Individuals in this profession integrate knowledge from diverse engineering disciplines, such as aerodynamics, propulsion, structural analysis, and control systems, to develop and implement complex aerospace projects. Their responsibilities encompass the entire lifecycle of a project, from initial concept and design to testing, implementation, and ongoing maintenance. For example, these professionals may be involved in designing a new satellite communication system or optimizing the performance of a commercial aircraft.

The expertise provided by these professionals is crucial for ensuring the safety, efficiency, and performance of aerospace vehicles and related technologies. Historically, their role has been fundamental to advancing air and space travel, contributing to innovations such as improved fuel efficiency, enhanced flight control systems, and the development of spacecraft capable of exploring distant planets. The benefits of their work extend to national security, scientific discovery, and economic growth.

The following sections will delve into specific aspects of this engineering discipline, including the skills required, the typical projects undertaken, and the future trends shaping the field. Further discussion will also address the educational pathways for entering this career and the potential for specialization within this demanding yet rewarding profession.

Tips from an Aerospace Systems Engineer

The following advice stems from established practices within the profession, intended to guide individuals seeking to excel in the field. These tips focus on skill development, project management, and maintaining a commitment to excellence.

Tip 1: Emphasize Interdisciplinary Knowledge: Proficiency in multiple engineering disciplines is paramount. Projects often require a working knowledge of aerodynamics, propulsion, control systems, and materials science. Develop a broad understanding across these areas to facilitate effective collaboration and problem-solving.

Tip 2: Master Systems Engineering Principles: A thorough understanding of requirements management, system architecture, and verification/validation processes is essential. These principles ensure projects stay on track, meet specifications, and operate reliably.

Tip 3: Prioritize Effective Communication: Clearly communicate complex technical information to both technical and non-technical audiences. Hone written and verbal communication skills to ensure all stakeholders are informed and aligned throughout the project lifecycle.

Tip 4: Embrace Continuous Learning: The aerospace industry is constantly evolving. Stay abreast of the latest technological advancements, industry standards, and regulatory changes through continuing education, professional development, and engagement with professional organizations.

Tip 5: Develop Strong Analytical Skills: Critical thinking and problem-solving are vital. Cultivate the ability to analyze data, identify root causes, and develop innovative solutions to complex engineering challenges.

Tip 6: Focus on Risk Management: Proactively identify and mitigate potential risks throughout the project lifecycle. Implementing robust risk management strategies can prevent costly delays and ensure project success.

Tip 7: Strive for Precision and Accuracy: Attention to detail is crucial in aerospace engineering. Ensure all calculations, simulations, and designs are meticulously reviewed and validated to prevent errors and maintain the highest standards of quality and safety.

Following these guidelines can significantly enhance an engineer’s effectiveness and contribution to aerospace projects. These points highlight the importance of both technical expertise and professional skills.

The subsequent section will address the career paths available to those in this field, highlighting opportunities for specialization and advancement.

1. Integration

Integration stands as a core competency within the domain of aerospace systems engineering. It represents the process of combining disparate components and subsystems into a unified, functional whole. This process is paramount for the successful realization of complex aerospace systems, where numerous elements must operate synergistically to achieve desired outcomes.

- Hardware-Software Integration

This facet involves seamlessly merging physical components with their corresponding software control systems. An example includes integrating flight control surfaces (hardware) with the autopilot software that governs their movement. The implications for engineers involve deep understanding of both hardware characteristics and software algorithms to ensure precise control and responsiveness.

- System-of-Systems Integration

Certain aerospace projects involve the integration of multiple independent systems, forming a “system-of-systems.” Consider integrating a satellite communication network (one system) with ground-based command and control centers (another system). Challenges here relate to ensuring interoperability, data exchange, and coordinated operation between these distinct entities.

- Multi-Disciplinary Team Integration

Aerospace projects require collaborative efforts from diverse engineering disciplines, such as aerodynamics, structural engineering, propulsion, and electronics. Integrating the knowledge and expertise of these teams is essential for a holistic system design. Effective communication, clear roles, and a shared understanding of project goals are crucial for success.

