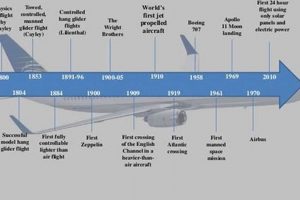

The application of advanced analytical techniques to the design, development, and operation of aircraft and spacecraft is transforming the field. It involves utilizing statistical modeling, machine learning, and data visualization to extract meaningful insights from large and complex datasets inherent in aerospace projects. For example, analyzing sensor data from flight tests allows engineers to optimize aircraft performance and identify potential design flaws early in the development cycle.

This interdisciplinary approach offers significant advantages, enabling more efficient designs, improved safety, and reduced operational costs. Historically, aerospace relied heavily on physics-based simulations and empirical testing. However, the increasing availability of data from sources like wind tunnels, flight recorders, and manufacturing processes has created opportunities to complement traditional methods with data-driven approaches. These techniques facilitate more accurate predictions, proactive maintenance strategies, and enhanced decision-making throughout the lifecycle of aerospace systems.

Subsequent sections will delve into specific applications within areas such as aircraft design optimization, predictive maintenance of aerospace components, and the development of autonomous flight systems. Furthermore, the role of computational infrastructure and the challenges associated with handling the unique characteristics of aerospace data will be explored.

Essential Considerations for Applying Analytical Methods to Aeronautics and Astronautics

The effective integration of advanced analytical methods into the aerospace sector requires careful planning and execution. The following tips offer guidance on key considerations for maximizing the value derived from this integration.

Tip 1: Data Quality is Paramount: Invest in rigorous data validation and cleaning processes. Erroneous or incomplete datasets will lead to inaccurate models and flawed conclusions. Examples include ensuring consistent sensor calibration, removing outlier data points resulting from instrument malfunctions, and standardizing data formats across different sources.

Tip 2: Domain Expertise is Indispensable: Effective utilization of analytical tools requires a deep understanding of aerospace principles and engineering practices. Collaboration between data scientists and aerospace engineers is crucial for formulating relevant research questions, interpreting results accurately, and translating insights into actionable solutions.

Tip 3: Embrace Physics-Informed Machine Learning: Integrate physical laws and domain knowledge into machine learning models to improve their accuracy, robustness, and interpretability. This can be achieved by incorporating governing equations as constraints during model training or by using physics-based simulations to generate synthetic training data.

Tip 4: Prioritize Model Explainability: In safety-critical aerospace applications, understanding why a model makes a particular prediction is as important as the prediction itself. Employ techniques such as SHAP values or LIME to explain model behavior and identify potential biases or vulnerabilities.

Tip 5: Implement Robust Validation Strategies: Thoroughly validate models using independent datasets and appropriate performance metrics. Avoid overfitting by employing techniques such as cross-validation and regularization. Rigorous testing is essential to ensure the model’s generalizability and reliability in real-world scenarios.

Tip 6: Ensure Data Security and Compliance: Implement stringent security measures to protect sensitive aerospace data from unauthorized access and cyber threats. Adhere to relevant regulatory requirements, such as ITAR and EAR, when handling export-controlled information.

Tip 7: Invest in Scalable Infrastructure: Processing and analyzing large volumes of aerospace data requires robust and scalable computing infrastructure. Consider leveraging cloud computing platforms or high-performance computing clusters to handle demanding workloads.

These tips underscore the importance of a holistic approach to integrating sophisticated analytical methods into aerospace engineering. By addressing these considerations, the aerospace community can unlock the full potential of these techniques to drive innovation, enhance safety, and optimize performance.

The subsequent sections will provide more specific examples of successful applications and address potential challenges in the implementation of these advanced analytical approaches.

1. Design Optimization

Design optimization, when interwoven with advanced analytical methods, significantly enhances the efficiency and effectiveness of aerospace engineering processes. This synergy enables the creation of superior aircraft and spacecraft designs by leveraging the power of data-driven insights and computational techniques.

- Computational Fluid Dynamics (CFD) Enhancement

Analytical techniques augment traditional CFD simulations by providing more accurate turbulence models and boundary conditions. For example, machine learning algorithms can be trained on experimental data to predict flow separation and improve the design of airfoil shapes. This leads to reduced drag and enhanced lift characteristics, optimizing fuel efficiency and overall aerodynamic performance.

