Positions focused on the logistics involved in the aerospace sector, handling the movement of parts, equipment, and finished goods, are critical to the industry. These roles encompass the intake of incoming materials, ensuring accuracy and proper documentation, as well as the preparation and dispatch of outgoing shipments. Examples include verifying received parts against purchase orders, packaging sensitive avionics equipment for secure transport, and coordinating with freight carriers for timely delivery of aircraft components.

Effective supply chain management within the aerospace field is paramount due to the high value, precision requirements, and stringent safety regulations associated with its products. The seamless flow of materials directly impacts production schedules, maintenance operations, and overall operational efficiency. Historically, advancements in transportation technology and inventory management systems have continuously shaped the demands and responsibilities of personnel in these logistics roles, ensuring a constant drive for improvement and optimization.

The following sections will delve deeper into the specific duties, required skills, typical work environments, and career advancement opportunities associated with these essential logistical functions within the aerospace industry. Furthermore, insights into training programs and relevant certifications will be provided, offering a comprehensive overview of this vital segment of the aerospace workforce.

Essential Guidance for Aerospace Logistics Professionals

The following recommendations are intended to assist individuals involved in the logistical aspects of the aerospace sector. These insights focus on optimizing operational efficiency and ensuring compliance with industry standards.

Tip 1: Maintain Rigorous Documentation: Precise record-keeping is critical for traceability and regulatory compliance. All incoming and outgoing shipments must be meticulously documented, including serial numbers, part numbers, and condition upon arrival or departure.

Tip 2: Prioritize Secure Packaging: Aerospace components are often delicate and high-value. Employ packaging methods that offer maximum protection against damage during transit, utilizing appropriate cushioning, bracing, and anti-static measures.

Tip 3: Ensure Compliance with Export Regulations: International shipments require adherence to strict export control regulations, such as those governed by ITAR (International Traffic in Arms Regulations) and EAR (Export Administration Regulations). Familiarize oneself with these regulations to avoid penalties and delays.

Tip 4: Optimize Inventory Management: Implement a robust inventory management system to minimize storage costs and prevent obsolescence. Regularly assess stock levels and adjust ordering patterns based on demand forecasts and lead times.

Tip 5: Foster Strong Carrier Relationships: Establish effective communication and collaboration with freight carriers to ensure reliable and timely delivery. Negotiate favorable rates and service agreements based on volume and frequency of shipments.

Tip 6: Implement Quality Control Checks: Conduct thorough quality control inspections upon receipt of materials to identify any discrepancies or damage. Promptly report any issues to the supplier and initiate corrective action.

Tip 7: Stay Informed on Industry Best Practices: The aerospace industry is constantly evolving. Remain current on the latest advancements in logistics technology, regulatory changes, and supply chain management strategies through continuous learning and professional development.

Effective implementation of these guidelines will contribute to improved operational efficiency, reduced costs, and enhanced compliance within the aerospace logistics environment.

The next section will explore the future trends impacting this crucial field.

1. Precision

Within aerospace shipping and receiving, precision is not merely a desired attribute but a fundamental operational requirement. The handling of components, often high-value and critical for aircraft functionality, demands meticulous attention to detail at every stage of the logistical process. The slightest error can lead to significant delays, financial losses, and, in the worst-case scenario, compromised safety.

- Dimensional Accuracy Verification

The confirmation of dimensional accuracy against engineering specifications is crucial upon receipt of aerospace components. This involves utilizing calibrated measuring instruments and adherence to strict inspection protocols. For instance, a deviation of even a few micrometers in the dimensions of a turbine blade could render it unsuitable for installation, leading to engine performance degradation or potential failure.

- Material Identification and Traceability

Ensuring the correct identification of materials and maintaining complete traceability throughout the shipping and receiving process is paramount. Aerospace components are often manufactured from specialized alloys with specific properties. Misidentification can lead to the use of incorrect parts, compromising the structural integrity of the aircraft. A clear audit trail, from the point of origin to the final installation, is essential for accountability and regulatory compliance.

