An academic and research unit combines the principles of aeronautical science with those of mechanical design and manufacturing. This integration fosters a multi-faceted approach to solving complex engineering problems, preparing graduates for a wide array of careers and research endeavors. The combination is typical in many institutions offering advanced engineering degrees.

Such a collaborative structure offers advantages like shared resources, interdisciplinary research opportunities, and a broader curriculum for students. Historically, this grouping reflects the increasing overlap between aerospace technologies and conventional mechanical engineering principles, particularly in areas like materials science, fluid dynamics, and control systems. The synergy encourages innovation and allows researchers to tackle projects that require expertise in both domains.

The following sections will explore current research initiatives, educational programs, and industry collaborations within such integrated entities, illustrating their impact on technological advancements and the training of future engineers.

Guidance for Success in an Integrated Engineering Program

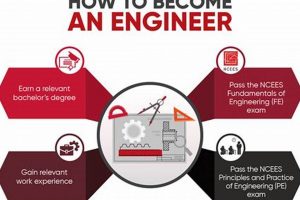

The following guidance aims to provide prospective and current students with strategies for maximizing their academic and professional development within an integrated aerospace and mechanical engineering curriculum. These recommendations are designed to foster a strong foundation for a successful career in these demanding fields.

Tip 1: Prioritize Foundational Knowledge: A solid understanding of core mechanical engineering principles, such as thermodynamics, fluid mechanics, and materials science, is critical for success in aerospace applications. Conversely, aerospace-specific knowledge, like aerodynamics and propulsion, enhances mechanical engineering design projects. Focus on mastering fundamentals.

Tip 2: Cultivate Interdisciplinary Collaboration: Seek opportunities to work on projects that bridge the gap between aerospace and mechanical engineering. Participating in multi-disciplinary teams enhances problem-solving skills and exposes students to different perspectives. For example, design a remotely operated vehicle (ROV) which required skills for both disciplines.

Tip 3: Engage in Hands-on Experience: Supplement theoretical knowledge with practical experience through internships, research projects, or participation in engineering competitions. Building a small-scale wind tunnel, designing and fabricating aircraft components, or working on a rocket propulsion system provides invaluable hands-on skills. These actions solidify concepts learned in the classroom.

Tip 4: Develop Strong Computational Skills: Proficiency in computational tools is essential for analyzing complex engineering problems. Familiarize oneself with software packages commonly used in both aerospace and mechanical engineering, such as CAD/CAM software, finite element analysis (FEA) tools, and computational fluid dynamics (CFD) software. Practice using these tools to simulate real-world scenarios.

Tip 5: Seek Mentorship and Guidance: Connect with experienced professionals and faculty members who can offer mentorship and guidance. Their insights can prove invaluable in navigating career choices, identifying research opportunities, and overcoming challenges encountered during one’s academic journey. Actively participate in departmental seminars and workshops to learn from experts in the field.

Tip 6: Stay Current with Industry Trends: Keep abreast of the latest developments and emerging technologies in both aerospace and mechanical engineering. Read industry publications, attend conferences, and engage in online forums to stay informed. Emerging technologies such as additive manufacturing, advanced composite materials, and autonomous systems are rapidly transforming these fields.

These strategies highlight the importance of a well-rounded educational experience and a commitment to continuous learning. By focusing on foundational knowledge, practical experience, and interdisciplinary collaboration, students can maximize their potential for success.

The subsequent sections will delve into specific research areas and career paths that are particularly relevant to individuals trained in both aerospace and mechanical engineering.

1. Curriculum Integration

Curriculum integration within an academic unit merging aerospace and mechanical engineering disciplines is a critical determinant of program effectiveness. The intentional alignment of courses, projects, and research opportunities allows students to develop a comprehensive understanding of both fields and their interdependencies. A poorly integrated curriculum may result in graduates lacking the breadth necessary to address complex, multi-faceted engineering challenges. Real-world examples of successful integration include the development of courses that apply mechanical engineering principles to aerospace design problems, or vice versa. For example, a course on finite element analysis might be applied to the design of both aircraft wings and automotive suspension systems, highlighting the shared analytical tools and techniques.

A well-integrated curriculum can enhance student learning outcomes by fostering a deeper appreciation for the underlying principles of engineering, regardless of specific application. Practical applications of this understanding extend to the design of advanced technologies, such as unmanned aerial vehicles (UAVs), which require expertise in both aerodynamics and mechanical systems. Furthermore, students benefit from increased career flexibility, as they are prepared for roles in either aerospace or mechanical engineering industries. Curriculum committees must carefully consider the sequencing of courses and the inclusion of interdisciplinary projects to achieve effective integration. For example, students should have foundational knowledge of thermodynamics and fluid mechanics before progressing to courses on propulsion systems.

