Career opportunities at Crane Aerospace located in Lynnwood, Washington, represent employment prospects within a specific division of a larger aerospace company. These roles encompass various positions related to the design, manufacturing, and support of critical aerospace components and systems at the Lynnwood facility.

The significance of securing employment within this sector stems from the stability and advanced technological environment characteristic of the aerospace industry. These positions often provide opportunities for professional growth, competitive compensation packages, and the chance to contribute to cutting-edge advancements in flight and related technologies. Historically, such roles have been vital for maintaining the United States’ leadership in aerospace innovation and manufacturing.

The following sections will elaborate on the types of positions available, required qualifications, application processes, and the overall work environment at this Crane Aerospace location. This exploration aims to provide a clear understanding for individuals considering pursuing such career paths.

This section provides essential guidance for individuals interested in pursuing employment at Crane Aerospace in Lynnwood. Careful preparation and a targeted approach significantly enhance candidacy.

Tip 1: Conduct Thorough Research: Prior to applying, comprehensively investigate Crane Aerospace’s Lynnwood operations. Understand the division’s specific products, services, and its role within the broader company. This knowledge demonstrates genuine interest and preparedness.

Tip 2: Tailor Application Materials: Generic applications are often overlooked. Customize resumes and cover letters to directly address the specific requirements and preferred qualifications outlined in each job posting. Highlight relevant skills and experiences.

Tip 3: Emphasize Technical Proficiency: Crane Aerospace is a technology-driven company. Showcase technical skills, certifications, and experience with relevant software, equipment, or processes. Quantifiable achievements are particularly impactful.

Tip 4: Network Strategically: Attending industry events or connecting with current or former employees on professional networking platforms can provide valuable insights and potential referrals. Informational interviews can offer a deeper understanding of the company culture and expectations.

Tip 5: Prepare for Technical Interviews: Technical roles typically involve rigorous interviews assessing problem-solving abilities and technical expertise. Practice common interview questions and be prepared to discuss past projects in detail.

Tip 6: Demonstrate Problem-Solving Skills: Aerospace companies value individuals who can effectively address complex challenges. Provide concrete examples of how prior problem-solving experience has led to positive outcomes.

Effective preparation, targeted application materials, and strategic networking are crucial components of a successful job search. Demonstrating a strong understanding of the company and its technical requirements significantly increases the likelihood of securing employment.

The subsequent sections will delve deeper into the typical roles available and the necessary qualifications for success.

1. Engineering Positions at Crane Aerospace Lynnwood

Engineering roles at Crane Aerospace’s Lynnwood location are central to the company’s operations. These positions drive the design, development, and testing of advanced aerospace components and systems, directly contributing to the facility’s output and technological advancements. Understanding the facets of these engineering positions is crucial for prospective employees.

- Design and Development Engineering

These roles focus on creating new aerospace products and improving existing designs. Responsibilities include conceptual design, detailed engineering analysis, prototyping, and testing. For example, engineers might work on designing more efficient hydraulic systems or developing advanced sensors for aircraft. The implications of this work directly impact the performance, safety, and reliability of aircraft systems.

- Systems Engineering

Systems engineers are responsible for integrating various components into cohesive aerospace systems. They define system requirements, manage interfaces, and ensure that all components work together seamlessly. A systems engineer might oversee the integration of a new avionics system into an aircraft, ensuring compatibility and functionality. These roles are crucial for ensuring overall system performance and preventing integration issues.

- Test Engineering

Test engineers design and execute test plans to validate the performance and reliability of aerospace components and systems. They analyze test data, identify potential issues, and recommend corrective actions. For instance, a test engineer might conduct vibration testing on a newly designed actuator to ensure it meets performance specifications. This testing is vital for identifying and mitigating potential failures before components are deployed in aircraft.

- Materials and Process Engineering

These engineers focus on selecting and optimizing materials and manufacturing processes for aerospace components. They work to improve product performance, reduce costs, and ensure compliance with industry regulations. For example, a materials engineer might research and select lightweight alloys for use in aircraft structures to improve fuel efficiency. Their expertise is critical for ensuring the durability, safety, and cost-effectiveness of aerospace products.

These engineering facets collectively underscore the critical role that engineering positions play within Crane Aerospace’s Lynnwood operations. From initial design to final testing and material selection, engineers are involved in every stage of the product lifecycle. Understanding these roles and their responsibilities provides a comprehensive overview of engineering opportunities and their potential impact on the aerospace industry.

