Advanced structural materials, engineered through the combination of two or more distinct constituents, are extensively utilized in modern aircraft and spacecraft construction. These materials typically consist of a reinforcement phase, such as fibers, embedded within a matrix phase, such as resin. The resulting material exhibits enhanced properties compared to its individual components. Carbon fiber reinforced polymers (CFRPs) and glass fiber reinforced polymers (GFRPs) are examples commonly found in aircraft components like wings, fuselages, and control surfaces.

The adoption of these advanced materials in the aeronautical sector has revolutionized design and performance capabilities. Significant advantages include reduced weight, increased strength-to-weight ratio, improved corrosion resistance, and enhanced fatigue life. The lighter weight translates to improved fuel efficiency and increased payload capacity. Historically, the use of metals like aluminum dominated airframe construction; however, the superior characteristics of these materials have driven a paradigm shift, leading to greater integration in both commercial and military applications. Their ability to be molded into complex shapes also reduces the need for fasteners, further decreasing weight and improving aerodynamic performance.

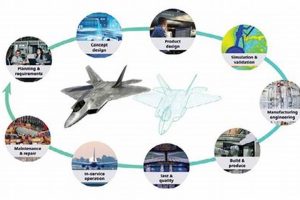

The subsequent sections will delve into the specific types of such materials employed, examine their manufacturing processes, explore their applications in various aircraft components, and address the challenges associated with their use, including repair, maintenance, and end-of-life disposal considerations. Furthermore, advancements in materials science and engineering are constantly pushing the boundaries of what is possible, with ongoing research focused on developing even stronger, lighter, and more durable materials for the future of flight.

Guidance for Implementation and Advancement

The following points offer focused guidance concerning the strategic integration and ongoing development involving advanced structural materials within the aeronautical sector.

Tip 1: Prioritize Material Selection Based on Performance Requirements: Thoroughly evaluate the specific operational demands of each aircraft component to ensure optimal material selection. Consider factors such as load-bearing capacity, temperature resistance, and environmental exposure to maximize performance and longevity.

Tip 2: Invest in Advanced Manufacturing Techniques: Implement cutting-edge fabrication methods, such as automated fiber placement (AFP) and resin transfer molding (RTM), to enhance manufacturing precision, reduce material waste, and improve the overall structural integrity of parts.

Tip 3: Emphasize Non-Destructive Inspection and Testing (NDT): Employ rigorous NDT procedures, including ultrasonic testing, radiography, and thermography, to detect defects and ensure quality control throughout the manufacturing and service life of components. Early defect detection minimizes the risk of catastrophic failures.

Tip 4: Develop Comprehensive Repair and Maintenance Strategies: Establish detailed protocols for the repair and maintenance of parts made from advanced materials. Train personnel in specialized repair techniques and ensure the availability of appropriate repair materials and equipment to maintain airworthiness.

Tip 5: Promote Collaboration between Material Scientists, Engineers, and Manufacturers: Foster strong partnerships between researchers, designers, and producers to facilitate knowledge transfer, accelerate innovation, and optimize the implementation of new materials and technologies.

Tip 6: Focus on Sustainable Material Solutions: Explore the development and implementation of bio-based resins and recyclable reinforcement fibers to reduce the environmental impact of aircraft manufacturing and disposal. Consider life cycle assessments to evaluate the overall sustainability of material choices.

Tip 7: Invest in Continuous Research and Development: Support ongoing research efforts aimed at developing new materials with enhanced properties, improving manufacturing processes, and addressing the challenges associated with repair, maintenance, and end-of-life disposal. Innovation is critical for maintaining a competitive edge.

Strategic implementation of these guidelines will enhance the efficiency, safety, and sustainability of aircraft, ensuring continued advancements in the field. Addressing these points allows the aeronautics industry to realize the full potential of advanced structural materials.

The subsequent discussion will focus on the challenges and future directions for this transformative sector.

1. Lightweighting

The term “lightweighting” signifies the reduction of structural weight while maintaining or improving performance characteristics. In the context of the aeronautical sector, its connection to the materials revolution is paramount. These materials, characterized by their high strength-to-weight ratio, directly enable lighter aircraft structures compared to traditional metallic counterparts like aluminum. This weight reduction translates to a cascading series of benefits, including decreased fuel consumption, increased payload capacity, and improved aircraft maneuverability.

