A manufacturing facility located in a Mexican city bordering Arizona, specializes in the production of aerospace components and systems. The site functions as a key element within a larger, global corporation focused on supplying technology and services to the aviation and defense industries. This specific operation contributes to the overall supply chain, providing crucial parts for aircraft manufacturing and maintenance. For example, it may produce wiring harnesses, electronic assemblies, or other essential components incorporated into commercial and military aircraft.

The presence of this operation in this location offers several advantages. It provides employment opportunities for the local community, contributing to regional economic growth. Furthermore, its location near the U.S. border facilitates efficient logistics and supply chain management. Historically, the area has attracted manufacturing investment due to a combination of factors including favorable labor costs, proximity to key markets, and established trade agreements. This allows for cost-effective production and streamlined delivery of products to customers in North America and beyond.

The discussion will now proceed to examine the specific manufacturing processes employed within such facilities, the types of products manufactured, and the role these operations play in the broader aerospace industry landscape. Considerations regarding labor practices, environmental regulations, and the impact on the local economy will also be explored.

The subsequent points provide insights applicable to understanding the operational realities and strategic considerations associated with aerospace manufacturing in a border region.

Tip 1: Compliance with Regulatory Standards: Strict adherence to international aerospace standards, such as AS9100, is paramount. Rigorous quality control processes and traceability measures are essential to ensure product integrity and regulatory compliance. For instance, meticulous documentation of every stage of the manufacturing process, from raw material sourcing to final inspection, is crucial.

Tip 2: Workforce Development and Training: Investing in continuous workforce development is vital. Implementing comprehensive training programs that focus on specialized skills, such as precision assembly, soldering, and quality assurance, enhances operational efficiency and reduces defects. An example would be sponsoring employees for certifications in relevant technical fields.

Tip 3: Supply Chain Optimization: Effective management of the supply chain is critical for minimizing lead times and reducing costs. Establishing strong relationships with reliable suppliers, implementing just-in-time inventory management, and utilizing advanced logistics solutions streamline the flow of materials. For example, employing vendor-managed inventory systems can ensure a consistent supply of critical components.

Tip 4: Cost Control and Efficiency: Continuous improvement initiatives focused on reducing waste and optimizing processes are necessary for maintaining competitiveness. Implementing lean manufacturing principles, such as value stream mapping and kaizen events, can identify and eliminate inefficiencies. Automating repetitive tasks can also significantly improve productivity and lower labor costs.

Tip 5: Understanding Trade Regulations and Compliance: Thorough knowledge of international trade regulations, including customs procedures and tariffs, is essential for smooth cross-border operations. Maintaining accurate documentation, complying with export control laws, and utilizing free trade agreements can minimize delays and reduce costs. For example, understanding the specific rules of origin requirements can optimize tariff benefits.

Tip 6: Leveraging Local Partnerships: Building strong relationships with local government agencies, educational institutions, and business organizations can provide valuable support and resources. Collaborating with local universities to develop customized training programs or partnering with government agencies to access funding opportunities can enhance operational capabilities.

Adherence to these guidelines promotes operational excellence, regulatory compliance, and sustainable growth within the aerospace manufacturing sector.

The discussion will now shift towards analyzing the future trends and challenges facing the aerospace manufacturing industry.

1. Manufacturing Facility

The existence of a manufacturing facility is fundamental to understanding the nature of operations. The phrase describes a physical location equipped for the production of goods, in this instance, aerospace components. The term’s connection to “collins aerospace nogales sonora” is direct; the latter designates a specific instance of a manufacturing facility operated by a particular corporation in a defined geographic location. This facilitys importance lies in its role as a node within a global supply chain. For example, consider the assembly of wiring harnesses: the facility provides the physical infrastructure and skilled labor necessary for their production, which are then integrated into aircraft manufactured elsewhere.

