Positions within the aerospace sector that focus on the design, development, implementation, and maintenance of robotic systems constitute a specialized field. These roles involve applying robotic technology to various aspects of the aerospace industry, such as manufacturing, assembly, inspection, and exploration. For instance, engineers might create robotic arms for assembling aircraft components or develop autonomous rovers for planetary exploration.

The significance of this area lies in its potential to enhance efficiency, reduce costs, and improve safety in aerospace operations. Robotic systems can perform tasks that are either too dangerous or too repetitive for human workers, leading to increased productivity and reduced risk of injury. Historically, the integration of automation and robotic systems in aerospace has propelled advancements in manufacturing precision and exploration capabilities.

The following sections will delve into the specific types of roles available, the required qualifications and skills, and the future outlook for professionals in this evolving technological domain.

Navigating the landscape of career opportunities within the application of robotics to the aerospace sector requires a strategic and informed approach. The following guidelines offer insights into optimizing one’s professional trajectory within this specialized domain.

Tip 1: Acquire a Strong Foundation in Engineering Principles: A robust understanding of mechanical, electrical, and software engineering is crucial. Academic pursuits should emphasize coursework in areas such as control systems, robotics, and automation.

Tip 2: Cultivate Expertise in Robotics Software and Hardware: Familiarity with industry-standard software platforms (e.g., ROS, MATLAB) and hardware components (e.g., sensors, actuators) is essential. Hands-on experience through projects and internships will prove invaluable.

Tip 3: Seek Specialized Knowledge in Aerospace Applications: Understanding the unique challenges and requirements of aerospace environments (e.g., extreme temperatures, radiation exposure) is critical. This can be achieved through specialized courses, research, or internships within aerospace companies.

Tip 4: Develop Proficiency in Simulation and Modeling: The ability to simulate and model robotic systems in aerospace applications is highly valued. Proficiency in software tools used for these purposes is essential.

Tip 5: Obtain Relevant Certifications: Industry-recognized certifications in robotics or related fields can enhance credibility and demonstrate competence to potential employers.

Tip 6: Network Strategically: Attend industry conferences, join professional organizations, and connect with individuals working in aerospace robotics. Networking can provide valuable insights and potential career leads.

Tip 7: Highlight Relevant Project Experience: Showcase relevant projects and experiences in resumes and interviews. Demonstrate the ability to apply robotics principles to solve real-world aerospace challenges.

By prioritizing these strategies, individuals can significantly enhance their prospects within the competitive arena of aerospace robotics. The effective combination of technical expertise, specialized knowledge, and strategic networking will contribute to a successful career trajectory.

The concluding section will provide a future-oriented perspective on the evolving demands and opportunities within this dynamic field.

1. Engineering

Engineering disciplines form the bedrock upon which the field of robotics in aerospace is built. Mechanical engineering principles underpin the design and construction of robotic arms and manipulators, ensuring they possess the required strength, precision, and range of motion. Electrical engineering is crucial for developing the power systems, control circuitry, and sensor integration that enable robots to function autonomously or semi-autonomously. Software engineering expertise is necessary to create the algorithms that govern robot behavior, enabling them to interpret sensor data, plan movements, and interact with their environment.

The relationship between engineering and careers in implementing robotics in the aerospace sector is causal. A strong foundation in one or more engineering disciplines is a prerequisite for designing, building, deploying, and maintaining robotic systems used in aircraft manufacturing, space exploration, and satellite maintenance. For example, mechanical engineers might design a robotic system to automate the drilling and fastening of aircraft fuselage panels, thereby increasing production efficiency and reducing human error. Electrical engineers could develop a power management system for a lunar rover, ensuring its reliable operation in the harsh conditions of the Moon’s surface. Software engineers might create algorithms to control a robotic arm that performs delicate repairs on a satellite in orbit.

In summary, a robust understanding of core engineering principles is indispensable for those seeking professional engagement at the intersection of aviation and automation. The ability to apply these principles to the design, development, and implementation of robotic systems directly contributes to advancements in efficiency, safety, and capability within the aerospace industry. As such, ongoing investment in engineering education and research remains vital to the continued growth and innovation of aerospace robotics.

2. Automation

Automation is an integral component of modern aerospace operations, significantly influencing the nature and scope of opportunities in the domain of aviation robotic roles. The incorporation of automated systems drives efficiency, precision, and safety across various facets of the aerospace industry, demanding a specialized workforce skilled in their design, implementation, and maintenance.

- Increased Production Efficiency

Automation streamlines manufacturing processes, allowing for faster production rates and reduced labor costs. Automated assembly lines, for example, can assemble aircraft components with greater speed and accuracy than manual labor. This necessitates personnel capable of designing, programming, and maintaining these automated systems.