- Data Integration and Analysis

Modern aerospace systems generate vast amounts of data from various sensors and monitoring systems. Integrating this data into a unified platform allows for comprehensive analysis and informed decision-making. This facet is particularly important for real-time system monitoring, anomaly detection, and performance optimization.

These facets of integration highlight the breadth and depth of the challenges faced by specialists in aerospace systems engineering. Effective integration is not merely about connecting components; it requires a comprehensive understanding of system architecture, interoperability standards, data management, and cross-disciplinary collaboration. Mastery of these areas is essential for delivering successful and reliable aerospace solutions.

2. Optimization

Optimization represents a cornerstone of aerospace systems engineering, profoundly influencing design, performance, and overall project success. The core objective involves refining systems and processes to achieve peak efficiency and effectiveness, considering diverse constraints and objectives. Specialists in this field actively engage in optimizing various aspects, ranging from aerodynamic profiles to fuel consumption and structural integrity. The effects of optimization are far-reaching, directly impacting operational costs, mission capabilities, and environmental footprint. For instance, the careful optimization of an aircraft’s wing design, conducted by such engineers, directly reduces drag, thereby lowering fuel consumption and increasing flight range. Without a focus on optimization, aerospace systems would operate suboptimally, leading to increased expenses, reduced performance, and potential safety compromises.

Practical applications of optimization are numerous and diverse. Algorithm development, often executed by a professional of the field, aims to minimize weight while maintaining structural strength. Trajectory planning algorithms optimize routes to minimize flight time and fuel expenditure, particularly vital for space missions. Thermal management systems are optimized to dissipate heat efficiently, ensuring the reliability of sensitive electronic components in extreme environments. These optimization tasks, carried out by engineers in the field, rely on sophisticated modeling, simulation, and computational techniques. These techniques facilitate an understanding of complex system interactions and enable the identification of optimal design parameters and operating conditions.

In summary, optimization serves as an indispensable element within the discipline of aerospace systems engineering. It is the continuous pursuit of improvement, driving advancements in system performance, efficiency, and reliability. While complex and demanding, the benefits of successful optimization are significant, yielding economic advantages, enhanced mission capabilities, and a reduced environmental impact. The ongoing pursuit of optimization presents challenges related to computational complexity, model accuracy, and the need for interdisciplinary collaboration. However, these challenges only underscore the importance of a skilled and dedicated engineering workforce.

3. Coordination

Effective coordination forms the bedrock of successful aerospace projects, directly influencing the timely and safe realization of complex systems. The diverse nature of such projects necessitates seamless collaboration among various engineering disciplines, manufacturing teams, and regulatory bodies. In the absence of proficient coordination, projects are prone to delays, cost overruns, and potential safety compromises. For example, designing a new commercial aircraft requires input and collaboration from aerodynamicists, structural engineers, avionics specialists, and manufacturing experts. A failure to coordinate effectively among these groups can lead to design conflicts, manufacturing inefficiencies, and certification delays. The effectiveness of a professional of this field is contingent on their ability to synchronize these diverse activities and manage interfaces.

These professionals often serve as central points of communication and integration, ensuring that all stakeholders are informed and aligned. Their responsibilities include facilitating meetings, managing documentation, tracking progress, and resolving conflicts. Real-world examples highlight the critical role of coordination. The development of the International Space Station (ISS) involved numerous international partners, each responsible for specific modules and systems. The success of the ISS hinged on the ability of engineers to coordinate the design, manufacturing, and integration of these components from different countries, ensuring compatibility and seamless operation. Similarly, the development of advanced missile defense systems requires coordination between radar developers, guidance system engineers, and weapons manufacturers, requiring such an engineer to be effective.

In summary, coordination constitutes a vital function within aerospace systems engineering. It transcends mere communication, encompassing active synchronization of diverse activities and the management of complex interfaces. While the challenges of coordination can be significant, particularly in large-scale, international projects, the benefits of effective collaboration are undeniable. These benefits include reduced risks, improved efficiency, and ultimately, the successful delivery of safe and reliable aerospace systems. Continued advancements in project management tools and communication technologies are likely to further enhance the ability of this profession to coordinate increasingly complex projects.

