Understanding the typical activities and responsibilities assumed by professionals in this field provides a realistic perspective on the career. It encompasses a broad range of tasks, from designing aircraft and spacecraft to testing prototypes and analyzing data. For example, one might begin the day reviewing project specifications, followed by collaborative design sessions and concluding with performance analysis reports.

Gaining insight into the daily routines is beneficial for career exploration, aiding students and aspiring engineers in determining if the profession aligns with their interests and skills. It offers transparency into the challenges and rewards experienced in the aerospace sector. Furthermore, studying the evolution of these daily tasks reflects the advancements in technology and the changing demands within the industry over time.

The subsequent sections will delve into specific aspects such as common tasks, required skills, work environment, career progression, and future outlook within the aerospace engineering domain. These detailed explanations aim to provide a more granular understanding of what individuals entering this field can expect.

For individuals pursuing a career path in aerospace engineering, strategic planning and continuous development are paramount. The following recommendations offer guidance based on observations of successful professionals.

Tip 1: Cultivate a Strong Foundation in Core Sciences: A deep understanding of mathematics, physics, and computer science is essential. Mastery of these subjects provides the necessary analytical tools for problem-solving in aerospace contexts. Coursework should be supplemented with independent study to reinforce these concepts.

Tip 2: Develop Proficiency in CAD and Simulation Software: Proficiency in industry-standard software is crucial for design, analysis, and simulation. Practice with programs such as CATIA, ANSYS, and MATLAB enhances productivity and contributes to effective collaboration within engineering teams. Explore available tutorials and participate in relevant workshops.

Tip 3: Seek Internships and Research Opportunities: Practical experience is invaluable for bridging the gap between academic knowledge and real-world application. Internships at aerospace companies or participation in research projects provides exposure to engineering workflows and industry best practices. Actively seek out these opportunities and leverage them for skill development.

Tip 4: Enhance Communication and Teamwork Skills: Aerospace projects require collaboration among diverse teams. Effective communication, both written and verbal, is essential for conveying technical information and coordinating efforts. Participate in group projects and seek opportunities to improve these interpersonal skills.

Tip 5: Pursue Advanced Certifications and Continuing Education: The aerospace industry is constantly evolving. Staying current with emerging technologies and industry standards requires ongoing professional development. Consider pursuing relevant certifications or advanced degrees to enhance expertise and remain competitive.

Tip 6: Network with Industry Professionals: Building connections within the aerospace community can open doors to career opportunities and provide valuable insights. Attend industry conferences, join professional organizations, and connect with experienced engineers to expand professional network.

These guidelines emphasize the importance of a well-rounded skill set, blending theoretical knowledge with practical experience and interpersonal abilities. A commitment to continuous learning and networking is vital for long-term success.

The next section will explore the future trends shaping the aerospace engineering landscape and the opportunities they present for aspiring professionals.

1. Problem-solving

Problem-solving forms a cornerstone of the professional experience. Design, testing, and implementation processes invariably encounter unforeseen obstacles requiring analytical assessment and innovative solutions. The daily workflow necessitates identifying root causes, formulating potential remedies, and evaluating their effectiveness. This continuous cycle of challenge and resolution defines a substantial portion of the time commitment.

A practical example illustrating this connection can be found in the design of a new aircraft wing. During wind tunnel testing, engineers may discover unexpected aerodynamic instability. This requires a systematic approach to identify the source of the instability, which may involve computational fluid dynamics simulations, modifications to the wing geometry, and further testing. The engineer’s ability to analyze the problem, propose solutions, and validate them through experimentation directly impacts project timelines and performance outcomes. The ability to address these issues efficiently is critical to maintaining project momentum.

The capacity to effectively problem-solve not only ensures the successful completion of engineering tasks but also fosters innovation within the field. By continually addressing challenges and refining existing designs, engineers contribute to the advancement of aerospace technology and enhance the safety and efficiency of air and space travel. Addressing these issue in the aerospace industry are critical to advancement within it.