- Enhanced Precision and Quality Control

Robotic systems equipped with advanced sensors and control algorithms can perform tasks with a level of precision unattainable by humans. This is particularly critical in manufacturing components with stringent dimensional tolerances. Such precision demands experts with advanced capabilities in robot calibration and advanced control systems.

- Improved Worker Safety

Automation enables the performance of tasks that are hazardous or physically demanding, reducing the risk of injury to human workers. Examples include painting aircraft fuselages with automated spray systems or working in confined spaces within aircraft wings. Expertise in risk assessment and safety system design is therefore crucial.

- Expanded Exploration Capabilities

Autonomous robots can explore environments that are inaccessible or too dangerous for humans, such as deep space or disaster zones. Space exploration programs rely heavily on robotic probes and rovers to gather data and conduct experiments. Professionals with specialization in autonomous navigation, sensor integration, and extreme environment robotics are invaluable.

In summary, automation pervades various aspects of the aerospace sector, directly shaping the demand for skilled professionals. As aerospace continues to push technological boundaries, the role of automationand those who can effectively manage itwill only continue to grow in significance.

3. Robotics

The field of robotics constitutes the core technology underpinning the existence and evolution of specialized job roles within the aerospace sector. Without advancements in robotic systems, the capabilities required to automate manufacturing processes, conduct remote inspections, and facilitate space exploration would be severely limited. The relationship is causative: robotics provides the fundamental tools and techniques necessary for performing specific tasks associated with relevant positions. For example, the development of precision robotic arms has enabled automated composite layup in aircraft manufacturing, directly leading to demand for engineers skilled in robotic programming and maintenance. Similarly, the creation of autonomous rovers equipped with sophisticated sensors has created opportunities for scientists and engineers specializing in planetary exploration.

Practical applications of robotics in aerospace are widespread. Robotic systems are employed for non-destructive testing of aircraft structures, ensuring safety and preventing failures. These systems use sensors to detect cracks or defects that are invisible to the naked eye, reducing the need for manual inspections and improving reliability. In space, robotic manipulators are crucial for maintaining and repairing satellites, extending their lifespan and reducing the cost of replacement. The International Space Station relies heavily on robotic arms for construction, maintenance, and scientific experiments. These applications highlight the importance of specialized expertise in robot control, sensor integration, and fault diagnosis.

In summary, robotics is not merely an ancillary technology, but an essential component of numerous opportunities in aerospace. The ability to design, develop, deploy, and maintain robotic systems is central to addressing the challenges and seizing the opportunities presented by the modern aerospace industry. As technology advances, the demand for individuals with expertise in robotics will continue to increase, necessitating ongoing investment in education and training. A crucial factor is the inherent challenge of operating complex systems in dynamic and often unpredictable environments, where the robustness and reliability of robotic solutions is paramount.

4. Aerospace

The aerospace industry, encompassing the design, development, and manufacturing of aircraft and spacecraft, serves as the primary arena for the application of robotic systems. This sector’s unique demands and challenges create a specific need for skilled professionals proficient in the development and implementation of automation in extreme environments, leading directly to “aerospace robotics jobs”.

- Aircraft Manufacturing

The construction of modern aircraft relies increasingly on automated processes. Robotic systems are used for tasks such as composite material layup, precision drilling, and component assembly. These systems require specialized engineers and technicians capable of programming, maintaining, and troubleshooting robotic equipment. Examples include the automated wing assembly lines used by major aircraft manufacturers, which necessitate skilled personnel for their operation.

- Space Exploration

The exploration of space depends heavily on robotic probes and rovers. These autonomous vehicles navigate distant planets, collect data, and perform experiments in environments too hazardous for human presence. The design and operation of these robotic explorers demand experts in areas such as autonomous navigation, sensor integration, and remote control systems. The Mars rovers, for example, are operated by a team of engineers and scientists who specialize in robotic exploration.

- Satellite Maintenance and Repair

The maintenance and repair of satellites in orbit presents significant challenges. Robotic systems can be deployed to perform tasks such as refueling, repairing damaged components, and repositioning satellites. This requires professionals skilled in designing and operating robotic manipulators in the vacuum of space, as well as developing advanced control algorithms for remote operation. NASA’s robotic servicing missions are examples of this type of activity.

- Aircraft Inspection and Maintenance

The inspection and maintenance of aircraft require meticulous attention to detail. Robotic systems are used to perform non-destructive testing, detect structural damage, and apply protective coatings. This reduces the need for manual inspections, improves safety, and increases efficiency. The operation and maintenance of these robotic inspection systems require trained technicians with expertise in robotics and aerospace engineering.