- Surrogate Modeling for Rapid Evaluation

Constructing surrogate models from high-fidelity simulations enables rapid evaluation of design alternatives. Gaussian Process Regression or Kriging methods, for instance, can create accurate approximations of complex performance metrics. This allows engineers to explore a vast design space efficiently, identifying optimal configurations without the computational expense of repeatedly running full-scale simulations.

- Multidisciplinary Design Optimization (MDO) Improvement

Analytical approaches facilitate the integration of multiple disciplines, such as aerodynamics, structures, and propulsion, into a unified optimization framework. By employing techniques like co-Kriging or hierarchical optimization, engineers can simultaneously consider the interactions between these disciplines. This results in designs that are not only aerodynamically efficient but also structurally sound and propulsion-compatible, leading to holistic optimization of the entire aircraft system.

- Topology Optimization with Performance Prediction

Advanced analytical methods can be coupled with topology optimization to create lightweight and structurally efficient aerospace components. Machine learning algorithms can predict the structural performance of various topological designs, enabling engineers to identify optimal material distributions. This results in lighter components with improved strength-to-weight ratios, contributing to overall weight reduction and enhanced aircraft performance.

The facets of design optimization demonstrate the transformative potential of integrating analytical methods within the aerospace sector. By leveraging these techniques, engineers can create more efficient, safer, and higher-performing aircraft and spacecraft, pushing the boundaries of aerospace technology.

2. Predictive Maintenance

Predictive maintenance in the aerospace sector represents a significant application of advanced analytical techniques to enhance safety, reduce operational costs, and improve asset utilization. Its core principle involves utilizing sensor data, historical records, and analytical models to forecast potential equipment failures before they occur. This proactive approach stands in stark contrast to traditional maintenance strategies, such as reactive maintenance (repairing only after a failure) and preventative maintenance (performing maintenance at fixed intervals regardless of actual condition). The deployment of analytical methods, including statistical modeling and machine learning, allows for the detection of subtle anomalies in equipment performance that might otherwise go unnoticed. For instance, analyzing vibration data from aircraft engines can identify bearing wear or imbalance issues long before they lead to catastrophic failure. Similarly, monitoring hydraulic system pressure and temperature can reveal developing leaks or pump degradation. These early warnings enable maintenance teams to schedule repairs at optimal times, minimizing downtime and preventing costly disruptions to flight schedules.

The importance of predictive maintenance as a component of advanced analytical applications in aerospace extends beyond cost savings. It directly contributes to improved safety by mitigating the risk of in-flight equipment malfunctions. Examples include the use of data-driven models to predict the remaining useful life of critical components like turbine blades or landing gear actuators. By accurately estimating when a component is likely to fail, maintenance can be performed proactively, preventing accidents and enhancing passenger safety. Furthermore, the data collected through predictive maintenance programs can provide valuable insights into the design and manufacturing of aerospace equipment. Analyzing failure patterns and identifying root causes can inform design improvements and enhance the reliability of future generations of aircraft and spacecraft. For example, understanding the specific conditions that lead to corrosion in certain aircraft structures can guide the development of more corrosion-resistant materials and coatings.

In conclusion, predictive maintenance, driven by sophisticated analytical methods, is a cornerstone of modern aerospace operations. Its practical significance lies in its ability to improve safety, reduce costs, and enhance the overall efficiency of aircraft and spacecraft maintenance. While challenges remain in the implementation of these techniques, such as the need for robust data infrastructure and skilled personnel, the benefits of predictive maintenance far outweigh the costs. As the volume and complexity of aerospace data continue to grow, the role of advanced analytical applications in predictive maintenance will become increasingly critical to ensuring the continued safety and reliability of air travel and space exploration.

3. Flight Dynamics

Flight dynamics, the study of aircraft motion and stability, has undergone a significant transformation through the integration of advanced analytical methods. These methods allow for more precise modeling, analysis, and control of aircraft, enhancing performance and safety.

- System Identification and Modeling

Analytical methods enable the development of more accurate flight dynamics models by identifying system parameters from flight test data. Techniques such as Kalman filtering and system identification algorithms are used to estimate aerodynamic coefficients and stability derivatives. These models are essential for flight simulator development, control system design, and aircraft certification. For example, the accurate identification of an aircraft’s stability derivatives from flight test data can inform the design of autopilot systems that enhance stability during turbulent conditions.

