Aerospace engineering focuses on the design, development, and testing of aircraft, spacecraft, and related systems. This field requires a strong foundation in aerodynamics, propulsion, and materials science. Chemical engineering, conversely, deals with the design, operation, and optimization of chemical processes, transforming raw materials into valuable products. It necessitates expertise in thermodynamics, reaction kinetics, and transport phenomena. For example, an aerospace engineer might design a new wing for a commercial airliner, while a chemical engineer could develop a more efficient method for producing biofuels.

The importance of both these disciplines is undeniable. Aerospace advancements contribute significantly to transportation, communication, and exploration, pushing the boundaries of human achievement. Chemical engineering breakthroughs are crucial for addressing challenges in energy, medicine, and environmental sustainability, directly impacting the quality of life. Historically, aerospace engineering emerged from the early development of flight, evolving rapidly during the space race. Chemical engineering has its roots in industrial processes, continually adapting to address emerging needs and technological advancements.

The subsequent sections will delve into the core curriculum, career opportunities, and required skill sets associated with each of these distinct, yet vital, engineering branches. A detailed comparison will highlight the differences in daily tasks, potential work environments, and opportunities for professional growth, ultimately aiding prospective students in making informed decisions about their future career paths within engineering.

This section offers guidance to individuals considering a career path in either aerospace or chemical engineering. Understanding the nuances of each field is crucial for making an informed decision.

Tip 1: Evaluate Foundational Skills: Assess aptitude in mathematics and physics. Aerospace engineering heavily relies on advanced physics and calculus for aerodynamics and structural analysis. Chemical engineering requires a strong understanding of chemistry, thermodynamics, and differential equations for process design and optimization.

Tip 2: Explore Curricular Differences: Research typical coursework. Aerospace engineering involves subjects like flight mechanics, propulsion systems, and aerospace structures. Chemical engineering focuses on unit operations, chemical reaction engineering, and process control.

Tip 3: Consider Career Aspirations: Define long-term career goals. Aerospace engineers may work in aircraft design, spacecraft development, or research and development. Chemical engineers find opportunities in pharmaceuticals, energy, materials science, and environmental engineering.

Tip 4: Investigate Industry Trends: Stay informed about the evolving landscape of each field. Aerospace is currently experiencing growth in areas like unmanned aerial vehicles and space exploration. Chemical engineering is seeing advancements in sustainable technologies and bioprocessing.

Tip 5: Seek Shadowing or Internship Experiences: Gain practical exposure through internships or shadowing programs. This provides firsthand insight into the daily tasks and challenges within each profession, clarifying career interests.

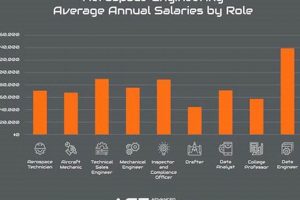

Tip 6: Analyze Salary Expectations: Research average salaries for both professions. While compensation varies based on experience and location, understanding potential earning capacity can inform financial planning.

Tip 7: Assess Personal Interests: Reflect on individual passions and interests. A genuine interest in flight, space, and aircraft may align with aerospace engineering. An inclination towards chemistry, materials, and process optimization may indicate a better fit for chemical engineering.

By carefully considering these factors, prospective engineering students can make well-informed decisions that align with their skills, interests, and career aspirations, maximizing their potential for success in either aerospace or chemical engineering.

The following sections will further elaborate on the distinctions between these two engineering disciplines, providing a more comprehensive understanding of their respective roles and contributions.

1. Design Complexity

Design complexity differentiates aerospace and chemical engineering in fundamental ways. In aerospace engineering, complexity arises from the need to integrate multiple systems propulsion, aerodynamics, structural integrity, and avionics into a single, functioning aircraft or spacecraft. Each component interacts with the others in often non-linear and unpredictable ways, requiring extensive modeling and simulation to ensure stability and performance. A prime example is the design of a modern jet engine; the precise shape and configuration of each turbine blade, the fuel injection system, and the control algorithms must be optimized to maximize thrust while minimizing fuel consumption and emissions. This intricate interplay demands expertise across diverse engineering disciplines.

