The details outlining the responsibilities, required skills, and qualifications for a professional who fabricates and repairs precision parts for aircraft and spacecraft. Such documentation clarifies the expectations and scope of the role, ensuring both the employer and prospective employee have a clear understanding of the position. For example, this write-up typically includes specifics regarding proficiency with Computer Numerical Control (CNC) machinery, blueprint interpretation, and adherence to stringent safety protocols.

Its significance lies in its ability to attract qualified candidates and provide a benchmark for performance evaluation. A well-defined outline can minimize misunderstandings, reduce employee turnover, and improve the overall efficiency of the manufacturing process. Historically, formalized role specifics have evolved alongside technological advancements in the aerospace sector, reflecting the increasing complexity and precision demanded in modern aerospace component production.

Therefore, a thorough examination of the constituent elements comprising these details is warranted. This exploration should encompass the required technical proficiencies, the expected daily tasks, the necessary educational background, and the prevalent industry standards that dictate performance within this specialized field.

Essential Considerations for Crafting Effective Role Specifications

The following guidelines serve to assist in the creation of comprehensive and informative role specifications for individuals specializing in the precision manufacturing of aerospace components.

Tip 1: Clearly Define Required Technical Proficiencies: Specify the necessary experience with Computer Numerical Control (CNC) milling, turning, and grinding operations. Include details regarding specific machine models or programming languages (e.g., G-code) essential for the role.

Tip 2: Emphasize Precision Measurement and Inspection Skills: Articulate the expectation for competence in utilizing precision measuring instruments, such as micrometers, calipers, and coordinate measuring machines (CMMs), to ensure adherence to exacting tolerances.

Tip 3: Detail Blueprint Reading and Interpretation Abilities: Mandate a thorough understanding of engineering drawings, including Geometric Dimensioning and Tolerancing (GD&T), to accurately interpret design specifications.

Tip 4: Outline Material Knowledge and Application: Specify familiarity with various aerospace-grade materials, such as aluminum alloys, titanium, and composites, and their respective machining characteristics.

Tip 5: Highlight Adherence to Safety Regulations and Quality Standards: Underscore the importance of compliance with Occupational Safety and Health Administration (OSHA) regulations and industry-specific quality management systems (e.g., AS9100).

Tip 6: State Expected Problem-Solving and Troubleshooting Capabilities: Describe the ability to identify and resolve machining issues, such as tool wear, surface finish imperfections, and dimensional inaccuracies.

Tip 7: Indicate the Level of Required Experience: Clearly state the minimum number of years of experience, including any specific industry experience, which is essential for performing the role effectively.

Adherence to these recommendations will facilitate the recruitment of qualified candidates capable of meeting the rigorous demands of aerospace manufacturing, thereby contributing to the overall quality and reliability of aerospace components.

These guidelines provide a foundation for building a robust and informative document, which in turn enhances the chances of attracting and retaining top talent within the aerospace manufacturing sector.

1. CNC Proficiency

Computer Numerical Control (CNC) proficiency constitutes a foundational element within the skill set delineated in the aerospace machinist role specification. Its significance stems from the critical role CNC machining plays in the precise fabrication of aerospace components.

- Program Generation and Optimization

The ability to generate, interpret, and optimize CNC programs is paramount. This includes expertise in G-code programming and the utilization of Computer-Aided Manufacturing (CAM) software. An aerospace machinist must be capable of translating engineering designs into efficient and accurate machine instructions, ensuring components meet exacting specifications. For example, crafting a program to machine a complex turbine blade requires meticulous attention to detail and a deep understanding of toolpaths and cutting parameters.

- Machine Setup and Operation

Proficiency extends to the setup and operation of CNC milling machines, lathes, and grinders. This involves selecting appropriate cutting tools, configuring machine parameters, and monitoring the machining process to maintain dimensional accuracy and surface finish. An aerospace machinist is expected to troubleshoot issues that arise during operation, such as tool wear or vibration, and make necessary adjustments to maintain production quality. Consider the setup of a five-axis milling machine for machining a structural component of an aircraft wing; proper alignment and calibration are critical for achieving the required tolerances.