2. Technical Analysis

Technical analysis is an integral component of the professional’s routine. The ability to scrutinize complex data sets, interpret engineering schematics, and evaluate system performance is critical for informed decision-making. This process frequently involves employing specialized software tools and methodologies to dissect intricate problems and derive actionable insights. Deficiencies in technical analysis capabilities can directly impede progress, resulting in flawed designs, inaccurate performance predictions, and potential safety hazards. The application of technical principles is pivotal for ensuring that projects adhere to stringent performance criteria and regulatory standards.

A real-world example of the application of this concept is the structural analysis of aircraft components. Engineers routinely use finite element analysis (FEA) software to model the stress and strain distribution within a wing structure. This involves meticulously defining material properties, applying representative loads, and interpreting the resulting stress contours. The identification of stress concentrations, for example, would necessitate design modifications to improve structural integrity and prevent potential failure. Similarly, analyzing the performance data from flight tests to validate computational models and refine aerodynamic designs exemplifies the practical significance of technical analytical processes.

In summary, technical analytical proficiency is a fundamental requirement for achieving success within this profession. The ability to conduct thorough analyses, derive meaningful insights, and translate findings into tangible improvements is paramount. Ongoing professional development and familiarity with industry-standard tools are critical for maintaining a competitive advantage and contributing to the advancement of aerospace technologies. Therefore, the connection between proficiency in this area and the workflow cannot be overstated.

3. Team Collaboration

Aerospace projects, by their very nature, are multidisciplinary endeavors requiring extensive collaboration. The daily routine of an aerospace engineer is fundamentally intertwined with interactions across various teams, including design, manufacturing, testing, and regulatory compliance. The scope and complexity of these projects necessitate a synchronized effort, wherein expertise is shared, ideas are debated, and decisions are collectively made. A breakdown in team coordination can lead to critical errors, delays, and increased costs, directly affecting the project’s overall success. The aerospace industry is built on the efforts of many.

Consider, for example, the development of a new aircraft engine. This process involves mechanical engineers designing the engine core, electrical engineers developing control systems, and software engineers writing the flight control algorithms. These teams must communicate effectively to ensure that all components function seamlessly and meet performance specifications. Design reviews, progress meetings, and shared documentation platforms are essential for maintaining transparency and fostering a collaborative environment. Problems arising in one area of the project can cascade to others, underscoring the need for robust communication channels and a shared understanding of project goals. Coordination is critical for project success.

In conclusion, the aerospace engineer’s professional life is inextricably linked to the ability to collaborate effectively within diverse teams. Success hinges on fostering open communication, respecting different viewpoints, and working cohesively towards shared objectives. Understanding and cultivating team collaboration skills is not merely beneficial but rather a core competency for anyone seeking to excel in this demanding field, with the ability to achieve the best for the project.

4. Design Implementation

Design implementation, as a critical aspect, represents the transition of theoretical concepts and engineering schematics into tangible, functional prototypes or final products. It occupies a significant portion of the daily activities, requiring a combination of technical expertise, practical skill, and meticulous attention to detail. The success of design implementation directly impacts project timelines, performance metrics, and overall mission objectives.

- Material Selection and Fabrication

The selection of appropriate materials and the application of suitable fabrication techniques are fundamental to effective design implementation. The choice of materials must align with performance requirements, environmental conditions, and cost constraints. Engineers are often involved in specifying material properties, overseeing fabrication processes, and ensuring adherence to quality control standards. Incorrect material selection or flawed fabrication can lead to structural failures or performance degradation, ultimately impacting safety and reliability. For example, during aircraft design, engineers decide the correct aluminum alloy. This then must be fabricated into the aircraft body.