Chemical engineering complexity stems from the control and optimization of chemical reactions and processes. The challenge lies in manipulating variables such as temperature, pressure, and catalyst concentration to achieve desired reaction rates and product yields while minimizing byproducts and waste. For instance, the design of a pharmaceutical manufacturing plant involves numerous reactors, separators, and purification units, each optimized for a specific step in the synthesis process. Furthermore, safety considerations are paramount, requiring rigorous adherence to regulations and the implementation of robust control systems to prevent accidents. Effective design in chemical engineering demands a thorough understanding of chemical kinetics, thermodynamics, and transport phenomena, combined with meticulous attention to safety and environmental impact.

In summary, while both fields grapple with complex designs, the nature of that complexity differs significantly. Aerospace engineering confronts the challenge of integrating diverse physical systems into a cohesive whole, while chemical engineering focuses on controlling and optimizing chemical reactions and processes within defined parameters. Understanding these differing types of design complexity is essential for students considering careers in either discipline, as it illuminates the specific skill sets and knowledge bases required for success.

2. Material Science

Material science serves as a critical foundation for both aerospace and chemical engineering, although the specific material requirements and applications vary substantially between the two disciplines. The properties of materials directly influence the performance, safety, and longevity of systems designed by engineers in both fields.

- Strength-to-Weight Ratio in Aerospace

Aerospace engineering prioritizes materials with high strength-to-weight ratios. Lightweight materials like aluminum alloys, titanium alloys, and composite materials reduce the overall weight of aircraft and spacecraft, leading to improved fuel efficiency and payload capacity. For instance, carbon fiber reinforced polymers are increasingly used in aircraft fuselages and wings due to their superior strength-to-weight characteristics compared to traditional aluminum.

- Corrosion Resistance in Chemical Processing

Chemical engineering places a premium on materials resistant to corrosion and chemical degradation. Equipment used in chemical processing plants, such as reactors, storage tanks, and pipelines, must withstand exposure to corrosive chemicals and extreme temperatures. Stainless steel, specialized polymers, and ceramic materials are commonly employed to prevent material failure and ensure the integrity of chemical processes. The selection of appropriate materials is crucial for maintaining safety and preventing environmental contamination.

- High-Temperature Performance in Aerospace Propulsion

Aerospace propulsion systems require materials that can withstand extremely high temperatures. Turbine blades in jet engines, for example, are exposed to temperatures exceeding the melting point of many metals. Nickel-based superalloys and ceramic matrix composites are used in these applications due to their exceptional high-temperature strength and creep resistance. Ongoing research aims to develop even more advanced materials that can withstand higher temperatures, enabling greater engine efficiency and thrust.

- Material Compatibility in Chemical Reactions

Chemical engineers must carefully consider the compatibility of materials with the chemical reactions they facilitate. Catalysts, for example, often rely on specific material properties to promote chemical transformations. The choice of reactor materials can also influence reaction kinetics and product selectivity. In some cases, the reactor material itself can act as a catalyst or participate in the reaction, requiring careful consideration of its chemical properties and stability.

In summary, material science is integral to both aerospace and chemical engineering, although the desired material properties and performance requirements differ significantly. Aerospace engineers focus on lightweight, high-strength materials for structural components and high-temperature materials for propulsion systems. Chemical engineers prioritize corrosion resistance, chemical compatibility, and thermal stability in materials used for chemical processing equipment. Selecting appropriate materials is crucial for ensuring the safety, efficiency, and reliability of systems designed by engineers in both disciplines.

3. Thermodynamic Principles

Thermodynamic principles are foundational to both aerospace and chemical engineering, though their application and relative importance differ significantly. These principles govern energy transfer and transformation, dictate the efficiency of systems, and inform the design of critical components within each field. The efficient utilization of energy and understanding its limitations are crucial to the success of projects in both disciplines.

