Opportunities within the sector encompass a variety of roles related to the design, manufacturing, and maintenance of aircraft and related systems. These positions require diverse skill sets, ranging from engineering and technical expertise to project management and administrative capabilities, all contributing to the advancement of flight technology and its applications. A technician working on the guidance system of a missile or an engineer designing a new aircraft wing are examples of these roles.

The significance of these career paths lies in their contribution to national security, economic growth, and technological innovation. Historically, the industry has been a driver of research and development, leading to breakthroughs in materials science, aerodynamics, and computer science. The benefits extend beyond direct employment, fostering related industries and supporting regional economies through investment and infrastructure development.

The following sections will delve into specific facets of the aerospace industry, exploring current employment trends, required qualifications, and potential career trajectories for individuals seeking to contribute to this dynamic and ever-evolving field.

This section presents guidance for individuals pursuing opportunities in the sector. Attention to these points may enhance the prospects of securing and thriving in relevant positions.

Tip 1: Cultivate Foundational Knowledge: A robust understanding of aerospace principles, whether through formal education or specialized training, is paramount. Proficiency in mathematics, physics, and relevant engineering disciplines is often a prerequisite.

Tip 2: Develop Specialized Skills: The industry values specific expertise. Pursuing certifications or advanced training in areas such as avionics, aerodynamics, or composite materials can significantly increase employability.

Tip 3: Network Strategically: Engaging with industry professionals through conferences, online forums, and professional organizations can provide valuable insights and networking opportunities. Informational interviews can offer a firsthand perspective on various roles.

Tip 4: Tailor Application Materials: Resumes and cover letters should be meticulously tailored to highlight relevant skills and experiences for each specific position. Quantifiable achievements and demonstrable project experience are highly valued.

Tip 5: Prepare for Technical Assessments: Expect technical interviews and assessments that evaluate problem-solving abilities and subject matter expertise. Practicing common aerospace-related calculations and design principles can aid in preparedness.

Tip 6: Demonstrate Adaptability: The aerospace landscape is constantly evolving. A willingness to learn new technologies and adapt to changing industry trends is essential for long-term career success.

Tip 7: Prioritize Safety Awareness: A deep understanding of safety protocols and regulatory compliance is critical. The industry places a strong emphasis on maintaining safety standards in all aspects of design, manufacturing, and operations.

Adhering to these guidelines can improve the likelihood of securing a fulfilling and impactful career. Developing a combination of technical proficiency, strategic networking, and continuous learning is key to success in this field.

The following sections will offer insights into the future of the aerospace industry and the skills required to thrive in it.

1. Engineering

Engineering forms a cornerstone of the aerospace industry. These roles encompass a wide spectrum of activities, from conceptual design and development to testing, analysis, and refinement of aircraft, spacecraft, and related systems. The demand for skilled engineers is directly proportional to the industry’s growth, innovation, and operational needs. As a consequence, individuals with backgrounds in aerospace, mechanical, electrical, and computer engineering are heavily recruited for various roles. For example, aerospace engineers are crucial in designing aircraft that are more fuel-efficient, quieter, and safer. Without robust engineering practices, the feasibility and success of aerospace endeavors are severely compromised.

A practical application of engineering involves the design and implementation of advanced control systems for autonomous aircraft. These systems require expertise in control theory, robotics, and artificial intelligence. Engineers work on algorithms and sensors to enable aircraft to navigate without human intervention, improving safety and reducing pilot workload. The design and maintenance of propulsion systems also fall under engineering. Engineers are tasked with developing more efficient engines to reduce fuel consumption and emissions, adhering to stringent environmental regulations. These activities are vital for the competitiveness and sustainability of the aerospace sector. The safety and reliability of all components depend on meticulous engineering oversight.

In summary, engineering is not just a component of “arrowhead aerospace jobs,” it is the driving force behind innovation, safety, and performance. Securing and retaining qualified engineers presents a persistent challenge, requiring continuous investment in education, training, and research. Addressing this challenge is essential for maintaining global competitiveness and ensuring the continued advancement of aviation technology.

2. Manufacturing

Manufacturing constitutes a critical function within the aerospace industry. Roles in this sector are responsible for translating engineering designs into tangible products, demanding precision, adherence to strict quality standards, and efficient production processes. The availability of skilled manufacturing personnel directly impacts the industry’s capacity to meet global demand for aircraft and related systems.

- Precision Machining and Fabrication

This facet involves the use of computer-controlled machinery and specialized techniques to create components with exacting tolerances. For example, the fabrication of turbine blades for jet engines requires micron-level precision to ensure optimal performance and durability. Positions in precision machining demand a high degree of technical skill and attention to detail. Error in precision machining can lead to aircraft failure.