- Flight Control System Optimization

Analytical approaches optimize flight control system design to improve aircraft handling qualities and performance. Reinforcement learning and adaptive control algorithms can be used to develop flight controllers that automatically adjust to changing flight conditions or aircraft configurations. This can result in improved fuel efficiency, reduced pilot workload, and enhanced safety margins. For instance, adaptive control systems can compensate for aerodynamic changes caused by icing or damage, maintaining stable flight characteristics.

- Maneuver Optimization and Trajectory Planning

The use of analytical techniques enables the optimization of flight maneuvers and trajectory planning for various mission objectives. Algorithms such as optimal control and model predictive control are employed to determine the most efficient flight paths for minimizing fuel consumption, maximizing range, or avoiding obstacles. For instance, data-driven trajectory optimization can be used to design fuel-efficient descent profiles for commercial aircraft, reducing emissions and operating costs.

- Real-Time Flight Monitoring and Anomaly Detection

Advanced analytical methods play a crucial role in real-time flight monitoring and anomaly detection, enhancing aviation safety. By analyzing sensor data from aircraft systems, machine learning algorithms can identify deviations from normal operating conditions, potentially indicating equipment malfunctions or adverse environmental factors. These algorithms provide early warnings to pilots and ground control, enabling proactive measures to prevent accidents. For example, detecting subtle changes in engine performance or hydraulic system pressure can alert the crew to potential problems before they escalate, improving safety and reliability.

The utilization of advanced analytical methods within flight dynamics has led to more efficient, safer, and higher-performing aircraft. As the volume and complexity of flight data continue to grow, the role of sophisticated analytical applications will become increasingly critical in advancing aerospace technology.

4. Autonomous Systems

The development of autonomous systems within the aerospace engineering domain relies heavily on the capabilities afforded by data science. This synergy enables the creation of aircraft and spacecraft capable of operating with minimal or no human intervention, performing complex tasks in dynamic and often unpredictable environments.

- Perception and Environmental Modeling

Autonomous navigation necessitates accurate perception of the surrounding environment. Data science techniques, such as computer vision and sensor fusion, process data from onboard cameras, LiDAR, radar, and other sensors to create comprehensive environmental models. These models enable autonomous systems to identify obstacles, track other aircraft, and navigate through complex airspace. For example, machine learning algorithms can be trained to recognize and classify different types of aircraft from visual data, improving situational awareness.

- Decision-Making and Path Planning

Once an autonomous system has a clear understanding of its environment, it must make decisions about its path and actions. Data science facilitates this process through the application of algorithms for path planning, trajectory optimization, and decision-making under uncertainty. Reinforcement learning, for instance, can be used to train autonomous agents to navigate complex environments while minimizing fuel consumption and avoiding obstacles. Model Predictive Control (MPC) is employed to generate optimal trajectories that account for the system’s dynamics and constraints.

- Fault Detection and Diagnosis

Autonomous systems must be capable of detecting and responding to failures or anomalies. Data science enables the development of fault detection and diagnosis systems that analyze sensor data to identify potential problems. Machine learning algorithms can be trained to recognize patterns associated with specific types of failures, allowing the system to take corrective action. For example, analyzing engine performance data can identify anomalies that may indicate an impending engine failure, allowing the system to initiate a safe landing procedure.

- Adaptive Learning and Optimization

Autonomous systems can continuously learn and improve their performance through adaptive learning techniques. Data science enables the development of algorithms that analyze past performance data to optimize control parameters, refine environmental models, and improve decision-making strategies. For example, reinforcement learning can be used to adapt an autonomous system’s control strategy based on its experience in different flight conditions, improving its overall robustness and efficiency.

These facets underscore the integral role that data science plays in the realization of autonomous systems in aerospace engineering. The ability to process and interpret vast amounts of data, coupled with advanced analytical techniques, empowers these systems to operate effectively and safely in complex environments, pushing the boundaries of what is possible in aviation and space exploration.