- Energy Conversion Efficiency

Both disciplines utilize thermodynamic cycles for energy conversion. In aerospace, the Brayton cycle is central to gas turbine engines, dictating the efficiency with which fuel energy is converted into thrust. Maximizing the efficiency of this cycle is paramount for reducing fuel consumption and increasing flight range. In chemical engineering, the Rankine cycle is fundamental to power generation plants. The efficiency of this cycle determines how effectively thermal energy (often from chemical reactions) is converted into electricity. Chemical engineers also focus on minimizing energy losses in chemical processes, often through heat integration and optimization of reaction conditions.

- Phase Equilibrium and Material Properties

Understanding phase equilibrium is vital in both fields. Aerospace engineers must understand how materials behave under extreme temperature and pressure conditions, such as those encountered during atmospheric reentry. Accurate knowledge of phase diagrams and material properties is essential for selecting materials that can withstand these conditions. Chemical engineers rely on phase equilibrium data for designing separation processes, such as distillation and extraction. These processes separate mixtures based on differences in boiling points or solubility, and their efficiency depends on accurate knowledge of phase behavior.

- Combustion Thermodynamics

Combustion is a central process in both aerospace and chemical engineering. In aerospace, combustion provides the energy for propulsion systems. The efficiency and stability of combustion processes directly impact engine performance and emissions. Chemical engineers study combustion for various applications, including power generation, waste incineration, and chemical synthesis. Understanding the thermodynamics of combustion reactions is crucial for optimizing these processes and minimizing pollutants. Chemical engineers also investigate alternative fuels and combustion technologies to reduce reliance on fossil fuels and mitigate environmental impact.

- Heat Transfer Mechanisms

Heat transfer is a critical consideration in both aerospace and chemical engineering. Aerospace vehicles experience significant aerodynamic heating during flight, particularly at high speeds. Effective thermal management systems are essential for dissipating this heat and preventing damage to sensitive components. Chemical engineers design heat exchangers and other heat transfer equipment to control the temperature of chemical reactions and processes. Efficient heat transfer is crucial for maximizing reaction rates, improving product yields, and minimizing energy consumption.

In summary, while thermodynamic principles form a common foundation, their application differs significantly between aerospace and chemical engineering. Aerospace engineering emphasizes energy conversion for propulsion, material behavior under extreme conditions, and heat transfer management in flight. Chemical engineering focuses on optimizing chemical processes, designing separation techniques, and managing energy flow in chemical plants. Both fields require a deep understanding of thermodynamics, but the specific focus areas reflect the unique challenges and objectives of each discipline.

4. Fluid Dynamics

Fluid dynamics, the study of fluids (liquids and gases) in motion, holds paramount importance in both aerospace and chemical engineering, albeit with differing focal points and applications specific to each discipline. Its principles govern a vast array of phenomena, dictating performance, efficiency, and safety in various engineering endeavors.

- Aerodynamics in Aerospace Engineering

Aerodynamics, a branch of fluid dynamics, is foundational to aerospace engineering. It governs the motion of air around aircraft and spacecraft, directly impacting lift, drag, and stability. The design of airfoils, wings, and control surfaces relies heavily on aerodynamic principles, which dictate the forces generated by air flowing around these structures. Computational Fluid Dynamics (CFD) simulations are routinely employed to predict and optimize aerodynamic performance, ensuring efficient and stable flight characteristics. For example, the design of a high-speed jet aircraft necessitates careful consideration of shockwave formation and minimization of wave drag, achieved through advanced aerodynamic shaping.

- Transport Phenomena in Chemical Engineering

In chemical engineering, fluid dynamics manifests as transport phenomena, encompassing fluid flow, heat transfer, and mass transfer. These phenomena govern the movement of fluids within chemical reactors, pipelines, and separation equipment. Understanding fluid flow patterns is crucial for optimizing mixing, enhancing heat transfer rates, and promoting efficient mass transport between phases. For instance, the design of a chemical reactor often involves detailed CFD simulations to ensure uniform mixing of reactants and efficient heat removal, thereby maximizing product yield and minimizing byproduct formation. The flow characteristics of non-Newtonian fluids, common in the chemical industry, further complicate design considerations.