The adoption of CFRPs in the Boeing 787 Dreamliner exemplifies this relationship. The aircraft’s extensive use of parts from advanced structural materials resulted in a significant reduction in overall weight, contributing to a reported 20% improvement in fuel efficiency compared to similarly sized aircraft. Similarly, Airbus utilizes these materials in the A350 XWB, achieving comparable weight savings and performance enhancements. This reduction in fuel consumption not only lowers operating costs for airlines but also reduces greenhouse gas emissions, aligning with growing environmental concerns within the industry. Beyond commercial aviation, military aircraft also benefit greatly from lightweighting, enabling increased speed, range, and payload capabilities.

In conclusion, lightweighting, facilitated by the utilization of materials with superior strength-to-weight ratios, constitutes a cornerstone of modern aircraft design. The benefits derived from reduced weight extend beyond fuel efficiency, encompassing improved performance, reduced emissions, and lower operating costs. Continuous research and development efforts aimed at further enhancing the properties of these materials will undoubtedly play a crucial role in shaping the future of aviation, driving further advancements in aircraft design and performance. The ongoing challenge lies in optimizing material selection, manufacturing processes, and maintenance procedures to ensure the long-term durability and safety of aircraft structures.

2. Strength

The inherent strength of materials represents a critical parameter in aircraft design, directly influencing structural integrity, safety margins, and overall performance. Parts built from composite materials, particularly those incorporating high-strength fibers like carbon or aramid, exhibit exceptional strength-to-weight ratios. This characteristic allows engineers to design lighter components without compromising structural integrity, a crucial advantage in aerospace applications where minimizing weight is paramount. The strength of the final part is dependent on factors such as the fiber type, the matrix material, the fiber orientation, and the manufacturing process. High-strength fibers, when properly aligned and embedded within a durable matrix, provide exceptional resistance to tensile, compressive, and shear forces.

Consider the example of aircraft wings constructed with CFRPs. The material’s high tensile strength enables the wing to withstand significant aerodynamic loads during flight, preventing bending or failure. Similarly, composite fuselage sections offer enhanced resistance to buckling under pressurization, contributing to increased passenger safety. Furthermore, the ability to tailor the fiber orientation within a composite structure allows engineers to optimize the material’s strength characteristics for specific load-bearing requirements. This anisotropic behavior provides a design flexibility unmatched by traditional isotropic materials like aluminum.

In conclusion, the superior strength characteristics of materials are fundamental to their widespread adoption in the aeronautical sector. This property directly contributes to safer, lighter, and more efficient aircraft designs. Ongoing research focuses on further enhancing the strength and durability of these materials, as well as developing advanced manufacturing techniques to ensure consistent and reliable performance. Addressing challenges related to damage tolerance and repair methods remains crucial for realizing the full potential in future aerospace applications.

3. Durability

Durability, defined as the ability to withstand wear, pressure, or damage, is a critical performance attribute in the aeronautical sector, directly influencing aircraft lifespan, maintenance requirements, and overall operational costs. The connection between durability and advanced structural materials is profound; the selection of these materials is often driven by the need for components that can endure the harsh conditions inherent in flight operations, including extreme temperatures, exposure to ultraviolet radiation, and constant stress from aerodynamic forces. The implementation of parts constructed from these materials aims to reduce the frequency of structural repairs, extend the service life of aircraft, and minimize the risk of catastrophic failures. For instance, aircraft control surfaces manufactured using CFRPs exhibit superior resistance to fatigue cracking compared to traditional aluminum alloys, directly enhancing the aircraft’s operational lifespan and reducing maintenance downtime.

The enhanced durability offered by these materials translates into tangible economic benefits for airlines. Reduced maintenance schedules, fewer unscheduled repairs, and prolonged component lifecycles contribute to lower operating costs. Furthermore, durable aircraft structures maintain their structural integrity over extended periods, ensuring consistent performance and safety. The Boeing 787 Dreamliner serves as a prime example; its airframe, largely constructed from these materials, is designed for a longer service life with reduced maintenance intervals compared to previous generation aircraft. The initial investment in advanced materials is offset by the long-term savings derived from improved durability and reduced maintenance.

In summary, durability is a key performance driver in the aeronautical sector. The utilization of advanced materials, characterized by their superior resistance to wear, stress, and environmental degradation, directly enhances aircraft lifespan, reduces maintenance costs, and improves overall safety. Continued advancements in materials science and engineering are focused on further improving the durability of parts, thereby maximizing the long-term economic and operational benefits for airlines and aircraft operators. Addressing challenges related to damage detection and repair methodologies remains crucial for ensuring the continued safe and efficient operation of aircraft utilizing these advanced materials.