Further exploration of this connection reveals the facility’s contribution to regional economic development. The establishment of such a facility typically brings employment opportunities and generates revenue for local businesses through the supply of goods and services. The operational effectiveness of the manufacturing facility directly impacts the corporation’s ability to meet production targets and maintain its competitive edge. An inefficient facility, due to outdated equipment or poor management, can create bottlenecks in the supply chain and increase production costs. Conversely, a well-managed and technologically advanced facility enhances the corporations efficiency and responsiveness to market demands. For example, a facility equipped with advanced robotics might be able to produce components more quickly and with greater precision than a facility reliant on manual labor.

In conclusion, recognizing the importance of the manufacturing facility is critical for understanding the operation. Without the physical location and production capabilities it provides, the corporations ability to manufacture and deliver aerospace components would be significantly impaired. The challenges associated with managing a manufacturing facility, such as ensuring regulatory compliance, maintaining quality control, and optimizing production processes, are directly relevant to the overall success and sustainability of the organization. The existence of this facility links to the broader theme of globalization and the interconnectedness of the aerospace industry’s supply chains.

2. Aerospace Components

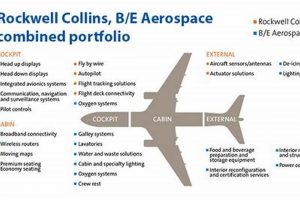

The term “Aerospace Components” refers to the individual parts and sub-assemblies that constitute an aircraft or spacecraft. In the context of “collins aerospace nogales sonora,” it designates the specific types of items manufactured at that facility. The relationship is direct and causal: the facility exists to produce these components. These items are essential building blocks for larger aerospace systems, their quality and reliability directly impacting the safety and performance of the finished product. For instance, wiring harnesses produced at the facility serve as the nervous system of an aircraft, transmitting signals between various electronic systems. Similarly, electronic control units manage critical functions such as engine performance or flight control. Without the reliable manufacture of these components, the broader aerospace industry could not function. The successful operation of Collins Aerospace in Nogales, Sonora, is predicated on the consistent and high-quality production of aerospace components, making it a crucial link in the supply chain.

Further analysis reveals the practical implications of this connection. The facility’s specialization in certain aerospace components allows for focused expertise and optimized production processes. This specialization may translate into cost efficiencies, improved product quality, and faster turnaround times. For example, if the facility specializes in avionics components, it can invest in specialized equipment and training to ensure that these components meet stringent industry standards. This also enables the efficient scaling of production to meet fluctuations in demand. Moreover, the location of the facility in Nogales, Sonora, may provide access to a skilled labor force and reduced manufacturing costs, further enhancing its competitiveness. For instance, the lower labor costs in Mexico compared to the United States can result in a cost advantage for the facility, allowing it to offer competitive pricing to its customers. The focus on aerospace components also allows the company to concentrate on meeting rigorous regulatory requirements unique to the aerospace industry.

In summary, the link between “Aerospace Components” and “collins aerospace nogales sonora” signifies the facility’s purpose and its role in the aerospace industry’s supply chain. Challenges associated with this connection include maintaining stringent quality control, adapting to evolving technological demands, and navigating complex international trade regulations. However, by focusing on the efficient and reliable production of aerospace components, the facility contributes to the advancement of the aerospace industry. Understanding this relationship is essential for stakeholders seeking to grasp the facility’s strategic importance and its impact on the global aerospace market.

3. Border Location

The term “Border Location,” in relation to “collins aerospace nogales sonora,” signifies the geographical positioning of the manufacturing facility in a Mexican city adjacent to the United States. This positioning is not arbitrary but a strategic decision with direct consequences for the facility’s operations and overall business model. The border location serves as a facilitator for efficient cross-border logistics, streamlining the movement of raw materials, components, and finished products between the manufacturing site and the broader North American supply chain. For example, components manufactured in Nogales can be transported to assembly plants in the United States with relative ease, minimizing transportation costs and reducing lead times. The importance of this border location is underscored by the fact that it directly influences the facility’s ability to compete in the global aerospace market. If the facility were located further inland, transportation costs and logistical complexities would increase, potentially negating the cost advantages associated with manufacturing in Mexico.