In conclusion, curriculum integration is not merely an administrative task, but a fundamental aspect of the academic unit. Its effectiveness directly impacts the quality of education, the preparation of graduates for the workforce, and the overall success of the academic and research programs. The challenge lies in continually adapting the curriculum to reflect advancements in both fields and ensuring that students develop a holistic understanding of engineering principles and practices.

2. Research Synergies

Research synergies within an academic department integrating aerospace and mechanical engineering represent a critical element driving innovation and progress. These synergies arise from the convergence of expertise, resources, and methodologies across the two disciplines, creating opportunities for collaborative projects and advancements that would not be possible within isolated research groups.

- Cross-Disciplinary Projects

Collaborative research projects are a direct result of the integration, where the expertise of mechanical engineers complements and enhances aerospace endeavors, and vice versa. For example, advanced materials developed for aerospace applications, like high-strength composites, can be adapted and improved upon for use in automotive or industrial machinery, benefiting from the different testing and validation approaches used in each field. Similarly, mechanical engineering expertise in robotics and automation can be leveraged to enhance the efficiency and precision of aircraft manufacturing processes.

- Shared Resources and Infrastructure

A combined department typically pools resources such as advanced testing facilities, computational resources, and specialized equipment. This shared infrastructure allows researchers to access tools and technologies that might otherwise be unavailable, fostering a more diverse and comprehensive research environment. Wind tunnels, materials testing labs, and high-performance computing clusters can be utilized by researchers from both disciplines, leading to more efficient use of resources and increased research output.

- Interdisciplinary Education and Training

The integrated structure encourages interdisciplinary education and training opportunities for graduate students and postdoctoral researchers. This exposure to different engineering perspectives broadens their skill sets and prepares them for careers that require a holistic understanding of engineering principles. Students trained in both aerospace and mechanical engineering are well-equipped to tackle complex engineering challenges that span multiple disciplines, such as the development of advanced propulsion systems or the design of autonomous vehicles.

- Funding Opportunities and Grants

A collaborative research environment can enhance the department’s ability to secure external funding and grants. Research proposals that address challenges requiring expertise in both aerospace and mechanical engineering are often more competitive, as they demonstrate a broader impact and potential for innovation. Funding agencies often prioritize projects that foster interdisciplinary collaboration and address societal needs that require a multi-faceted approach.

These research synergies are vital for maintaining a vibrant and competitive academic environment. The cross-pollination of ideas and expertise between aerospace and mechanical engineering leads to advancements in both fields, benefiting society through the development of innovative technologies and the training of highly skilled engineers.

3. Faculty Expertise

The strength and reputation of an academic unit combining aerospace and mechanical engineering are inextricably linked to the expertise of its faculty. Their collective knowledge, experience, and research acumen are the cornerstones upon which the educational and research missions of the department are built.

- Disciplinary Breadth and Depth

A successful integrated department requires faculty with expertise spanning a wide range of disciplines within both aerospace and mechanical engineering. This includes, but is not limited to, aerodynamics, propulsion, structural mechanics, materials science, control systems, manufacturing processes, and robotics. The presence of faculty with deep knowledge in specialized areas ensures that students receive comprehensive training and that the department can conduct cutting-edge research across multiple fronts. For instance, faculty specializing in computational fluid dynamics can contribute to both aircraft design and turbomachinery research, while experts in composite materials can advance both aerospace structures and automotive components.

- Research Productivity and Innovation

Faculty members are the primary drivers of research innovation within the department. Their research activities not only contribute to the advancement of knowledge in their respective fields but also provide valuable opportunities for students to participate in cutting-edge projects. High research productivity, as evidenced by publications in peer-reviewed journals and presentations at international conferences, enhances the department’s reputation and attracts top students and funding. Examples include faculty leading research on novel propulsion systems for spacecraft, developing advanced materials for lightweight aircraft structures, or designing innovative robotic systems for manufacturing aerospace components.

- Teaching Excellence and Mentorship

Effective teaching is essential for imparting knowledge and skills to the next generation of engineers. Faculty members must be able to clearly communicate complex concepts and engage students in active learning experiences. Furthermore, mentorship plays a crucial role in guiding students’ academic and career development. Faculty who are actively involved in mentoring students can provide valuable advice, guidance, and support, helping them to achieve their full potential. This may involve providing research opportunities, writing letters of recommendation, or connecting students with industry professionals.