- Compressible Flow in Aerospace Propulsion

Compressible flow, the study of fluids undergoing significant density changes, is critical in aerospace propulsion systems. Supersonic and hypersonic flight regimes require a deep understanding of compressible flow phenomena, including shockwaves, expansion fans, and choked flow. The design of jet engine inlets and nozzles necessitates precise control over compressible flow to maximize thrust and minimize losses. Rocket propulsion systems also rely heavily on compressible flow principles, as the high-speed exhaust gases expand through nozzles to generate thrust. Advanced CFD techniques are employed to model and optimize compressible flow in these systems.

- Multiphase Flow in Chemical Processes

Chemical engineers frequently encounter multiphase flow, where two or more phases (e.g., liquid-gas, liquid-solid) coexist and interact. Examples include bubble columns, fluidized beds, and slurry transport. The behavior of multiphase flows is complex, influenced by factors such as interfacial tension, particle size distribution, and fluid properties. Understanding multiphase flow dynamics is crucial for designing efficient chemical reactors, separators, and transport systems. Specialized CFD models are used to simulate multiphase flows and optimize process performance. For example, the design of a fluidized bed reactor requires careful consideration of particle segregation, gas distribution, and heat transfer characteristics to ensure uniform reaction conditions and prevent channeling or slugging.

In conclusion, while both aerospace and chemical engineering rely heavily on the principles of fluid dynamics, the specific applications and challenges differ significantly. Aerospace engineering primarily focuses on aerodynamics and compressible flow to optimize aircraft and spacecraft performance. Chemical engineering emphasizes transport phenomena and multiphase flow to design efficient chemical processes. A strong understanding of fluid dynamics is essential for engineers in both disciplines to address the complex challenges inherent in their respective fields.

5. Process Optimization

Process optimization, the systematic methodology for improving the efficiency, reliability, and cost-effectiveness of engineered systems, is a critical component in both aerospace and chemical engineering, albeit with distinct applications and objectives. In aerospace engineering, this involves refining the design and manufacturing processes of aircraft and spacecraft to enhance performance metrics such as fuel efficiency, payload capacity, and operational lifespan. In chemical engineering, process optimization focuses on maximizing product yield, minimizing waste generation, and improving energy efficiency in chemical manufacturing facilities. The drive for process optimization in both fields is fueled by economic pressures, environmental concerns, and the need to meet increasingly stringent regulatory standards. A direct cause-and-effect relationship exists between optimized processes and enhanced competitiveness, reduced environmental footprint, and improved safety within these industries. For instance, advanced composite manufacturing techniques, incorporating optimized curing cycles and automated fiber placement, have significantly reduced the weight and cost of aircraft structures, directly translating into improved fuel economy for airlines.

The practical significance of understanding process optimization lies in the ability to develop more sustainable and economically viable solutions in both aerospace and chemical industries. For example, computational fluid dynamics (CFD) and finite element analysis (FEA) are routinely used to optimize the aerodynamic design of aircraft wings, reducing drag and improving lift. These simulations allow engineers to explore a vast design space and identify optimal configurations before committing to expensive wind tunnel testing. Similarly, in chemical engineering, process optimization techniques such as model predictive control (MPC) are employed to maintain process stability and maximize product yield in complex chemical reactors. MPC uses real-time data and sophisticated process models to adjust operating conditions dynamically, ensuring that the process operates at its optimal performance point despite disturbances and variations in feedstock quality. The development and implementation of such optimization strategies necessitate a strong understanding of both theoretical principles and practical constraints specific to each industry.

