The availability of employment opportunities in the aircraft and spacecraft manufacturing and related services sectors within the Tacoma, Washington, metropolitan area represents a significant component of the regional economy. These positions span a wide array of disciplines, from engineering and manufacturing to quality control and administrative support, all located within and around the city of Tacoma.

These opportunities offer substantial benefits to the local community, fostering economic growth, technological innovation, and a skilled workforce. Historically, the Puget Sound region, including Tacoma, has maintained a strong presence in the aerospace industry, driven by major manufacturers and a network of supporting businesses. This long-standing industry presence contributes significantly to the area’s stability and prosperity.

The subsequent sections will delve into the specific types of roles available, the skills and qualifications sought by employers, and the factors that contribute to the area’s attractiveness as a hub for this sector. It will also address resources available to individuals seeking to enter or advance within this field.

The following provides actionable guidance for individuals seeking positions within the aerospace industry situated in the Tacoma, Washington area. Adherence to these recommendations may enhance an applicant’s prospects for securing suitable employment.

Tip 1: Target Relevant Skills: Emphasize skills aligned with common aerospace requirements. Examples include proficiency in CAD/CAM software, knowledge of materials science, experience with quality control procedures, and familiarity with FAA regulations. Tailor resumes and cover letters to highlight these competencies.

Tip 2: Network Strategically: Attend industry-specific events, job fairs, and professional organization meetings within the Puget Sound region. Networking can provide access to unadvertised job openings and valuable industry insights. Consider joining organizations such as the Pacific Northwest Aerospace Alliance.

Tip 3: Leverage Online Resources: Utilize online job boards and company career pages to identify current openings. Regularly monitor websites of major aerospace manufacturers and their suppliers operating in the Tacoma area. Websites like LinkedIn and Indeed are valuable resources.

Tip 4: Acquire Necessary Certifications: Obtain relevant certifications to demonstrate specialized knowledge and skills. Examples include certifications in aerospace manufacturing processes, quality assurance, or specific software applications. Certifications can significantly increase an applicant’s competitiveness.

Tip 5: Understand Local Industry Dynamics: Research the specific companies operating in the Tacoma area and their respective areas of specialization. Understanding their products, services, and company culture can aid in tailoring applications and interview responses. Publicly available company information is a valuable resource.

Tip 6: Consider Apprenticeships and Internships: Pursue apprenticeships or internships to gain practical experience and build a professional network. These opportunities can provide a pathway to full-time employment within the aerospace sector. Many local companies offer structured training programs.

Adhering to these recommendations can significantly increase the probability of securing employment within the aerospace sector of Tacoma. By focusing on relevant skills, strategic networking, and targeted job searching, candidates can effectively navigate this competitive landscape.

The subsequent sections will address long-term career prospects and future growth within the Tacoma aviation economy.

1. Engineering and Design

Engineering and design roles are fundamental to the aerospace sector in the Tacoma, Washington region, driving innovation, efficiency, and safety in aircraft and spacecraft development. These positions encompass a broad spectrum of specializations, each contributing uniquely to the lifecycle of aerospace products.

- Aerodynamic Design

Aerodynamic design engineers optimize aircraft shapes to minimize drag and maximize lift. These professionals utilize computational fluid dynamics and wind tunnel testing to refine designs. This is crucial for improving fuel efficiency and aircraft performance, aligning with market demands for more sustainable aviation solutions in the Tacoma area.

- Structural Engineering

Structural engineers ensure the integrity and safety of aircraft structures by analyzing stress, strain, and material properties. They design components to withstand extreme conditions, such as high altitudes and turbulent weather. These skills are essential for maintaining airworthiness standards and preventing structural failures, directly impacting passenger safety and regulatory compliance.

- Systems Engineering

Systems engineers integrate various subsystems within an aircraft, including avionics, propulsion, and control systems. They ensure seamless communication and coordination between these components. This integration is vital for optimizing overall system performance and reliability, enhancing the operational capabilities of aircraft manufactured or maintained in Tacoma.