2. Manufacturing Roles

Manufacturing roles constitute a significant component of the employment landscape at Crane Aerospace’s Lynnwood facility. These positions are directly responsible for the physical creation and assembly of aerospace components, translating engineering designs into tangible products. The effectiveness and efficiency of these manufacturing operations have a direct impact on the overall output and quality of the products produced by Crane Aerospace Lynnwood. For example, machinists, assemblers, and technicians work collaboratively to fabricate hydraulic systems, critical for aircraft control. Delays or deficiencies in manufacturing directly affect delivery schedules and product reliability, underscoring the importance of these roles within the organizational structure.

The range of manufacturing positions spans various skill levels and specializations. Precision machining, welding, composite fabrication, and electronics assembly are examples of specialized manufacturing processes employed at the Lynnwood facility. Consequently, employees in these roles require specific training, certifications, and experience to perform their duties effectively. Further, quality control is integrated into the manufacturing process, with inspectors ensuring adherence to stringent aerospace standards. The reliance on specialized skill sets highlights the need for continuous training and development to maintain a competitive manufacturing workforce.

In conclusion, manufacturing positions are integral to Crane Aerospace’s operations in Lynnwood. These roles serve as the tangible realization of engineering designs, ensuring the production of high-quality aerospace components. An understanding of these manufacturing processes and the importance of skilled labor is crucial for individuals seeking employment and for the continued success of Crane Aerospace in the competitive aerospace market.

3. Quality Assurance

Quality assurance within Crane Aerospace’s Lynnwood operations is not merely a procedural step but an essential function intricately linked to all employment roles. The aerospace industry demands stringent adherence to safety and performance standards, making quality assurance paramount to the company’s success and the safety of its products.

- Inspection and Testing

Roles directly involved in inspection and testing are responsible for verifying that components and finished products meet established specifications. This includes dimensional inspections, material testing, and functional testing. For example, inspectors might use coordinate measuring machines (CMMs) to ensure that machined parts adhere to precise tolerances. A failure to identify non-conforming parts at this stage can lead to costly rework, delays in production, or, more critically, compromise the safety and reliability of the final product. Therefore, qualified and meticulous personnel are essential for these positions.

- Process Control and Monitoring

Quality assurance professionals are involved in monitoring manufacturing processes to identify and correct deviations from established procedures. This includes statistical process control (SPC), process audits, and root cause analysis. An example would be monitoring the temperature and humidity in a cleanroom environment to ensure that sensitive electronic components are not compromised during assembly. Effective process control minimizes defects, reduces waste, and ensures consistent product quality.

- Documentation and Compliance

Maintaining accurate and complete documentation is a critical aspect of quality assurance in the aerospace industry. Quality assurance personnel are responsible for creating and maintaining quality control plans, inspection reports, and corrective action reports. They also ensure that the company complies with industry standards such as AS9100. Thorough documentation is essential for traceability, audits, and continuous improvement efforts. Any discrepancies in documentation can lead to regulatory issues and jeopardize the company’s reputation.

- Continuous Improvement

Quality assurance is not a static function but a continuous process of improvement. Quality assurance professionals analyze data, identify areas for improvement, and implement corrective and preventive actions (CAPA). For example, they might analyze defect rates to identify the root cause of recurring problems and implement changes to the manufacturing process to prevent future occurrences. Continuous improvement efforts lead to increased efficiency, reduced costs, and improved product quality.

These facets highlight the pervasive influence of quality assurance on all roles within Crane Aerospace’s Lynnwood facility. From entry-level inspectors to senior quality managers, every employee contributes to maintaining the highest standards of quality. The emphasis on quality assurance provides both opportunities and challenges for individuals seeking employment, requiring attention to detail, adherence to procedures, and a commitment to continuous improvement.

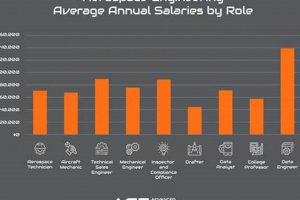

4. Competitive Salaries

The provision of competitive salaries is a central factor in attracting and retaining qualified personnel for Crane Aerospace positions in Lynnwood. These salaries directly influence the caliber of candidates applying for available roles and impact employee satisfaction and productivity.

- Market Benchmarking

Crane Aerospace positions in Lynnwood often utilize market benchmarking data to establish salary ranges. This involves comparing compensation packages with similar roles at competing aerospace companies and within the broader manufacturing sector in the region. For example, salary surveys from organizations like WorldatWork or Radford may be consulted to determine appropriate pay scales for engineers, technicians, and managers. Adherence to market rates ensures that Crane Aerospace remains competitive in the talent acquisition process.

