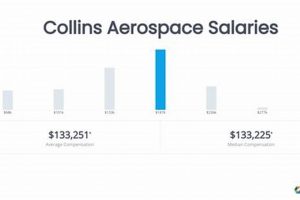

Compensation for professionals in quality engineering roles at Collins Aerospace, a major player in the aerospace and defense sectors, is a critical element of the overall employment package. This remuneration reflects the expertise, responsibilities, and contributions these individuals make to ensuring product and process conformance to stringent industry standards. As an example, such compensation packages often include base pay, benefits, and potential performance-based incentives.

Understandably, the value attached to this compensation is significant, both for the individuals accepting these positions and for the company attracting and retaining skilled talent. Historically, compensation in engineering fields, including quality assurance, has reflected the increasing complexity of aerospace technology and the growing demand for skilled professionals capable of navigating rigorous regulatory environments. Such compensation helps ensure product reliability, customer satisfaction, and adherence to critical safety standards.

This article delves into the various factors influencing the earnings of quality engineers at Collins Aerospace, exploring elements such as experience, education, location, and specific job responsibilities. Subsequent sections will also address industry benchmarks and potential career advancement opportunities that may impact earnings trajectory.

This section provides informed guidance for professionals seeking roles in quality engineering at Collins Aerospace, specifically concerning compensation negotiations and career progression.

Tip 1: Research Industry Benchmarks: Thoroughly investigate average compensation ranges for quality engineers with similar experience and qualifications within the aerospace sector. Websites like Salary.com, Glassdoor, and Payscale offer valuable data points.

Tip 2: Highlight Relevant Experience: Emphasize specific skills and experiences that directly align with Collins Aerospace’s quality standards and operational needs. Quantify accomplishments whenever possible, demonstrating a tangible impact on previous employers.

Tip 3: Understand the Geographic Cost of Living: Account for the cost of living in the specific location where the position is based. Compensation packages may vary to reflect regional differences in housing, transportation, and other expenses.

Tip 4: Consider the Total Compensation Package: Evaluate the comprehensive benefits package offered, including health insurance, retirement plans, paid time off, and professional development opportunities. These benefits can significantly impact the overall value of the compensation.

Tip 5: Negotiate Strategically: Be prepared to articulate a clear rationale for the desired compensation level, based on experience, skills, and market data. Approach negotiations professionally and respectfully, demonstrating a willingness to collaborate.

Tip 6: Invest in Continuous Learning: Pursue certifications, advanced degrees, or relevant training to enhance expertise and increase earning potential within the field of quality engineering. Examples include ASQ certifications such as Certified Quality Engineer (CQE).

Tip 7: Network with Industry Professionals: Engage with other quality engineers in the aerospace industry to gain insights into current compensation trends and career advancement opportunities. Networking can provide valuable information and support throughout a career.

By diligently researching, preparing, and negotiating, aspiring and current quality engineers at Collins Aerospace can effectively navigate compensation discussions and optimize their earning potential.

The following sections will explore the factors contributing to the determination of compensation and strategies for long-term career growth within the organization.

1. Experience Level

The level of experience held by a quality engineer directly correlates with the compensation offered at Collins Aerospace. This relationship reflects the increasing value an engineer brings to the organization with accumulated knowledge, proven skills, and demonstrated performance in the field. The progression through various experience tiers signifies enhanced competency and the ability to handle increasingly complex challenges.

- Entry-Level Positions

Entry-level quality engineers typically possess 0-3 years of relevant experience. Their roles often involve supporting senior engineers in conducting inspections, collecting data, and assisting with root cause analysis. Compensation at this level is generally lower, reflecting the need for further on-the-job training and supervision. Responsibilities might include documenting non-conformances and assisting in the implementation of corrective actions under guidance.

- Mid-Level Positions

Mid-level quality engineers usually have 3-7 years of experience and can independently manage quality projects, lead audits, and develop quality control procedures. Their increased expertise allows them to perform more complex analyses and contribute to process improvement initiatives. As a result, compensation at this level increases, reflecting their growing autonomy and contributions to the organization’s objectives. Examples include leading internal audits, developing statistical process control charts, and participating in supplier quality management activities.

- Senior-Level Positions

Senior-level quality engineers possess 7+ years of experience and demonstrate a deep understanding of quality management principles, aerospace regulations, and industry best practices. They often lead cross-functional teams, mentor junior engineers, and develop strategic quality plans. Their compensation reflects their extensive knowledge and ability to make significant contributions to the organization’s overall quality performance. Examples include developing and implementing quality management systems, leading failure investigations, and serving as subject matter experts on regulatory compliance.