- Assembly and Integration

The assembly and integration phase brings together various manufactured components to create larger subsystems or complete aircraft. This process necessitates careful coordination, meticulous documentation, and adherence to established procedures. For example, the assembly of an aircraft wing requires the integration of hundreds of parts, each precisely positioned and secured according to engineering specifications. Proper assembly is crucial for the airworthiness of any aircraft.

- Quality Control and Assurance

Maintaining stringent quality control measures throughout the manufacturing process is essential to ensure the reliability and safety of aerospace products. Quality control personnel employ a variety of inspection techniques, including non-destructive testing, to identify and correct defects. A failure in quality control, such as a flaw in a critical structural component, can have catastrophic consequences.

- Supply Chain Management

Effective supply chain management is vital for ensuring the timely delivery of materials and components to support manufacturing operations. This involves coordinating with a network of suppliers, managing inventory levels, and optimizing logistics. Disruptions in the supply chain, such as delays in the delivery of critical parts, can significantly impact production schedules.

In summary, manufacturing functions are integral to realizing the potential of design concepts and are essential for converting them into functional and dependable systems. The success of “arrowhead aerospace jobs” reliant on manufacturing depends on the integration of advanced manufacturing technologies, rigorous quality control, and strategic supply chain management. Each step in the manufacturing process must adhere to the highest standards to guarantee safety and performance.

3. Maintenance

Maintenance operations are a vital, recurring aspect of the aerospace industry. “Arrowhead aerospace jobs” linked to maintenance guarantee operational safety, regulatory compliance, and the prolonged lifespan of aircraft and related systems. This field demands specialized skills, technical expertise, and adherence to rigorous protocols to ensure airworthiness and prevent catastrophic failures.

- Scheduled Inspections and Overhauls

Scheduled maintenance involves periodic inspections, repairs, and overhauls performed at predetermined intervals or flight hour milestones. These activities aim to identify and address potential issues before they escalate into critical failures. For example, a heavy maintenance check on a commercial aircraft includes a thorough inspection of structural components, engines, and avionics systems, replacing worn parts and performing necessary repairs. Aircraft maintenance ensures safety and the avoidance of costly unexpected repairs.

- Unscheduled Maintenance and Repairs

Unscheduled maintenance addresses unforeseen issues that arise during operations, such as component malfunctions, damage from foreign objects, or system failures. This requires rapid diagnosis, troubleshooting, and repair to minimize downtime and restore the aircraft to service. A real-world example includes replacing a faulty sensor in the engine control system to prevent engine failure during flight. Swift, accurate responses save airlines time and revenue.

- Component Repair and Overhaul

Component repair and overhaul activities focus on restoring individual components, such as engines, landing gear, and avionics units, to their original performance specifications. This involves disassembly, inspection, repair or replacement of worn parts, testing, and reassembly. The overhaul of a jet engine, which requires specialized tools and expertise, demonstrates the complex procedures in this aspect of maintenance. Component repair helps reduce costs and increase the use life of expensive aircraft parts.

- Line Maintenance and Servicing

Line maintenance encompasses routine checks, servicing, and minor repairs performed at airports between flights. This includes tasks such as refueling, fluid replenishment, tire pressure checks, and basic troubleshooting. A technician inspecting and servicing an aircraft before its next departure exemplifies line maintenance. Proper line maintenance contributes to safe and timely flights.

In conclusion, the effective execution of maintenance procedures is paramount for ensuring the continued safe and efficient operation of aircraft. “Arrowhead aerospace jobs” within the maintenance sector are indispensable for preserving the integrity of aerospace assets, upholding stringent regulatory standards, and mitigating the risks associated with air travel.

4. Technology

The aerospace industry is profoundly shaped by technological advancements. The evolution of materials science, propulsion systems, avionics, and digital technologies directly influences the nature and scope of career opportunities within the field. These advancements necessitate a workforce equipped with specialized skills and knowledge to design, develop, implement, and maintain increasingly complex systems. Furthermore, technological progress drives the demand for innovative solutions to enhance efficiency, safety, and environmental sustainability.

