Compensation for professionals ensuring adherence to stringent standards within the aeronautics and space sector, specifically those performing quality control, is a key aspect of career planning. This remuneration reflects the level of expertise required to maintain safety and reliability in aircraft and spacecraft manufacturing and maintenance.

The significance of appropriate pay scales is evident in attracting and retaining qualified personnel, thereby upholding the high degree of precision and error prevention demanded by regulatory bodies like the FAA and NASA. Historically, such compensation has evolved in response to increasing technological complexity and the growing emphasis on quality assurance within the industry.

The following sections will delve into factors influencing earnings, regional variations in pay, the impact of experience and education, and the potential career paths associated with quality control roles in the aerospace industry. These elements collectively determine the earning potential for individuals in this specialized field.

Maximizing Earning Potential

This section outlines actionable strategies that may contribute to enhanced compensation for professionals focused on quality assurance within the aeronautics and space industries. A proactive approach to career development is essential for optimizing financial prospects in this field.

Tip 1: Pursue Advanced Certifications: Obtain certifications such as ASQ Certified Quality Technician (CQT) or similar industry-recognized credentials. These demonstrate a commitment to professional development and validate expertise, potentially leading to higher earning opportunities.

Tip 2: Specialize in High-Demand Areas: Focus on developing expertise in specialized areas like composite materials, non-destructive testing (NDT), or specific aircraft systems. Specialization can increase value to employers and justify higher pay.

Tip 3: Gain Experience with Regulatory Compliance: Become proficient in understanding and applying relevant regulations, such as FAA regulations or AS9100 standards. This knowledge is critical for ensuring product compliance and minimizing risk, making individuals more valuable to employers.

Tip 4: Develop Strong Communication Skills: Hone the ability to communicate technical information clearly and concisely, both verbally and in writing. Effective communication is crucial for collaborating with engineers, technicians, and management, which is essential for career progression.

Tip 5: Seek Opportunities for Continuous Learning: Stay abreast of the latest technological advancements, quality control methodologies, and industry best practices. Continuous learning ensures ongoing relevance and enhances career prospects, potentially leading to increased pay.

Tip 6: Network with Industry Professionals: Engage in industry events, join professional organizations (e.g., ASQ), and build relationships with colleagues and mentors. Networking can expose individuals to new opportunities and provide valuable insights into compensation trends.

Tip 7: Document Achievements and Quantify Results: Keep a detailed record of accomplishments and quantifiable results achieved in quality control roles. This documentation can serve as evidence of expertise and contributions during performance reviews and salary negotiations.

These strategies provide a framework for maximizing career potential. By focusing on continuous learning, specialization, and professional development, individuals can enhance their skills and demonstrate their value to employers, ultimately contributing to increased compensation.

The concluding section will summarize the key aspects discussed in this article, emphasizing the importance of comprehensive career planning for professionals in the aerospace quality control sector.

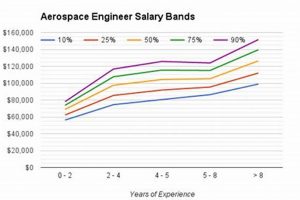

1. Experience and tenure

The correlation between experience and tenure and compensation within the aerospace quality control domain is demonstrably positive. As technicians accumulate practical experience, their proficiency in identifying and rectifying defects, interpreting technical documentation, and adhering to regulatory standards increases. This proficiency directly translates into higher value for employers, justifying increased remuneration. For example, a newly certified technician may start at an entry-level salary, while a technician with five years of experience, demonstrating a proven track record of reducing defects and improving efficiency, can command a significantly higher salary.

The importance of experience is amplified by the complex nature of aerospace manufacturing. Tenured professionals possess an institutional knowledge that is invaluable for maintaining consistent quality standards. They are often adept at anticipating potential problems, implementing preventive measures, and training junior personnel. This level of expertise minimizes the risk of costly errors and production delays, further contributing to their higher earning potential. Senior technicians may also assume leadership roles, overseeing quality control teams and contributing to process improvements, thereby increasing their responsibilities and compensation accordingly. They have deep understanding about aerospace quality technician salary.

In summary, experience and tenure serve as critical determinants of compensation within the aerospace quality control field. The accumulation of practical expertise, institutional knowledge, and leadership skills significantly enhances an individual’s value to employers. This direct correlation reinforces the importance of continuous professional development and long-term commitment within this specialized sector. Recognizing this link is essential for individuals seeking career advancement and improved earning potential in aerospace quality assurance.