- Management/Leadership Positions

Quality engineering managers and leaders have extensive experience and proven leadership abilities. They are responsible for overseeing quality engineering teams, developing and executing quality strategies, and ensuring compliance with all applicable regulations. Their compensation is commensurate with the scope of their responsibilities and their impact on the organization’s success. Examples include managing quality budgets, leading continuous improvement initiatives, and representing the organization in external audits and regulatory inspections.

In summary, advancement within a quality engineering career track at Collins Aerospace is significantly tied to accumulated experience. Each progressive level brings increased responsibility, specialized skills, and a corresponding rise in compensation, rewarding professionals for their dedication and contributions to maintaining high standards of quality and safety within the aerospace industry.

2. Educational Background

Educational attainment significantly influences compensation for quality engineers at Collins Aerospace. Formal education provides the theoretical foundation and specialized knowledge essential for effective performance in quality assurance roles, directly impacting the perceived value of an engineers skillset and, subsequently, their earning potential.

- Bachelor’s Degree in Engineering or Related Field

A bachelors degree in a relevant engineering discipline, such as aerospace, mechanical, or electrical engineering, is generally considered a baseline requirement for entry-level quality engineering positions. The curriculum provides a fundamental understanding of engineering principles, materials science, and statistical analysis all crucial for assessing and maintaining product quality. While it allows entry into the profession, it may limit long-term salary growth compared to candidates with advanced degrees. For instance, an engineer with a bachelor’s degree might focus on routine inspections and data collection initially, earning a competitive entry-level compensation, but progressing to more complex roles requiring greater analytical skills may necessitate further education.

- Master’s Degree in Quality Engineering or Related Field

A master’s degree specializing in quality engineering, or a related field such as systems engineering or industrial engineering, offers a deeper understanding of quality management systems, statistical process control, and advanced problem-solving methodologies. This advanced knowledge enables engineers to tackle more complex quality challenges and lead improvement initiatives. Individuals with a masters degree typically command higher salaries due to their enhanced analytical capabilities and ability to contribute to strategic decision-making. An example would be leading a team in implementing a new quality management system or conducting advanced statistical analysis to identify and address process inefficiencies.

- Specialized Certifications (e.g., CQE, Six Sigma Black Belt)

Industry certifications, such as Certified Quality Engineer (CQE) from the American Society for Quality (ASQ) or Six Sigma Black Belt certification, validate an engineer’s proficiency in specific quality tools and techniques. These certifications demonstrate a commitment to professional development and a mastery of industry best practices. Holding these certifications can positively impact compensation, as they signify a higher level of expertise and competence in quality management. For example, a CQE-certified engineer may be entrusted with leading critical root cause analysis investigations or developing comprehensive quality control plans, justifying a higher salary due to the added value they bring to the organization.

In summary, the level and type of education significantly affect the remuneration of quality engineers at Collins Aerospace. While a bachelor’s degree provides a foundation for entry-level roles, advanced degrees and specialized certifications can enhance an engineer’s capabilities, leading to greater responsibilities and higher earning potential. The investment in continuous learning and professional development is, therefore, a key factor in maximizing career advancement and compensation within the field of quality engineering.

3. Geographic Location

Geographic location significantly influences compensation levels for quality engineers at Collins Aerospace. The cost of living, regional demand for skilled professionals, and local economic conditions all contribute to variations in salary offerings across different locations. Understanding these factors is essential for candidates evaluating job opportunities and negotiating compensation packages.

- Cost of Living Adjustments

Salaries are often adjusted to reflect the cost of living in a specific geographic area. Locations with higher living expenses, such as major metropolitan areas or regions with limited housing availability, typically offer higher compensation to offset these costs. For example, a quality engineer based in Los Angeles, California, may receive a higher base salary compared to a counterpart in Cedar Rapids, Iowa, due to the significant difference in housing costs, transportation expenses, and general cost of goods and services. These adjustments aim to ensure that employees maintain a comparable standard of living regardless of location.

- Regional Demand for Expertise

The demand for skilled quality engineers can vary across different regions depending on the presence of aerospace manufacturing facilities, research and development centers, and regulatory agencies. Regions with a high concentration of aerospace companies often experience greater competition for qualified professionals, driving up salaries. For instance, a quality engineer with expertise in FAA regulations may be in high demand in areas near major airports or aerospace hubs, commanding a higher salary compared to regions with less aerospace activity. The interplay between demand and supply directly impacts the compensation packages offered by Collins Aerospace and its competitors.

