Compensation for professionals engaged in the upkeep, repair, and overhaul of aircraft and spacecraft is a critical element within the broader aviation and space industries. This remuneration reflects the specialized skills, technical knowledge, and rigorous training required to ensure the safety and operational efficiency of complex airborne vehicles. As an example, experienced technicians working on commercial airliners typically command a higher pay scale than entry-level assistants in general aviation.

Adequate earnings in this sector are essential for attracting and retaining qualified individuals, thereby guaranteeing a competent workforce capable of adhering to stringent regulatory standards. Historically, the increasing complexity of aircraft and the heightened focus on safety have driven upward pressure on income levels for these skilled trades. Furthermore, competitive benefit packages and opportunities for career advancement are often tied to the baseline financial rewards.

The following sections will delve into the factors influencing levels of income in this field, explore regional variations, and analyze the impact of experience and certifications on earning potential. Furthermore, it will provide insight into the career trajectories associated with maintenance roles in the aviation and space sectors.

Maximizing financial returns within the aerospace maintenance profession necessitates strategic career planning and continuous professional development. This section provides actionable guidance for optimizing earnings potential.

Tip 1: Acquire Specialized Certifications: Obtaining certifications relevant to specific aircraft types or maintenance procedures often correlates with higher pay grades. Examples include FAA Airframe and Powerplant (A&P) licenses or certifications in advanced composite repair.

Tip 2: Pursue Advanced Training: Investing in continuous education, such as manufacturer-specific training courses or advanced technical degrees, enhances skill sets and increases value to employers. This may include training on new engine technologies or avionics systems.

Tip 3: Gain Experience with High-Demand Aircraft: Focusing on gaining experience with aircraft types experiencing high operational demand or those utilized by major airlines can lead to improved job security and compensation packages. Familiarity with Boeing 737 or Airbus A320 families is beneficial.

Tip 4: Relocate to High-Demand Geographic Areas: Certain geographic locations, particularly those with major airline hubs or aerospace manufacturing centers, often offer more competitive wages due to higher demand for skilled technicians. Regions with robust aerospace industries like Seattle, Dallas-Fort Worth, or Southern California present opportunities.

Tip 5: Specialize in a Niche Area: Developing expertise in a specific, less common maintenance discipline, such as avionics troubleshooting or non-destructive testing (NDT), can create a competitive advantage and justify higher compensation. Specialized skills translate to enhanced earning potential.

Tip 6: Negotiate Effectively: Research industry standards and local market conditions to understand the appropriate range of compensation for a given position and experience level. Present a well-researched case during salary negotiations, highlighting skills and accomplishments.

Tip 7: Seek Opportunities for Advancement: Actively pursue opportunities for promotion into supervisory or management roles. These positions typically command higher salaries and offer greater responsibility and autonomy. Demonstrate leadership potential and a commitment to continuous improvement.

Strategic career planning, continuous skill enhancement, and a proactive approach to professional development are crucial for achieving optimal financial rewards. These tactics are essential for maximizing one’s earning capacity.

The following section will summarize the key findings of this article and offer concluding remarks on the importance of aerospace maintenance personnel.

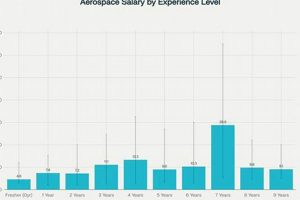

1. Experience Level

Experience level constitutes a primary determinant of compensation within the aerospace maintenance field. Increased tenure and accumulated practical knowledge directly correlate with augmented remuneration. Novice technicians typically enter the profession at entry-level positions, commanding lower salaries reflecting their limited expertise. As individuals accrue hands-on experience diagnosing and resolving intricate mechanical or electronic issues, their value to employers escalates. A technician with ten years of experience troubleshooting engine malfunctions on commercial aircraft, for instance, will invariably earn more than a newly certified graduate performing routine inspections.