2. Education and Certifications

A demonstrable correlation exists between educational attainment, professional certifications, and compensation levels for professionals in aerospace quality control. While practical experience remains valuable, formal education and industry-recognized certifications provide a structured foundation of knowledge and skills, enhancing an individual’s capabilities and marketability. Possessing a relevant degree, such as an associate’s or bachelor’s degree in engineering technology or a related field, often results in a higher starting salary compared to individuals with only a high school diploma. This reflects the employer’s recognition of the enhanced theoretical understanding and problem-solving abilities gained through formal education.

Furthermore, specific certifications, such as those offered by the American Society for Quality (ASQ), can significantly impact earning potential. Certifications like Certified Quality Technician (CQT), Certified Quality Engineer (CQE), and Certified Quality Auditor (CQA) validate an individual’s proficiency in specific areas of quality control. These certifications demonstrate to employers that the individual possesses the necessary knowledge and skills to perform their job effectively and contribute to improved quality outcomes. For example, a technician with a CQT certification may be entrusted with more complex tasks and responsibilities, leading to increased compensation. The financial investment in obtaining these certifications is often recouped through salary increases and career advancement opportunities.

In conclusion, investing in education and pursuing relevant certifications are strategic decisions for individuals seeking to maximize their earning potential within the aerospace quality control field. These credentials provide a competitive advantage in the job market, enhance technical skills, and demonstrate a commitment to professional development, all of which contribute to increased compensation levels. While experience remains crucial, a solid educational foundation and industry-recognized certifications serve as powerful catalysts for career advancement and improved financial prospects. The linkage underscores the importance of viewing education and certifications as integral components of a comprehensive career strategy within this specialized domain.

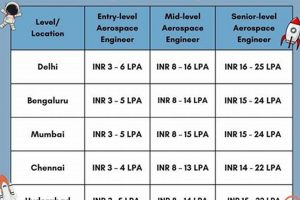

3. Geographic Location

Geographic location exerts a significant influence on compensation for aerospace quality technicians. Regional variations in economic conditions, industry presence, and cost of living directly impact prevailing pay scales. Understanding these geographic dynamics is crucial for professionals seeking to optimize their earning potential.

- Cost of Living Adjustments

Higher cost of living areas, such as those in major metropolitan centers like Seattle, Los Angeles, and Boston, typically offer higher salaries to compensate for increased expenses related to housing, transportation, and general living costs. These adjustments aim to maintain a comparable standard of living across different regions, reflecting the economic realities of each location. Aerospace quality technicians residing in such areas can expect to receive commensurate pay relative to their counterparts in regions with lower costs of living.

- Industry Concentration and Demand

Areas with a high concentration of aerospace manufacturing and maintenance facilities often experience increased demand for qualified quality control personnel. This heightened demand can drive up salaries, as employers compete to attract and retain skilled technicians. Regions like the Pacific Northwest (Boeing), Southern California (various aerospace companies), and Florida (space industry) are examples where industry presence significantly impacts compensation. The presence of major aerospace employers creates a competitive job market, benefiting technicians seeking higher remuneration.

- State and Local Tax Policies

State and local tax policies can indirectly influence the attractiveness of a particular location for aerospace quality technicians. States with lower income tax rates or more favorable tax structures may be more appealing, as technicians retain a larger portion of their earnings. Conversely, states with higher taxes may necessitate higher salaries to offset the increased tax burden. Understanding these regional tax implications is essential for accurately assessing the overall financial benefits of a specific geographic location.

- Labor Market Competition

The level of competition within the labor market can also affect compensation levels. Regions with a large pool of qualified aerospace quality technicians may experience downward pressure on salaries due to increased competition for available positions. Conversely, areas with a shortage of qualified personnel may see increased salaries as employers strive to attract talent. Factors influencing labor market competition include the presence of vocational schools, universities with aerospace engineering programs, and the overall attractiveness of the region to potential employees.

In summary, geographic location is a multifaceted factor influencing compensation for aerospace quality technicians. Cost of living adjustments, industry concentration, tax policies, and labor market competition all contribute to regional variations in pay scales. A thorough understanding of these geographic dynamics is essential for professionals seeking to make informed decisions about career opportunities and optimize their earning potential within this specialized field.

4. Company Size

The size of an aerospace company demonstrably influences the compensation offered to its quality technicians. This correlation stems from various factors related to the operational scale, financial resources, and organizational structure inherent to companies of different sizes.