- Adherence to Handling Procedures

Strict adherence to specified handling procedures minimizes the risk of damage during transit and storage. Many aerospace components are sensitive to environmental factors such as temperature, humidity, and electrostatic discharge. Employing appropriate packaging materials, climate-controlled storage facilities, and anti-static measures is vital for preserving component integrity. For example, sensitive avionics equipment requires specialized packaging to protect against vibrations and electromagnetic interference.

- Documentation Accuracy

Precise documentation is essential for tracking components, ensuring regulatory compliance, and facilitating efficient inventory management. This includes maintaining accurate records of part numbers, serial numbers, lot numbers, and inspection results. Discrepancies in documentation can lead to delays in production, difficulty in tracing defects, and potential non-compliance with aviation safety regulations.

The facets of dimensional accuracy verification, material identification and traceability, adherence to handling procedures, and documentation accuracy underscore the inextricable link between precision and successful aerospace logistics. The meticulous application of these principles safeguards the integrity of components, ensures regulatory compliance, and ultimately contributes to the safe and efficient operation of aircraft.

2. Compliance

Adherence to stringent regulations is paramount in aerospace shipping and receiving. The industry’s unwavering commitment to safety mandates strict compliance with international, national, and organizational standards throughout the logistics chain. Failure to comply can result in severe consequences, including significant financial penalties, operational delays, and potential compromise of aircraft safety. For instance, non-compliance with ITAR regulations governing the export of sensitive defense articles could lead to hefty fines and legal repercussions. Thus, individuals involved in these logistics functions must demonstrate a comprehensive understanding of applicable regulations and implement robust procedures to ensure consistent adherence.

Consider the practical implications of compliance regarding hazardous materials handling. Aerospace components often contain or require the use of hazardous substances. Adherence to IATA regulations for the transport of dangerous goods is critical. Proper labeling, packaging, and documentation are essential to prevent accidents and ensure safe transportation. Furthermore, compliance extends to quality control processes. Thorough inspection and testing procedures, in accordance with AS9100 standards, are necessary to verify the integrity and conformity of parts. This ensures that only approved and certified components are integrated into aircraft, mitigating the risk of equipment failure.

In summary, the strong connection between regulatory compliance and the safe, efficient operation of aerospace shipping and receiving cannot be overstated. Challenges exist in staying abreast of evolving regulations and maintaining consistent adherence across global operations. However, prioritizing compliance through investment in training, robust quality management systems, and proactive risk assessment is essential for safeguarding the aerospace industry’s commitment to safety and reliability.

3. Documentation

Documentation forms the backbone of aerospace shipping and receiving operations. Without thorough and accurate records, the movement of parts, equipment, and materials becomes susceptible to errors, delays, and regulatory violations. The cause-and-effect relationship is direct: meticulous documentation leads to streamlined processes and adherence to compliance standards, while its absence invariably results in inefficiencies and increased risk. In essence, it functions as a crucial component ensuring accountability, traceability, and the overall integrity of the supply chain.

Consider the scenario of receiving a shipment of critical engine components. The receiving personnel are responsible for verifying that the received items match the purchase order, packing list, and accompanying certifications. This includes confirming part numbers, serial numbers, and quantities. Any discrepancies must be meticulously documented and reported immediately. This documentation then triggers a chain of actions, including initiating investigations, issuing discrepancy reports, and potentially rejecting the shipment if non-conforming. Similarly, in shipping operations, accurate documentation of outbound shipments, including bills of lading, export licenses, and customs declarations, is crucial for ensuring timely delivery and compliance with international trade regulations. The absence of correct documentation can cause shipments to be held at customs, leading to costly delays and potential fines. The maintenance of these records creates an auditable trail that satisfies regulatory oversight and quality control standards. For instance, airworthiness directives (ADs) often require that specific parts or modifications be documented and tracked throughout the aircraft’s lifecycle. Proper documentation ensures that these requirements are met and that the aircraft remains compliant.