In summary, process optimization is an indispensable element within both aerospace and chemical engineering, driving innovation, efficiency, and sustainability. The challenges associated with process optimization include the complexity of real-world systems, the need for accurate process models, and the computational resources required for simulation and analysis. Despite these challenges, the potential benefits of process optimization including reduced costs, improved performance, and enhanced environmental protection make it a vital area of focus for both engineering disciplines. The increasing integration of data analytics and machine learning techniques into process optimization workflows promises to further enhance its effectiveness and expand its applicability across a wide range of engineering applications.

6. Regulatory Compliance

Regulatory compliance serves as a critical, non-negotiable aspect of both aerospace and chemical engineering, albeit with varying areas of emphasis and specific governing bodies. The consequences of non-compliance can range from financial penalties and reputational damage to catastrophic failures and loss of life. In aerospace, regulatory oversight is primarily concerned with aircraft safety, airworthiness standards, and emissions control. Agencies such as the Federal Aviation Administration (FAA) in the United States and the European Union Aviation Safety Agency (EASA) establish and enforce regulations governing aircraft design, manufacturing, maintenance, and operation. These regulations dictate stringent testing protocols, material specifications, and maintenance schedules, all aimed at ensuring the safety of passengers and crew. A notable example is the FAA’s oversight of Boeing’s 737 MAX aircraft following the accidents attributed to the Maneuvering Characteristics Augmentation System (MCAS), highlighting the potential consequences of non-compliance and the importance of rigorous regulatory scrutiny.

In chemical engineering, regulatory compliance centers on environmental protection, worker safety, and product safety. Agencies such as the Environmental Protection Agency (EPA) in the United States and the European Chemicals Agency (ECHA) enforce regulations concerning the handling, storage, and disposal of hazardous materials, as well as emissions to air and water. These regulations require chemical facilities to implement comprehensive risk management plans, monitor emissions, and adhere to strict safety protocols. An example is the EPA’s enforcement of the Clean Air Act, which limits the emission of volatile organic compounds (VOCs) from chemical plants. Failure to comply with these regulations can result in substantial fines and legal action. Furthermore, chemical engineers must also adhere to regulations concerning the safety and efficacy of chemical products, particularly in industries such as pharmaceuticals and food processing. Compliance with these regulations requires careful attention to detail, rigorous testing, and adherence to established standards, such as Good Manufacturing Practices (GMP).

In summary, regulatory compliance is a fundamental requirement for both aerospace and chemical engineering, although the specific areas of focus and governing bodies differ. In aerospace, the emphasis is on aircraft safety and airworthiness standards, while in chemical engineering, it is on environmental protection, worker safety, and product safety. Non-compliance can have severe consequences, ranging from financial penalties to catastrophic failures. Therefore, engineers in both disciplines must possess a thorough understanding of the applicable regulations and be committed to upholding the highest standards of safety and ethical conduct. The increasing complexity of regulations and the growing emphasis on sustainability require continuous learning and adaptation to ensure ongoing compliance and responsible engineering practices.

7. Sustainability Factors

Sustainability factors exert a significant influence on both aerospace and chemical engineering, though their specific manifestations and impacts differ considerably. The increasing global awareness of environmental concerns and resource limitations has placed heightened pressure on both industries to adopt more sustainable practices. For aerospace engineering, this translates to a focus on reducing fuel consumption, minimizing emissions, and developing more sustainable materials for aircraft construction. Chemical engineering, on the other hand, is increasingly concerned with developing cleaner production processes, utilizing renewable feedstocks, and minimizing waste generation. The implementation of sustainable practices in both fields requires innovative solutions and a holistic approach to engineering design, considering the entire life cycle of products and processes.

In aerospace, the development of more fuel-efficient aircraft designs directly reduces greenhouse gas emissions, contributing to a reduction in the industry’s carbon footprint. The use of lightweight composite materials, such as carbon fiber reinforced polymers, not only improves fuel efficiency but also reduces the overall material consumption in aircraft construction. Furthermore, research into alternative fuels, such as biofuels and hydrogen, holds the potential to significantly reduce the industry’s reliance on fossil fuels. Chemical engineering contributes to sustainability through the development of cleaner and more efficient chemical processes. For example, the use of catalytic reactors can reduce energy consumption and minimize waste generation in the production of various chemicals. The development of bio-based polymers and chemicals offers a sustainable alternative to traditional petroleum-based products, reducing reliance on fossil fuels and mitigating environmental impact. Green chemistry principles, which emphasize the design of chemical processes that minimize the use and generation of hazardous substances, are increasingly being integrated into chemical engineering practice.