- Skill Set and Experience

Salaries for Crane Aerospace positions are contingent upon the specific skills, qualifications, and experience of the applicant. Roles requiring advanced technical expertise, specialized certifications, or extensive experience in the aerospace industry command higher compensation. An experienced aerospace engineer with a Professional Engineer (PE) license, for example, would likely receive a higher salary offer than a recent graduate with limited practical experience. This differentiation incentivizes professional development and rewards individuals with proven capabilities.

- Cost of Living Adjustments

Salary considerations at Crane Aerospace in Lynnwood factor in the local cost of living. Lynnwood’s proximity to Seattle results in a relatively high cost of living compared to other regions. Compensation packages are often adjusted to reflect these costs, ensuring that employees can maintain a reasonable standard of living. For example, housing costs, transportation expenses, and local taxes are considered when determining appropriate salary levels. These adjustments contribute to employee financial stability and reduce attrition rates.

- Performance-Based Incentives

In addition to base salaries, Crane Aerospace positions may offer performance-based incentives such as bonuses or stock options. These incentives are tied to individual or team performance goals and provide opportunities for employees to increase their earnings based on their contributions. For example, engineers involved in successful product development projects may receive bonuses based on achieving specific performance metrics. These incentives align employee interests with company objectives and encourage high levels of performance.

These interconnected facets demonstrate how competitive salaries are strategically employed by Crane Aerospace in Lynnwood to attract, motivate, and retain a skilled workforce. By considering market benchmarks, individual qualifications, cost of living, and performance incentives, the company aims to provide compensation packages that are both competitive and equitable, ensuring the continued success of its operations in the aerospace sector.

5. Benefits packages

Benefit packages are a crucial element of the overall compensation offered in connection with positions at Crane Aerospace in Lynnwood. These packages provide employees with security and contribute significantly to the attractiveness of employment opportunities. The nature and comprehensiveness of these benefits are vital factors for candidates evaluating prospective roles.

- Health Insurance

Health insurance is a cornerstone of employee benefits. Crane Aerospace’s Lynnwood offerings typically include medical, dental, and vision coverage, designed to mitigate healthcare costs for employees and their dependents. For example, a plan might cover preventative care, prescription medications, and hospitalization. The quality and extent of this coverage directly impact an employee’s ability to access healthcare services, which in turn affects their overall well-being and job satisfaction.

- Retirement Plans

Retirement plans provide a mechanism for employees to save for their future. These plans may include 401(k) options, pension plans, or a combination of both. Employer matching contributions are a significant component of these plans, effectively augmenting employee savings. For instance, Crane Aerospace could match a percentage of an employee’s 401(k) contributions, thereby increasing their retirement nest egg. The availability and generosity of retirement plans are critical in attracting and retaining long-term employees.

- Paid Time Off (PTO)

Paid time off encompasses vacation days, sick leave, and holidays. These benefits allow employees to balance work with personal needs and recuperation. A comprehensive PTO policy provides employees with the flexibility to manage unforeseen circumstances, pursue personal interests, and maintain a healthy work-life balance. For example, an employee might use PTO for vacation, family emergencies, or personal appointments. The amount of PTO offered is a key determinant in the perceived value of the employment package.

- Life Insurance and Disability Coverage

Life insurance and disability coverage provide financial protection in the event of unforeseen circumstances. Life insurance provides a death benefit to beneficiaries, while disability coverage provides income replacement if an employee becomes unable to work due to illness or injury. These benefits provide a safety net for employees and their families, offering peace of mind and financial security. For instance, a basic life insurance policy might provide a death benefit equal to one or two times an employee’s annual salary. The presence of these protections demonstrates a commitment to employee well-being beyond the workplace.

These benefits packages, therefore, are integral to the employment proposition at Crane Aerospace in Lynnwood, influencing not only the financial security of employees but also their overall satisfaction and productivity. A comprehensive and competitive benefits package can serve as a differentiator in attracting top talent and fostering a positive work environment.

6. Aerospace Innovation

Aerospace innovation is a driving force shaping the nature and scope of roles available at Crane Aerospace’s Lynnwood facility. The facility’s involvement in developing cutting-edge technologies directly translates into a demand for skilled personnel capable of contributing to and managing these advancements.