- System Integration and Interface Management

Aerospace systems are inherently complex, comprising numerous interconnected components. Design implementation necessitates careful integration of these subsystems, ensuring seamless communication and functionality. This involves defining interface specifications, managing signal compatibility, and verifying system-level performance. Poor integration can lead to system malfunctions, reduced efficiency, or even catastrophic failures. For instance, integrating an aircraft’s avionics with its flight control systems is crucial for navigation and stability.

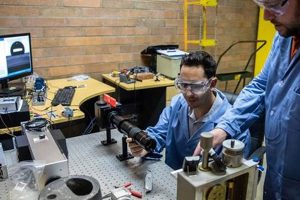

- Prototyping and Testing

The construction and rigorous testing of prototypes are essential elements of design implementation. Prototypes enable engineers to validate design assumptions, identify potential flaws, and refine system performance. Testing protocols must simulate real-world operating conditions and encompass a range of failure scenarios. The results of prototype testing inform design modifications and ensure that the final product meets performance requirements. An example in the field of rocket engine design. Engineers can build scaled down version of rocket components, to test various parameters.

- Adherence to Regulatory Standards and Safety Protocols

The aerospace industry is subject to stringent regulatory oversight and safety standards. Design implementation must adhere to these regulations, ensuring that all products meet established safety criteria. This involves documenting design decisions, conducting safety analyses, and complying with certification requirements. Failure to comply with regulatory standards can result in project delays, fines, or even the grounding of aircraft. During the design of the fuselage, the engineers must comply with Federal Aviation Administration requirements.

These interconnected facets highlight the critical role within this field. From initial concept to final product, is shaped by their ability to translate ideas into reality while adhering to strict technical and regulatory constraints. Understanding these aspects offers valuable insight into the challenges and rewards inherent in this area.

5. Testing and Validation

Testing and validation are paramount in aerospace engineering, forming an essential part of the daily workflow. It assures the integrity, reliability, and safety of aerospace systems and components, therefore it constitutes a substantial time investment for those in the field. Failure to adequately test and validate designs can have catastrophic consequences, highlighting the critical nature of these activities.

- Simulation and Modeling Verification

A significant aspect involves verifying the accuracy of simulations and models used in the design process. Engineers utilize computational tools to predict the behavior of aerospace systems under various conditions. Testing provides empirical data to validate these models, ensuring their fidelity. For example, wind tunnel testing of aircraft wing models provides data to validate computational fluid dynamics simulations, confirming the predicted aerodynamic performance. This directly relates to the professional routine, as it involves planning, executing, and analyzing the output of simulation runs and physical tests, and making iterative adjustments to design. Discrepancies are thoroughly investigated, possibly leading to design changes or refinement of the simulation methodology.

- Component and System-Level Testing

Aerospace systems undergo rigorous testing at both the component and system levels. Component-level testing focuses on individual parts, such as sensors, actuators, and structural elements. System-level testing evaluates the integrated performance of multiple components working together. For example, engineers may test the landing gear system of an aircraft to ensure it can withstand the stresses of landing. Testing activities consume considerable time, as the systems must be properly setup, instrumented, and operated throughout the process. The information acquired during the process often directs engineers in future revisions.

- Environmental Qualification Testing

Aerospace systems must operate reliably under extreme environmental conditions, including high and low temperatures, vibration, and radiation exposure. Environmental qualification testing simulates these conditions to verify that systems can withstand them. For instance, satellite components undergo thermal vacuum testing to simulate the conditions of space. The amount of time spent developing test plans and performing these activities adds up. In this instance, design considerations can also be changed.

- Flight Testing and Data Analysis

Flight testing is the ultimate validation of an aircraft’s performance and safety. Test pilots and engineers conduct flight tests to evaluate the aircraft’s handling characteristics, stability, and performance under real-world conditions. Data from flight tests is carefully analyzed to identify any issues or areas for improvement. The flight data is then utilized to ensure models and simulations are correct. Planning for these events can take time in the initial stages. Then once the data is received, it is analyzed and compared to models.