- Local Economic Conditions

Local economic conditions, including unemployment rates, economic growth, and industry trends, can influence salary levels for quality engineers. Regions with strong economic growth and low unemployment rates tend to offer more competitive compensation to attract and retain skilled professionals. Conversely, areas experiencing economic downturns may see salary stagnation or even reductions. Monitoring local economic indicators provides valuable insights into the potential earning potential for quality engineers in a specific geographic area. Positive economic conditions typically translate to increased investment in quality assurance and a higher demand for qualified engineers.

- State and Local Taxes

The level of income tax in a certain location affects employees’ decision making and their salary negotiation. An engineer accepting offer may consider net income instead of the gross income, which vary from states to states. Quality Engineers may want to compare the income after tax from different states. This is a practical step in evaluating compensation levels.

In conclusion, geographic location is a critical determinant of compensation for quality engineers at Collins Aerospace. Cost of living, regional demand, local economic conditions and tax implications all contribute to variations in salary offerings. Professionals should carefully consider these factors when evaluating job opportunities and negotiating compensation packages to ensure fair and competitive remuneration relative to the specific location.

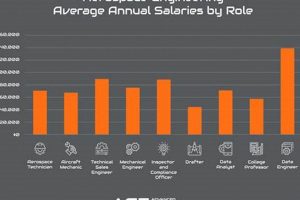

4. Specific Responsibilities

The precise duties assigned to a quality engineer within Collins Aerospace significantly influence the compensation offered. Job roles requiring higher levels of technical skill, greater decision-making authority, and broader project oversight typically command higher salaries. These responsibilities are a direct reflection of the value an engineer brings to the organization in ensuring product quality and regulatory compliance.

- Root Cause Analysis and Corrective Action (RCCA) Leadership

Leading root cause analysis investigations and implementing corrective actions for product defects or process failures requires advanced problem-solving skills and a deep understanding of engineering principles. Engineers responsible for RCCA leadership must effectively identify the underlying causes of non-conformances and develop sustainable solutions to prevent recurrence. This role often involves collaborating with cross-functional teams and presenting findings to senior management. Due to the critical nature of these responsibilities in maintaining product reliability and safety, quality engineers in RCCA leadership positions generally receive higher compensation compared to those in more routine roles.

- Supplier Quality Management

Managing the quality of components and materials sourced from external suppliers is essential for ensuring the overall quality of Collins Aerospace products. Engineers responsible for supplier quality management conduct supplier audits, evaluate supplier quality systems, and work collaboratively with suppliers to improve performance. These activities require strong communication, negotiation, and analytical skills. The complexity of managing a diverse supplier base and the direct impact on product quality warrant higher compensation for engineers in supplier quality management roles. For example, an engineer managing critical component suppliers for aircraft engines would command a higher salary than one focused on less critical commodities.

- Quality System Development and Implementation

Developing and implementing quality management systems (QMS) that comply with industry standards and regulatory requirements is a critical responsibility for senior quality engineers. This role involves designing quality policies, procedures, and processes that ensure consistent product quality and adherence to customer specifications. Engineers in this role must possess a comprehensive understanding of ISO 9001, AS9100, and other relevant standards. The strategic importance of QMS development and implementation in maintaining organizational compliance and driving continuous improvement justifies higher compensation for engineers with these responsibilities.

- Regulatory Compliance and Auditing

Ensuring compliance with aviation regulations (e.g., FAA, EASA) and conducting internal and external audits are critical responsibilities for quality engineers at Collins Aerospace. These activities require a thorough understanding of regulatory requirements, auditing principles, and quality management systems. Engineers responsible for regulatory compliance and auditing play a vital role in maintaining the organization’s reputation and avoiding costly penalties. The high level of accountability and specialized knowledge required for these responsibilities warrants higher compensation.

In summary, the specific responsibilities assigned to a quality engineer at Collins Aerospace are a primary determinant of their compensation. Roles involving complex problem-solving, supplier management, quality system development, and regulatory compliance generally command higher salaries due to the critical nature of these responsibilities in ensuring product quality, safety, and regulatory compliance. These roles contribute directly to mitigating risk, improving efficiency, and ensuring customer satisfaction.