- Industry Engagement and Collaboration

Strong connections with industry are vital for ensuring that the department’s research and education programs remain relevant and aligned with the needs of the workforce. Faculty members who actively engage with industry can bring real-world problems into the classroom and provide students with opportunities for internships, co-op programs, and industry-sponsored research projects. Collaboration with industry can also lead to the development of new technologies and the transfer of knowledge from academia to industry. Examples include faculty working with aerospace companies to develop advanced manufacturing techniques for aircraft components or collaborating with automotive manufacturers to improve the performance and efficiency of engines.

In summary, the expertise of the faculty is a critical factor in determining the success of an integrated aerospace and mechanical engineering unit. A department with a strong and diverse faculty can provide students with a world-class education, conduct groundbreaking research, and contribute to the advancement of engineering knowledge and practice.

4. Industry Partnerships

Industry partnerships are a cornerstone of a thriving aerospace and mechanical engineering academic department. These collaborations directly influence curriculum relevance, research direction, and graduate employability. The connection operates as a feedback loop: industry identifies needs and technological gaps, prompting the department to tailor its research and academic programs accordingly. This ensures that graduates possess skills and knowledge aligned with current industry demands. The practical significance of these partnerships is evident in the increased opportunities for students to participate in internships, co-op programs, and sponsored research projects, thereby gaining real-world experience and building professional networks.

One manifestation of this relationship involves collaborative research projects. For example, a major aerospace manufacturer might partner with the department to investigate new materials for aircraft wings, providing funding, resources, and technical expertise. Simultaneously, mechanical engineering-focused companies can partner with the same department to improve efficiency and reliability of internal combustion engine. These projects expose students and faculty to real-world engineering challenges and contribute to advancements in both theoretical knowledge and practical application. Furthermore, industry experts often serve on advisory boards, providing guidance on curriculum development and ensuring that the department remains at the forefront of technological innovation. This practical knowledge ensures students gain exposure to the most relevant and up-to-date practices.

In conclusion, industry partnerships are not merely beneficial but essential for an aerospace and mechanical engineering department. These collaborations drive innovation, enhance educational programs, and improve graduate employment prospects. The challenges lie in cultivating and maintaining these relationships, ensuring mutual benefit, and adapting to the evolving needs of both academia and industry. The strength of these partnerships ultimately determines the department’s ability to contribute meaningfully to the advancement of aerospace and mechanical engineering fields.

5. Resource Allocation

Resource allocation is a critical function within any academic entity, particularly so in a department dedicated to aerospace and mechanical engineering. The strategic deployment of available funds, facilities, and personnel directly influences the quality of education, the scope and impact of research, and the overall competitiveness of the department. Effective resource allocation ensures that the department can fulfill its core missions of teaching, research, and service to the community.

- Capital Equipment and Infrastructure

A significant portion of resource allocation is dedicated to the acquisition and maintenance of capital equipment and infrastructure. This includes specialized laboratories for materials testing, wind tunnels for aerodynamic studies, high-performance computing clusters for simulations, and advanced manufacturing equipment for prototyping. The availability of state-of-the-art facilities is essential for conducting cutting-edge research and providing students with hands-on experience. For example, a department might invest in a new electron microscope to enable research on advanced composite materials, or upgrade its wind tunnel to accommodate larger-scale testing of aircraft models. These investments directly impact the department’s ability to attract top researchers and students.

- Faculty and Staff Support

Attracting and retaining qualified faculty and staff is another key aspect of resource allocation. This includes providing competitive salaries, benefits, and research funding to support their scholarly activities. Departments must also invest in professional development opportunities for faculty and staff to keep them abreast of the latest advancements in their fields. Resource allocation decisions must also consider the need for administrative and technical support staff to ensure the smooth operation of the department. For instance, a department might allocate funds to hire a laboratory manager to oversee the maintenance and operation of specialized equipment, or to provide travel grants for faculty to attend conferences and present their research.

- Student Support and Scholarships

Resource allocation decisions also have a direct impact on student support and scholarships. Providing financial assistance to students can help to attract and retain top talent, and can also make education more accessible to students from diverse backgrounds. Departments may allocate funds to provide scholarships, fellowships, and research assistantships to deserving students. Furthermore, resources may be allocated to support student organizations, design teams, and other extracurricular activities that enhance their educational experience. For example, a department might provide funding to support a student team competing in a national aerospace design competition, or to offer scholarships to students who demonstrate exceptional academic achievement.