- Design and Drafting

Design and Drafting professionals utilize CAD (Computer-Aided Design) software to create detailed technical drawings and models of aircraft components and systems. These drawings serve as the blueprints for manufacturing and assembly. Accurate and precise design is essential for efficient production and ensuring that components meet stringent aerospace standards.

The prevalence of these engineering and design specializations underscores the sophisticated nature of aerospace employment in Tacoma. These roles necessitate a strong foundation in engineering principles, coupled with specialized knowledge of aerospace technologies. Their importance cannot be overstated, as they directly influence the safety, performance, and economic viability of the region’s aerospace industry.

2. Manufacturing Operations

Manufacturing operations form a critical link in the aerospace sector of Tacoma, Washington, converting engineering designs into tangible aircraft components and systems. The efficiency and precision of these operations directly influence the quality, cost-effectiveness, and timely delivery of aerospace products, thereby shaping the demand for specialized labor within the region.

- Assembly and Integration

Assembly and integration technicians are responsible for physically assembling aircraft components and integrating complex systems. This involves following detailed blueprints and adhering to strict quality control protocols. For instance, assembling wing structures or integrating avionics systems requires precision and expertise, impacting both safety and operational efficiency within Tacoma’s aerospace facilities.

- Machining and Fabrication

Machining and fabrication specialists operate advanced machinery to create parts from raw materials. This involves processes such as milling, turning, and welding to produce components that meet precise specifications. Fabricating fuselage panels or engine components demands skilled machinists and fabricators, impacting the precision and durability of aircraft manufactured in the Tacoma region.

- Quality Control and Inspection

Quality control inspectors examine manufactured parts and assembled systems to ensure compliance with engineering standards and regulatory requirements. This involves using precision measurement tools and conducting non-destructive testing. Inspecting welds, checking dimensions, and verifying material properties are crucial for maintaining airworthiness and safety within the aerospace industry.

- Supply Chain Management

Supply chain managers oversee the flow of materials, components, and finished products from suppliers to manufacturing facilities and ultimately to customers. This involves coordinating logistics, managing inventory, and ensuring timely delivery. Efficient supply chain operations minimize delays, reduce costs, and ensure the availability of materials needed for manufacturing aircraft in the Tacoma area.

The interdependence of these manufacturing operations underscores the complexity and specialized nature of aerospace production in Tacoma. The demand for skilled workers in these areas remains contingent upon factors such as production volume, technological advancements, and the overall health of the aerospace industry. Continuous improvements in manufacturing processes and technologies will likely drive further evolution in the skills and expertise required of workers in this sector.

3. Quality Assurance Roles

Quality assurance positions represent a vital element within the spectrum of aerospace-related employment opportunities in the Tacoma, Washington region. These roles are directly responsible for upholding the rigorous safety and performance standards mandated by both regulatory bodies and industry best practices, thereby safeguarding the integrity of aerospace products and operations within the local economy.

- Inspection and Testing

Inspection and testing personnel meticulously examine aerospace components and systems to identify defects, deviations from specifications, or potential points of failure. They employ a variety of techniques, including visual inspection, non-destructive testing (NDT), and functional testing. For example, radiographic testing of welds in aircraft fuselages or ultrasonic inspection of composite materials would be conducted to verify structural integrity. The thoroughness of these inspections directly impacts the reliability and longevity of aircraft, thus mitigating risks and ensuring passenger safety.

- Compliance and Auditing

Compliance specialists ensure that aerospace manufacturers and suppliers adhere to all applicable regulations, standards, and internal policies. This involves conducting regular audits, reviewing documentation, and implementing corrective actions to address any identified non-conformities. For instance, an audit of a manufacturing facility might verify compliance with FAA regulations or ISO 9001 standards. Maintaining rigorous compliance is essential for avoiding penalties, upholding the company’s reputation, and ensuring the continued airworthiness of aerospace products.