4. Corrosion Resistance

Corrosion poses a significant threat to the structural integrity and longevity of aircraft, leading to increased maintenance costs and potential safety hazards. The integration of composite materials addresses this challenge by providing superior resistance to corrosive environments compared to traditional metallic alloys, contributing to enhanced aircraft durability and reduced operational expenses.

- Galvanic Corrosion Elimination

Unlike metallic structures, parts made from these materials do not suffer from galvanic corrosion, a process that occurs when dissimilar metals are in contact in the presence of an electrolyte. The absence of metallic constituents in most material formulations eliminates the risk of galvanic corrosion, particularly in areas where dissimilar materials are joined, such as fasteners and fittings. This property is especially beneficial in marine environments or regions with high humidity and salt content.

- Resistance to Chemical Degradation

The polymer matrix within parts often exhibits excellent resistance to a wide range of chemicals, including fuels, lubricants, and hydraulic fluids commonly used in aircraft operations. This resistance prevents chemical degradation of the structure, preserving its mechanical properties and structural integrity over extended periods. Protective coatings can further enhance resistance to particularly aggressive chemicals or environmental factors.

- Reduced Maintenance Requirements

The inherent corrosion resistance of these materials translates directly into reduced maintenance requirements for aircraft structures. Less frequent inspections, repairs, and replacements of corroded components contribute to lower operational costs and increased aircraft availability. This reduction in maintenance burden is especially valuable for aircraft operating in harsh environments or those with demanding flight schedules.

- Extended Component Lifespan

By minimizing corrosion-related degradation, advanced structural materials contribute to an extended component lifespan. This longer lifespan reduces the need for frequent replacements, further decreasing maintenance costs and maximizing the return on investment for aircraft operators. The increased durability also enhances the overall safety and reliability of aircraft structures.

The enhanced corrosion resistance offered by composite materials represents a significant advantage in aerospace applications. This property not only reduces maintenance costs and extends component lifespan but also enhances the overall safety and reliability of aircraft structures operating in diverse and challenging environments. Continued research and development efforts are focused on further optimizing the corrosion resistance of these materials and developing advanced coatings to provide even greater protection against environmental degradation.

5. Manufacturing Flexibility

The utilization of composite materials in the aeronautical sector introduces a degree of manufacturing flexibility unattainable with traditional metallic alloys. This flexibility stems from the capacity to tailor material properties and component geometry during the fabrication process, enabling the production of complex shapes and integrated structures with optimized performance characteristics. The ability to mold and shape these materials allows for the creation of aerodynamic designs with minimized drag and improved fuel efficiency. Complex curves and contours, difficult or impossible to achieve with conventional metal forming techniques, are readily realized through composite layup and molding processes. This, in turn, allows for the integration of multiple components into a single, structurally sound unit, reducing the need for fasteners and further minimizing weight.

Consider the manufacturing of aircraft wings. Instead of assembling numerous individual metal parts, an entire wing section can be fabricated as a single composite structure. This reduces manufacturing time, minimizes potential failure points associated with fasteners, and allows for precise control over the aerodynamic profile. The Airbus A350 XWB, for example, features a wing manufactured using resin transfer molding (RTM), a process that allows for the creation of large, complex, and highly integrated composite structures. This manufacturing flexibility extends to the internal architecture of composite parts, enabling the incorporation of stiffening ribs, stringers, and other structural elements directly into the material during the molding process. The capability eliminates the need for secondary bonding operations, improving structural integrity and reducing manufacturing costs. Moreover, composite materials allow for a wide range of fiber orientations, enabling engineers to optimize the strength and stiffness of a component to meet specific load requirements.

The manufacturing flexibility afforded by composite materials is a key driver in the ongoing evolution of aircraft design. This property enables the creation of lighter, stronger, and more aerodynamically efficient aircraft structures. Ongoing research and development efforts are focused on further refining composite manufacturing techniques, including automated fiber placement (AFP) and automated tape laying (ATL), to reduce manufacturing costs, improve production rates, and enhance the overall quality and reliability of composite aircraft components. Overcoming challenges related to process control, tooling design, and material handling remains crucial for realizing the full potential of materials within the aeronautical sector.

6. Fuel Efficiency

Fuel efficiency in the aeronautical sector is directly and substantially improved through the integration of parts from advanced structural materials. The primary mechanism driving this enhancement is weight reduction. These materials, characterized by their high strength-to-weight ratio, allow for the construction of lighter aircraft structures compared to those made from traditional metallic alloys such as aluminum. This weight reduction translates to a decrease in the energy required to propel the aircraft, resulting in lower fuel consumption per flight. A direct causal relationship exists: decreased weight leads to decreased fuel burn.