Further analysis reveals that the border location also impacts access to a skilled labor pool. Nogales, Sonora, benefits from a workforce that is familiar with manufacturing processes and often possesses technical skills relevant to the aerospace industry. The proximity to the United States also facilitates the transfer of knowledge and technology, allowing the facility to adopt best practices and maintain high standards of quality. This strategic advantage may also lead to the establishment of nearshoring operations, where companies relocate manufacturing processes closer to their primary markets to reduce risks associated with distant supply chains. The location also allows for easier access to U.S. based engineering talent for training and process oversight. As an example, U.S. engineers could visit the facility in Nogales to implement new manufacturing processes and train the local workforce with minimal disruption.

In summary, the border location is a critical determinant of “collins aerospace nogales sonora’s” operational effectiveness and competitive advantage. Challenges associated with this include navigating customs regulations, managing potential security risks, and mitigating political or economic instability. However, by leveraging the benefits of its border location, the facility can enhance its supply chain efficiency, access a skilled workforce, and maintain its position as a key player in the aerospace manufacturing sector. The existence of the facility reinforces the broader theme of international trade and the integration of global supply chains.

4. Economic Impact

The presence of a manufacturing operation significantly influences the economic landscape of its host community. In the context of “collins aerospace nogales sonora,” the facility’s economic influence encompasses direct and indirect effects on employment, local revenue generation, and regional development.

- Direct Employment and Wage Contribution

The most immediate effect is the creation of jobs within the facility. Manufacturing positions, ranging from assembly line workers to specialized engineers, provide direct employment opportunities for the local population. These jobs translate into wages, which then circulate within the local economy, supporting families and increasing consumer spending. For example, if the facility employs several hundred individuals, the aggregate wage contribution represents a substantial infusion of income into the community.

- Supply Chain Effects and Indirect Employment

Beyond direct employment, the operation generates indirect employment through its supply chain. Local businesses that supply raw materials, components, or services to the facility benefit from the company’s presence. This ripple effect creates additional jobs in related industries, expanding the economic benefits beyond the confines of the manufacturing plant. For example, transportation companies, packaging suppliers, and maintenance services experience increased demand due to the facility’s operations.

- Tax Revenue and Public Services

The facility’s operations contribute to local and state tax revenues. Property taxes, payroll taxes, and sales taxes generate funds that support public services such as schools, infrastructure, and healthcare. These revenues enhance the quality of life for residents and improve the overall business environment. For instance, increased tax revenue could be used to improve local roads, making it easier for goods to be transported to and from the facility, or to fund educational programs that train workers for jobs in the aerospace industry.

- Skills Development and Human Capital Formation

The facility’s presence often leads to the development of specialized skills within the local workforce. Training programs, apprenticeships, and partnerships with local educational institutions enhance the skills and knowledge of workers, making them more competitive in the labor market. This investment in human capital creates a more attractive environment for other businesses to invest in the region. For example, a local technical college might partner with the facility to offer courses in advanced manufacturing techniques, providing workers with the skills needed to operate sophisticated equipment.

These facets collectively underscore the multifaceted economic impact of “collins aerospace nogales sonora.” The operation not only generates jobs and income but also stimulates regional development by supporting local businesses, contributing to public services, and enhancing the skills of the local workforce. The sustained economic health of the facility is therefore intertwined with the overall prosperity of the community. Furthermore, it illustrates how the operation can be compared to other manufacturing facilities in border regions, offering insights into the economic dynamics of globalized supply chains.

5. Supply Chain

The efficient management of the supply chain is paramount to the operational success of any manufacturing enterprise. Regarding “collins aerospace nogales sonora,” the supply chain represents the interconnected network of resources, activities, and technologies involved in the creation and distribution of aerospace components. Its effectiveness directly influences production costs, lead times, and the ability to meet customer demand.

- Inbound Logistics and Raw Material Sourcing

This aspect encompasses the procurement of raw materials and components necessary for manufacturing. The efficient sourcing and transportation of these materials to the Nogales facility are critical. For example, the timely delivery of aluminum alloys or electronic components from global suppliers is essential to maintain continuous production. Disruptions in this stage can lead to delays and increased costs.