- Material Selection and Machining Techniques

A comprehensive understanding of material properties and appropriate machining techniques is essential. Aerospace machinists must be knowledgeable about the characteristics of various aerospace-grade materials, including aluminum alloys, titanium, and composites, and how these materials respond to different cutting conditions. Selecting the correct cutting speeds, feed rates, and coolants is crucial for preventing material deformation and ensuring the desired surface finish. Machining titanium, for instance, requires specific techniques to mitigate heat generation and prevent work hardening.

- Quality Control and Inspection

CNC proficiency is intrinsically linked to quality control and inspection procedures. Aerospace machinists are responsible for verifying the accuracy of machined parts using precision measuring instruments, such as micrometers, calipers, and coordinate measuring machines (CMMs). They must be able to interpret inspection reports and identify any deviations from specified tolerances. The ability to make informed adjustments to CNC programs or machine settings based on inspection results is a critical aspect of ensuring component conformity. Checking the dimensions of a machined engine mount to ensure it meets the stringent requirements of aerospace safety standards is an example.

In conclusion, CNC proficiency is not merely a technical skill but an integral component of the broader expertise required of an aerospace machinist. This skillset impacts production efficiency, component quality, and overall adherence to stringent aerospace industry standards, solidifying its place as a core competency within the defined role.

2. Blueprint interpretation

Blueprint interpretation represents a cornerstone skill stipulated within aerospace machinist roles. A machinists ability to accurately decipher engineering drawings directly impacts the conformity of manufactured components to design specifications. Erroneous interpretation leads to dimensional inaccuracies, material waste, and potential safety hazards. The connection between blueprint reading and precision manufacturing is, therefore, causal: proficiency in the former directly enables success in the latter.

Consider the fabrication of a complex aircraft wing spar. The machinist must extract precise dimensional data, tolerance values, and material specifications from the engineering blueprint. These details dictate the machining parameters, tooling selection, and inspection procedures. A misread tolerance value could result in a part that fails structural integrity tests, jeopardizing flight safety. The AS9100 quality management system, prevalent in aerospace manufacturing, mandates rigorous documentation and verification processes to mitigate risks associated with blueprint misinterpretation.

Proficiency in blueprint reading also involves understanding geometric dimensioning and tolerancing (GD&T). GD&T provides a standardized language for defining allowable variations in part geometry. An aerospace machinist must be able to interpret GD&T symbols and apply them to the machining process. In summary, accurate blueprint reading underpins the production of safe, reliable, and high-performance aerospace components, thereby emphasizing its critical importance in aerospace machinist roles.

3. Material Knowledge

Material knowledge forms an indispensable component of the expertise required within the aerospace machinist role. The demanding operating environments and stringent safety requirements of aerospace applications necessitate a comprehensive understanding of material properties and their response to various machining processes. This expertise directly impacts component performance, longevity, and overall safety.

- Material Selection for Specific Applications

An aerospace machinist must possess the ability to select appropriate materials based on the performance requirements of specific aerospace components. This includes considering factors such as strength-to-weight ratio, corrosion resistance, thermal stability, and fatigue life. For instance, titanium alloys are often selected for high-stress components due to their exceptional strength and heat resistance, while aluminum alloys are favored for their lightweight properties in non-critical structural elements. Improper material selection can lead to premature failure and catastrophic consequences.

- Machining Characteristics of Aerospace Materials

Different aerospace materials exhibit distinct machining characteristics that impact the selection of cutting tools, machining parameters, and coolant systems. For example, machining titanium alloys requires specialized techniques to mitigate heat generation and prevent work hardening, while composites necessitate the use of diamond-coated tools to avoid delamination and fiber pull-out. A thorough understanding of these characteristics is crucial for achieving desired surface finishes and dimensional tolerances.

- Heat Treatment and Surface Finishing

Material knowledge extends to an understanding of heat treatment processes and surface finishing techniques used to enhance the mechanical properties and corrosion resistance of aerospace components. Heat treatment can be employed to increase the strength and hardness of metals, while surface finishing treatments such as anodizing and passivation provide protection against environmental degradation. Applying the wrong heat treatment or surface finish can compromise the integrity of the material and lead to premature failure.

