This role involves the design, development, and testing of aircraft and spacecraft components and systems at a major aerospace corporation. Individuals in this capacity apply engineering principles to create innovative solutions for flight vehicles, contributing to advancements in aviation and space exploration. For example, one may be involved in designing the wing structure of a new aircraft or developing propulsion systems for satellites.

The work of these professionals is critical to maintaining safety, efficiency, and technological leadership in the aerospace industry. Historically, their contributions have driven significant advancements in air travel, space travel, and national defense. The expertise they possess ensures that projects are completed within budget and adhere to regulatory standards, contributing to a company’s overall success and reputation.

The following sections will delve deeper into the specific responsibilities, required qualifications, skills needed, and career trajectories associated with this profession in the aerospace sector.

Guidance for Aspiring Professionals

The following recommendations are based on insights from professionals in the field and offer advice to those seeking a career focused on the design, development, and testing of aircraft and spacecraft systems within a large aerospace organization.

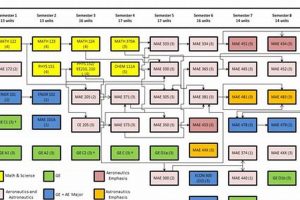

Tip 1: Emphasize a Strong Foundation in Core Engineering Principles: A thorough understanding of fundamental concepts such as aerodynamics, thermodynamics, materials science, and structural analysis is essential. Courses and independent study in these areas will provide a solid base for more specialized knowledge.

Tip 2: Pursue Relevant Internships: Practical experience is highly valued. Seek internship opportunities at aerospace companies to gain hands-on exposure to real-world engineering challenges and to develop valuable skills. Previous experience with computer-aided design (CAD) or finite element analysis (FEA) is a strong asset.

Tip 3: Develop Proficiency in Software Tools: Familiarity with industry-standard software such as CATIA, ANSYS, MATLAB, or similar programs is crucial. Mastering these tools will significantly enhance design and analysis capabilities.

Tip 4: Cultivate Strong Communication Skills: The ability to communicate technical information clearly and concisely, both verbally and in writing, is essential for effective collaboration within multidisciplinary teams. Practice presenting findings and writing reports effectively.

Tip 5: Focus on Continuous Learning: The aerospace field is constantly evolving. Staying abreast of the latest technological advancements and industry trends through professional development courses, conferences, and technical publications is vital.

Tip 6: Consider Advanced Education: A master’s degree or doctorate in aerospace engineering or a related field can significantly enhance career prospects, particularly for roles involving research and development.

Tip 7: Become Knowledgeable of Industry Regulations and Standards: A thorough understanding of aerospace regulations, standards, and safety protocols is crucial for ensuring compliance and mitigating risks in design and development processes.

These recommendations provide a framework for building a successful career in the aerospace sector. A commitment to excellence and a proactive approach to learning are key to achieving long-term success.

The subsequent sections will further explore the specific skills, educational background, and career path considerations essential for excelling in this domain.

1. Design Expertise

Design Expertise forms a cornerstone of the abilities expected of individuals functioning as aerospace engineers. It encompasses a broad spectrum of capabilities related to the creation, analysis, and refinement of aerospace systems and components.

- Conceptualization and Modeling

Aerospace engineers must possess the ability to translate abstract ideas into tangible designs using computer-aided design (CAD) software and other modeling tools. This includes generating detailed 3D models of aircraft structures, propulsion systems, and other critical components. Examples include the design of a new wing configuration for improved fuel efficiency or the development of a structural model for a spacecraft module. Accuracy and attention to detail are paramount in this phase.

- Performance Analysis and Optimization

The design process requires rigorous analysis to ensure that components and systems meet specified performance criteria. This involves using computational fluid dynamics (CFD) to analyze aerodynamic characteristics, finite element analysis (FEA) to assess structural integrity, and simulation tools to evaluate system performance under various operating conditions. Engineers optimize designs based on these analyses to maximize efficiency, reliability, and safety. An example might be using CFD to minimize drag on an aircraft fuselage or FEA to ensure a landing gear can withstand expected loads.

