A significant operational hub for a major aerospace and defense technologies provider exists in the Phoenix metropolitan area. This facility contributes to the engineering, manufacturing, and support of diverse aviation and high-technology systems.

The presence of this center fosters regional economic development through job creation and technological innovation. Its location in Arizona offers strategic advantages relating to access to skilled labor, logistical infrastructure, and a favorable business climate. The history of aerospace activity in the region has contributed to a concentration of expertise within the local workforce.

The following sections will delve into specific operational capabilities, contributions to industry advancements, and its role within the broader organization.

Operational Insights

The following represent key considerations based on the operational model of a major aerospace technology provider’s Phoenix location, useful for understanding industry best practices.

Tip 1: Prioritize Comprehensive Employee Training: Investment in continuous employee training is essential. It ensures personnel are proficient in advanced manufacturing techniques, quality control procedures, and safety protocols relevant to aerospace component production.

Tip 2: Emphasize Supply Chain Resilience: Establish a robust and diversified supply chain to mitigate risks associated with material shortages or disruptions. This includes developing strong relationships with multiple suppliers and implementing inventory management strategies.

Tip 3: Promote a Culture of Innovation: Encourage employees to contribute ideas for process improvements, product development, and technological advancements. This can be fostered through dedicated innovation programs and recognition of employee contributions.

Tip 4: Implement Rigorous Quality Assurance Systems: Adherence to stringent quality assurance standards is paramount in aerospace manufacturing. Employ statistical process control, non-destructive testing, and other techniques to ensure product reliability and compliance with regulatory requirements.

Tip 5: Focus on Sustainable Manufacturing Practices: Implement initiatives to reduce waste, conserve energy, and minimize environmental impact. This includes exploring opportunities for material recycling, process optimization, and the use of renewable energy sources.

Tip 6: Leverage Strategic Partnerships: Collaborate with academic institutions, research organizations, and other industry partners to access specialized expertise, advanced technologies, and skilled talent. This can accelerate innovation and enhance competitiveness.

Tip 7: Optimize Facility Layout for Efficiency: Design and optimize facility layout to minimize material handling, reduce production cycle times, and improve overall operational efficiency. This includes implementing lean manufacturing principles and employing simulation tools to model process flows.

These insights emphasize the importance of a skilled workforce, a resilient supply chain, and a commitment to quality, innovation, and sustainability in the competitive aerospace industry. Implementing such strategies can foster operational excellence and ensure long-term success.

The subsequent section will cover ongoing challenges and future opportunities within the aerospace technology sector, considering factors such as evolving market demands, technological advancements, and regulatory changes.

1. Engineering Expertise

Engineering expertise is a foundational element of operations at the Phoenix location. It directly influences the development, testing, and refinement of aerospace systems and components. The presence of a highly skilled engineering workforce enables the site to contribute significantly to the broader company’s innovation pipeline. For instance, engineers at the facility are involved in designing advanced avionics, developing more efficient aircraft engine components, and improving the overall safety and performance of flight systems. This expertise also ensures compliance with stringent industry standards and regulatory requirements.

Furthermore, the engineering talent pool fosters a culture of continuous improvement. Processes are regularly evaluated and optimized to enhance efficiency, reduce costs, and improve product quality. Collaboration between engineers and other departments such as manufacturing and supply chain management, results in solutions that are both technically sound and practically feasible. For example, engineers work closely with manufacturing teams to identify potential bottlenecks in the production process and develop solutions that streamline operations. They also engage with supply chain partners to ensure the availability of high-quality materials and components.

In summary, engineering expertise at the Phoenix site drives innovation, enhances operational efficiency, and ensures product quality. This expertise is not only crucial for maintaining a competitive edge in the aerospace industry but also for contributing to the long-term growth and success of the organization and its role in local technological advancement.

2. Manufacturing Capabilities

The manufacturing capabilities located in Phoenix are critical to this organizations ability to fulfill its role as a major aerospace technology provider. The presence of advanced manufacturing operations directly enables the production of components and systems that meet stringent industry specifications. This ensures the delivery of high-quality products to commercial and government clients. Without robust manufacturing capabilities in place, the company’s ability to meet customer demand and maintain its position as a key industry player would be significantly undermined. For example, the Phoenix facility may specialize in producing advanced avionics or critical engine components, each requiring precise manufacturing processes and rigorous quality control.

The locations manufacturing expertise also fosters innovation. By integrating design, engineering, and manufacturing teams within the same geographic area, the company facilitates a streamlined process for translating conceptual designs into tangible products. This close collaboration allows for rapid prototyping, testing, and refinement, leading to faster innovation cycles and improved product performance. For example, feedback from the manufacturing floor informs design modifications, ensuring products are not only technologically advanced but also practical and efficient to manufacture. Further, the company may partner with local universities or research institutions to access cutting-edge manufacturing technologies and expertise.