- Material Identification and Traceability

Accurate material identification and traceability are paramount in aerospace manufacturing to ensure compliance with regulatory standards and prevent the use of counterfeit or substandard materials. Aerospace machinists must be able to identify different materials based on their physical properties, chemical composition, and markings. Implementing robust traceability systems allows for the tracking of materials throughout the manufacturing process, from raw stock to finished component, ensuring accountability and preventing the introduction of non-conforming materials.

These facets highlight the crucial role material knowledge plays in the aerospace machinist role. Competence in material selection, machining characteristics, heat treatment, and traceability ensures the production of reliable, high-performance aerospace components that meet stringent industry standards. A lack of understanding in these areas can lead to manufacturing defects, safety hazards, and regulatory non-compliance, underscoring the importance of material expertise within the aerospace manufacturing sector.

4. Precision Measurement

Precision measurement is an indispensable element of the aerospace machinist role, forming a critical link between design specifications and final component conformity. Its application ensures that parts meet the exacting tolerances necessary for safe and efficient operation in aerospace environments. Accurate measurement mitigates risks associated with component failure and ensures compliance with stringent industry standards.

- Use of Calibrated Instruments

The aerospace machinist job specification necessitates proficiency in the use of calibrated measuring instruments. This includes micrometers, calipers, height gauges, and coordinate measuring machines (CMMs). Regular calibration of these instruments is vital to ensure the accuracy and reliability of measurements. For instance, the dimensional accuracy of a turbine blade must be verified using a calibrated CMM to ensure that it conforms to the design specifications, preventing aerodynamic inefficiencies and potential failure. Adherence to calibration schedules and proper instrument handling are critical components of the role.

- Interpretation of Technical Drawings and Specifications

The ability to interpret technical drawings and specifications is intrinsically linked to precision measurement. Machinists must accurately translate dimensional and geometric tolerance information from blueprints into measurable quantities. This involves understanding geometric dimensioning and tolerancing (GD&T) symbols and their implications for component acceptance. For example, interpreting a positional tolerance on a hole location requires the machinist to measure the actual hole position and compare it to the specified tolerance zone, ensuring proper fit and functionality within an assembly.

- Application of Statistical Process Control (SPC)

Precision measurement is a fundamental aspect of statistical process control (SPC) in aerospace manufacturing. SPC techniques utilize measurement data to monitor and control the machining process, identifying and addressing sources of variation. Aerospace machinists apply SPC charts and statistical analysis to track critical dimensions and ensure process stability. An example would be monitoring the diameter of a machined shaft over time to detect tool wear or machine drift, allowing for timely adjustments to maintain process control and prevent the production of non-conforming parts.

- Non-Destructive Testing (NDT) Techniques

In certain aerospace applications, precision measurement extends to non-destructive testing (NDT) techniques used to evaluate the integrity of materials and components without causing damage. Aerospace machinists may be involved in performing or interpreting NDT inspections, such as ultrasonic testing or radiographic testing, to detect internal flaws or defects. For instance, ultrasonic testing can be used to measure the thickness of a composite panel or detect subsurface cracks in a metal component, ensuring that the part meets the required structural integrity standards.

These facets highlight the critical connection between precision measurement and the aerospace machinist role. The ability to accurately measure, interpret, and apply measurement data is essential for ensuring the quality, reliability, and safety of aerospace components. A competent aerospace machinist understands the importance of precision measurement and employs it diligently throughout the manufacturing process, adhering to industry standards and best practices. The effective implementation of precision measurement techniques ultimately contributes to the success of aerospace manufacturing operations.

5. Quality standards

The aerospace machinist job description inherently incorporates stringent quality standards. These standards are not merely suggested guidelines; they are obligatory parameters that dictate every aspect of the machinist’s work, from material selection to final part inspection. Failure to adhere to these standards can result in catastrophic consequences, including aircraft failure and loss of life. Therefore, familiarity with and commitment to quality protocols are indispensable components of the role.