- Process Control and Improvement

Process control engineers monitor and analyze manufacturing processes to identify opportunities for improvement in efficiency, quality, and cost-effectiveness. They implement statistical process control (SPC) techniques, conduct root cause analysis, and implement corrective and preventative actions (CAPA). For example, analyzing data from machining operations to reduce scrap rates or optimizing assembly processes to minimize errors would fall under this category. Continual process improvement is crucial for enhancing competitiveness and reducing the risk of defects in aerospace manufacturing.

- Documentation and Record Keeping

Accurate and comprehensive documentation is paramount in the aerospace industry. Quality assurance personnel are responsible for maintaining detailed records of inspections, tests, audits, and corrective actions. This documentation serves as evidence of compliance and provides a historical record of product quality. For example, maintaining records of material certifications, inspection results, and maintenance activities is essential for tracing the history of an aircraft and ensuring its continued airworthiness throughout its lifespan. Effective documentation management is critical for liability protection and regulatory compliance.

The diverse range of responsibilities encompassed by quality assurance roles highlights their integral position within the aerospace sector of Tacoma. The unwavering commitment to quality control directly contributes to the safety and reliability of air travel, bolstering the regional reputation for aerospace excellence and sustaining the demand for skilled professionals in this critical area.

4. Supply Chain Logistics

Supply chain logistics constitutes a critical element within the aerospace jobs ecosystem of Tacoma, Washington. The aerospace industry demands precision, reliability, and efficiency in the movement of materials and components. This reliance on complex logistics networks directly generates a spectrum of employment opportunities within the Tacoma region, ranging from procurement specialists and warehouse managers to transportation coordinators and logistics analysts. Disruptions in the supply chain, whether due to natural disasters or geopolitical instability, can directly impact production schedules and profitability for aerospace manufacturers in Tacoma, underscoring the importance of robust and resilient logistical operations. For example, the sourcing of specialized alloys for aircraft engines requires meticulous planning and coordination to ensure timely delivery to production facilities. This, in turn, creates jobs for individuals skilled in global logistics, customs regulations, and inventory management.

Effective supply chain logistics not only ensures the smooth flow of materials but also contributes to cost reduction and improved operational efficiency. By optimizing transportation routes, streamlining warehousing processes, and implementing advanced inventory management systems, aerospace companies in Tacoma can minimize delays, reduce waste, and enhance their overall competitiveness. The implementation of just-in-time inventory management, for instance, minimizes storage costs and reduces the risk of obsolescence, but it necessitates highly efficient logistics operations capable of delivering materials precisely when needed. This creates demand for professionals with expertise in supply chain optimization, data analytics, and risk management.

In conclusion, the interplay between supply chain logistics and aerospace jobs in Tacoma is undeniable. The aerospace industry’s dependence on intricate supply networks creates numerous employment opportunities across various skill levels. Addressing challenges in supply chain management, such as mitigating risks associated with global sourcing and adapting to evolving regulatory requirements, is essential for maintaining a thriving aerospace sector in Tacoma. The ability to effectively manage and optimize supply chain logistics directly contributes to the sustained growth and competitiveness of the region’s aerospace industry, thereby supporting a robust job market.

5. Technical Support Staff

Technical support personnel represent a critical, yet often understated, component within the landscape of aerospace jobs in Tacoma, WA. The aerospace industry, characterized by complex systems and stringent operational requirements, relies heavily on skilled technicians and engineers to provide ongoing support for its products and services. The demand for these roles is directly correlated to the presence of aerospace manufacturing, maintenance, and engineering firms within the Tacoma area. For example, after an aircraft sale, manufacturers need field service engineers who can support the customer post sales.

The significance of technical support extends beyond mere troubleshooting. These professionals are essential for ensuring the continued airworthiness and operational efficiency of aircraft. Their responsibilities often include providing on-site support to airlines and operators, conducting maintenance and repairs, and providing technical training to customer personnel. The expertise they offer directly impacts the safety and reliability of air travel, thus contributing to the overall reputation and competitiveness of the Tacoma aerospace sector. Technical support can span from software to mechanics jobs.