- Materials Selection and Integration

Choosing appropriate materials is critical to achieving desired performance characteristics while meeting weight, cost, and durability requirements. Aerospace engineers must be knowledgeable about the properties of various materials, including metals, composites, and polymers, and how they interact within a system. This involves selecting materials that can withstand extreme temperatures, pressures, and stresses, while also considering factors such as corrosion resistance and manufacturability. For example, engineers decide which specific Aluminum material alloy and what fabrication process should be used to create the primary structural components for the 777x airplane.

- Design Verification and Validation

Before a design can be implemented, it must undergo rigorous verification and validation to ensure that it meets all requirements and performs as intended. This involves conducting simulations, physical testing, and inspections to identify and resolve any design flaws or weaknesses. Verification confirms that the design conforms to specifications, while validation ensures that the design meets the intended operational needs. One example is the extensive wind tunnel testing required to validate the aerodynamic performance of a new aircraft wing design.

In the context of aerospace engineering, design expertise enables the creation of innovative and reliable aerospace systems. By effectively applying these abilities, engineers contribute directly to advancements in aviation, space exploration, and national defense. This ability guarantees safety and successful deployment in the complex aerospace industry.

2. System Optimization

System Optimization, within the scope of roles held by professionals in the aerospace sector, involves maximizing the efficiency, performance, and reliability of complex aerospace systems. This is crucial for aerospace companies striving to maintain competitive advantage and to adhere to stringent safety and operational requirements. Their ability to refine existing systems and innovate new solutions directly impacts the overall capabilities of the aerospace fleet.

- Aerodynamic Efficiency Enhancement

Aerodynamic Efficiency Enhancement is a pivotal aspect of system optimization, focusing on minimizing drag and maximizing lift to improve fuel consumption and aircraft performance. Examples include designing advanced winglets, optimizing fuselage shapes, and implementing active flow control systems. Reduced fuel consumption translates into lower operating costs and decreased environmental impact for airlines.

- Propulsion System Refinement

Propulsion System Refinement involves enhancing the efficiency and power output of aircraft engines while reducing emissions and noise. Examples include developing advanced turbine blade designs, optimizing combustion processes, and integrating electric or hybrid propulsion systems. Improved engine performance leads to increased range, payload capacity, and operational flexibility for aircraft.

- Structural Weight Reduction

Structural Weight Reduction focuses on minimizing the weight of aircraft structures without compromising strength or safety. This is achieved through the use of lightweight materials, optimized structural designs, and advanced manufacturing techniques. Examples include employing composite materials, topology optimization, and additive manufacturing. Reduced weight results in improved fuel efficiency and payload capacity.

- Operational Efficiency Improvement

Operational Efficiency Improvement encompasses optimizing flight routes, air traffic management systems, and maintenance schedules to minimize delays, fuel consumption, and operational costs. Examples include implementing data analytics to predict maintenance needs, optimizing flight paths using real-time weather data, and integrating automated air traffic control systems. Improved operational efficiency translates into reduced costs, improved on-time performance, and enhanced customer satisfaction.

The ability to perform effective system optimization is central to the success of those working as aerospace engineers. Their expertise in these areas drives continuous improvements in aerospace technology, enhancing safety, reducing costs, and minimizing environmental impact. Examples of this include Boeing’s continuous effort to redesign the 737’s wings, air frame and engines throughout it’s various revisions over the past decades and the efforts to achieve a similar effect in the 787 dreamliner. The ongoing demand for further optimization underscores the importance of this expertise in the evolving aerospace landscape.

3. Regulatory Compliance

Regulatory Compliance is integral to the responsibilities of engineers in the aviation sector. A thorough understanding of aviation regulations and standards is essential for ensuring the safety and airworthiness of aircraft designed and manufactured by Boeing. A lack of compliance can result in significant financial penalties, reputational damage, and, most critically, jeopardize passenger safety.

- Federal Aviation Administration (FAA) Regulations

Boeing engineers must adhere to the FAA’s regulations, which cover design, manufacturing, testing, and maintenance of aircraft. Compliance includes demonstrating that aircraft meet stringent safety standards related to structural integrity, engine performance, and avionics systems. For instance, any modification to an aircraft’s design requires FAA approval, necessitating comprehensive documentation and testing to prove compliance with relevant airworthiness directives. Failure to meet these requirements can lead to grounding of aircraft and costly redesign efforts.