Consider the development and integration of advanced composite materials in aircraft manufacturing. This technological shift creates a demand for engineers and technicians skilled in composite design, fabrication, and repair. Similarly, the proliferation of autonomous flight systems requires expertise in artificial intelligence, robotics, and sensor technology. These examples illustrate how specific technologies directly impact the skillsets required for “arrowhead aerospace jobs” and the types of roles that emerge within the sector. Additionally, digital technologies such as additive manufacturing (3D printing) are transforming production processes, creating opportunities for specialists in design for additive manufacturing and related fields. Maintenance operations are also affected, with predictive maintenance strategies leveraging sensor data and machine learning to anticipate potential failures and optimize maintenance schedules, requiring expertise in data analytics and reliability engineering.

In conclusion, technology is not merely a contributing factor but an integral determinant of the trajectory of “arrowhead aerospace jobs”. The continuous influx of innovative technologies dictates the required skillsets, shapes the roles available, and drives the demand for specialized expertise within the aerospace industry. A comprehensive understanding of technological trends and their implications is crucial for individuals seeking to pursue or advance their careers in this dynamic field. Future success depends on adaptability, continuous learning, and a proactive engagement with emerging technologies.

5. Regulation

Adherence to regulatory standards is paramount in the aerospace industry, directly influencing the responsibilities, skills, and operational practices associated with many “arrowhead aerospace jobs”. These regulations ensure safety, security, and environmental compliance across all aspects of aircraft design, manufacturing, operation, and maintenance.

- Airworthiness Standards and Certification

National aviation authorities, such as the Federal Aviation Administration (FAA) in the United States and the European Aviation Safety Agency (EASA) in Europe, establish airworthiness standards that dictate the design, performance, and maintenance requirements for aircraft. Engineering positions are directly impacted, requiring compliance with these standards to obtain type certification for new aircraft designs. For example, engineers must demonstrate compliance with structural integrity requirements, engine performance standards, and avionics system reliability guidelines. Without adhering to these standards, aircraft cannot legally operate.

- Operational Regulations and Safety Management Systems

Operational regulations govern the conduct of air carriers and flight operations, encompassing pilot training requirements, maintenance procedures, and safety management systems (SMS). Airline pilots, maintenance personnel, and flight dispatchers must adhere to these regulations to ensure safe and efficient air travel. SMS programs require airlines to identify and mitigate potential safety hazards, impacting risk assessment and mitigation roles. Compliance failures can lead to operational restrictions or license revocation.

- Environmental Regulations and Emissions Standards

Environmental regulations aim to minimize the impact of aviation on air quality and noise pollution. These regulations, such as those established by the International Civil Aviation Organization (ICAO), set limits on aircraft engine emissions and noise levels. Engineers involved in engine design and aircraft aerodynamics must develop technologies that meet these stringent environmental standards. Penalties for non-compliance can include fines and operational limitations. Development of alternative fuels is an ongoing effort due to these regulations.

- Security Regulations and Compliance

Security regulations address threats to aviation safety, including those related to terrorism and cyberattacks. Compliance with these regulations requires the implementation of security measures at airports, on aircraft, and within air traffic control systems. Security personnel, aviation maintenance technicians, and cybersecurity specialists are involved in ensuring compliance with these regulations. Non-compliance can result in severe penalties and reputational damage.

In summary, regulatory compliance is not merely an external requirement but an integral aspect of “arrowhead aerospace jobs.” It shapes the responsibilities of various roles, influencing design decisions, operational procedures, and maintenance practices. A thorough understanding of and adherence to these regulations is essential for ensuring safety, security, and sustainability within the aerospace industry, contributing directly to its long-term viability and public trust.

6. Innovation

Innovation serves as a critical driver of advancement and competitiveness within the aerospace industry. Its influence permeates all facets of the sector, creating and reshaping “arrowhead aerospace jobs” and fundamentally altering the required skill sets for individuals seeking to contribute.

- Advanced Materials Development

The ongoing pursuit of lighter, stronger, and more durable materials is a central focus of aerospace innovation. The development and implementation of composite materials, nanomaterials, and advanced alloys necessitate specialized expertise in materials science, engineering, and manufacturing. For example, the design and fabrication of carbon fiber reinforced polymer (CFRP) components for aircraft structures require engineers and technicians with a thorough understanding of composite materials properties, manufacturing processes, and non-destructive testing techniques. These advancements not only improve aircraft performance but also create new roles focused on materials research, development, and quality control.

- Propulsion Systems Advancement

Innovation in propulsion systems is crucial for enhancing fuel efficiency, reducing emissions, and increasing aircraft performance. The development of advanced engine designs, such as geared turbofans and hybrid-electric propulsion systems, requires expertise in thermodynamics, fluid dynamics, and combustion engineering. For instance, the design and testing of a new jet engine incorporating advanced blade designs and high-pressure turbine technologies demand engineers with specialized knowledge of computational fluid dynamics (CFD) and experimental testing methodologies. These innovations drive demand for engineers capable of designing, analyzing, and testing advanced propulsion systems.