5. Material Science

The intersection of material science and advanced analytical techniques in aerospace engineering is crucial for developing high-performance, lightweight, and durable materials essential for aircraft and spacecraft. The increasing complexity of aerospace designs and the stringent requirements for safety and efficiency necessitate the application of sophisticated data-driven approaches to material development and characterization.

- Material Discovery and Design

Analytical methods accelerate the discovery and design of novel aerospace materials with tailored properties. Machine learning algorithms can analyze vast datasets of material compositions, processing parameters, and performance characteristics to identify promising candidate materials. For example, machine learning can predict the mechanical properties of new alloy compositions based on their chemical makeup and processing history, reducing the need for extensive experimental testing. This approach also facilitates the design of composite materials with optimized fiber orientations and matrix compositions to achieve specific strength and stiffness requirements.

- Material Characterization and Testing

The application of advanced analytical methods enhances the precision and efficiency of material characterization and testing processes. Techniques such as image analysis and pattern recognition can be used to extract quantitative information from microscopy images, providing insights into the microstructure of materials and its correlation with mechanical properties. Data-driven models can also be used to predict the fatigue life and fracture behavior of aerospace components based on non-destructive testing data, such as ultrasonic or X-ray scans. This enables more accurate assessment of material integrity and prediction of component lifespan.

- Process Optimization and Control

Analytical approaches enable the optimization and control of material processing techniques used in aerospace manufacturing. Machine learning algorithms can analyze sensor data from manufacturing processes, such as additive manufacturing or composite layup, to identify optimal processing parameters and detect process deviations. This results in improved material quality, reduced manufacturing defects, and enhanced process efficiency. For instance, data-driven models can be used to predict the porosity and density of additively manufactured parts based on laser power, scanning speed, and material composition, allowing for real-time process adjustments to ensure consistent quality.

- Failure Analysis and Prediction

The application of analytical methods to failure analysis helps identify the root causes of material failures in aerospace components. Techniques such as finite element analysis (FEA) and computational fracture mechanics can be combined with experimental data to simulate failure mechanisms and predict component lifespan. Data-driven models can also be used to analyze historical failure data to identify patterns and predict the likelihood of future failures based on operating conditions and material properties. This enables proactive maintenance and mitigation strategies to prevent catastrophic failures.

These components illustrate the crucial role of data science in advancing material science for aerospace engineering. The ability to analyze complex datasets, predict material behavior, and optimize manufacturing processes is essential for developing the next generation of high-performance aerospace materials. By harnessing the power of analytical methods, engineers can create lighter, stronger, and more durable aircraft and spacecraft, pushing the boundaries of aerospace technology.

6. Risk Mitigation

The integration of advanced analytical techniques significantly enhances risk mitigation strategies across various facets of aerospace engineering. This integration enables more accurate hazard identification, improved risk assessment, and more effective implementation of mitigation measures, contributing to safer and more reliable aerospace operations.

- Predictive Failure Analysis

By analyzing historical maintenance records, sensor data from aircraft systems, and environmental factors, analytical models can predict the likelihood of component failures. This allows for proactive maintenance interventions, preventing potential accidents and minimizing operational disruptions. For example, machine learning algorithms can identify subtle anomalies in engine performance data that indicate an impending engine failure, providing early warning and allowing for scheduled maintenance before a catastrophic event occurs. This reduces the risk of in-flight engine failures and enhances overall flight safety.

- Flight Path Optimization for Hazard Avoidance

Analytical methods facilitate the optimization of flight paths to minimize exposure to potential hazards, such as severe weather conditions or restricted airspace. By integrating real-time weather data, airspace restrictions, and aircraft performance characteristics, data-driven algorithms can generate optimal flight paths that minimize risk and maximize efficiency. For example, advanced weather forecasting models can predict the location and intensity of thunderstorms along a flight path, allowing pilots or automated flight systems to reroute the aircraft around hazardous weather conditions, reducing the risk of turbulence-related incidents.

- Cybersecurity Threat Detection

With the increasing reliance on interconnected systems in modern aircraft and spacecraft, cybersecurity has become a critical risk mitigation concern. Analytical techniques are used to detect and prevent cyberattacks on aerospace systems. By analyzing network traffic, system logs, and user behavior, machine learning algorithms can identify anomalous patterns that indicate a potential cyber intrusion. For example, intrusion detection systems can be trained to recognize unauthorized access attempts or malicious software installations, allowing security personnel to respond quickly and prevent data breaches or system compromises.