4. Verification

Verification, within the domain of aerospace systems engineering, is a critical process that ensures a system, subsystem, or component meets its specified requirements and design intent. This rigorous evaluation mitigates risks associated with deploying complex aerospace technologies and maintains the highest standards of safety and performance. The role of specialists is central to planning, executing, and interpreting verification activities.

- Requirements-Based Testing

This facet involves designing and executing tests directly derived from system requirements. For example, if a requirement specifies that an aircraft’s autopilot must maintain altitude within a certain tolerance, a flight test will be conducted to verify this performance. Professionals in this field develop test procedures, analyze results, and document findings to demonstrate compliance with each requirement.

- Model Verification and Validation (V&V)

Aerospace systems are often modeled and simulated extensively before physical prototypes are built. Model V&V ensures that these models accurately represent the real-world system and can be used for reliable predictions. Professionals employ statistical techniques, sensitivity analyses, and comparison with empirical data to assess model fidelity and identify potential discrepancies. This process is crucial for validating designs and optimizing performance before committing to hardware fabrication.

- Hardware-in-the-Loop (HIL) Simulation

HIL simulation involves integrating physical hardware components with simulated environments to test their performance under realistic conditions. For instance, an aircraft’s flight control computer might be connected to a flight simulator to evaluate its response to various flight scenarios. Professionals design HIL testbeds, develop simulation scenarios, and analyze hardware performance data to identify potential issues and ensure seamless integration.

- Independent Verification and Validation (IV&V)

IV&V involves having an independent team verify and validate a system, separate from the development team. This provides an unbiased assessment of system quality and reduces the risk of overlooking potential errors or vulnerabilities. Specialists in this role review requirements, design specifications, test plans, and test results, offering an objective perspective on system readiness and compliance.

The listed verification facets underscore the comprehensive and multifaceted nature of this critical aspect within aerospace systems engineering. Verification provides assurance that aerospace systems are reliable, safe, and effective. Professionals involved in this area must possess a deep understanding of engineering principles, testing methodologies, and regulatory requirements.

5. Innovation

Innovation serves as a core driver in the field of aerospace systems engineering, dictating the evolution of air and space travel, national security, and scientific exploration. It is the engine propelling advancements in aircraft design, propulsion systems, materials science, and control mechanisms, enabling the development of increasingly efficient, capable, and reliable aerospace vehicles. Those in this field are tasked with not only applying established engineering principles but also with conceiving and implementing novel solutions to complex challenges. The very nature of the aerospace environment, with its extreme conditions and stringent performance requirements, necessitates a constant pursuit of groundbreaking technologies and approaches. Therefore, the degree to which such engineers can drive innovation directly affects the progress and competitiveness of the aerospace industry.

Consider the development of composite materials in aircraft construction. Innovation in materials science has led to the creation of lightweight, high-strength composites that have revolutionized aircraft design, leading to fuel efficiency and improved performance. These advances have required engineers not only to understand the properties of these new materials but also to develop innovative manufacturing techniques and structural designs to maximize their benefits. Similarly, the development of advanced propulsion systems, such as scramjets and electric propulsion, relies on innovative engineering solutions to overcome fundamental limitations in existing technologies. The implementation of these innovative technologies requires a thorough understanding of system integration, risk assessment, and verification and validation procedures to ensure safety and reliability.

In summary, innovation is not merely a desirable trait but rather a critical component of professional competence in aerospace systems engineering. It drives advancements that benefit national security, scientific discovery, and economic growth. Ongoing challenges involve balancing the pursuit of novel solutions with the need for robust verification and validation, ensuring the safety and reliability of aerospace systems. A continued focus on fostering innovation through education, research, and collaboration is essential to maintaining the industry’s position at the forefront of technological advancement.

6. Management

Within the field of aerospace systems engineering, management encompasses a range of critical functions aimed at ensuring the successful execution of complex projects. Effective management practices are integral to coordinating diverse teams, controlling costs, mitigating risks, and delivering high-quality aerospace systems on schedule. An engineer in this field needs to balance technical proficiency with management acumen to contribute effectively to project outcomes.