In conclusion, the varied and demanding nature of the aerospace sector directly drives the demand for specialized roles involving robotic systems. The examples provided illustrate the diverse applications of robotic technology within this industry and highlight the critical need for skilled professionals to support their development, implementation, and maintenance. These factors all contribute to the growing importance and prevalence of opportunities in related roles.

5. Manufacturing

The manufacturing sector within aerospace represents a primary driver for the creation and evolution of specialized roles focused on robotic systems. The relationship is causal: the increasing complexity and precision demands of modern aircraft and spacecraft construction necessitate automation through robotics. This directly impacts the need for engineers, technicians, and programmers skilled in designing, implementing, and maintaining these automated systems. Without the drive for efficient, high-quality manufacturing, the prevalence and significance of roles in implementing robotics in aviation would be considerably diminished. For example, the implementation of robotic drilling and fastening systems in Boeing’s 777X program directly resulted in new “aerospace robotics jobs” focused on system integration, operation, and maintenance. The understanding of this connection highlights the critical importance of manufacturing as a catalyst for advancement and innovation.

Further analysis reveals specific applications where manufacturing and implementation of robotics in aviation intersect. The production of composite materials, increasingly used in aircraft construction for their strength and lightweight properties, relies heavily on automated fiber placement and layup processes. Robotic arms precisely deposit layers of composite material onto molds, ensuring consistent thickness and minimizing defects. This process requires highly skilled individuals capable of programming the robots’ movements, optimizing material deposition parameters, and troubleshooting system malfunctions. Additionally, the manufacturing of small, intricate components for avionics systems and satellite payloads often involves micro-robotics, demanding expertise in miniaturization, precision assembly, and advanced control algorithms.

In conclusion, the manufacturing sector is inextricably linked to the landscape of employment opportunities in the application of robotics to the aerospace sector. Demands for increased efficiency, improved quality control, and the adoption of novel materials and manufacturing techniques have fueled the integration of robotic systems into aerospace production processes. This trend has generated a corresponding demand for a skilled workforce capable of designing, implementing, and maintaining these advanced technologies. Addressing the challenges of workforce development and technological innovation will be crucial for ensuring the continued growth and competitiveness of the industry.

6. Exploration

Exploration, particularly in the context of space, acts as a significant impetus for the creation and advancement of positions focused on robotic systems within the aerospace sector. The inherent challenges and limitations of human spaceflight necessitate the deployment of robotic proxies for remote reconnaissance, sample collection, and infrastructure construction, making robotic systems invaluable. Therefore, the ambition to explore beyond Earth directly fosters the development and employment of specialists skilled in aerospace robotics.

The connection is further substantiated by numerous examples. The Mars rovers, such as Curiosity and Perseverance, exemplify this relationship. Their design, construction, and operation require a diverse team of engineers, scientists, and technicians specializing in robotic control, autonomous navigation, sensor integration, and remote data analysis. Similarly, future lunar missions, including those aimed at establishing a permanent lunar base, will rely heavily on robotic systems for resource extraction, habitat construction, and scientific research. These endeavors create opportunities for professionals with expertise in areas such as lunar robotics, in-situ resource utilization (ISRU), and autonomous construction techniques. The Europa Clipper mission, designed to explore Jupiter’s moon Europa, will rely on radiation-hardened robotic systems to investigate the subsurface ocean, creating demand for specialists in robotic design and operation within extreme environments. Space exploration is the driver, robotic capabilities are the vehicle, and specialized professionals are the crew.

In summary, space exploration is a vital catalyst for the growth and evolution of opportunities in the field. The inherent challenges of operating in remote, hazardous, and poorly understood environments necessitate the development and deployment of increasingly sophisticated robotic systems, thereby driving the demand for skilled professionals. Overcoming challenges related to autonomous operation, extreme environment resilience, and remote control will be crucial for unlocking the full potential of robotic exploration and ensuring continued progress in the field of implementing robotic roles in aviation.

7. Maintenance

Maintenance within the aerospace sector is inextricably linked to the emergence and evolution of positions centered on robotic systems. A direct relationship exists: the increasingly complex and demanding maintenance requirements of modern aircraft and spacecraft necessitate the implementation of automated and robotic solutions. This dependence creates a need for skilled engineers, technicians, and programmers proficient in the design, operation, and repair of these robotic maintenance systems. For instance, traditional manual inspection processes for aircraft structural integrity are gradually being replaced by robotic systems equipped with non-destructive testing (NDT) capabilities. This shift results in new job roles focused on the development and deployment of these NDT robotic platforms.