- Operating Expenses and Supplies

A significant portion of the department’s budget is allocated to operating expenses and supplies. This includes costs associated with utilities, maintenance, office supplies, and laboratory consumables. Efficient management of these expenses is essential for ensuring that the department can operate effectively within its budgetary constraints. Departments may implement strategies to reduce costs, such as energy conservation measures or the use of shared laboratory facilities. The efficient allocation of resources to cover these essential expenses directly impacts the department’s ability to maintain a functional and productive learning and research environment.

These facets of resource allocation are interconnected and collectively determine the department’s overall success. The effective management and strategic deployment of available resources are essential for fostering a vibrant and innovative academic environment, attracting top talent, and contributing to advancements in aerospace and mechanical engineering. Failure to adequately address any of these facets can have significant consequences, limiting the department’s ability to achieve its full potential.

Frequently Asked Questions

The following questions address common inquiries regarding integrated programs of study combining aerospace and mechanical engineering, aiming to clarify the scope, benefits, and potential challenges of such academic pursuits.

Question 1: What are the primary advantages of pursuing a degree that combines aerospace and mechanical engineering?

A combined degree program provides a broader foundation in engineering principles, enhancing versatility and adaptability in the job market. Graduates possess expertise applicable to a wider range of industries and are well-suited for interdisciplinary roles requiring knowledge of both aerospace and mechanical systems.

Question 2: How does the curriculum of a combined program differ from that of separate aerospace and mechanical engineering programs?

While core courses in each discipline are typically retained, a combined program often integrates coursework and projects that highlight the synergies between aerospace and mechanical engineering. This may involve cross-listed courses, interdisciplinary design projects, and research opportunities that span both fields.

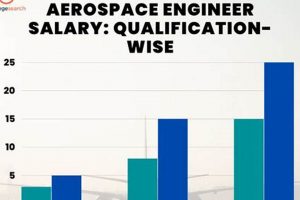

Question 3: What career paths are typically available to graduates of a combined aerospace and mechanical engineering program?

Graduates are well-prepared for careers in aerospace, automotive, manufacturing, energy, and other industries requiring a broad understanding of engineering principles. Specific roles may include design engineering, research and development, project management, and consulting.

Question 4: What are the potential challenges of pursuing a combined degree program, and how can these be overcome?

A combined program can be more demanding than a single-discipline program, requiring a significant commitment of time and effort. To mitigate this challenge, students should prioritize effective time management, seek out mentorship and support from faculty, and actively engage in interdisciplinary learning opportunities.

Question 5: Are there specific research areas that are particularly well-suited to an integrated aerospace and mechanical engineering approach?

Yes, several research areas benefit significantly from an integrated approach, including advanced materials development, propulsion systems design, robotics and automation, and sustainable energy technologies. These areas often require expertise in both aerospace and mechanical engineering principles.

Question 6: How important are internships and co-op experiences for students in a combined aerospace and mechanical engineering program?

Internships and co-op experiences are highly valuable for students in this field. They provide opportunities to apply classroom knowledge to real-world engineering problems, develop practical skills, and build professional networks, enhancing their career prospects after graduation.

In summary, pursuing a degree that integrates aerospace and mechanical engineering offers numerous advantages, including a broader foundation in engineering principles, increased career flexibility, and enhanced opportunities for interdisciplinary research. However, it is important to be aware of the potential challenges and to take proactive steps to ensure success.

The following section will delve into specific examples of successful interdisciplinary projects and collaborations within integrated aerospace and mechanical engineering programs.

Conclusion

The preceding discussion has illuminated the multifaceted nature of an integrated academic structure. Key aspects such as curriculum integration, research synergies, faculty expertise, industry partnerships, and resource allocation were analyzed, demonstrating their interconnectedness and impact on the overall effectiveness of the department of aerospace and mechanical engineering. These factors collectively determine the quality of education, the scope of research endeavors, and the preparedness of graduates for professional careers.

Sustained commitment to these principles is essential for ensuring continued relevance and advancement in the rapidly evolving fields of aerospace and mechanical engineering. The ongoing pursuit of innovative teaching methods, cutting-edge research initiatives, and strategic collaborations will be vital for maintaining a competitive edge and contributing meaningfully to technological progress. Therefore, continued strategic investment and adaptation within the department of aerospace and mechanical engineering are imperative for its sustained success and broader societal impact.

![Why Australian Aerospace Engineering Matters - [Year] Trends Innovating the Future of Flight with Reliable Aviation Solutions Why Australian Aerospace Engineering Matters - [Year] Trends | Innovating the Future of Flight with Reliable Aviation Solutions](https://mixaerospace.com/wp-content/uploads/2026/01/th-836-300x200.jpg)