- Project Planning and Scheduling

Involves defining project scope, establishing timelines, allocating resources, and creating detailed schedules. This facet requires engineers to estimate task durations, identify dependencies, and manage critical paths to ensure projects stay on track. For example, in the development of a new satellite, management principles are applied to coordinate the design, manufacturing, testing, and launch activities, ensuring that each phase is completed within budget and on time. Failure to plan effectively can lead to delays, cost overruns, and compromised performance.

- Resource Allocation and Budgeting

Focuses on distributing resources effectively across project activities and managing budgets to ensure financial viability. Engineers must track expenses, control costs, and make informed decisions about resource allocation to maximize efficiency. The development of a new aircraft engine requires careful budgeting and resource allocation to fund research, development, testing, and manufacturing. Effective cost management is critical to maintaining competitiveness and profitability.

- Team Leadership and Coordination

Encompasses motivating teams, fostering collaboration, and resolving conflicts. Engineers must effectively communicate project goals, delegate tasks, and provide guidance to team members. The integration of complex avionics systems requires close collaboration between software engineers, hardware engineers, and test engineers. Strong leadership and coordination are essential to ensuring seamless integration and optimal performance.

- Risk Management and Mitigation

Involves identifying potential risks, assessing their impact, and developing mitigation strategies to minimize their effects. Engineers must proactively identify risks related to technical challenges, schedule delays, and budget overruns, implementing contingency plans to address these issues. During the development of a new spacecraft, engineers must manage risks associated with launch failures, radiation exposure, and system malfunctions. Effective risk management is critical to ensuring mission success and crew safety.

Effective management practices are essential for the successful execution of aerospace systems engineering projects. They enable the effective allocation of resources, the coordination of diverse teams, and the mitigation of potential risks, ultimately contributing to the delivery of high-quality, reliable, and cost-effective aerospace systems.

7. Reliability

Reliability stands as a paramount concern within aerospace systems engineering. It directly affects safety, mission success, and operational costs. A comprehensive understanding of reliability principles and their application is essential for professionals in this field to design, develop, and maintain dependable aerospace systems.

- Fault Tolerance Design

Fault tolerance involves designing systems that can continue operating even in the presence of component failures. This can be achieved through redundancy, where critical components are duplicated, or through graceful degradation, where performance is reduced but the system remains functional. An example is the triple-redundant flight control system used in commercial aircraft, ensuring continued operation even if two of the three computers fail. Professionals incorporate fault tolerance principles into system architecture and component selection to enhance overall reliability.

- Reliability Modeling and Prediction

Reliability modeling uses mathematical techniques to predict the probability of system failure over time. These models consider factors such as component failure rates, operating conditions, and maintenance schedules. A common method is Failure Modes, Effects, and Criticality Analysis (FMECA), which identifies potential failure modes, their effects on the system, and their criticality. Professionals use reliability models to identify weak points in the system, optimize maintenance strategies, and make informed decisions about design trade-offs.

- Component Selection and Qualification

The choice of components plays a significant role in overall system reliability. Professionals must carefully select components that meet stringent performance and reliability requirements, considering factors such as operating temperature, vibration levels, and radiation exposure. Qualification testing is performed to verify that components meet specified performance criteria and can withstand harsh operating conditions. This rigorous selection and qualification process ensures that only high-quality, reliable components are used in aerospace systems.

- Maintenance and Support

Effective maintenance and support strategies are crucial for maintaining system reliability throughout its operational life. Maintenance schedules must be designed to prevent failures and extend system lifespan. Condition-based maintenance, where maintenance is performed based on the actual condition of the system rather than fixed intervals, can optimize maintenance efforts and reduce costs. Professionals develop maintenance procedures, train maintenance personnel, and manage spare parts inventory to ensure the continued reliability of aerospace systems.