- Research and Development Roles

Innovation necessitates investment in research and development. Crane Aerospace Lynnwood jobs include positions focused on exploring new materials, designs, and manufacturing processes. For example, engineers may be tasked with developing lighter, more durable composites for aircraft components. These roles require a strong understanding of scientific principles and the ability to translate theoretical concepts into practical applications. The implications for employees involve continuous learning and the opportunity to work at the forefront of technological progress.

- Advanced Manufacturing Technologies

Aerospace innovation often hinges on the adoption of advanced manufacturing technologies. This includes additive manufacturing (3D printing), robotic automation, and precision machining. Crane Aerospace Lynnwood jobs in this area involve operating, maintaining, and optimizing these technologies. For instance, technicians may be responsible for programming and overseeing robotic welding systems. Proficiency in these technologies is crucial for maintaining competitiveness and producing high-quality components efficiently. This, in turn, drives demand for personnel with specialized skills.

- Systems Integration and Optimization

Innovation in aerospace requires seamless integration of various systems and components. Crane Aerospace Lynnwood jobs in systems engineering focus on ensuring that new technologies are compatible with existing aircraft infrastructure and that they function optimally together. An example would be integrating advanced sensors into flight control systems to improve safety and efficiency. These roles require a broad understanding of aerospace systems and the ability to troubleshoot complex integration challenges. Successful integration is essential for realizing the full benefits of aerospace innovation.

- Quality Assurance for Novel Technologies

The introduction of new technologies necessitates robust quality assurance processes. Crane Aerospace Lynnwood jobs in quality control are responsible for developing and implementing testing protocols to ensure that innovative components meet stringent aerospace standards. This includes non-destructive testing methods, advanced inspection techniques, and rigorous performance evaluations. For example, quality engineers may design tests to assess the durability and reliability of 3D-printed parts. These roles are critical for mitigating risks associated with new technologies and ensuring the safety and reliability of aircraft.

These facets underscore the symbiotic relationship between aerospace innovation and the skill sets demanded within “crane aerospace lynnwood jobs”. The pursuit of innovation generates a demand for specialized expertise across various functional areas, ultimately shaping the character of employment opportunities at the facility.

Frequently Asked Questions Regarding Crane Aerospace Lynnwood Employment

The following questions address common inquiries regarding career opportunities at Crane Aerospace’s Lynnwood facility. These responses provide factual information to guide prospective applicants.

Question 1: What types of positions are typically available at Crane Aerospace in Lynnwood?

Answer: Commonly available roles encompass a range of engineering disciplines (mechanical, electrical, systems, manufacturing), as well as manufacturing technicians, quality assurance specialists, and administrative support staff. Specific openings vary depending on current business needs.

Question 2: What are the typical educational requirements for engineering positions?

Answer: A bachelor’s degree in a relevant engineering field is generally required. Advanced degrees (Master’s or PhD) may be preferred for certain specialized roles.

Question 3: Does Crane Aerospace in Lynnwood offer internships or co-op programs?

Answer: Internship and co-op opportunities may be available for students pursuing degrees in engineering or related fields. These programs provide practical experience within the aerospace industry.

Question 4: How can one apply for positions at Crane Aerospace in Lynnwood?

Answer: Applications are typically submitted online through the company’s careers website. The website lists current openings and provides instructions for submitting resumes and cover letters.

Question 5: What is the company culture like at Crane Aerospace in Lynnwood?

Answer: The culture is generally described as professional, technically focused, and team-oriented. Emphasis is placed on innovation, quality, and continuous improvement.

Question 6: What are the opportunities for professional development and advancement?

Answer: Crane Aerospace generally supports professional development through training programs, tuition reimbursement, and opportunities to take on new responsibilities. Advancement opportunities depend on individual performance and company growth.

In summary, opportunities at Crane Aerospace in Lynnwood span various disciplines and skill levels. Prospective applicants should carefully review job postings and prepare tailored application materials.

The subsequent section will provide a concluding summary of key considerations for prospective employees.

Conclusion

This exploration has detailed pertinent aspects of “crane aerospace lynnwood jobs,” emphasizing the variety of roles available, requisite qualifications, and the commitment to quality and innovation inherent within the organization. The importance of competitive compensation, comprehensive benefits packages, and opportunities for professional development have been highlighted as key factors for prospective employees.

Individuals considering a career path within this sector are encouraged to conduct thorough research and tailor their applications to align with specific job requirements. The aerospace industry presents ongoing challenges and opportunities, and a commitment to continuous learning will be essential for sustained success. The future of aerospace depends on skilled professionals dedicated to innovation and safety, making contributions in this field both meaningful and impactful.