- International Aviation Standards

Given the global nature of the aviation industry, engineers must also consider international aviation standards set by organizations such as the European Aviation Safety Agency (EASA). These standards ensure that Boeing aircraft can operate safely in different countries and regions. Compliance involves adapting designs to meet varying requirements for noise levels, emissions, and operational procedures. Overlooking these international standards can restrict an aircraft’s ability to fly in certain countries, reducing its marketability.

- Safety Management Systems (SMS)

Compliance extends beyond technical specifications to encompass safety management systems, which require engineers to actively identify and mitigate potential hazards throughout the aircraft’s lifecycle. This involves conducting risk assessments, implementing safety controls, and continuously monitoring system performance to prevent accidents and incidents. A robust SMS helps identify potential design flaws or operational hazards before they lead to catastrophic events. Boeing engineers must also take additional precautions following two fatal crashes of the 737 MAX, which prompted the FAA to investigate if the aerospace company properly accounted for human factors in the aircrafts design.

- Environmental Regulations

Engineers must adhere to environmental regulations aimed at reducing aircraft noise and emissions. This includes designing aircraft with quieter engines, optimizing fuel efficiency, and exploring alternative fuels to minimize the environmental impact of air travel. Compliance involves meeting increasingly stringent standards for carbon emissions and noise pollution, which may require significant investments in research and development. For example, Boeing has been actively investing in sustainable aviation fuels as a means to reduce carbon emissions.

These facets of regulatory compliance demonstrate the critical role Boeing aerospace engineers play in ensuring the safety, reliability, and environmental sustainability of aircraft. Adherence to FAA, EASA, and other international standards is not merely a matter of legal obligation but a fundamental aspect of responsible engineering practice. The ramifications of non-compliance can have severe consequences for both the company and the flying public.

4. Innovation Mindset

An Innovation Mindset is a crucial attribute for individuals employed as aerospace engineers at Boeing. The company operates in a highly competitive, technologically driven industry where continuous improvement and breakthrough innovations are essential for maintaining market leadership. The ability to conceive, develop, and implement novel solutions is directly linked to Boeing’s capacity to produce cutting-edge aircraft and aerospace systems. For example, the development of the 787 Dreamliner, with its composite materials and advanced systems, exemplifies how an innovation-focused approach can lead to significant advancements in fuel efficiency and passenger comfort. Engineers must challenge conventional thinking, explore new technologies, and take calculated risks to drive progress.

The integration of an Innovation Mindset manifests in several practical applications within Boeing. It fuels research and development efforts, leading to the creation of more efficient engines, lighter and stronger materials, and advanced avionics systems. It also fosters a culture of continuous improvement, where engineers are encouraged to identify and address areas for enhancement in existing products and processes. The application of additive manufacturing (3D printing) to produce complex components, the exploration of electric propulsion systems, and the development of autonomous flight technologies are all examples of how this mindset translates into tangible results. A proactive approach to embracing change and new ideas is critical for navigating the evolving landscape of the aerospace sector.

In summary, the connection between an Innovation Mindset and a Boeing aerospace engineer is both symbiotic and vital. The former is a catalyst for the latter’s effectiveness and a driver for the company’s success. Challenges exist in fostering and sustaining such a mindset, including overcoming resistance to change, managing risk, and allocating resources effectively. However, a commitment to cultivating this attribute is essential for maintaining Boeing’s position as a global leader in aerospace technology and ensuring its continued contribution to advancements in aviation and space exploration. Future progress in the sector hinges on embracing and nurturing this critical element.

5. Team Collaboration

Effective team collaboration is essential for individuals working as aerospace engineers at Boeing. The complexity of modern aircraft and spacecraft requires the integration of diverse expertise from various engineering disciplines. Mechanical, electrical, software, and materials engineers must collaborate to design, test, and manufacture these complex systems. A successful project requires seamless communication, coordinated problem-solving, and a shared understanding of project goals. For instance, the development of a new aircraft wing requires input from aerodynamicists, structural engineers, and manufacturing specialists, each contributing their unique knowledge to ensure the wing meets performance, safety, and manufacturability requirements.

