Opportunities for students in relevant fields to gain practical experience in the design, development, and testing of aircraft, spacecraft, and related systems are often sought after. These programs typically involve working alongside experienced engineers on real-world projects, providing exposure to industry standards and practices. The experience gained could involve tasks such as designing components, analyzing data, and contributing to research and development efforts.

Participation in such a program offers considerable advantages. It allows the development of crucial technical skills and provides invaluable professional networking opportunities. Furthermore, it often significantly improves career prospects upon graduation. Historically, these experiences have been instrumental in shaping the careers of many successful aerospace engineers, providing a critical bridge between academic knowledge and practical application in a highly competitive industry.

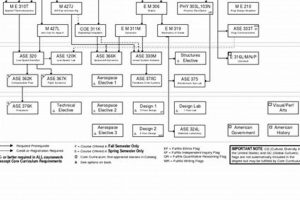

The subsequent sections will delve into the specific responsibilities involved, required qualifications, typical program structures, and strategies for securing these sought-after placements.

Securing a Desired Placement

Gaining a position in a relevant program requires meticulous preparation and strategic application. A proactive approach is essential to maximize opportunities.

Tip 1: Maintain a Strong Academic Record: Grade point average often serves as an initial screening criterion. Consistently high performance in relevant coursework demonstrates a fundamental understanding of engineering principles.

Tip 2: Develop Relevant Technical Skills: Proficiency in computer-aided design (CAD) software, finite element analysis (FEA), and programming languages (such as MATLAB or Python) significantly strengthens an application. Specific skills relevant to the target aerospace company are particularly valuable.

Tip 3: Seek Out Relevant Projects: Participation in university-sponsored projects, design competitions (e.g., SAE Aero Design), or personal engineering projects showcases practical application of theoretical knowledge. Document and present these projects effectively in a portfolio.

Tip 4: Network Actively: Attend industry conferences, career fairs, and university-organized events to connect with professionals working in the field. Utilize platforms like LinkedIn to engage with engineers and recruiters at target companies.

Tip 5: Tailor Resumes and Cover Letters: Generic applications are often overlooked. Customize each application to highlight skills and experiences that directly align with the specific requirements and objectives of the program.

Tip 6: Prepare for Technical Interviews: Expect technical questions related to core engineering principles, problem-solving scenarios, and specific projects detailed in the application. Practice answering these questions clearly and concisely.

Tip 7: Demonstrate Passion and Initiative: Express genuine interest in aerospace engineering and a willingness to learn and contribute to the team. Highlight experiences that demonstrate initiative, leadership, and teamwork skills.

Adhering to these guidelines significantly increases the likelihood of securing a valuable opportunity. Diligence and strategic planning are crucial for success in a competitive field.

The following sections will address common responsibilities and expectations during the duration of the work.

1. Design Implementation

Design implementation, within the context of aerospace mechanical engineering, represents a core function directly relevant to internship programs. These placements offer students the opportunity to translate theoretical knowledge into tangible aerospace components and systems. The process typically involves participation in the entire design lifecycle, from initial concept generation and CAD modeling to detailed engineering drawings and manufacturing specifications. A direct consequence of this involvement is the development of practical skills in areas such as component design, material selection, and structural analysis. For example, an intern might be tasked with designing a bracket for a satellite component, requiring them to consider factors such as load-bearing capacity, weight minimization, and compatibility with existing systems. This hands-on experience provides a valuable complement to academic coursework.

The importance of design implementation in these programs extends beyond skill acquisition. Interns contribute to real-world engineering projects, often under the guidance of experienced professionals. This provides invaluable exposure to industry standards, design methodologies, and the collaborative nature of aerospace engineering. Furthermore, it allows them to witness the impact of their designs on the overall performance and reliability of aerospace systems. For example, an intern’s design improvements to an aircraft wing could directly translate to enhanced aerodynamic efficiency and reduced fuel consumption. The practical significance of this understanding is crucial, as it bridges the gap between theoretical concepts and the complexities of real-world engineering challenges.