The Boeing 787 Dreamliner provides a significant real-world example of this principle. Its extensive use of parts from advanced structural materials resulted in a demonstrably lighter airframe, contributing to a reported 20% improvement in fuel efficiency compared to earlier-generation aircraft of similar size. Similarly, the Airbus A350 XWB leverages these materials to achieve comparable gains in fuel economy. This improved efficiency reduces operating costs for airlines and diminishes the environmental impact of air travel through lower carbon emissions. Furthermore, the enhanced aerodynamic properties achievable with parts constructed from advanced materials contribute to reduced drag, further optimizing fuel consumption. The ability to mold complex shapes and integrate structural components minimizes the need for fasteners and joints, thereby creating smoother surfaces and reducing air resistance.

The connection between advanced structural materials and fuel efficiency is not merely theoretical but has profound practical implications for the economics and environmental sustainability of the aeronautical industry. However, the widespread adoption of these materials presents challenges, including the need for specialized manufacturing techniques, rigorous quality control procedures, and the development of effective repair and maintenance strategies. Continuous research and development efforts are focused on addressing these challenges, optimizing the performance of composite structures, and exploring new material systems with even greater potential for weight reduction and improved fuel efficiency. The aeronautics industry is continually evolving to adopt efficient solutions.

Frequently Asked Questions

This section addresses common inquiries regarding the implementation of advanced structural materials in aircraft construction.

Question 1: What specific types of composite materials are typically employed in aircraft construction?

Carbon fiber reinforced polymers (CFRPs) and glass fiber reinforced polymers (GFRPs) are common choices. CFRPs offer a high strength-to-weight ratio, while GFRPs provide a more cost-effective solution for less critical components. Other materials, such as aramid fibers and ceramic matrix composites, are utilized in specialized applications requiring enhanced temperature resistance or impact strength.

Question 2: How do composite materials contribute to enhanced aircraft fuel efficiency?

The primary contribution stems from weight reduction. These materials possess a significantly higher strength-to-weight ratio compared to traditional metallic alloys, enabling the construction of lighter aircraft structures. This reduced weight translates directly to lower fuel consumption per flight.

Question 3: What are the primary challenges associated with repairing composite aircraft structures?

Damage detection can be challenging, as internal damage may not always be visible on the surface. Repair techniques require specialized training and equipment to ensure structural integrity is restored. The bonding process, in particular, is critical and must be carefully controlled to prevent delamination or other defects.

Question 4: How does the cost of composite materials compare to that of traditional aircraft materials?

The initial cost of these materials is generally higher than that of aluminum alloys. However, the life cycle cost can be lower due to reduced maintenance requirements, increased fuel efficiency, and extended component lifespan. The overall economic benefit depends on factors such as aircraft type, operating conditions, and maintenance practices.

Question 5: Are composite materials susceptible to environmental degradation, and if so, how is this mitigated?

Exposure to ultraviolet (UV) radiation, moisture, and certain chemicals can degrade composite materials over time. Protective coatings, such as paints and sealants, are employed to mitigate this degradation. Regular inspections and maintenance procedures are also essential for identifying and addressing any signs of environmental damage.

Question 6: What are the end-of-life disposal considerations for composite aircraft components?

The disposal of parts presents challenges due to the non-biodegradable nature of many composite materials. Recycling technologies are being developed to recover valuable fibers from end-of-life components. Incineration and landfill disposal are also options, but these methods raise environmental concerns.

In summary, the implementation of advanced structural materials in the aeronautical sector presents both opportunities and challenges. A thorough understanding of material properties, manufacturing techniques, and maintenance requirements is essential for realizing the full potential of this technology.

The subsequent section will address the future trends and emerging technologies.

Conclusion

The preceding discussion underscores the transformative impact of composite materials in the aerospace industry. The unique combination of lightweight characteristics, high strength, durability, corrosion resistance, and manufacturing flexibility has driven their increasing adoption in modern aircraft design. As a result, fuel efficiency has improved, operational costs have decreased, and aircraft performance capabilities have expanded, marking a significant advancement in aeronautical engineering.

Continued research and development efforts focused on material innovation, advanced manufacturing techniques, and sustainable disposal methods are crucial for unlocking the full potential of composite materials. The aerospace industry must prioritize these areas to ensure the continued safe, efficient, and environmentally responsible operation of aircraft in the future. The ongoing evolution of composite materials represents a significant opportunity to further revolutionize aircraft technology and enhance the capabilities of air travel.