In conclusion, the significance of documentation in aerospace shipping and receiving cannot be overstated. It is the foundational element upon which efficiency, compliance, and the secure movement of critical aerospace components depend. Challenges related to the volume and complexity of documentation exist, but the implementation of robust electronic record-keeping systems and standardized procedures can mitigate these challenges. Understanding and prioritizing documentation is essential for all individuals involved in aerospace logistics, ultimately contributing to the safety and reliability of air travel.

4. Coordination

Effective coordination is crucial for the smooth operation of aerospace shipping and receiving functions. The complexity of the aerospace supply chain, characterized by high-value components, strict regulatory requirements, and time-sensitive deliveries, necessitates a highly coordinated approach to logistics management. Failure to coordinate effectively can result in delays, increased costs, and potential compromise of aircraft safety.

- Supplier and Vendor Management

Coordination with suppliers and vendors is essential for ensuring the timely and accurate delivery of parts and materials. This involves establishing clear communication channels, managing purchase orders, and coordinating delivery schedules. For example, if a critical engine component is delayed by a supplier, the receiving team must coordinate with the production team to adjust production schedules and minimize disruptions.

- Internal Departmental Collaboration

Efficient collaboration between different internal departments, such as procurement, engineering, quality control, and production, is vital for seamless shipping and receiving operations. Engineering specifications must be clearly communicated to the receiving team to ensure accurate inspection of incoming materials. Similarly, the shipping team must coordinate with the sales department to ensure that customer orders are fulfilled in a timely manner.

- Freight and Carrier Management

Coordination with freight carriers and logistics providers is critical for the transportation of aerospace components. This includes selecting appropriate transportation methods, negotiating rates, and tracking shipments. For instance, transporting oversized aircraft components requires specialized equipment and permits. The shipping team must coordinate with the carrier to ensure that all necessary arrangements are in place to avoid delays or damage.

- Customs and Regulatory Compliance

Navigating customs regulations and ensuring compliance with export control laws requires careful coordination with customs brokers and regulatory agencies. Accurate documentation and timely submission of required information are essential for avoiding delays and penalties. Exporting sensitive aerospace technology requires close coordination with government agencies to obtain necessary licenses and permits.

These elements of supplier and vendor management, internal collaboration, freight coordination, and regulatory compliance highlight the critical role of coordination in aerospace shipping and receiving. By prioritizing effective communication, collaboration, and adherence to established procedures, organizations can optimize their logistics operations, reduce costs, and enhance customer satisfaction. Successfully navigating these complex processes ensures that essential components arrive safely and on schedule, maintaining the operational readiness of aircraft and supporting the broader aerospace industry.

5. Inspection

Inspection is an indispensable component of aerospace shipping and receiving operations, serving as a critical control point to ensure the quality and integrity of incoming and outgoing materials. The cause-and-effect relationship between rigorous inspection procedures and successful logistics is direct: thorough inspection minimizes the risk of defective parts entering the supply chain, thereby preventing costly production delays, potential equipment failures, and, most critically, compromised aircraft safety. The practical significance of this understanding cannot be overstated, as the aerospace industry operates under stringent safety regulations and zero-tolerance for errors. Examples include meticulous examination of incoming turbine blades for surface imperfections or dimensional deviations, verifying the authenticity and airworthiness certifications of avionics components, and assessing the integrity of packaging to prevent damage during transit.

The inspection process extends beyond mere visual assessment. It often involves the use of specialized equipment and techniques, such as non-destructive testing (NDT) methods, to detect hidden flaws or material inconsistencies. For instance, radiographic testing may be employed to inspect welds on structural components, while ultrasonic testing can identify subsurface cracks in metal parts. The inspection team also plays a vital role in ensuring that all necessary documentation, including certificates of conformity, material test reports, and export licenses, are present and accurate. Any discrepancies or anomalies detected during inspection trigger a series of corrective actions, including quarantining the non-conforming parts, initiating investigations to determine the root cause of the defect, and coordinating with suppliers to resolve the issue. This proactive approach to quality control is essential for maintaining the high standards demanded by the aerospace industry.