In summary, design implementation is a foundational element of successful aerospace mechanical engineering placements. These positions offer opportunities to develop design skills, contribute to actual projects, and understand how design decisions influence the efficacy of components. Challenges in implementation, such as manufacturability or integration, highlight the importance of iterative design processes and collaborative problem-solving, ultimately preparing students for success in their future aerospace careers. This understanding is integral to maximizing the benefits derived from such opportunities.

2. Analysis Proficiency

Analysis proficiency is an indispensable asset for aspiring aerospace mechanical engineers, and internship programs in this field serve as a pivotal training ground for developing and refining this crucial skill set. The ability to perform rigorous analyses is paramount to ensuring the safety, reliability, and performance of aerospace systems.

- Finite Element Analysis (FEA)

FEA is extensively used to simulate the structural behavior of aerospace components under various load conditions. During an internship, individuals might utilize FEA software to assess the stress, strain, and deformation of a wing structure during flight, a rocket nozzle under extreme temperatures, or a satellite component subjected to launch vibrations. The results inform design modifications and validate structural integrity. This hands-on experience with FEA software and the interpretation of simulation results are invaluable skills.

- Computational Fluid Dynamics (CFD)

CFD is applied to model the airflow around aircraft, spacecraft, and internal flow within engines. An intern might use CFD to analyze the aerodynamic performance of a new wing design, optimize the flow characteristics within a rocket engine combustion chamber, or predict the heat transfer characteristics of electronic components on a satellite. Understanding CFD principles and applying them to real-world aerospace problems is crucial for optimizing performance and ensuring efficient operation.

- Statistical Analysis

Aerospace engineering relies heavily on statistical analysis to assess the reliability and performance of systems based on experimental data. Interns may be involved in analyzing flight test data to determine the statistical characteristics of aircraft performance parameters, assessing the reliability of components based on failure data, or performing uncertainty quantification to account for variations in manufacturing processes. Proficiency in statistical methods and software is essential for ensuring the robust and reliable operation of aerospace systems.

- Thermal Analysis

Managing thermal conditions in aerospace systems is critical, given the extreme temperature variations encountered in space and high-speed flight. Interns may conduct thermal analysis of satellite components to ensure proper temperature control, analyze the heat transfer characteristics of aircraft engines, or design thermal protection systems for spacecraft re-entry. Using software to simulate heat transfer and understand thermal behavior are essential skills for aerospace engineers.

In conclusion, analysis proficiency, encompassing FEA, CFD, statistical methods, and thermal analysis, is fundamental to aerospace mechanical engineering. Internship programs offer invaluable opportunities to develop and apply these skills to practical challenges, ensuring the safety, performance, and reliability of aerospace systems. Mastering these analytical tools and techniques positions aspiring engineers for success in this demanding field.

3. Materials Knowledge

Materials knowledge constitutes a cornerstone of aerospace mechanical engineering, critically influencing design decisions and operational performance. Internship programs serve as a pivotal platform for aspiring engineers to acquire practical expertise in this domain, bridging the gap between theoretical understanding and real-world application.

- Material Selection for Extreme Environments

Aerospace systems operate under demanding conditions, necessitating materials that withstand extreme temperatures, pressures, and corrosive environments. Interns gain exposure to selecting appropriate alloys, composites, and ceramics based on their specific properties and performance characteristics. For instance, an intern might evaluate the suitability of titanium alloys for high-temperature engine components or carbon fiber composites for lightweight aircraft structures. These selections directly impact system longevity and reliability.

- Understanding Material Failure Mechanisms

A comprehensive understanding of material failure modes is crucial for preventing catastrophic events. Interns learn to identify potential failure mechanisms such as fatigue, creep, corrosion, and fracture. They may participate in failure analysis investigations, utilizing techniques like microscopy and non-destructive testing to determine the root cause of material failures. This knowledge informs design improvements and ensures structural integrity.

