precision Machining and Fabrication

This area involves the use of advanced machinery, such as CNC mills and lathes, to create components with tight tolerances. Examples include manufacturing turbine blades for jet engines or creating structural elements for aircraft fuselages. The demand for machinists, programmers, and quality control inspectors directly correlates with the level of precision required in aerospace manufacturing.

- Composite Material Processing

Many modern aircraft rely heavily on composite materials for their superior strength-to-weight ratios. Manufacturing processes include resin transfer molding, prepreg lay-up, and autoclave curing. Technicians, engineers, and specialists in composite materials are needed to handle these processes, ensuring the integrity and performance of the finished components.

- Assembly and Integration

The assembly of aircraft involves integrating various components and systems, from avionics and electrical wiring to hydraulic systems and flight controls. Assembly technicians, mechanics, and engineers are crucial for ensuring that all systems function correctly and are properly integrated according to strict aerospace standards. This work is exemplified by the final assembly of regional aircraft or the integration of mission-critical sensors onto spacecraft.

- Surface Treatment and Finishing

Surface treatment processes, such as anodizing, painting, and coating, protect aircraft components from corrosion and wear. Finishing operations ensure that components meet aesthetic requirements and aerodynamic performance standards. Skilled technicians and inspectors are required to perform these tasks and verify compliance with stringent aerospace specifications.

The demand for personnel with expertise in these manufacturing processes is sustained by the ongoing production, maintenance, and repair activities within British Columbias aerospace industry. The integration of advanced technologies and materials ensures that skilled workers will continue to be essential for maintaining the province’s competitive position in the global aerospace market.

3. Maintenance and Repair

Maintenance and repair activities are fundamentally linked to opportunities in British Columbia’s aircraft and spacecraft industry. The ongoing need to maintain existing aircraft fleets and ensure the operational readiness of various systems creates a consistent demand for skilled personnel. This facet of the aerospace sector is not merely about fixing malfunctions; it encompasses a broad range of specialized tasks and expertise.

- Aircraft Maintenance Engineering

Aircraft maintenance engineers (AMEs) are responsible for the inspection, repair, and overhaul of aircraft structures, engines, and systems. These professionals adhere to strict regulatory standards and procedures to ensure airworthiness. In British Columbia, AMEs find employment with airlines, maintenance, repair, and overhaul (MRO) facilities, and aviation service providers. The scope of their work can range from routine inspections and component replacements to complex engine overhauls and structural repairs, each contributing to flight safety.

- Avionics Maintenance and Repair

Avionics technicians specialize in maintaining and repairing the electronic systems found on modern aircraft. This includes navigation systems, communication equipment, radar, and flight control systems. With the increasing complexity of avionics technology, demand for skilled avionics technicians is strong. Their expertise is critical for ensuring the reliability and accuracy of aircraft electronic systems, which directly affects flight safety and operational efficiency. This role also focuses on ensuring that software is also safe to use for any aircrafts that is maintained.

- Component Overhaul and Repair

Many aerospace components, such as landing gear, hydraulic systems, and actuators, require periodic overhaul and repair to ensure continued functionality. Specialized technicians and engineers are involved in disassembling, inspecting, repairing, and reassembling these components. The demand for component overhaul services is driven by the need to extend the lifespan of aircraft and reduce the cost of replacing expensive parts. Component overhaul jobs are common at maintenance facilities throughout British Columbia.

- Non-Destructive Testing (NDT)

Non-destructive testing (NDT) is a critical aspect of aerospace maintenance, involving the use of techniques such as radiography, ultrasonic testing, and dye penetrant inspection to detect hidden flaws and defects in aircraft structures and components without causing damage. NDT technicians play a vital role in ensuring the structural integrity of aircraft and preventing catastrophic failures. Their services are essential for maintaining the safety and reliability of aging aircraft fleets and are often required by aviation regulatory bodies.

These specialized areas within maintenance and repair highlight the diverse range of opportunities available within the British Columbia aircraft and spacecraft industry. The demand for skilled professionals in these roles is driven by the ongoing need to maintain and extend the operational life of aircraft, ensuring that these jobs are essential for a safe and reliable aerospace sector. These factors establish “Maintenance and Repair” as a key component in BC’s aerospace economy.

4. Quality Assurance Standards

Quality assurance standards are fundamentally intertwined with opportunities within British Columbia’s aircraft and spacecraft sector. Strict adherence to established protocols is not merely a regulatory requirement; it is a cornerstone of the industry, directly impacting job roles and responsibilities. Standards such as AS9100, a widely adopted quality management system specific to the aerospace industry, dictate processes and procedures throughout the design, manufacturing, and maintenance phases. This creates a demand for professionals skilled in implementing, auditing, and maintaining these standards.