Consider the AS9100 standard, a widely recognized quality management system specifically designed for the aerospace industry. A machinist working under this standard must meticulously document every step of the manufacturing process, ensuring traceability and accountability. For example, the origin and processing history of a titanium alloy used in a landing gear component must be fully documented to prevent the use of substandard or counterfeit materials. Furthermore, adherence to quality standards requires the use of calibrated measuring instruments and the consistent application of statistical process control (SPC) techniques to maintain dimensional accuracy and process stability. The practical effect of this rigorous adherence is the production of reliable and safe aerospace components.

In conclusion, the integration of quality standards within the aerospace machinist job description is not simply a matter of compliance; it is a fundamental requirement for ensuring the safety, reliability, and performance of aerospace products. The ability to understand, apply, and consistently adhere to these standards is a critical factor in determining the competence and suitability of an individual for this demanding role. Challenges remain in maintaining consistent quality across diverse manufacturing environments, but the unwavering commitment to these standards is paramount for sustaining the integrity of the aerospace industry.

6. Safety Compliance

Safety compliance constitutes a non-negotiable requirement within the aerospace machinist job description. The inherent hazards associated with operating heavy machinery, handling hazardous materials, and working with precision components necessitate strict adherence to established safety protocols. A failure in safety compliance can have immediate and severe consequences, including workplace injuries, equipment damage, and environmental contamination. The causal relationship between adherence to safety regulations and a safe working environment is direct and undeniable.

The Occupational Safety and Health Administration (OSHA) provides a framework for safety standards that aerospace machinists must follow. This includes guidelines for machine guarding, personal protective equipment (PPE), and hazard communication. For example, machinists are required to wear safety glasses, hearing protection, and appropriate respirators when working with certain materials or processes. Proper handling and disposal of cutting fluids and other hazardous chemicals are also crucial to prevent environmental contamination and ensure worker safety. Non-compliance with these regulations can result in significant fines and legal liabilities for both the machinist and the employer. Regular safety training and drills are essential to reinforce safety protocols and ensure that machinists are prepared to respond effectively to emergencies.

In summary, safety compliance is an integral and indispensable component of the aerospace machinist job description. It is not merely a matter of following rules, but a commitment to protecting oneself and others from harm. The stringent requirements and potential consequences associated with aerospace manufacturing necessitate a proactive approach to safety, where adherence to established protocols is prioritized above all else. This dedication to safety ultimately contributes to a more productive and sustainable working environment, safeguarding both personnel and the integrity of the manufacturing process.

7. Problem-solving

Problem-solving is inextricably linked to the aerospace machinist role, acting as a critical competency for navigating the complexities inherent in precision manufacturing. The ability to identify, analyze, and resolve technical challenges directly influences the quality and efficiency of aerospace component production.

- Troubleshooting Machining Issues

The capacity to diagnose and rectify machining problems represents a core problem-solving skill. This includes identifying the root cause of dimensional inaccuracies, surface finish defects, or tool wear issues. For example, a machinist may need to determine why a CNC mill is producing parts that consistently deviate from specified tolerances. This requires analyzing machine parameters, toolpaths, and material properties to pinpoint the source of the error and implement corrective actions, such as adjusting cutting speeds or replacing worn tooling. Failure to effectively troubleshoot machining issues can lead to production delays, material waste, and compromised component quality.

- Interpreting and Responding to Non-Conformances

Aerospace machinists are frequently confronted with non-conforming parts that deviate from engineering drawings or quality standards. The ability to interpret inspection reports, identify the nature and extent of the non-conformance, and determine appropriate corrective actions is crucial. This may involve reworking the part to bring it into compliance, rejecting the part and initiating a new production run, or collaborating with engineers to determine if a design modification is necessary. An example would be identifying a crack in a machined component through non-destructive testing and determining whether the crack can be repaired or if the part must be scrapped. Effective problem-solving in this context requires a thorough understanding of material properties, manufacturing processes, and quality control procedures.

- Adapting to Unforeseen Circumstances

The aerospace manufacturing environment is often subject to unforeseen circumstances, such as equipment malfunctions, material shortages, or design changes. The ability to adapt to these unexpected events and develop creative solutions is essential for maintaining production schedules and minimizing disruptions. This might involve finding alternative materials, modifying machining processes, or collaborating with other departments to address logistical challenges. For instance, if a specific cutting tool is unavailable, the machinist may need to research and implement an alternative tooling solution that can achieve the required surface finish and dimensional accuracy. Adaptability and resourcefulness are key attributes for navigating the uncertainties inherent in aerospace manufacturing.