In summary, inspection forms a vital link in the aerospace shipping and receiving chain, safeguarding the quality and reliability of aircraft components. The challenges lie in maintaining consistency and accuracy across diverse product lines and global supply networks. However, by investing in skilled personnel, advanced inspection technologies, and robust quality management systems, the aerospace industry can ensure that inspection remains a cornerstone of its commitment to safety and operational excellence. This rigorous approach ultimately contributes to the continued safety and reliability of air travel.

6. Packaging

Packaging is an essential component within aerospace shipping and receiving. Its function extends beyond mere containment; it serves as a critical barrier against damage, contamination, and environmental factors that could compromise the integrity of sensitive aerospace components. The correlation between appropriate packaging and successful logistics operations is significant. Improper packaging directly increases the risk of damage during transit, leading to costly delays, potential rework, and, in critical cases, jeopardizing airworthiness. For instance, inadequate protection of a sensitive avionics unit against vibration or electrostatic discharge could render it inoperable, necessitating replacement and disrupting aircraft maintenance schedules. Thus, aerospace shipping and receiving personnel must possess a comprehensive understanding of packaging materials, techniques, and regulatory requirements to ensure the safe and secure transport of aerospace components.

Specific packaging requirements vary depending on the nature of the item being shipped. Large structural components require robust crating and specialized handling to prevent bending or distortion. Delicate instruments necessitate cushioning materials and shock-absorbing containers to mitigate the effects of impact. Furthermore, certain materials are subject to strict export controls and must be packaged in accordance with international regulations. The packaging process also involves meticulous documentation, including labeling with appropriate hazard warnings and handling instructions. These details are essential for enabling safe and efficient handling throughout the supply chain. Furthermore, the effective use of environmentally controlled packaging can safeguard components from corrosion or degradation due to temperature or humidity fluctuations, particularly during long-distance transport.

In conclusion, packaging is not merely a supplementary activity within aerospace shipping and receiving, but an integrated component that directly impacts the safety, efficiency, and regulatory compliance of these operations. Challenges may arise in keeping pace with evolving packaging technologies and adapting to the diverse requirements of different aerospace components. However, by prioritizing comprehensive training, adhering to established packaging standards, and utilizing appropriate packaging materials, the industry can effectively minimize the risk of damage and ensure the safe and secure delivery of critical aerospace components.

7. Traceability

Traceability forms a cornerstone of aerospace shipping and receiving operations. It establishes a verifiable record of a component’s history, location, and application, from its point of origin through the entire supply chain to its final installation and beyond. The connection between traceability and these positions is inextricable, with personnel directly responsible for maintaining and verifying this data at each stage of the logistics process. Without meticulous traceability, the ability to ensure regulatory compliance, manage inventory effectively, and respond to potential safety issues is significantly diminished. The cause-and-effect relationship is clear: comprehensive traceability enables accountability and proactive risk management, while its absence invites errors, delays, and potential safety hazards. For instance, the ability to quickly identify and trace a batch of potentially faulty fasteners used in aircraft construction is essential for initiating recalls and preventing accidents. Personnel involved in aerospace shipping and receiving are instrumental in ensuring that such traceability systems are maintained accurately and consistently.

The practical application of traceability involves a variety of processes and technologies. These may include the use of barcode scanners, RFID tags, and sophisticated database management systems to track components as they move through the supply chain. Aerospace shipping and receiving positions necessitate the accurate documentation of part numbers, serial numbers, batch numbers, and expiration dates. Furthermore, these personnel are responsible for verifying the authenticity and integrity of documentation accompanying incoming shipments, ensuring that all components meet required specifications. Traceability extends beyond the initial delivery of parts, encompassing the recording of maintenance activities, repairs, and modifications performed on aircraft. This information is critical for ensuring compliance with airworthiness directives and for managing the long-term maintenance requirements of aircraft fleets.