The causal relationship stems from the enhanced proficiency and efficiency seasoned professionals demonstrate. Their accumulated knowledge base allows for quicker and more accurate diagnoses, reduced downtime for aircraft, and a decreased likelihood of errors. This translates directly into cost savings and operational improvements for employers, justifying higher pay scales. Moreover, experienced technicians often mentor junior colleagues, contributing to the overall skill development of the maintenance team. Their ability to handle complex tasks autonomously minimizes the need for supervision, further enhancing their worth. Example: An experienced Avionics Technician may earn higher pay for knowing how to do advanced troubleshooting and installation of new systems and wiring harnesses.

In summary, experience level is an indispensable component of an aerospace maintenance professional’s earning potential. The practical significance lies in the understanding that continuous learning and a commitment to career longevity are vital for maximizing financial rewards within the industry. While formal education and certifications provide a foundational base, the acquisition of real-world experience remains the cornerstone of career advancement and increased earning capacity. Professionals should prioritize opportunities to expand their skill sets, tackle challenging projects, and demonstrate consistent performance to capitalize on the inherent value of experience.

2. Certifications Held

The attainment of industry-recognized certifications significantly influences compensation levels within the aerospace maintenance profession. These credentials validate specialized knowledge and skills, demonstrating competence to employers and regulatory bodies.

- FAA Airframe and Powerplant (A&P) License

The Federal Aviation Administration (FAA) A&P license is a foundational certification for aircraft mechanics. This license permits holders to inspect, maintain, repair, and alter aircraft and engine systems. Technicians possessing an A&P license command higher salaries due to their broad-based skillset and regulatory authorization. For example, a technician holding both Airframe and Powerplant certifications is far more valuable to aviation companies.

- Avionics Certifications (e.g., FCC GROL)

Certifications related to avionics systems, such as the Federal Communications Commission (FCC) General Radiotelephone Operator License (GROL), are highly valued. These certifications demonstrate proficiency in maintaining and troubleshooting complex electronic and communication systems within aircraft. The growing sophistication of avionics makes these credentials increasingly important, leading to enhanced earning potential. Modern aircraft depend on highly integrated systems, and avionics specialists are in great demand.

- Manufacturer-Specific Training

Aircraft and engine manufacturers often offer specialized training courses and certifications on their specific products. Completing these courses demonstrates expertise in maintaining and repairing those particular systems. For example, a technician certified to work on a specific model of Rolls-Royce engine will earn a premium compared to someone without that certification. Manufacturer training showcases dedication to continuous improvement.

- Specialized Inspection Certifications (e.g., NDT)

Certifications in non-destructive testing (NDT) methods, such as ultrasonic testing, radiographic testing, and liquid penetrant testing, are crucial for ensuring aircraft structural integrity. Technicians holding these certifications play a vital role in identifying hidden defects and preventing catastrophic failures. Their specialized expertise is highly sought after and commands higher compensation. In the aerospace industry, precision and accuracy are paramount.

Possessing relevant certifications directly translates into higher earning potential for aerospace maintenance professionals. These credentials serve as tangible evidence of expertise, increasing marketability and justifying higher salary demands. Continuous investment in professional development and certification attainment is essential for maximizing career advancement and financial rewards.

3. Location of Employment

The geographic location of employment exerts a significant influence on compensation levels for aerospace maintenance personnel. Regional economic factors, cost of living variations, and the concentration of aerospace industry activity all contribute to observable salary discrepancies across different locations.

- Metropolitan Areas with Major Airline Hubs

Metropolitan areas hosting major airline hubs typically offer more competitive compensation packages. These hubs concentrate airline maintenance operations, creating high demand for qualified technicians. Cities such as Atlanta, Dallas-Fort Worth, and Chicago often exhibit higher average salaries due to the presence of large airlines and associated maintenance facilities. Example: A&P mechanics in Atlanta, home to Delta Air Lines headquarters and a major maintenance base, may command a higher premium.

- Aerospace Manufacturing Centers

Regions with significant aerospace manufacturing activity, such as Seattle and Southern California, tend to have elevated salary scales for maintenance personnel. These locations support not only airline operations but also the production and testing of aircraft, necessitating a skilled workforce and driving up wages. For instance, the presence of Boeing in Seattle contributes to a competitive labor market for aerospace technicians.