The integration of sustainability factors into aerospace and chemical engineering requires a multidisciplinary approach, involving collaboration between engineers, scientists, and policymakers. Challenges remain in both fields, including the high cost of developing and implementing sustainable technologies, the need for robust performance metrics to assess sustainability, and the lack of clear regulatory frameworks to incentivize sustainable practices. Despite these challenges, the long-term benefits of sustainable engineering practices including reduced environmental impact, enhanced resource efficiency, and improved public health make it a critical priority for both aerospace and chemical engineering. The continued advancement of sustainable technologies and the widespread adoption of sustainable engineering principles are essential for ensuring a more sustainable future for both industries and society as a whole.

Frequently Asked Questions

The following questions address common inquiries regarding the distinctions and similarities between aerospace and chemical engineering. These aim to provide clarity for prospective students and professionals seeking to understand the nuances of each field.

Question 1: What are the primary differences in the core curriculum for aerospace and chemical engineering programs?

Aerospace engineering curricula typically emphasize aerodynamics, propulsion, structures, and control systems related to aircraft and spacecraft. Chemical engineering curricula focus on thermodynamics, transport phenomena, reaction engineering, and process design for chemical and biochemical systems.

Question 2: What are the typical career paths available to graduates of aerospace engineering versus chemical engineering programs?

Aerospace engineering graduates often find employment in the design, development, and testing of aircraft, spacecraft, and related systems. Chemical engineering graduates pursue careers in chemical manufacturing, pharmaceuticals, energy, environmental engineering, and materials science.

Question 3: Which of the two fields, aerospace or chemical engineering, generally requires a stronger background in physics?

Aerospace engineering typically requires a more extensive background in physics, particularly in areas such as fluid dynamics, mechanics, and electromagnetism, due to the nature of flight and space travel.

Question 4: Which field, aerospace or chemical engineering, is more heavily involved with computer modeling and simulation?

Both fields rely extensively on computer modeling and simulation. Aerospace engineering utilizes computational fluid dynamics (CFD) and finite element analysis (FEA) for aerodynamic design and structural analysis. Chemical engineering employs process simulation software for designing and optimizing chemical processes.

Question 5: How do the typical work environments differ for aerospace and chemical engineers?

Aerospace engineers may work in research laboratories, design offices, manufacturing plants, or test facilities related to aircraft and spacecraft. Chemical engineers often work in chemical plants, refineries, research laboratories, or consulting firms.

Question 6: Are there opportunities for interdisciplinary collaboration between aerospace and chemical engineers?

Yes, opportunities for collaboration exist, particularly in areas such as the development of advanced materials for aerospace applications, the design of life support systems for spacecraft, and the development of sustainable aviation fuels.

These answers offer a concise overview of key distinctions and connections between aerospace and chemical engineering. Further research and exploration are encouraged for a more comprehensive understanding of each discipline.

The following section will delve into specific examples of projects and technologies where both aerospace and chemical engineering principles converge, highlighting the potential for innovation and collaboration between these two fields.

Conclusion

This exploration of aerospace versus chemical engineering reveals two distinct yet equally vital engineering disciplines. Aerospace engineering concerns itself with the design and construction of flight vehicles, operating at the forefront of air and space travel. Chemical engineering, conversely, focuses on the transformation of matter and energy at the molecular level, impacting industries from pharmaceuticals to energy production.

The choice between these fields depends on individual aptitude, interests, and career aspirations. Continued advancement in both areas promises to address critical challenges, demanding skilled professionals prepared to innovate and contribute to future technological progress. Further investigation into specific specializations and research areas within each field is encouraged for informed decision-making.