In summary, testing and validation are crucial elements in ensuring the dependability and safety of air and space systems. These operations involve thorough analyses and careful planning, consuming a significant amount of time for aerospace engineers. The information obtained guarantees models are correct and up to date, and design features are validated for final use.

Frequently Asked Questions Regarding a Day in the Life of an Aerospace Engineer

The following section addresses common inquiries concerning the daily activities and responsibilities of professionals within this field. The objective is to provide clarity and realistic expectations for individuals considering or pursuing a career in aerospace engineering.

Question 1: What constitutes the primary focus of the daily tasks undertaken by an aerospace engineer?

The daily tasks typically encompass a combination of design, analysis, testing, and collaboration. Engineers may work on designing aircraft components, analyzing aerodynamic performance, conducting simulations, or collaborating with other team members to solve technical challenges. The specific activities vary depending on the engineer’s specialization and the project phase.

Question 2: What are the key technical skills that are essential for effective performance as an aerospace engineer?

Essential technical skills include proficiency in mathematics, physics, computer-aided design (CAD) software, computational fluid dynamics (CFD), finite element analysis (FEA), and programming languages such as MATLAB or Python. A strong understanding of aerospace principles, such as aerodynamics, propulsion, and structural mechanics, is also crucial.

Question 3: How much time is typically spent on collaborative activities versus individual work?

The proportion of time dedicated to collaboration versus individual work varies depending on the project and the engineer’s role. However, given the multidisciplinary nature of aerospace projects, engineers often spend a significant portion of their day collaborating with other team members, including designers, manufacturing specialists, and testing personnel. Team meetings, design reviews, and collaborative problem-solving sessions are common occurrences.

Question 4: What types of software tools are commonly utilized by aerospace engineers in their daily work?

Aerospace engineers employ a variety of software tools for design, analysis, and simulation. Common examples include CAD software such as CATIA or SolidWorks for creating 3D models, CFD software such as ANSYS Fluent or OpenFOAM for simulating fluid flow, and FEA software such as ABAQUS or NASTRAN for structural analysis. MATLAB is often used for data analysis and algorithm development.

Question 5: What are the typical challenges encountered in this profession, and how are they addressed?

Aerospace engineers often face challenges related to design optimization, system integration, and performance validation. These challenges may arise from conflicting requirements, technological limitations, or unforeseen issues during testing. Engineers address these challenges through rigorous analysis, iterative design improvements, and collaboration with experts from various disciplines.

Question 6: What opportunities exist for career advancement and specialization within the aerospace engineering field?

Career advancement opportunities include roles such as project manager, lead engineer, or technical specialist. Specialization options encompass areas such as aerodynamics, propulsion, structures, avionics, and space systems. Engineers may pursue advanced degrees or certifications to enhance their expertise and qualify for specialized positions.

In summary, the daily experiences of professionals are multifaceted, demanding a blend of technical expertise, collaborative skills, and problem-solving abilities. A clear understanding of these aspects is beneficial for career planning and professional development.

The subsequent section will provide a conclusion, summarizing key insights and offering a final perspective on the realities of this engineering field.

Conclusion

The preceding analysis has illuminated the multifaceted nature of “day in the life of an aerospace engineer.” Emphasis has been placed on the critical roles of problem-solving, technical analysis, team collaboration, design implementation, and testing and validation. The integration of these elements defines the operational realities and professional responsibilities assumed by individuals in this field. Further, addressing the common questions has provided clarity regarding required skills, typical challenges, and opportunities for career advancement.

The aerospace engineering profession demands a continuous commitment to learning, adaptation, and innovation. Understanding the daily workflow, responsibilities, and challenges associated with this career is crucial for informed decision-making and successful navigation within the industry. The evolution of aerospace technology presents both challenges and opportunities, requiring engineers to remain at the forefront of scientific and technological advancements.