- Composite Materials and Manufacturing Techniques

Composite materials have become increasingly prevalent in aerospace applications due to their high strength-to-weight ratio. Interns gain hands-on experience with composite materials, learning about different types of fibers, resins, and manufacturing processes. They may be involved in the design and fabrication of composite structures, such as aircraft wings or fuselage panels, understanding the intricacies of layup techniques, curing processes, and quality control measures.

- Material Testing and Characterization

Thorough material testing and characterization are essential for validating material properties and performance. Interns participate in various testing methods, including tensile testing, hardness testing, fatigue testing, and impact testing. They learn to interpret test results, analyze material behavior, and validate material models used in design simulations. This ensures that materials meet the stringent requirements of aerospace applications.

These facets of materials knowledge, acquired and refined during aerospace mechanical engineering placements, equip interns with the skills to make informed material selection decisions, mitigate potential failures, and contribute to the development of innovative aerospace systems. Mastery of these concepts is paramount for ensuring the safety, reliability, and performance of aircraft, spacecraft, and related technologies.

4. Systems Integration

Systems integration, a core discipline within aerospace mechanical engineering, assumes particular significance during internship programs. These opportunities provide practical exposure to the complex challenges inherent in combining disparate components and subsystems into a cohesive, functional aerospace vehicle or system.

- Interdisciplinary Collaboration

Aerospace systems integration mandates collaboration across diverse engineering disciplines, including electrical, software, and structural engineering. Interns participate in multidisciplinary teams, gaining firsthand experience in communication, coordination, and conflict resolution. For example, integrating a new flight control system requires close collaboration between mechanical engineers designing the physical actuators, electrical engineers developing the control circuits, and software engineers programming the control algorithms. Internships provide the opportunity to witness and contribute to this intricate collaborative process.

- Interface Management

Managing interfaces between subsystems is critical for ensuring compatibility and preventing interference. Interns learn to define, document, and test interfaces between mechanical, electrical, and software components. This might involve specifying mechanical mounting points, electrical connector pinouts, or data communication protocols. Proper interface management prevents issues such as mechanical misalignment, electrical short circuits, or software communication errors, ensuring seamless system operation.

- Verification and Validation Testing

Rigorous verification and validation (V&V) testing is essential to ensure that the integrated system meets performance requirements. Interns participate in V&V activities, assisting with test planning, execution, and data analysis. This might involve conducting wind tunnel tests to validate aerodynamic performance, vibration tests to assess structural integrity, or functional tests to verify software behavior. V&V testing identifies potential problems early in the development cycle, preventing costly redesigns and ensuring system reliability.

- Troubleshooting and Problem Solving

Integrating complex systems inevitably involves unforeseen challenges and problems. Interns gain valuable experience in troubleshooting and problem-solving, working alongside experienced engineers to diagnose and resolve integration issues. This might involve identifying the source of a vibration problem, tracing a software bug, or resolving an electrical interference issue. These hands-on problem-solving experiences are crucial for developing the critical thinking skills required for aerospace engineering.

Systems integration challenges, encountered during placements, offer insights into the practical constraints of engineering design and development. These are invaluable experiences. Internships provide the exposure necessary to excel in this multidisciplinary field.

5. Testing Protocols

Testing protocols are an integral component of aerospace mechanical engineering, especially within the context of internship programs. These protocols ensure the reliability, safety, and performance of aerospace systems through rigorous evaluation and validation procedures. The knowledge and application of these protocols are critical skills developed during relevant internships.

- Non-Destructive Testing (NDT) Proficiency

NDT methods, such as ultrasonic testing, radiographic testing, and dye penetrant inspection, are used to identify flaws and defects in aerospace components without causing damage. Interns may gain experience in performing NDT inspections, interpreting results, and assessing the structural integrity of components. For example, an intern could use ultrasonic testing to inspect a composite aircraft wing for delamination or radiographic testing to examine a weld joint for porosity. Mastery of these techniques is essential for ensuring that aerospace components meet stringent quality standards.