- Cost of Living Adjustments

Salary levels often reflect the cost of living in a particular area. Locations with higher costs of housing, transportation, and general expenses typically offer higher wages to compensate employees. While a given salary may appear substantial in a low-cost area, the same amount may be insufficient in a more expensive region. Therefore, potential income must be considered in the context of local living expenses. Example: A similar position in New York City vs. Jacksonville, Florida, may reflect these differences.

- International Locations and Overseas Contracts

Employment in international locations or on overseas contracts can offer significantly higher compensation, particularly in regions where skilled aerospace maintenance personnel are in short supply. These positions often involve hardship duty pay, housing allowances, and other benefits to attract qualified individuals. However, factors such as cultural differences and geopolitical instability should also be considered. Example: Technicians working in the Middle East or Southeast Asia might receive enhanced compensation packages.

Variations in compensation based on location underscore the importance of conducting thorough research before accepting a position in aerospace maintenance. Factors such as local market conditions, cost of living, and the concentration of aerospace activity must be carefully evaluated to ensure that the offered salary aligns with the individual’s financial needs and career aspirations. These elements will determine if the offered salary provides the most advantages.

4. Aircraft Type

The specific type of aircraft maintained exerts a considerable influence on the potential compensation for aerospace maintenance personnel. A cause-and-effect relationship exists, wherein the complexity, operational demands, and regulatory requirements associated with different aircraft directly impact the skills and knowledge required of technicians, subsequently affecting their earnings. The importance of aircraft type as a determinant of earnings stems from the specialized expertise needed for certain models. For instance, maintaining a wide-body commercial jetliner necessitates a broader understanding of complex systems compared to maintaining a small general aviation aircraft. The former demands proficiency in areas such as advanced avionics, sophisticated hydraulic systems, and turbine engine maintenance, which are typically associated with higher pay scales. A technician with certifications and experience on Boeing 777 or Airbus A350 aircraft will likely command a premium compared to one specializing in Cessna 172s. The practical significance of understanding this connection lies in informing career planning and professional development choices. Technicians seeking to maximize their income potential should consider specializing in aircraft types that are in high demand and require advanced skill sets.

Further analysis reveals that the operational context of the aircraft also plays a role. Maintaining aircraft used in critical roles, such as cargo transport or military operations, often requires adherence to stringent maintenance schedules and performance standards. This heightened responsibility and pressure can translate into increased compensation for technicians. Consider the example of a helicopter mechanic specializing in search-and-rescue operations, where equipment reliability is paramount. Their expertise is valued accordingly. The type of engine, whether piston, turboprop, or turbofan, also influences income. Modern turbofan engines often require specialized tooling and diagnostic equipment, increasing training requirements. In addition, an aircraft with fly-by-wire technology will command a greater salary for those maintaining that skill set. Practical applications include technicians pursuing training on the aircraft types prevalent in their local area or the models operated by major employers.

In conclusion, the type of aircraft maintained directly affects earning potential in aerospace maintenance. Complex and highly regulated aircraft demand greater skills and command higher pay. Challenges can include accessing specialized training or gaining experience on less common aircraft types. Recognizing the value and differences in the needs of different aircraft is crucial for technicians to make informed decisions about their career paths and to maximize their financial benefits. The practical understanding of this relationship will help those pursuing this career path to make smart decisions. As well, aerospace manufacturers may want to focus on training programs for advanced aircraft, that will benefit the technicians that pursue this line of work.

5. Employer Type

The identity of the employer significantly impacts compensation structures within the aerospace maintenance sector. Different types of organizations adhere to varying financial models, operational priorities, and labor agreements, which consequently influence the salaries offered to maintenance personnel.

- Major Commercial Airlines

Major commercial airlines often provide the most competitive compensation packages due to their substantial revenue streams and unionized workforces. These companies typically offer higher base salaries, comprehensive benefits packages, and opportunities for overtime pay. The strength of union contracts and the scale of operations contribute to this premium. Maintenance positions at major airlines also often come with travel privileges and retirement plans.