- Improving Manufacturing Processes

Problem-solving also extends to the continuous improvement of manufacturing processes. Aerospace machinists are often encouraged to identify opportunities for streamlining operations, reducing waste, and enhancing efficiency. This may involve analyzing workflow patterns, identifying bottlenecks, and implementing process improvements based on data analysis and Lean Manufacturing principles. An example would be developing a new fixture design to reduce setup time or optimizing a CNC program to minimize cycle time. Proactive problem-solving in this area can lead to significant cost savings and improved productivity.

These facets underscore the pivotal role of problem-solving within the aerospace machinist job description. Competence in troubleshooting, interpreting non-conformances, adapting to unforeseen circumstances, and improving manufacturing processes directly contributes to the production of high-quality, reliable aerospace components. The ability to effectively address technical challenges is, therefore, a defining characteristic of a successful aerospace machinist.

Frequently Asked Questions Regarding the Aerospace Machinist Role

This section addresses common inquiries and provides clarification regarding the responsibilities, qualifications, and career prospects associated with the profession.

Question 1: What are the primary responsibilities outlined in an aerospace machinist job description?

The primary duties typically encompass the setup and operation of Computer Numerical Control (CNC) machinery, the interpretation of engineering blueprints, the precision measurement of manufactured parts, adherence to stringent quality standards, and the implementation of safety protocols.

Question 2: What educational background is generally required for an aerospace machinist position?

A high school diploma or equivalent is generally the minimum educational requirement. However, many employers prefer candidates with vocational training, an associate’s degree in manufacturing technology, or completion of a formal apprenticeship program. Certification in CNC machining or related fields is also highly valued.

Question 3: What types of skills are essential for success in this profession?

Essential skills include proficiency in CNC programming and operation, a thorough understanding of blueprint reading and geometric dimensioning and tolerancing (GD&T), expertise in material selection and machining techniques, meticulous attention to detail, and the ability to troubleshoot manufacturing problems.

Question 4: What are the common tools and equipment used by aerospace machinists?

Aerospace machinists utilize a wide range of tools and equipment, including CNC milling machines, lathes, grinders, micrometers, calipers, coordinate measuring machines (CMMs), and various hand tools. Familiarity with these tools and their proper usage is critical for performing the job effectively.

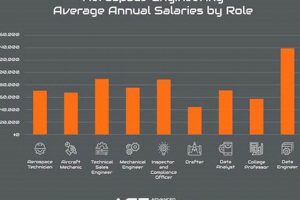

Question 5: What career advancement opportunities are available for aerospace machinists?

Career advancement opportunities may include progression to senior machinist roles, lead machinist positions, manufacturing engineering technician roles, or quality control inspector positions. Further education and certifications can enhance career prospects.

Question 6: What are the typical working conditions for aerospace machinists?

Aerospace machinists typically work in manufacturing environments that may be noisy and require the use of personal protective equipment (PPE). The work often involves standing for extended periods and performing repetitive tasks. Adherence to safety regulations is paramount to minimize the risk of injury.

This FAQ section has aimed to clarify essential aspects of the role, providing a concise overview of its requirements and expectations.

Following these considerations, a concluding summation of the key elements is warranted.

Aerospace Machinist Job Description

The preceding exploration has illuminated the critical facets of the aerospace machinist job description, encompassing the requisite technical proficiencies, the imperative of quality and safety compliance, and the necessity for adept problem-solving capabilities. Competence in CNC machining, blueprint interpretation, material knowledge, and precision measurement constitutes the foundation of this demanding profession. The stringent requirements reflect the high-stakes nature of aerospace manufacturing, where precision and reliability are paramount.

Therefore, a comprehensive and meticulous approach to crafting role specifications is essential for attracting qualified candidates capable of meeting the rigorous demands of the aerospace sector. Continuous professional development and adherence to industry best practices remain crucial for ensuring sustained excellence and maintaining the integrity of aerospace components. The future of aerospace manufacturing hinges on the expertise and dedication of skilled machinists who uphold the highest standards of quality and safety.