- Environmental Testing Exposure

Aerospace systems are subjected to extreme environmental conditions, including temperature variations, vacuum, vibration, and radiation. Environmental testing simulates these conditions to assess the performance and reliability of components. Interns may participate in environmental testing programs, assisting with test setup, data acquisition, and analysis. For example, an intern could conduct thermal vacuum testing on a satellite component to ensure its functionality in the harsh environment of space. These testing procedures are vital for guaranteeing system performance under real-world conditions.

- Performance Validation Methodology

Performance validation is the process of verifying that an aerospace system meets its specified performance requirements. Interns contribute to performance validation by conducting functional tests, analyzing test data, and comparing results against design specifications. For instance, an intern could participate in flight testing of an aircraft, analyzing data on lift, drag, and fuel consumption to validate its aerodynamic performance. This ensures that the system operates as intended and meets all performance criteria.

- Failure Analysis Protocol

Failure analysis is a systematic process of investigating the root cause of failures in aerospace systems. Interns may assist in failure analysis investigations, utilizing techniques such as microscopy, fractography, and chemical analysis to determine the cause of a failure. For example, an intern could analyze a fractured turbine blade from a jet engine to identify the cause of failure, such as fatigue or corrosion. A thorough failure analysis protocol informs design improvements and prevents future failures.

The mastery of testing protocols is a key differentiator for candidates in aerospace mechanical engineering. Internship programs provide the means to not only learn testing principles but also to apply them in real-world scenarios, thereby enhancing practical experience and ensuring future competence in the field.

Frequently Asked Questions Regarding Aerospace Mechanical Engineering Internships

The following addresses common inquiries concerning practical experience opportunities within the aerospace mechanical engineering sector. The information presented is intended to provide clarity and guidance for students and aspiring professionals.

Question 1: What is the typical duration of placements within aerospace mechanical engineering?

The duration varies, although the majority of such positions last between ten to twelve weeks during the summer months. Some opportunities extend to a full semester or academic year, often structured as cooperative education programs.

Question 2: Are opportunities primarily located at aerospace company headquarters?

Location depends on the specific projects and company structure. While some positions are at main headquarters, others may be at research and development facilities, testing sites, or manufacturing plants located across the country or even internationally.

Question 3: What level of academic standing is generally required to be eligible for such placements?

Eligibility often requires completion of at least the sophomore year of a bachelor’s degree program in mechanical engineering, aerospace engineering, or a closely related field. Some companies may prefer applicants with junior or senior standing. Graduate students are also frequently considered.

Question 4: Is prior experience in CAD software essential for obtaining placements in this discipline?

Proficiency in CAD software, such as SolidWorks, CATIA, or AutoCAD, is highly advantageous and often expected. Familiarity with FEA or CFD software can also significantly strengthen an application.

Question 5: What types of projects might individuals be assigned to during an engagement?

Projects can encompass a wide range of activities, including designing components, conducting structural analysis, performing thermal analysis, assisting in wind tunnel testing, contributing to research and development efforts, and supporting manufacturing processes. Responsibilities vary depending on the company and the specific team assignment.

Question 6: Are these positions typically paid or unpaid?

The vast majority of placements within established aerospace companies are paid. Compensation varies depending on location, company size, academic standing, and experience. Unpaid positions are less common, particularly within larger organizations.

In summary, these opportunities provide invaluable hands-on experience and exposure to the aerospace industry, significantly enhancing career prospects for aspiring engineers. Thorough preparation and a strategic application approach are essential for securing these positions.

The following section will provide guidance on resume building.

Conclusion

This exploration of aerospace mechanical engineering internships has elucidated the critical role these placements play in shaping the next generation of aerospace professionals. Key areas such as design implementation, analysis proficiency, materials knowledge, systems integration, and testing protocols have been identified as core developmental components within these programs. A strong academic foundation, coupled with proactive skill development and strategic networking, are essential for securing a sought-after placement.

The sustained demand for skilled aerospace engineers underscores the continued importance of these practical training opportunities. Aspiring engineers are strongly encouraged to pursue these valuable experiences to bridge the gap between academic theory and real-world application, thereby ensuring their future success and contributing to the advancement of the aerospace industry.