- Autonomous Systems and Artificial Intelligence

The integration of autonomous systems and artificial intelligence (AI) is transforming aircraft operations and creating new opportunities for “arrowhead aerospace jobs.” The development of autonomous flight control systems, predictive maintenance algorithms, and AI-powered air traffic management solutions requires expertise in robotics, machine learning, and software engineering. The development of autonomous flight control algorithms for unmanned aerial vehicles (UAVs) necessitates engineers and software developers with a deep understanding of control theory, sensor fusion, and artificial intelligence. These advancements generate roles in software development, algorithm design, and systems integration, as well as ethical considerations for AI implementation.

- Sustainable Aviation Technologies

Growing concerns about environmental sustainability are driving innovation in technologies aimed at reducing the carbon footprint of air travel. This includes the development of alternative fuels, electric propulsion systems, and more efficient aircraft designs. The development of sustainable aviation fuels (SAF) derived from biomass or other renewable sources requires expertise in chemistry, chemical engineering, and biofuel production. New aerospace jobs related to SAF are created by airlines, governments and private sectors.

In conclusion, innovation is the engine driving the evolution of “arrowhead aerospace jobs.” The continuous pursuit of new technologies and solutions necessitates a workforce equipped with specialized skills and a passion for pushing the boundaries of what is possible. To be part of a career in the industry, adaptability and continuous learning are essential.

Frequently Asked Questions

The following addresses common inquiries regarding opportunities within the field, providing concise responses to enhance understanding.

Question 1: What educational background is most advantageous for securing “arrowhead aerospace jobs?”

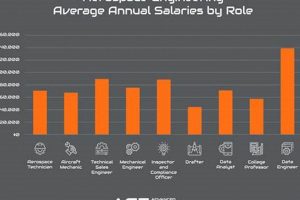

A strong foundation in engineering, particularly aerospace, mechanical, or electrical, is highly beneficial. Advanced degrees and specialized certifications can further enhance competitiveness.

Question 2: Are there specific skills that are consistently sought by employers in the aerospace sector?

Proficiency in CAD software, knowledge of aerospace materials, understanding of aerodynamics, and familiarity with industry regulations are highly valued.

Question 3: What are the primary challenges facing the aerospace industry in terms of workforce development?

Addressing the skills gap, attracting and retaining qualified talent, and keeping pace with rapidly evolving technologies are major challenges.

Question 4: How important is experience compared to formal education for “arrowhead aerospace jobs?”

While formal education provides a theoretical foundation, practical experience gained through internships, co-ops, or previous employment is highly valued by employers.

Question 5: What career paths are available within the aerospace industry for individuals with non-technical backgrounds?

Opportunities exist in areas such as project management, supply chain management, finance, and marketing, leveraging transferable skills and industry-specific knowledge.

Question 6: How can one stay current with the latest advancements and trends in the aerospace field?

Participation in professional organizations, attendance at industry conferences, and continuous learning through online courses and publications are essential for staying informed.

In essence, a combination of relevant education, specialized skills, and continuous learning is crucial for success in the aerospace domain.

The next section will provide resources for additional information on industry trends and career opportunities.

Arrowhead Aerospace Jobs

This exploration has traversed the diverse landscape of “arrowhead aerospace jobs,” examining essential components such as engineering, manufacturing, maintenance, technology, regulation, and innovation. The importance of specialized skills, continuous learning, and adaptation to technological advancements has been consistently emphasized as crucial for navigating a career in this dynamic sector. Opportunities exist across a wide spectrum of roles, demanding both technical expertise and transferable skills applicable to project management, supply chain logistics, and other support functions.

The future of this sector hinges on its ability to address workforce development challenges, foster innovation, and adhere to stringent regulatory standards. Individuals seeking to contribute to the aerospace industry must prioritize acquiring relevant education, cultivating specialized expertise, and remaining informed about the evolving technological landscape. The commitment to safety, efficiency, and sustainability will define the industry’s trajectory and its impact on the world.

![Find Top Aerospace Jobs in Phoenix, AZ - [Your Company Name] Innovating the Future of Flight with Reliable Aviation Solutions Find Top Aerospace Jobs in Phoenix, AZ - [Your Company Name] | Innovating the Future of Flight with Reliable Aviation Solutions](https://mixaerospace.com/wp-content/uploads/2026/01/th-729-300x200.jpg)