Poor team collaboration can lead to design flaws, schedule delays, and increased costs. Miscommunication between engineering teams can result in incompatible components, integration problems, and system failures. Conversely, effective collaboration fosters innovation, accelerates problem-solving, and improves overall project quality. Regular meetings, shared documentation, and collaborative design tools facilitate communication and coordination among team members. The Boeing 787 Dreamliner project, for example, involved teams located in different countries, requiring a robust communication infrastructure and standardized processes to ensure effective collaboration. Early challenges in the program underscored the criticality of streamlined teamwork across geographically dispersed groups.

In conclusion, team collaboration is not merely a desirable attribute but an indispensable element for aerospace engineers working at Boeing. The scale and complexity of aerospace projects necessitate a high degree of coordination and communication among diverse teams. By fostering a collaborative environment, promoting open communication, and utilizing effective collaboration tools, engineers can enhance project outcomes, improve efficiency, and contribute to the overall success of the organization. Addressing the challenges associated with remote collaboration, cross-cultural communication, and knowledge sharing remains crucial for maximizing the benefits of teamwork in this demanding field.

Frequently Asked Questions

This section addresses common inquiries regarding the role, responsibilities, and career path of an aerospace engineer employed at Boeing.

Question 1: What specific disciplines within aerospace engineering are most commonly sought after at Boeing?

Boeing typically seeks engineers with expertise in aerodynamics, structural analysis, propulsion, systems engineering, and avionics. The demand for each discipline may fluctuate based on current projects and technological advancements.

Question 2: What is the typical career trajectory for an aerospace engineer at Boeing?

A common trajectory begins with entry-level positions involving design, analysis, or testing. With experience and demonstrated proficiency, engineers may advance to roles with increased responsibility, such as project management, technical leadership, or specialized research. Senior-level positions often involve strategic planning and technical oversight.

Question 3: How important is advanced education (Master’s or Ph.D.) for career advancement at Boeing?

While not always mandatory for entry-level positions, advanced degrees can significantly enhance career prospects, particularly for roles involving research and development or specialized technical expertise. Boeing values continuous learning and often provides opportunities for employees to pursue advanced education.

Question 4: What are the key technical skills that Boeing looks for in aerospace engineering candidates?

Key technical skills include proficiency in computer-aided design (CAD) software, finite element analysis (FEA) tools, computational fluid dynamics (CFD) software, and programming languages such as MATLAB or Python. Strong analytical and problem-solving abilities are also essential.

Question 5: What are the most significant challenges currently facing aerospace engineers at Boeing?

Significant challenges include developing sustainable aviation technologies, enhancing aircraft safety and reliability, managing complex engineering projects within budget and schedule constraints, and adapting to evolving regulatory requirements.

Question 6: What opportunities exist for aerospace engineers at Boeing to contribute to innovative projects?

Boeing offers opportunities to work on a wide range of innovative projects, including the development of next-generation aircraft, advanced propulsion systems, autonomous flight technologies, and space exploration initiatives. Engineers are encouraged to contribute ideas and participate in research and development efforts.

These questions and answers provide a general overview of key aspects relevant to the role of an aerospace engineer at Boeing. Further research and exploration may be beneficial for specific career interests.

The next section will provide resources for further learning and exploration.

Conclusion

This exploration has elucidated the multifaceted role of the Boeing aerospace engineer. It has detailed the requisite expertise in design, optimization, and regulatory adherence, along with the vital attributes of innovation and teamwork. The analysis has emphasized the criticality of these elements to maintaining safety, efficiency, and technological leadership within the aerospace sector. The complexity of the role necessitates a rigorous educational background, continuous professional development, and a commitment to upholding the highest standards of engineering practice.

The demands on this profession continue to evolve, driven by the need for sustainable aviation, enhanced safety measures, and groundbreaking technological advancements. Continued diligence and a proactive approach to emerging challenges are essential to ensure the future success of the organization and the advancement of aerospace engineering as a whole. Interested parties are encouraged to pursue further research and engagement to contribute to the progression of this pivotal field.