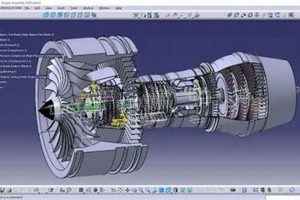

A virtual representation mirroring a physical object or system spanning its lifecycle, using real-time data and simulation, has become increasingly prevalent. These virtual models, especially within technically intricate sectors, offer opportunities for comprehensive analysis, prediction, and optimization of performance and design. For example, simulating the performance of a jet engine under varying conditions allows engineers to identify potential issues before physical prototyping occurs.

This technology offers numerous advantages, including reduced development costs, improved product quality, and enhanced operational efficiency. The capacity to perform virtual testing and predictive maintenance leads to substantial cost savings. Historically, industries relied heavily on physical prototypes and reactive maintenance strategies, often incurring significant expenses and downtime. This paradigm shift facilitates a proactive approach to problem-solving and continuous improvement.

The following sections will delve into specific applications, key technological components, and future trends shaping the development and implementation of this technology within demanding engineering disciplines. The exploration will consider the impact on design optimization, predictive maintenance strategies, and the overall lifecycle management of complex systems.

Best Practices

The effective implementation of virtual models requires a strategic approach focusing on data fidelity, model accuracy, and integration with existing workflows. The following guidelines provide insights for maximizing the benefits of this technology.

Tip 1: Prioritize Data Integrity. Accurate and timely data streams are fundamental. Implement robust sensor networks and data validation processes to ensure the virtual representation accurately reflects the physical counterpart’s state. For instance, inaccurate temperature readings in a turbine model will yield flawed performance predictions.

Tip 2: Emphasize Model Calibration and Validation. Regularly calibrate the virtual representation against real-world performance data. This iterative process refines model accuracy and improves predictive capabilities. Comparative analyses between simulated and physical test results are crucial for validation.

Tip 3: Integrate Across the Product Lifecycle. Extend the application of virtual representations beyond the design phase. Utilize these models for manufacturing process optimization, operational monitoring, and predictive maintenance planning. A holistic integration maximizes the return on investment.

Tip 4: Focus on Computational Efficiency. Complex simulations demand significant computational resources. Optimize algorithms and leverage high-performance computing infrastructure to reduce simulation runtimes. Efficient simulations enable rapid design iterations and real-time operational insights.

Tip 5: Address Cybersecurity Concerns. The interconnected nature of virtual representations exposes them to potential security threats. Implement robust cybersecurity protocols to protect sensitive design data and prevent unauthorized access to operational systems. Secure data transmission and access controls are paramount.

Tip 6: Promote Interdisciplinary Collaboration. Effective utilization requires expertise from diverse fields, including mechanical engineering, aerospace engineering, data science, and software development. Foster collaboration between these disciplines to create comprehensive and insightful virtual models.

Tip 7: Invest in Employee Training. Ensure personnel possess the necessary skills to effectively utilize and interpret the outputs of virtual models. Comprehensive training programs are essential for maximizing the value derived from this technology. Hands-on workshops and specialized courses are beneficial.

By adhering to these best practices, organizations can effectively leverage this technology to drive innovation, reduce costs, and enhance the performance of complex systems.

The subsequent sections will explore the evolving landscape of this tech, examining future trends and potential challenges in achieving widespread adoption.

1. Design Optimization

Design optimization, when integrated with virtual representations, revolutionizes the way mechanical and aerospace systems are conceived, analyzed, and refined. This synergy enables engineers to explore a vast design space, identify optimal configurations, and improve overall system performance with unprecedented efficiency.

- Parametric Analysis and Simulation

Virtual models facilitate extensive parametric studies by allowing engineers to modify design parameters and observe their impact on performance metrics. For example, in aircraft design, wing geometry can be iteratively adjusted within the virtual representation to minimize drag and maximize lift, prior to any physical prototyping. This accelerates the design cycle and reduces reliance on costly physical tests.

- Multi-Objective Optimization

Aerospace and mechanical systems often involve conflicting design objectives, such as minimizing weight while maximizing structural integrity. Virtual representations enable the simultaneous optimization of multiple objectives through advanced algorithms. This leads to balanced designs that meet diverse performance requirements effectively. Consider optimizing a turbine blade for both thermal resistance and mechanical strength under extreme operating conditions.

- Early Stage Validation and Verification

Virtual prototyping provides an opportunity to validate design concepts early in the development process. Potential design flaws and performance limitations can be identified and addressed before committing to manufacturing. For example, a virtual model of a mechanical assembly can be subjected to simulated loads and stresses to ensure structural integrity. This early validation process reduces the risk of costly rework later in the development cycle.