- Financial Capacity and Revenue Streams

Larger aerospace companies, characterized by substantial revenue streams and significant market share, typically possess greater financial capacity to offer competitive salaries and comprehensive benefits packages. These companies often engage in diverse projects, including commercial aviation, defense contracts, and space exploration, generating substantial profits. This financial stability enables them to attract and retain highly skilled quality technicians by providing attractive compensation packages, including higher base salaries, performance bonuses, and stock options. In contrast, smaller companies or startups with limited financial resources may offer lower salaries and fewer benefits due to budgetary constraints. While smaller entities may provide valuable experience, their compensation structures often lag behind those of larger corporations.

- Complexity of Operations and Specialized Roles

Larger aerospace companies frequently manage more complex operations involving intricate manufacturing processes, stringent regulatory requirements, and diverse product lines. This complexity necessitates a wider range of specialized quality control roles, such as non-destructive testing specialists, materials testing experts, and regulatory compliance officers. These specialized positions often command higher salaries due to the advanced skills and expertise required. Furthermore, larger companies may offer opportunities for quality technicians to specialize in specific areas of aerospace manufacturing, such as avionics, propulsion systems, or airframe structures, leading to further career advancement and increased earning potential. Smaller companies, with simpler operations, may offer fewer opportunities for specialization, resulting in a narrower range of salary options.

- Hierarchical Structure and Career Advancement

Larger aerospace companies typically have more elaborate hierarchical structures, providing more opportunities for career advancement and professional development. Quality technicians within these organizations can progress through various roles, such as quality inspector, quality engineer, quality manager, and senior quality director. Each upward move in the organizational hierarchy is often accompanied by a corresponding increase in salary and responsibility. Moreover, larger companies frequently invest in employee training programs, leadership development initiatives, and tuition reimbursement, further enhancing career prospects and earning potential for their quality technicians. Smaller companies may have flatter organizational structures, limiting opportunities for career advancement and salary growth.

- Union Representation and Collective Bargaining

Larger aerospace companies are more likely to have unionized workforces, where labor unions represent the interests of employees, including quality technicians. Union representation often leads to improved wages, benefits, and working conditions through collective bargaining agreements. These agreements typically establish standardized pay scales, annual salary increases, and comprehensive benefits packages, ensuring fair compensation for quality technicians. Furthermore, unionized environments may provide greater job security and protection against unfair labor practices. Smaller companies are less likely to have union representation, potentially leaving individual employees to negotiate their compensation and benefits independently.

In conclusion, the size of an aerospace company exerts a substantial influence on the compensation offered to quality technicians. Factors such as financial capacity, operational complexity, hierarchical structure, and union representation all contribute to the observed correlation between company size and salary levels. A comprehensive understanding of these dynamics is essential for quality technicians seeking to make informed career decisions and maximize their earning potential within the aerospace industry.

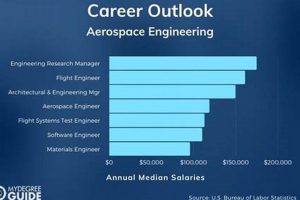

5. Industry Demand

The prevailing industry demand directly correlates with the compensation offered to aerospace quality technicians. A robust aerospace sector, characterized by high production rates, technological advancements, and expansion into new markets, invariably necessitates a larger and more skilled workforce of quality control professionals. This increased demand creates a competitive hiring environment, compelling employers to offer more attractive salaries to secure and retain qualified personnel. Conversely, periods of economic downturn or industry contraction often result in reduced hiring activity and potential downward pressure on wages. The cyclical nature of the aerospace industry therefore has a tangible impact on earning potential for these technicians.

Consider, for instance, the surge in demand for commercial aircraft fueled by the growth of air travel in emerging economies. This expansion requires a corresponding increase in the production of aircraft components, leading to a greater need for quality technicians to ensure adherence to stringent safety and performance standards. In such scenarios, companies actively recruit experienced professionals, often offering signing bonuses and enhanced benefits packages to attract top talent. Another example is the increasing complexity of modern aircraft, incorporating advanced materials and sophisticated electronic systems. This technological evolution necessitates quality technicians with specialized skills in areas such as non-destructive testing, composite materials analysis, and avionics systems testing, further driving up demand and associated salaries for these niche specializations. The persistent emphasis on safety and regulatory compliance in aerospace, coupled with advancements in manufacturing techniques, sustains the importance of quality control, and, by extension, sustains the need for competent personnel in the field.