5. Industry Certifications

The attainment of industry certifications directly influences the compensation packages offered to quality engineers at Collins Aerospace. These certifications, recognized benchmarks of professional competence, demonstrate a commitment to continuous learning and adherence to industry best practices. Possession of a relevant certification signifies to Collins Aerospace that a candidate or employee possesses a validated skillset applicable to quality assurance, risk management, and process improvement. For instance, a Certified Quality Engineer (CQE) designation from the American Society for Quality (ASQ) assures employers of an engineers understanding of quality principles, statistical methods, and auditing techniques. This, in turn, translates to a higher earning potential.

The correlation between certifications and compensation arises from the practical benefits these credentials offer to the organization. Certified engineers are often better equipped to lead complex projects, implement effective quality control measures, and ensure compliance with stringent aerospace regulations. Consider an example where a Six Sigma Black Belt certified engineer identifies and eliminates a critical process bottleneck, resulting in significant cost savings and improved product throughput. Such tangible contributions justify higher compensation, reflecting the quantifiable value the certified engineer brings to the company. Specific certifications demonstrate specialized knowledge relevant to Collins Aerospace’s operations, further enhancing their value. AS9100 Lead Auditor certification demonstrates expertise in aerospace quality management systems, making individuals more desirable and therefore able to command higher salaries.

In summary, industry certifications serve as a credible indicator of a quality engineer’s capabilities, directly impacting compensation levels at Collins Aerospace. These credentials validate expertise, demonstrate commitment to professional development, and equip engineers with the skills necessary to drive measurable improvements in quality and efficiency. Therefore, investment in relevant certifications is a strategic approach for quality engineers seeking to enhance their earning potential and advance their careers within the aerospace industry.

6. Performance Metrics

Performance metrics, meticulously tracked and evaluated within Collins Aerospace, constitute a pivotal component in determining the compensation structure for quality engineers. These metrics serve as quantifiable indicators of an engineer’s contribution to the organization’s quality objectives, influencing salary adjustments, bonuses, and career advancement opportunities. The objective assessment provided by these metrics ensures a transparent and equitable linkage between performance and remuneration.

- Defect Reduction Rate

The defect reduction rate directly reflects an engineer’s ability to identify and mitigate quality issues within manufacturing processes. A higher defect reduction rate signifies effective problem-solving skills and a proactive approach to quality improvement. For example, if a quality engineer implements a new process control system that reduces defects by 20% within a specific product line, this achievement would be recognized and rewarded through performance-based compensation. This metric highlights the engineer’s tangible impact on product quality and operational efficiency.

- Audit Findings and Resolution

The number and severity of audit findings, along with the timeliness and effectiveness of their resolution, are critical performance indicators. A quality engineer responsible for maintaining compliance with industry standards and internal quality procedures will be evaluated based on the results of internal and external audits. Fewer audit findings and prompt resolution of identified issues demonstrate a commitment to quality assurance and adherence to regulatory requirements. Consistently strong performance in this area translates to higher compensation and increased opportunities for advancement.

- Process Improvement Implementation

Successful implementation of process improvement initiatives that enhance efficiency, reduce costs, and improve product quality is a key performance metric for quality engineers. Engineers who identify opportunities for process optimization and effectively implement changes that yield measurable results are highly valued. For instance, if a quality engineer streamlines a manufacturing process, reducing cycle time by 15% and saving the company $50,000 annually, this accomplishment would be factored into their performance evaluation and reflected in their compensation.

- Customer Satisfaction Scores

Customer satisfaction scores, while not solely attributable to the efforts of quality engineers, reflect the overall effectiveness of the quality management system. Quality engineers contribute to customer satisfaction by ensuring that products meet customer requirements and expectations. A significant improvement in customer satisfaction scores, resulting from enhanced product quality and reliability, can positively impact the performance evaluations of quality engineers involved in the production process. This metric underscores the link between quality assurance and customer loyalty, demonstrating the importance of quality engineers in maintaining customer relationships.

In summary, performance metrics serve as objective measures of a quality engineer’s contribution to Collins Aerospace, directly influencing their compensation and career trajectory. Defect reduction, audit performance, process improvement, and customer satisfaction scores provide a comprehensive assessment of an engineer’s effectiveness in maintaining and enhancing product quality, ultimately impacting the organization’s overall success. These metrics ensure that high-performing engineers are appropriately recognized and rewarded for their contributions.