The importance of maintenance as a component driving robotics implementation is substantiated by various practical applications. Robotic systems are deployed to perform tasks such as aircraft painting, which reduces human exposure to hazardous chemicals and improves efficiency. They also conduct inspections of hard-to-reach areas, like inside wings or engine compartments, using remote visual inspection (RVI) technologies, minimizing the need for extensive disassembly. Furthermore, satellite maintenance and repair in orbit, a highly challenging and dangerous endeavor for humans, relies heavily on specialized robotic arms and remotely operated vehicles (ROVs). These applications demonstrate the growing reliance on robotics to ensure aircraft and spacecraft are safe, reliable, and operational, hence creating respective “aerospace robotics jobs.”

In summary, the ongoing need for efficient, safe, and cost-effective maintenance within the aerospace sector has fueled the development and deployment of robotic systems. This trend has, in turn, created a specialized job market demanding expertise in areas such as robotic design, programming, sensor integration, and remote operation. Addressing the challenges of training and workforce development will be crucial for ensuring the continued integration of robotic technologies into aerospace maintenance operations and capitalizing on the opportunities. It is paramount for professionals and job seekers to have solid foundation in this direction. Moreover, continued innovation of robotic inspection/maintenance platform should keep evolving with technology.

Frequently Asked Questions

This section addresses common inquiries and provides informative responses regarding professional opportunities within the specialized field of engineering robotics in the aerospace industry.

Question 1: What specific qualifications are typically required for related roles?

Generally, a bachelor’s degree in engineering (mechanical, electrical, aerospace, or computer) is a minimum requirement. Advanced degrees (master’s or doctoral) may be necessary for research-oriented positions. Expertise in robotics, control systems, automation, and programming languages (e.g., C++, Python) is also crucial. Relevant certifications can further enhance candidacy.

Question 2: What types of positions exist in the implementation of robotics in aviation?

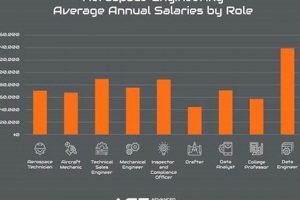

Positions vary widely, including roles such as robotics engineer, automation specialist, control systems engineer, robotics programmer, robotic technician, and research scientist. The specific job title and responsibilities depend on the company, industry sector, and project focus.

Question 3: What are the primary responsibilities associated with relevant roles?

Responsibilities can include designing, developing, testing, and deploying robotic systems for applications such as aircraft manufacturing, space exploration, satellite maintenance, and aircraft inspection. Tasks may involve programming robot controllers, integrating sensors, developing algorithms for autonomous navigation, and troubleshooting system malfunctions.

Question 4: Which software and hardware skills are most valuable?

Proficiency in industry-standard software packages such as ROS (Robot Operating System), MATLAB, and simulation tools is essential. Familiarity with hardware components such as robotic arms, sensors (e.g., lidar, cameras, inertial measurement units), actuators, and microcontrollers is also highly desirable.

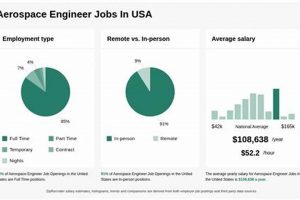

Question 5: What is the projected career outlook in “aerospace robotics jobs”?

The job outlook is generally positive due to increasing demand for automation and robotics in the aerospace industry. Technological advancements, coupled with the need for enhanced efficiency, safety, and precision, are expected to drive growth in related positions.

Question 6: What are the key challenges in related careers?

Challenges include operating complex systems in dynamic and unpredictable environments, ensuring the reliability and robustness of robotic solutions, developing algorithms for autonomous decision-making, and addressing safety concerns related to human-robot collaboration. Adapting to evolving technological advancements is also an ongoing challenge.

The responses above are intended to provide general guidance. Specific requirements and opportunities may vary depending on the particular organization and role.

The concluding section will offer insights into resources for further exploration of this dynamic field.

Conclusion

This exploration has illuminated the multifaceted landscape of “aerospace robotics jobs,” emphasizing the integral role of robotic systems within the aviation and space sectors. The analysis encompassed the core engineering principles, the driving forces of automation and exploration, and the critical requirements of manufacturing and maintenance. Each facet underscores the growing demand for specialized expertise in the design, development, and deployment of robotic technologies.

The continued advancement of aerospace necessitates ongoing innovation in robotic systems. Prospective professionals should strive to acquire a comprehensive understanding of the technical challenges and opportunities within this dynamic field. Adapting to these evolving demands will be paramount for ensuring the continued success and progress of the industry.