In summary, the dynamic interplay between industry demand and compensation for aerospace quality technicians is undeniable. Economic cycles, technological advancements, and regulatory requirements all influence the need for skilled professionals in this sector. A proactive approach to career development, including specialization in high-demand areas and continuous professional education, is essential for technicians seeking to capitalize on favorable market conditions. Understanding the broader economic and technological trends shaping the aerospace industry is crucial for navigating career paths and maximizing earning potential within this specialized field.

Frequently Asked Questions

This section addresses common inquiries regarding compensation for professionals specializing in quality control within the aeronautics and space sectors. Information is provided to clarify factors influencing earnings and to offer insights into career planning.

Question 1: What is the typical entry-level compensation for an aerospace quality technician?

Entry-level remuneration for an aerospace quality technician varies depending on geographic location, educational background, and specific employer. Generally, individuals with an associate’s degree or vocational training can expect a starting salary in the range of \$40,000 to \$50,000 annually. This figure may be lower in regions with a lower cost of living or for positions requiring minimal experience.

Question 2: How does obtaining professional certifications, such as ASQ certifications, impact compensation?

Professional certifications, particularly those offered by the American Society for Quality (ASQ), can significantly enhance earning potential. Certified Quality Technicians (CQTs), Certified Quality Engineers (CQEs), and Certified Quality Auditors (CQAs) often command higher salaries due to their validated expertise. Employers recognize the value of these certifications, as they demonstrate a commitment to quality and competence. The precise impact on compensation varies, but certified professionals can typically expect a salary increase of 5% to 15% compared to their non-certified counterparts.

Question 3: What factors contribute to salary growth for aerospace quality technicians over time?

Salary growth within this field is influenced by several factors, including experience, performance, education, and the acquisition of specialized skills. Technicians who consistently demonstrate strong performance, expand their knowledge base through continuous learning, and pursue advanced certifications are more likely to receive promotions and salary increases. Developing expertise in high-demand areas, such as non-destructive testing or composite materials, can also accelerate career progression and earning potential.

Question 4: How does geographic location affect compensation for aerospace quality technicians?

Geographic location is a significant determinant of compensation. Regions with a high concentration of aerospace manufacturing and maintenance facilities, such as Seattle, Southern California, and Florida, generally offer higher salaries due to increased demand and a higher cost of living. Conversely, salaries may be lower in areas with a smaller aerospace industry presence or a lower cost of living. Cost of living adjustments and regional economic factors play a crucial role in shaping pay scales.

Question 5: What is the salary range for experienced aerospace quality managers or supervisors?

Experienced aerospace quality managers or supervisors typically earn salaries in the range of \$80,000 to \$120,000 or more annually. This figure reflects the increased responsibility and leadership duties associated with these roles. Factors such as company size, geographic location, and the scope of responsibilities influence the specific compensation offered. Senior management positions within quality control may command even higher salaries.

Question 6: What are the typical benefits packages offered to aerospace quality technicians, in addition to base salary?

In addition to base salary, aerospace quality technicians typically receive a comprehensive benefits package, including health insurance (medical, dental, and vision), paid time off (vacation, sick leave, and holidays), retirement plans (401(k) with employer matching), life insurance, and disability insurance. Some employers may also offer tuition reimbursement for continuing education, professional development opportunities, and employee assistance programs. The specific benefits package offered can vary depending on the employer and the collective bargaining agreements in place.

Understanding these common questions and their answers provides a foundation for making informed decisions about career paths and salary expectations within the aerospace quality control sector. Careful consideration of education, certifications, experience, and geographic location is essential for optimizing earning potential.

The following section will offer concluding remarks summarizing the key points discussed and providing a final perspective on compensation trends.

Aerospace Quality Technician Salary

The preceding analysis has comprehensively examined various factors influencing compensation within the aerospace quality control domain. Education, certifications, experience, geographic location, company size, and prevailing industry demand all play critical roles in determining the remuneration for professionals in this specialized field. Understanding the interplay of these elements is essential for both aspiring and experienced technicians seeking to maximize their earning potential. Furthermore, continuous professional development and strategic career planning are crucial for navigating the evolving landscape of the aerospace industry and securing competitive compensation.

The commitment to ensuring the highest standards of quality and safety within the aeronautics and space sectors necessitates appropriate valuation of the skilled professionals who perform this vital function. As technology continues to advance and regulatory requirements become increasingly stringent, the demand for qualified aerospace quality technicians will likely persist, potentially driving further evolution in compensation structures. Individuals entering or advancing within this field are encouraged to remain informed of industry trends, pursue relevant certifications, and actively manage their career trajectory to achieve long-term financial success and contribute to the continued safety and reliability of air and space travel.