- Generative Design Exploration

Advanced algorithms, combined with virtual models, allow for the exploration of unconventional design solutions. Generative design tools can automatically generate a range of design options that meet specific performance criteria. This expands the design space and enables engineers to discover innovative solutions that might not have been conceived through traditional design methods. For instance, a generative design algorithm could create lightweight, high-strength components for aerospace applications, optimizing material usage and structural performance.

The integration of design optimization techniques with virtual representations offers a powerful approach to creating more efficient, reliable, and cost-effective mechanical and aerospace systems. By leveraging virtual prototyping, engineers can explore a broader range of design possibilities, identify optimal solutions, and reduce the risks associated with traditional design approaches.

2. Predictive Maintenance

Predictive maintenance, leveraged through virtual models, represents a paradigm shift in maintaining mechanical and aerospace systems. This approach moves beyond traditional reactive and preventative maintenance strategies, enabling proactive identification and mitigation of potential failures before they occur.

- Real-Time Condition Monitoring

Virtual models facilitate the continuous monitoring of critical system parameters, such as temperature, vibration, and pressure. Data streams from sensors embedded in physical assets are fed into the virtual representation, allowing for real-time assessment of component health. An anomaly detected in the virtual model can trigger alerts and initiate diagnostic procedures before a physical failure manifests. For example, detecting elevated bearing temperatures in a virtual engine model can prompt inspection and lubrication before a costly engine failure.

- Remaining Useful Life (RUL) Prediction

By integrating historical data, real-time sensor information, and physics-based simulation, virtual models enable the prediction of remaining useful life for critical components. This predictive capability allows maintenance to be scheduled proactively, minimizing downtime and optimizing resource allocation. For instance, predicting the RUL of a turbine blade based on its thermal and mechanical stress history allows for planned replacement before failure, preventing catastrophic engine damage.

- Failure Mode and Effects Analysis (FMEA) Simulation

Virtual models provide a platform for simulating potential failure scenarios and assessing their impact on system performance. By virtually testing various failure modes, engineers can identify critical vulnerabilities and develop mitigation strategies. For example, simulating a hydraulic system failure in a virtual aircraft model can inform the design of redundant systems and emergency procedures. This proactive approach enhances system safety and reliability.

- Optimized Maintenance Scheduling

The predictive capabilities of virtual models enable the optimization of maintenance schedules. By considering component health, operational demands, and resource constraints, maintenance activities can be scheduled to minimize downtime and maximize system availability. For example, optimizing the maintenance schedule for a fleet of aircraft based on individual component RUL predictions can significantly reduce maintenance costs and improve operational efficiency.

The integration of predictive maintenance strategies with virtual models offers a transformative approach to asset management. By leveraging real-time data, advanced simulation, and predictive algorithms, organizations can enhance system reliability, reduce maintenance costs, and improve overall operational efficiency. The proactive nature of predictive maintenance supported by virtual representation translates into significant cost savings and increased system uptime, making it a crucial component of modern engineering practices.

3. Lifecycle Management

Lifecycle management, encompassing design, manufacturing, operation, maintenance, and eventual disposal, is inextricably linked with virtual representations in mechanical and aerospace engineering. This technology facilitates a comprehensive understanding and optimization of a system’s performance at each stage of its existence. The integration allows for informed decision-making from initial conception to decommissioning, ensuring efficiency, reliability, and sustainability.

The significance lies in enabling a closed-loop feedback system. Data generated during the operational phase informs design improvements for subsequent generations. For instance, performance data from in-service aircraft engines, captured by sensors and integrated into the engine’s virtual representation, can identify design weaknesses or areas for optimization in future engine models. This iterative process leads to continuous improvements in performance, durability, and reduced environmental impact. Furthermore, simulations within the virtual environment can predict the effects of wear and tear, informing maintenance schedules and extending the operational life of the system. Effective lifecycle management, driven by a virtual representation, minimizes unforeseen costs and maximizes the value derived from complex assets.

In conclusion, the coupling of virtual representations with lifecycle management provides a strategic framework for mechanical and aerospace engineering. This integration fosters continuous improvement, informed decision-making, and optimized resource allocation throughout the entire system lifespan. By addressing challenges proactively and leveraging data-driven insights, this approach leads to more efficient, reliable, and sustainable engineering solutions. The capacity to simulate, predict, and optimize at every stage contributes significantly to long-term performance and reduced lifecycle costs.

4. System Performance

The relationship between system performance and virtual representations in mechanical and aerospace engineering is a symbiotic one, where the virtual model serves as both a predictor and an optimizer of physical system behavior. Performance, defined as the fulfillment of intended functions within specified constraints, is fundamentally enhanced by the predictive capabilities afforded by these virtual constructs. The creation and maintenance of a virtual representation demands a continuous influx of real-time operational data, coupled with sophisticated simulation algorithms. This data stream allows engineers to assess current system performance, predict future states, and identify potential areas for improvement before they manifest in the physical system. For example, in aerospace, a virtual representation of an aircraft wing constantly analyzes aerodynamic data to optimize wing settings, thereby enhancing fuel efficiency and lift-to-drag ratio in real time.