- Regional Airlines

Regional airlines generally offer lower salaries compared to major carriers due to their smaller scale and tighter profit margins. However, they can provide valuable experience and opportunities for rapid career advancement, particularly for entry-level technicians. While the base pay may be less, regional airlines can be a strategic stepping stone towards higher-paying positions at larger companies.

- Maintenance, Repair, and Overhaul (MRO) Facilities

MRO facilities, which specialize in providing maintenance services to airlines and other aircraft operators, offer a range of compensation levels depending on the size and scope of their operations. Large MRO facilities serving major airlines may offer competitive salaries, while smaller independent shops may pay less. The type of maintenance performed, such as heavy maintenance checks or specialized repairs, also influences compensation.

- Government Agencies and Military Contractors

Government agencies, such as the FAA, and military contractors often provide stable employment and competitive salaries, particularly for technicians with specialized skills or security clearances. These positions may involve maintaining government-owned aircraft or providing maintenance support to military operations. Compensation packages often include comprehensive benefits and retirement plans.

The employer type constitutes a critical factor influencing the earning potential of aerospace maintenance personnel. Understanding the compensation structures and benefits offered by different organizations enables technicians to make informed career choices and maximize their financial rewards. Factors such as the size of the organization, the presence of union representation, and the type of maintenance performed all contribute to the overall compensation package.

6. Skills Specialization

Within the aerospace maintenance profession, specialized skill sets directly correlate with enhanced earning potential. The demand for technicians possessing unique expertise in specific areas of aircraft maintenance drives market value and, consequently, higher compensation levels.

- Avionics Systems Expertise

Proficiency in troubleshooting, repairing, and maintaining complex avionics systems, including navigation, communication, and flight control systems, is highly valued. Technicians with in-depth knowledge of digital electronics, software interfaces, and advanced diagnostic techniques command premium salaries. The increasing reliance on sophisticated avionics in modern aircraft amplifies this demand. Example: Expertise in the Collins Aerospace Pro Line Fusion suite.

- Engine Overhaul and Repair

Specialization in engine overhaul and repair, particularly for specific engine types (e.g., Pratt & Whitney PW1000G, CFM International LEAP), is a significant asset. These skills involve disassembling, inspecting, repairing, and reassembling complex turbine engines to meet stringent performance standards. The intricate nature of engine maintenance necessitates specialized training and experience, resulting in higher compensation. Example: Holding certifications in borescope inspection or vibration analysis.

- Composite Materials Repair

Expertise in the repair of composite materials, increasingly utilized in modern aircraft structures, is in high demand. This specialization requires proficiency in techniques such as damage assessment, bonding, and non-destructive testing. The lightweight and high-strength properties of composites make them essential in aviation, and skilled technicians capable of repairing them are highly compensated. Example: Experience with vacuum bagging techniques or resin infusion processes.

- Non-Destructive Testing (NDT)

Certification and proficiency in NDT methods, such as ultrasonic testing, radiographic testing, and eddy current testing, are critical for ensuring aircraft structural integrity. NDT technicians identify hidden defects without disassembling components, playing a vital role in aircraft safety. Their specialized skills are highly sought after and justify higher compensation levels. Example: Holding ASNT Level II or Level III certifications in multiple NDT methods.

The interplay between specialized skills and “aerospace maintenance salary” is evident in the market’s valuation of unique expertise. Technicians who invest in developing specific skills in high-demand areas can significantly enhance their earning potential, reflecting the importance of continuous professional development within the field.

7. Union Membership

Union membership in the aerospace maintenance sector significantly influences compensation structures and often results in higher average salaries for represented employees. Collective bargaining agreements negotiated by unions typically establish standardized wage scales, benefits packages, and working conditions, providing a degree of financial security and predictability that may not exist in non-unionized environments. The cause-and-effect relationship is discernible: union representation leads to the negotiation of contracts that prioritize fair wages and benefits, thereby increasing the overall earnings of union members. The importance of union membership stems from its ability to empower employees to negotiate collectively for improved compensation and working conditions, which individual employees may struggle to achieve independently. For instance, the International Association of Machinists and Aerospace Workers (IAM) has successfully negotiated contracts with major airlines that provide for competitive wages, comprehensive health insurance, and retirement benefits for its members.