In summary, traceability is not merely a desirable attribute but an essential requirement for aerospace shipping and receiving operations. It is through the diligent efforts of logistics personnel that these systems are maintained and that the benefits of traceability are realized. The challenges include maintaining data accuracy across complex global supply chains and adapting to evolving regulatory requirements. However, by embracing advanced technologies and fostering a culture of accountability, the aerospace industry can continue to enhance its traceability capabilities and uphold its unwavering commitment to safety and reliability.

Frequently Asked Questions

The following provides answers to common inquiries regarding logistical roles within the aerospace sector. These responses aim to clarify requirements, responsibilities, and career prospects.

Question 1: What are the primary responsibilities associated with aerospace shipping and receiving?

Core responsibilities encompass the accurate and efficient handling of aerospace parts, components, and materials. This includes verifying incoming shipments against purchase orders, packaging outgoing shipments in accordance with industry standards, maintaining inventory records, and ensuring compliance with all applicable regulations.

Question 2: What skills are most valuable in the context of logistics positions within the aerospace field?

Valuable skills include attention to detail, strong organizational abilities, proficiency in inventory management systems, knowledge of shipping regulations (e.g., IATA, DOT), and the capacity to operate material handling equipment (e.g., forklifts, pallet jacks). Effective communication and problem-solving skills are also essential.

Question 3: Are there specific certifications or training programs that enhance career prospects?

Relevant certifications include Certified Supply Chain Professional (CSCP), Certified in Production and Inventory Management (CPIM), and Hazardous Materials (HAZMAT) certification. Completion of training programs focused on aerospace logistics, quality control, and regulatory compliance can also significantly improve job opportunities.

Question 4: What are some common challenges encountered in these functions?

Challenges include managing complex regulatory requirements, ensuring the safe handling of hazardous materials, coordinating with multiple stakeholders (e.g., suppliers, carriers, internal departments), and maintaining accurate inventory records in a fast-paced environment.

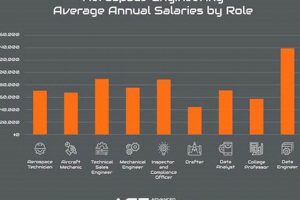

Question 5: What career advancement opportunities are typically available?

Career progression may involve advancing to supervisory or management roles within the shipping and receiving department, transitioning to other areas of logistics (e.g., procurement, supply chain management), or specializing in a particular area of expertise (e.g., export compliance, hazardous materials handling).

Question 6: What is the impact of technological advancements on roles in aerospace shipping and receiving?

Technological advancements, such as automated inventory management systems, real-time tracking technologies, and electronic documentation, are transforming these positions. Individuals with proficiency in these technologies are highly sought after, and continuous learning is essential to adapt to the evolving landscape.

In summary, these positions are integral to the functioning of the aerospace industry, requiring a unique blend of technical skills, attention to detail, and regulatory knowledge.

The next section will offer concluding thoughts on these functions’ vital importance.

Conclusion

This exploration has illuminated the critical functions associated with aerospace shipping and receiving, underscoring their direct impact on operational efficiency, regulatory compliance, and safety within the aerospace sector. Precision, documentation, coordination, and traceability are not merely procedural steps, but fundamental tenets that underpin the successful movement of high-value, mission-critical components. The information presented serves to highlight the multifaceted nature of these roles.

Given the aerospace industry’s unwavering commitment to safety and its increasingly complex global supply chains, the importance of well-trained, knowledgeable personnel in these positions cannot be overstated. Continued investment in training, technology, and process improvement will be essential to ensuring the continued success and integrity of aerospace logistics operations. The sector’s future depends, in part, on the dedication and expertise of those fulfilling these vital functions.