- Manufacturing Processes and Inventory Management

Within the facility, the supply chain involves managing the flow of materials through various manufacturing processes. Effective inventory management is crucial to minimize storage costs and prevent shortages. Implementing lean manufacturing principles can optimize production flow and reduce waste. For instance, a just-in-time inventory system ensures that materials arrive precisely when needed, minimizing storage requirements.

- Quality Control and Traceability

Maintaining stringent quality control standards throughout the supply chain is vital in the aerospace industry. Implementing robust traceability systems allows for tracking components from origin to final product, ensuring accountability and enabling rapid response to potential defects. For example, each component may be assigned a unique identifier that allows its production history to be traced throughout the supply chain.

- Outbound Logistics and Distribution

The final stage involves the distribution of finished aerospace components to customers, often located at different assembly plants or maintenance facilities. Efficient outbound logistics are necessary to meet delivery deadlines and minimize transportation costs. For example, strategic partnerships with transportation providers and the utilization of advanced logistics technologies can optimize delivery routes and ensure timely arrival of products.

These interconnected aspects of the supply chain are integral to “collins aerospace nogales sonoras” ability to operate effectively and competitively. The efficient management of each stage, from raw material sourcing to final distribution, is critical for meeting customer demands, maintaining quality standards, and controlling costs. Furthermore, these supply chain dynamics reinforce the facility’s role within the global aerospace manufacturing ecosystem.

Frequently Asked Questions

The following addresses common inquiries regarding the specific aerospace manufacturing operation in a Mexican border city.

Question 1: What types of aerospace components are manufactured at this location?

The facility specializes in the production of a range of components, potentially including wiring harnesses, electronic assemblies, and machined parts. The specific product portfolio may vary depending on customer demand and the facility’s capabilities.

Question 2: What certifications does the facility hold?

The manufacturing operation typically adheres to rigorous industry standards and holds certifications such as AS9100, an internationally recognized quality management system for the aerospace industry. Specific certifications may vary depending on the scope of operations.

Question 3: What is the facility’s contribution to the local economy?

The operation provides employment opportunities for the local community, generates tax revenue for local and state governments, and supports local businesses through its supply chain. The facility’s presence contributes to regional economic growth and development.

Question 4: How does the facility ensure product quality?

Stringent quality control measures are implemented throughout the manufacturing process, including rigorous testing, inspection, and traceability systems. The facility adheres to industry best practices to ensure the quality and reliability of its products.

Question 5: What is the facility’s environmental impact?

The operation strives to minimize its environmental footprint through responsible waste management practices, energy efficiency initiatives, and compliance with environmental regulations. The company may also implement sustainable manufacturing practices to reduce its impact on the environment.

Question 6: What is the supply chain structure for the components manufactured there?

The facility operates within a complex global supply chain, sourcing raw materials and components from various suppliers and distributing finished products to customers worldwide. Efficient supply chain management is critical for ensuring timely delivery and meeting customer demand.

These FAQs provide a concise overview of key aspects related to this manufacturing operation. It is essential to consult official company resources for the most up-to-date and detailed information.

The ensuing information will delve into the future prospects of aerospace manufacturing in border regions.

Concluding Remarks

The examination of Collins Aerospace Nogales Sonora reveals a nexus of manufacturing, strategic geography, and economic interplay. Its operation exemplifies the complex global supply chains characterizing the aerospace industry. Production activities, strategic border placement, economic contributions, and intricate supply chain dynamics collectively define the significance of this particular facility. These components must be analyzed cohesively to understand the organization’s function within the wider economic and industrial landscape.

Further inquiry into manufacturing processes, compliance standards, and workforce development within similar facilities remains essential. A deeper understanding of these elements will contribute to informed decision-making and strategic planning within the evolving aerospace manufacturing sector. Continued analysis is critical for navigating the challenges and opportunities presented by globalized production networks.