These facets of reliability underscore the multi-faceted approach employed by professionals in aerospace systems engineering. The pursuit of reliability necessitates a commitment to rigorous design practices, thorough testing, and proactive maintenance. The ongoing development of new reliability techniques and technologies continues to drive advancements in aerospace safety and performance.

Frequently Asked Questions

The following questions address common inquiries regarding the profession, providing insights into its scope, responsibilities, and requirements.

Question 1: What are the primary responsibilities associated with this profession?

Responsibilities encompass the design, development, testing, and maintenance of aerospace systems, including aircraft, spacecraft, and related technologies. Individuals analyze system requirements, create system architectures, conduct simulations, and oversee integration and validation efforts. The ultimate goal is ensuring the safety, reliability, and performance of aerospace vehicles and associated infrastructure.

Question 2: What educational background is required to pursue a career in this field?

A bachelor’s degree in aerospace engineering, systems engineering, or a closely related field is generally required. Advanced degrees, such as a master’s or doctorate, may be necessary for specialized roles or research-oriented positions. Coursework typically includes topics such as aerodynamics, propulsion, structural analysis, control systems, and systems engineering principles.

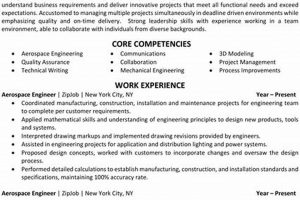

Question 3: What are the key skills necessary for success in this profession?

Essential skills include a strong understanding of engineering principles, analytical problem-solving abilities, proficiency in modeling and simulation tools, effective communication skills, and the ability to work collaboratively in multidisciplinary teams. Adaptability and a willingness to learn are also crucial, given the rapidly evolving nature of aerospace technology.

Question 4: What types of projects do professionals typically work on?

Projects vary widely depending on the employer and specific role. Examples include designing new aircraft, developing spacecraft propulsion systems, creating satellite communication networks, optimizing flight control algorithms, and integrating advanced sensor systems. Projects may involve both theoretical analysis and hands-on experimentation.

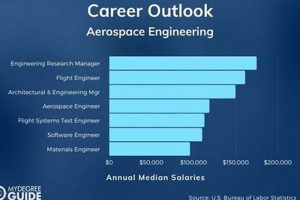

Question 5: What are the typical career paths and opportunities for advancement?

Career paths may lead to specialized engineering roles, project management positions, or leadership roles within aerospace organizations. Opportunities for advancement often depend on experience, education, and demonstrated technical expertise. Professionals may also pursue certifications or licenses to enhance their credentials.

Question 6: What are the major challenges and opportunities facing this field?

Challenges include managing increasing system complexity, addressing cybersecurity threats, reducing environmental impact, and adapting to evolving regulatory requirements. Opportunities lie in developing new technologies, such as hypersonic aircraft, autonomous systems, and advanced space exploration capabilities. The ongoing demand for skilled engineers ensures continued opportunities for innovation and growth.

These answers offer a foundational understanding of the role and demonstrate the importance of technical expertise and comprehensive skill sets within the aerospace industry.

The following sections will explore emerging trends and the future outlook for aerospace systems engineering.

Conclusion

The preceding discussion has presented a comprehensive overview of the role, responsibilities, and skill sets associated with being a qualified professional within this engineering specialty. Key aspects, including integration, optimization, coordination, verification, innovation, management, and reliability, have been explored to illustrate the multifaceted nature of this profession. A clear understanding of these core principles is crucial for anyone seeking to contribute to the advancement of aerospace technology.

The continuing demand for skilled personnel will shape the future of aerospace engineering. Professionals equipped with comprehensive expertise will be at the forefront of driving advancements in the aerospace industry. They play a vital role in addressing existing challenges, realizing innovative solutions, and ensuring that aerospace systems remain safe, effective, and sustainable.

![Top Aerospace Engineering Colleges in Europe [Rankings & Guide] Innovating the Future of Flight with Reliable Aviation Solutions Top Aerospace Engineering Colleges in Europe [Rankings & Guide] | Innovating the Future of Flight with Reliable Aviation Solutions](https://mixaerospace.com/wp-content/uploads/2026/02/th-247-300x200.jpg)