The Phoenix manufacturing operations are a foundational element for the aerospace technology providers success. They enable the production of high-quality components, foster innovation through close collaboration, and contribute significantly to the regional economy through job creation and technological advancement. Addressing challenges such as maintaining a skilled workforce and adapting to rapidly evolving manufacturing technologies is crucial for sustaining this competitive advantage.

3. Regional Employment

The Phoenix location serves as a significant source of employment within the region’s economy. Its presence generates a range of job opportunities, spanning from engineering and manufacturing to administrative and support roles. The demand for skilled labor in these areas directly impacts the employment rate and economic stability of the surrounding communities. For example, the facility attracts a diverse workforce, including recent graduates from local universities, experienced engineers, and skilled technicians, all seeking opportunities within the aerospace sector. This concentration of employment contributes to the overall economic vitality of the Phoenix metropolitan area.

The organizations investment in workforce development and training programs further enhances the value of regional employment. These initiatives equip local residents with the necessary skills and knowledge to succeed in the aerospace industry. This creates a positive feedback loop, where a skilled workforce attracts additional investment and expansion, further amplifying the employment benefits. For instance, partnerships with local community colleges and vocational schools enable the facility to cultivate a pipeline of qualified candidates for various positions. Furthermore, the presence of these jobs incentivizes educational pursuits in STEM fields, contributing to the long-term development of a skilled workforce in the region.

In summary, the organization’s presence creates a ripple effect, stimulating economic growth, fostering workforce development, and enhancing the overall quality of life for residents in the area. Addressing challenges such as attracting and retaining talent in a competitive job market remains crucial for sustaining these benefits.

4. Technological Innovation

Technological innovation is a driving force behind operations at the Phoenix facility. It fuels the development of next-generation aerospace solutions, enhancing efficiency, safety, and performance. The facility leverages its location within a tech-rich environment to foster collaboration with universities, research institutions, and other technology companies. This collaborative ecosystem enables the site to remain at the forefront of aerospace advancements. As an example, the development of more fuel-efficient engine components or advanced avionics systems is a direct outcome of dedicated research and development efforts.

The integration of innovative technologies into manufacturing processes also demonstrates the facility’s commitment to technological advancement. Automation, robotics, and additive manufacturing techniques are deployed to optimize production efficiency and improve product quality. Such advancements have direct applications in the creation of complex aerospace components with increased precision and reduced lead times. Furthermore, digital technologies, such as data analytics and artificial intelligence, are increasingly employed to monitor and optimize manufacturing processes, leading to improved resource utilization and reduced waste.

In summary, technological innovation is integral to the operational strategy. It drives the development of cutting-edge aerospace technologies, enhances manufacturing efficiency, and ensures the organization remains competitive. Addressing challenges related to talent acquisition, research funding, and regulatory compliance is crucial for sustaining this innovation momentum and solidifying the facility’s position as a leader in the aerospace industry.

5. Supply Chain Integration

Supply chain integration is a critical determinant of operational efficacy at the Phoenix facility. Effective integration ensures the seamless flow of materials, components, and information across the supply network, from raw material suppliers to end-users. Disruptions in the supply chain, such as delays in component delivery or shortages of raw materials, directly impede production schedules and impact the ability to meet customer demand. The complexity of aerospace manufacturing, which often involves thousands of unique parts sourced from geographically dispersed suppliers, necessitates a well-managed and tightly integrated supply chain. A practical example includes a scenario where a shortage of a specialized alloy used in engine component manufacturing could halt production lines if alternative sourcing and inventory management strategies are not implemented.

The Phoenix location likely employs several strategies to enhance supply chain integration. These may include establishing long-term partnerships with key suppliers to foster collaboration and improve communication. Implementing advanced planning and forecasting tools enables the site to anticipate demand fluctuations and proactively manage inventory levels. Technology plays a crucial role, with the implementation of supply chain management software providing real-time visibility into inventory levels, order status, and supplier performance. Consider the instance of a critical avionics component where proactive monitoring and management by the location can ensure it is ready to be integrated in the aviation vehicles and systems.

In summary, supply chain integration is essential for maintaining operational efficiency, minimizing disruptions, and ensuring the timely delivery of high-quality aerospace products and services. Continuous improvement efforts, focused on optimizing supplier relationships, enhancing information flow, and leveraging technology, are essential for sustaining a competitive advantage. A primary challenge involves mitigating risks associated with global supply chain vulnerabilities, such as geopolitical instability or natural disasters, which can significantly impact the flow of materials and components.

6. Economic Impact

The economic ramifications of the aerospace presence in the Phoenix area are substantial, extending across various sectors and influencing regional prosperity. This presence acts as a catalyst for economic activity, contributing to job creation, technological advancement, and overall economic stability.

- Direct Employment and Wage Contributions

The facility directly employs a sizable workforce, encompassing engineers, technicians, manufacturing personnel, and administrative staff. The salaries and wages earned by these employees contribute significantly to the local economy through consumer spending, property taxes, and other forms of revenue generation. For instance, employee spending supports local businesses, restaurants, and retail establishments, fostering economic growth within the surrounding communities. Property taxes contribute to local government’s ability to invest in schools, public facilities, and infrastructure development.