The practical application of quality assurance impacts various job functions. Quality control inspectors, for example, meticulously examine components and systems to ensure they meet stringent specifications. Manufacturing engineers develop and optimize processes to minimize defects and improve product reliability. Auditors conduct internal and external assessments to verify compliance with quality management systems. Failure to meet these standards can lead to significant consequences, including product recalls, regulatory penalties, and reputational damage. For instance, a failure to properly inspect a critical aircraft component during manufacturing could result in catastrophic failure during operation, highlighting the critical importance of quality assurance at every stage.

In summary, quality assurance standards are essential to the success of British Columbia’s aerospace sector. Understanding the requirements and impact of these standards is crucial for individuals seeking careers in this industry. As the sector continues to evolve and adopt new technologies, the demand for professionals with expertise in quality assurance will only increase, ensuring that maintaining rigorous standards remains a central component for these roles.

5. Regulatory Compliance

Regulatory compliance forms an integral link to opportunities within the British Columbia aerospace industry. Adherence to aviation regulations issued by Transport Canada and other international bodies dictates operational procedures and safety protocols. This imperative creates numerous specialized roles focused on ensuring that organizations meet all legal and technical requirements. The demand for personnel with expertise in regulatory affairs is driven by the need to mitigate risk, maintain airworthiness, and avoid legal penalties. A failure to comply can result in grounding of aircraft, revocation of operating licenses, and significant financial losses. For example, proper documentation of aircraft maintenance and adherence to scheduled inspections are crucial for satisfying Transport Canada’s Civil Aviation Regulations (CARs).

The practical implications of regulatory compliance manifest in several job functions. Compliance officers oversee internal audits, develop and implement safety management systems (SMS), and serve as liaisons with regulatory agencies. Aircraft maintenance engineers (AMEs) are trained to perform maintenance tasks in accordance with approved maintenance schedules and procedures. Quality assurance personnel verify that all processes meet regulatory standards. Real-world examples include ensuring compliance with mandatory service bulletins (SBs) issued by aircraft manufacturers or implementing changes to flight operations manuals to reflect updated regulations. Maintaining this compliance is necessary for any continued operations and related positions.

In summary, regulatory compliance is not merely an external constraint but an inherent element of the aerospace sector in British Columbia. The ongoing need to navigate evolving regulations and maintain a culture of safety drives demand for skilled professionals across various job functions. Understanding the importance of compliance is crucial for individuals seeking careers in the industry, as adherence to regulations directly affects operational efficiency, safety, and overall success. This ensures a standard for all aspects of aerospace roles in BC.

Frequently Asked Questions

The following section addresses common inquiries regarding employment within the aircraft and spacecraft industry in British Columbia. The information provided is intended to offer clarity on essential aspects of the sector.

Question 1: What are the primary qualifications required for aerospace engineering positions?

A bachelor’s degree in aerospace, mechanical, or electrical engineering is generally required. Advanced degrees may be necessary for specialized roles. Proficiency in CAD/CAM software and a strong understanding of aerospace materials and manufacturing processes are also expected.

Question 2: What type of aerospace jobs are currently in high demand in British Columbia?

Aircraft maintenance engineers, avionics technicians, and design engineers are consistently in demand. Roles related to composite materials and advanced manufacturing techniques are also experiencing growth.

Question 3: Are there opportunities for individuals without a formal aerospace degree?

Yes, opportunities exist in areas such as manufacturing, assembly, and quality control. Technical certifications and relevant experience can be valuable assets in these roles.

Question 4: How can individuals gain practical experience in the aerospace sector?

Internships, co-op programs, and entry-level positions are viable pathways for gaining practical experience. Networking at industry events and connecting with professionals can also provide valuable insights.

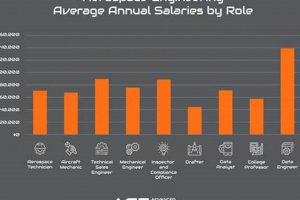

Question 5: What is the typical salary range for aerospace positions in British Columbia?

Salaries vary depending on the role, experience level, and company size. Entry-level positions may offer competitive wages, while specialized roles with significant experience can command higher salaries. Salary surveys from industry associations can offer more specific information.

Question 6: What resources are available for individuals seeking aerospace jobs in British Columbia?

Online job boards, industry associations, company websites, and career fairs are valuable resources. Networking with professionals and seeking guidance from career counselors can also be beneficial.

These responses offer a concise overview of key considerations for those interested in pursuing opportunities related to aerospace in British Columbia. Awareness of necessary qualifications, in-demand roles, and available resources contributes to a more informed job search.

The subsequent section explores available resources.

Conclusion

This exploration has outlined critical aspects of opportunities within British Columbia’s aerospace sector. Engineering, manufacturing, maintenance, quality assurance, and regulatory compliance form the cornerstones of this industry. These elements shape available positions and influence the skills required for success. Individuals seeking entry into the aerospace job market in British Columbia must carefully consider these factors.

The province’s aerospace industry continues to evolve. Prospective professionals should remain informed about emerging technologies and regulatory changes to maximize their opportunities. A commitment to continuous learning and professional development remains essential for contributing to and benefiting from the sector’s ongoing growth.Opportunities are constantly available.