- Material Degradation Prediction

The structural integrity of aircraft and spacecraft is paramount for safety. Analytical methods enable the prediction of material degradation due to factors such as fatigue, corrosion, and radiation exposure. By analyzing material properties, stress loads, and environmental conditions, data-driven models can estimate the remaining useful life of critical structural components. This allows for timely replacement or repair of components before they reach a critical failure point, reducing the risk of structural failures and ensuring the long-term safety of aerospace systems. Non-destructive testing data, such as ultrasonic scans or X-ray images, can be integrated into these models to provide more accurate assessments of material condition.

The application of advanced analytical techniques across these diverse areas of risk mitigation demonstrates the transformative potential of data science in aerospace engineering. The ability to predict failures, optimize flight paths, detect cyber threats, and assess material degradation enhances safety, reduces operational costs, and improves the overall reliability of aerospace systems.

Frequently Asked Questions

The following addresses common inquiries regarding the application of advanced analytical methods within the aerospace sector. These questions and answers aim to provide a clear and concise understanding of this evolving field.

Question 1: What specific types of data are analyzed within aerospace applications?

Aerospace utilizes a wide array of data, including sensor data from flight tests, wind tunnel measurements, satellite imagery, manufacturing process data, maintenance records, and meteorological information. The specific data types employed depend on the application and objectives of the analysis.

Question 2: How does this approach differ from traditional aerospace engineering methods?

Traditional aerospace engineering relies heavily on physics-based simulations and empirical testing. While these methods remain crucial, the data-driven approach complements them by extracting insights from large datasets. This allows for more accurate predictions, faster design cycles, and the identification of previously unknown relationships between various factors.

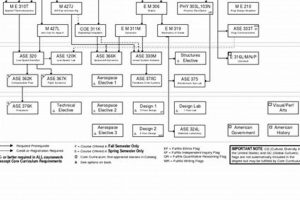

Question 3: What skills are required to work in this field?

A strong foundation in mathematics, statistics, and computer science is essential. Additionally, domain knowledge of aerospace engineering principles, such as aerodynamics, structures, and propulsion, is crucial for formulating relevant research questions and interpreting results effectively.

Question 4: Are there specific software tools and programming languages commonly used?

Python is widely used due to its extensive libraries for data analysis, machine learning, and visualization. Other tools include MATLAB, R, and specialized software packages for CFD analysis and finite element modeling. Proficiency in SQL and database management is also valuable for handling large datasets.

Question 5: What are the primary challenges associated with implementing these methods in aerospace?

Challenges include data quality issues, the need for robust computing infrastructure, the difficulty of integrating data from disparate sources, the shortage of skilled personnel, and the regulatory requirements associated with safety-critical aerospace applications.

Question 6: How is the accuracy and reliability of data-driven models validated in the aerospace context?

Rigorous validation is essential. Models are typically validated using independent datasets and assessed using appropriate performance metrics. Techniques such as cross-validation, sensitivity analysis, and uncertainty quantification are employed to ensure the robustness and reliability of the models.

Understanding these frequently asked questions provides a foundational understanding of the key considerations and nuances associated with data science applications in the aerospace sector.

Subsequent sections will delve into specific case studies and examples of successful implementations of these techniques in various aerospace domains.

Conclusion

The preceding discussion demonstrates that data science in aerospace engineering is more than a technological trend; it represents a fundamental shift in how aircraft and spacecraft are designed, manufactured, and operated. The application of advanced analytical techniques, ranging from machine learning to statistical modeling, enables a more data-driven approach to problem-solving, yielding tangible improvements in safety, efficiency, and performance. The ability to extract actionable insights from complex datasets is transforming traditional engineering practices, allowing for more informed decision-making at every stage of the aerospace lifecycle.

As the volume and complexity of aerospace data continue to grow, the importance of data science in aerospace engineering will only increase. Continued investment in developing skilled personnel, establishing robust data infrastructure, and refining analytical methodologies is essential to unlock the full potential of this powerful synergy. Embracing this data-driven paradigm will be critical for maintaining a competitive edge and ensuring continued innovation in the aerospace sector.