In conclusion, the link between technical support staff and aerospace jobs in Tacoma is a vital element of the industry’s ecosystem. The region’s strong aerospace presence drives demand for these skilled professionals, whose expertise is essential for maintaining the safety, reliability, and efficiency of aircraft operations worldwide. The demand will continue to climb and be part of the aerospace jobs in tacoma wa sector.

Frequently Asked Questions Regarding Aerospace Employment Opportunities in Tacoma, WA

The following addresses common inquiries concerning careers within the aerospace sector located in the Tacoma, Washington metropolitan area. Information provided is intended to offer clarity and guidance to prospective job seekers.

Question 1: What are the primary qualifications sought by employers for entry-level aerospace positions in Tacoma?

Employers generally seek candidates with a foundational understanding of engineering principles, manufacturing processes, or relevant technical skills. Specific requirements vary based on the role, but often include a degree in a related field (e.g., aerospace engineering, mechanical engineering, or a related technical discipline), certifications, or relevant experience obtained through internships or apprenticeships.

Question 2: Are there specific skills that are consistently in high demand within the Tacoma aerospace job market?

Skills in high demand often include proficiency in CAD/CAM software, knowledge of composite materials, experience with quality control procedures, and familiarity with FAA regulations. Expertise in areas such as robotics, automation, and data analytics is increasingly valuable as the industry adopts more advanced technologies.

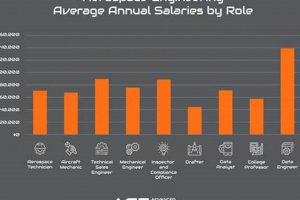

Question 3: What are the typical salary ranges for various aerospace positions in the Tacoma area?

Salary ranges vary significantly based on experience, education, and job responsibilities. Entry-level positions may offer salaries in the $40,000 to $60,000 range, while experienced engineers and managers can earn considerably more. Market conditions and company size also influence compensation levels. Resources such as salary.com and glassdoor.com may provide additional insights.

Question 4: How can individuals with military experience translate their skills into civilian aerospace jobs in Tacoma?

Military experience, particularly in aviation maintenance, electronics, or logistics, can be highly valuable in the aerospace sector. Translating military skills into civilian terms on resumes and highlighting relevant training and experience is essential. Certifications obtained during military service may also be directly applicable to civilian roles.

Question 5: What resources are available to assist individuals in finding aerospace jobs in Tacoma?

Numerous resources exist to support job seekers, including online job boards (e.g., Indeed, LinkedIn), company career pages, and networking events organized by industry associations such as the Pacific Northwest Aerospace Alliance. Local community colleges and technical schools also offer training programs and career services to assist individuals in entering the aerospace workforce.

Question 6: Are there any specific companies in Tacoma that consistently hire for aerospace positions?

While specific hiring patterns fluctuate, major aerospace manufacturers and their suppliers in the Tacoma area often have ongoing employment needs. Researching companies active in the region is recommended. Attending company presentations at job fairs or industry events can provide valuable insights into their hiring practices.

In summary, preparation, targeted skill development, and strategic utilization of available resources are key to navigating the aerospace job market in Tacoma. Continuous professional development is also advisable to maintain competitiveness in this evolving sector.

The following sections will provide insights into the future outlook for the aerospace industry.

Aerospace Jobs Tacoma WA

The preceding analysis has explored the multifaceted landscape of aerospace employment within the Tacoma, Washington region. Key aspects, including required skills, prevalent roles, and the significance of supporting functions like supply chain logistics and technical support, have been examined. A recurring theme is the industry’s demand for highly skilled professionals who can contribute to the safety, efficiency, and innovation that define the sector.

The continued strength of the aerospace industry in Tacoma hinges on factors such as sustained investment in technology, proactive workforce development initiatives, and adaptability to evolving global market conditions. The demand for “aerospace jobs tacoma wa” is not static; it will be shaped by these forces, requiring ongoing assessment and strategic planning by both job seekers and industry stakeholders.