Further analysis reveals that union contracts often include provisions for annual wage increases, cost-of-living adjustments, and overtime pay, contributing to a steady rise in earnings over time. Union representation also typically provides job security protections, such as limitations on layoffs and access to grievance procedures in the event of disputes with employers. This added security can indirectly contribute to financial well-being. Consider the example of a unionized technician who receives annual raises and benefits, while a non-union counterpart receives only sporadic increases with fewer benefits. The union member, after a few years, could receive a substantially higher yearly rate. The practical applications of this understanding include technicians evaluating union representation as a factor in employment decisions and recognizing the potential benefits of union membership in terms of improved compensation and working conditions.

In conclusion, union membership presents a tangible pathway to improved compensation and benefits for aerospace maintenance personnel. Although challenges can arise in negotiating contracts and managing labor relations, the collective bargaining power afforded by unions often translates into enhanced financial security and career stability for represented employees. Therefore, considering the potential benefits of union representation constitutes a crucial aspect of career planning for aerospace maintenance professionals. This is often linked to increased protection of salary and benefits.

Frequently Asked Questions

The following questions address common inquiries regarding compensation within the aerospace maintenance field, providing clarity and informed perspectives.

Question 1: What is the typical starting range for new A&P mechanics?

Entry-level compensation for newly licensed Airframe and Powerplant (A&P) mechanics varies depending on location and employer type, but generally falls within a specified range. Factors such as cost of living and demand for technicians in a given area influence this baseline.

Question 2: Do certifications beyond the A&P license increase earning potential?

Possessing specialized certifications, such as avionics certifications, manufacturer-specific training, or non-destructive testing (NDT) credentials, can significantly augment income. These certifications demonstrate expertise in specific areas of aircraft maintenance.

Question 3: How does location impact aerospace maintenance salary?

Geographic location exerts a considerable influence on salary levels. Metropolitan areas with major airline hubs or aerospace manufacturing centers typically offer more competitive wages. Cost of living also factors into compensation adjustments.

Question 4: What are the salary differences between commercial airlines and MRO facilities?

Major commercial airlines often provide the highest compensation packages due to substantial revenue streams and unionized workforces. Maintenance, Repair, and Overhaul (MRO) facilities offer a range of salary levels depending on their size and scope of operations.

Question 5: Is there a significant difference in pay for technicians working on different aircraft types?

The specific type of aircraft maintained can influence compensation. Technicians specializing in complex aircraft, such as wide-body jets, or aircraft requiring specialized skills, like composite repair, may command higher salaries.

Question 6: How does union membership affect compensation in aerospace maintenance?

Union membership typically leads to higher average salaries due to collective bargaining agreements that establish standardized wage scales, benefits packages, and working conditions. Union contracts often include provisions for annual wage increases and job security protections.

In summary, multiple factors impact remuneration in aerospace maintenance, including certifications, location, employer type, aircraft type, and union affiliation. Continuous professional development and strategic career planning are crucial for maximizing earning potential.

The following section will provide resources for aerospace maintenance career planning.

Aerospace Maintenance Salary

The preceding analysis has explored the multifaceted determinants of “aerospace maintenance salary,” encompassing the impact of experience, certifications, geographic location, employer type, skills specialization, and union membership. Understanding these variables is paramount for both current professionals and individuals contemplating entry into this critical sector. The complexity and regulatory rigor inherent in aerospace maintenance necessitate a highly skilled workforce, reflected in the varying levels of compensation associated with different roles and qualifications. Ultimately, continuous professional development and strategic career planning are essential for maximizing earning potential within this demanding field.

The financial stability and security derived from appropriate “aerospace maintenance salary” levels are key to ensuring the continued safety and operational integrity of the global aviation industry. By attracting and retaining qualified personnel, competitive compensation contributes directly to the maintenance of airworthiness standards and the prevention of accidents. Further investment in training and fair remuneration will be crucial to address the evolving technological landscape and growing demand for skilled technicians in the years to come.