- Indirect and Induced Economic Effects

Beyond direct employment, the location generates indirect economic effects through its supply chain relationships. The facility procures goods and services from numerous local suppliers, ranging from manufacturers of specialized components to providers of business services. This procurement activity supports additional employment and economic activity within these supplier firms. The induced effect stems from the increased household income resulting from direct and indirect employment, which further stimulates local spending and investment. The construction of new facilities and the expansion of existing operations create additional economic opportunities for construction companies and related industries.

- Tax Revenue Generation

The facility contributes significantly to local and state tax revenues through property taxes, corporate income taxes, and sales taxes generated by employee spending. These tax revenues provide critical funding for public services, such as education, infrastructure maintenance, and public safety initiatives. For instance, an increase in tax revenue allows local governments to invest in improving school facilities, upgrading transportation infrastructure, and providing additional resources for law enforcement. These investments enhance the quality of life for residents and contribute to the overall attractiveness of the region as a place to live and work.

- Attraction of Related Industries and Investment

The presence acts as a magnet for related industries and investment, creating a cluster of aerospace and technology companies within the Phoenix area. This concentration of expertise and resources fosters innovation, collaboration, and economic growth. The presence of other aerospace and technology companies attracts a skilled workforce and creates a vibrant ecosystem for entrepreneurship and investment. An example is how the success of this facility encouraged similar companies to expand their operations, thereby creating a dynamic, mutually supportive local economy.

The comprehensive economic impact underscores the strategic importance. It fuels local economic growth through job creation, supply chain relationships, tax revenue generation, and the attraction of related industries. Sustaining and expanding these economic benefits requires ongoing investment in infrastructure, workforce development, and innovation.

Frequently Asked Questions

The following questions address common inquiries regarding a major aerospace technology provider’s operations in the Phoenix, Arizona area. These responses aim to provide clarity and factual information regarding its activities and significance.

Question 1: What specific sectors does the Phoenix location support within the aerospace industry?

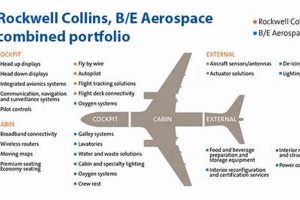

The Phoenix facility supports both commercial and defense aerospace sectors. Specific areas of focus may include avionics, cabin interiors, aircraft seating, and communication systems.

Question 2: How does the location contribute to technological innovation in aerospace?

The facility houses research and development teams that work on developing and improving aerospace technologies. Collaboration with local universities and research institutions often contributes to this innovation.

Question 3: What types of jobs are typically available at the Phoenix site?

Job opportunities typically span a range of disciplines including engineering (aerospace, mechanical, electrical), manufacturing, supply chain management, and administrative support.

Question 4: Does the Phoenix facility have any specific certifications or accreditations?

The site likely maintains industry-standard certifications relevant to aerospace manufacturing and quality management. These may include AS9100 or similar quality management systems.

Question 5: What is the scope of the economic impact the location has on the Phoenix metropolitan area?

The facility’s operations contribute to the local economy through direct employment, supply chain spending, and tax revenue generation. The presence of a major aerospace company often attracts related businesses and fosters technological development.

Question 6: How does this location contribute to sustainability efforts within the aerospace industry?

The facility may have initiatives focused on reducing waste, conserving energy, and using sustainable materials in manufacturing processes. These initiatives reflect the industry’s broader commitment to environmental responsibility.

These questions provide a general overview of the Phoenix location. For detailed information, consulting official company resources is recommended.

The subsequent section will explore the challenges and opportunities facing aerospace technology providers in the current market landscape.

Conclusion

This exploration has elucidated key facets of Collins Aerospace Phoenix Arizona. The site’s significance extends across engineering expertise, advanced manufacturing capabilities, regional employment contributions, technological innovation, supply chain integration, and profound economic impact. Each of these elements contributes to a substantial presence within the broader aerospace sector and regional economy.

Sustaining the operational efficacy and economic contributions of Collins Aerospace Phoenix Arizona requires ongoing strategic investment, adaptation to evolving technological landscapes, and a commitment to workforce development. Preserving its role as a vital center for aerospace technology and regional economic driver is paramount.

![Understanding Collins Aerospace Market Cap [Insights] Innovating the Future of Flight with Reliable Aviation Solutions Understanding Collins Aerospace Market Cap [Insights] | Innovating the Future of Flight with Reliable Aviation Solutions](https://mixaerospace.com/wp-content/uploads/2026/03/th-112-300x200.jpg)

![U.S. Hubs: Collins Aerospace US Locations Guide [2024] Innovating the Future of Flight with Reliable Aviation Solutions U.S. Hubs: Collins Aerospace US Locations Guide [2024] | Innovating the Future of Flight with Reliable Aviation Solutions](https://mixaerospace.com/wp-content/uploads/2026/03/th-97-300x200.jpg)