7. Company Performance

The fiscal health and overall performance of Collins Aerospace exert a direct influence on the compensation packages offered to its quality engineers. Strong company performance, characterized by increased revenue, profitability, and market share, typically translates into enhanced financial resources available for employee compensation. This can manifest as higher base salaries, more generous bonus structures, and expanded benefits programs. The rationale is that successful company performance is, in part, attributable to the diligence and expertise of its engineering workforce, including quality engineers, thus warranting commensurate rewards. For instance, if Collins Aerospace secures a major contract due to its reputation for superior product quality, the quality engineers responsible for maintaining those high standards may receive performance-based bonuses as a direct result.

Conversely, periods of economic downturn or reduced company profitability can lead to constraints on employee compensation. While base salaries may remain relatively stable, bonus opportunities may be reduced or eliminated, and cost-saving measures may impact benefits programs. An example would be a scenario where a significant decrease in air travel negatively impacts aircraft component sales, leading to reduced profitability for Collins Aerospace. In such a situation, performance bonuses for quality engineers might be scaled back or frozen altogether. Company performance directly impacts job security and the potential for salary growth within the organization. Continuous success helps ensure stability, creating a favourable environment for professional advancement and increased compensation.

In summary, company performance acts as a crucial determinant of compensation for quality engineers at Collins Aerospace. While individual performance and skills remain vital considerations, the overall financial health of the company dictates the resources available for employee remuneration. Monitoring company performance indicators, such as revenue growth, profitability, and market share, offers quality engineers valuable insights into their potential earning trajectory. A sound, thriving organization will allow the company to invest in its human capital, supporting and rewarding employees for their integral contributions to ongoing business success.

Frequently Asked Questions

This section addresses common inquiries regarding compensation for quality engineers at Collins Aerospace, providing insights into the elements that influence salary determinations.

Question 1: What is the typical starting salary for a quality engineer at Collins Aerospace with a bachelor’s degree and no prior experience?

Entry-level compensation is influenced by location, specific responsibilities, and the demand for engineering talent. Researching industry averages for comparable positions in the relevant geographic area is advised.

Question 2: How does obtaining a Certified Quality Engineer (CQE) certification impact salary potential at Collins Aerospace?

CQE certification can enhance earning potential by demonstrating expertise in quality principles and practices. Its impact varies based on the specific role and the relevance of the certification to the job responsibilities.

Question 3: Are there significant salary differences for quality engineers working at Collins Aerospace facilities in different states?

Geographic location exerts a substantial influence on compensation due to variations in cost of living, regional demand, and local economic conditions. Higher cost-of-living areas generally offer higher salaries.

Question 4: What role does performance-based compensation play in the overall earnings of a quality engineer at Collins Aerospace?

Performance-based bonuses and incentives can constitute a significant portion of overall compensation, rewarding engineers for achieving specific quality objectives, improving processes, and contributing to the company’s success.

Question 5: Does prior experience in the aerospace industry significantly increase a quality engineer’s starting salary at Collins Aerospace?

Prior aerospace experience is highly valued and typically translates to a higher starting salary due to the specialized knowledge and skills acquired. Relevant experience reduces the need for extensive on-the-job training.

Question 6: How does the company’s financial performance affect potential salary increases for quality engineers at Collins Aerospace?

Company financial performance directly impacts available resources for salary increases and bonuses. Strong financial results generally lead to more generous compensation packages for employees, including quality engineers.

Understanding the factors influencing compensation is crucial for career planning and negotiation. Individual skills, experience, education, and company performance all play a significant role.

This concludes the frequently asked questions section. The following sections will explore strategies for long-term career growth and development within the organization.

Concluding Remarks

This exploration has detailed the multifaceted influences on compensation for quality engineers at Collins Aerospace. Factors such as experience, education, geographic location, specific responsibilities, industry certifications, performance metrics, and the overall financial health of the company contribute to the determination of a quality engineer’s remuneration. Understanding these dynamics is crucial for professionals navigating career opportunities and salary negotiations within this sector.

The information presented should serve as a valuable resource for those seeking clarity on “collins aerospace quality engineer salary”. Continuous professional development and a strategic approach to career advancement are essential for optimizing earning potential within the dynamic aerospace industry. Informed decisions, grounded in research and a thorough understanding of market conditions, will empower individuals to secure competitive and rewarding compensation packages.

![Unlock: Aerospace Scientist Salary [2024 Guide] Insights Innovating the Future of Flight with Reliable Aviation Solutions Unlock: Aerospace Scientist Salary [2024 Guide] Insights | Innovating the Future of Flight with Reliable Aviation Solutions](https://mixaerospace.com/wp-content/uploads/2026/02/th-220-300x200.jpg)