The effectiveness of virtual representations in improving system performance is directly correlated to the accuracy and fidelity of the model. Imperfections in the model, whether due to inaccurate sensor data or incomplete physical modeling, can lead to misleading performance predictions and suboptimal operational decisions. Therefore, rigorous validation and calibration of virtual representations against real-world performance data are crucial steps. Furthermore, the computational resources required to execute complex simulations of system performance can be considerable. Efficient algorithms and high-performance computing infrastructure are often necessary to provide timely and actionable insights. In the mechanical engineering domain, virtual representations can be employed to simulate the thermal behavior of a power plant, optimizing energy production while minimizing emissions.

The understanding of this connectionbetween virtual representations and system performanceis of paramount importance in the current engineering landscape. It allows for proactive rather than reactive problem-solving, facilitating continuous improvements in efficiency, reliability, and safety. While challenges remain in ensuring model accuracy and computational efficiency, the practical benefits of leveraging this technology for system performance optimization are undeniable. The future of mechanical and aerospace engineering will undoubtedly be shaped by the growing integration of virtual models, offering unprecedented insights into the intricacies of system behavior and unlocking new avenues for performance enhancement.

5. Real-time Monitoring

Real-time monitoring forms a crucial element in leveraging the full potential of virtual representations within mechanical and aerospace engineering. It bridges the gap between the physical and virtual worlds, providing continuous data streams that maintain the fidelity and accuracy of the virtual model. This immediate data feedback loop enables proactive decision-making and optimized operational control.

- Sensor Integration and Data Acquisition

Real-time monitoring relies on integrating sensors into physical systems to capture data on various parameters such as temperature, pressure, vibration, and strain. This sensor data is then transmitted to the virtual representation, providing a continuous stream of information about the system’s current state. For instance, in a jet engine, numerous sensors provide data on turbine blade temperature, which is then used to update the virtual model and predict potential overheating issues. Data acquisition systems ensure the reliable and timely transfer of this sensor data to the virtual environment.

- Data Processing and Analysis

Raw sensor data often requires processing and analysis to extract meaningful insights. Signal processing techniques, statistical analysis, and machine learning algorithms are employed to filter noise, detect anomalies, and identify trends. This processed data is then used to update the virtual representation and drive simulations. For example, vibration data from a rotating machine can be analyzed to detect bearing wear, which is then reflected in the virtual model, triggering predictive maintenance alerts.

- Visualisation and Information Dissemination

The insights gained from real-time monitoring are often visualized to facilitate understanding and decision-making. Graphical dashboards, 3D visualizations, and augmented reality interfaces are used to present the data in a clear and intuitive manner. This allows engineers and operators to quickly assess the system’s current state and identify potential issues. For example, a 3D model of a wind turbine can be overlaid with real-time performance data, allowing operators to monitor the turbine’s performance and identify any anomalies.

- Closed-Loop Control and Automation

In some applications, real-time monitoring is integrated with closed-loop control systems to automate system operation. Data from the virtual representation is used to adjust control parameters in the physical system, optimizing performance and ensuring stability. For instance, in an automated manufacturing process, real-time monitoring data is used to adjust machine settings, maintaining product quality and minimizing waste.

The integration of real-time monitoring is paramount to harnessing the capabilities of virtual models. It facilitates condition-based maintenance, performance optimization, and proactive problem-solving in complex engineering systems. The continuous data feedback loop ensures the virtual model remains accurate and relevant, enabling informed decision-making and improved system outcomes.

6. Cost Reduction

Cost reduction is a significant driver for the adoption of virtual representations within mechanical and aerospace engineering. The financial implications of design flaws, operational inefficiencies, and unplanned downtime necessitate strategies for minimizing expenses throughout a system’s lifecycle. Virtual representations offer a means to proactively address these challenges, leading to substantial cost savings.

- Reduced Prototyping Expenses

Physical prototyping is an expensive and time-consuming aspect of traditional engineering design. Virtual representations allow for extensive virtual testing and simulation, minimizing the need for multiple physical prototypes. For example, an aerospace company can simulate the aerodynamic performance of a new aircraft wing design in a virtual environment, identifying and correcting potential issues before committing to a physical prototype. This significantly reduces material costs, manufacturing expenses, and testing time associated with physical prototyping.

- Optimized Maintenance Scheduling

Traditional maintenance strategies, such as time-based maintenance, often result in unnecessary maintenance activities and associated costs. Virtual representations, coupled with real-time monitoring data, enable predictive maintenance strategies. By predicting component failures and scheduling maintenance only when necessary, organizations can minimize downtime, reduce maintenance labor costs, and optimize spare parts inventory. The capacity to anticipate maintenance needs, rather than reacting to failures, translates into substantial cost savings over the system’s lifespan.

- Enhanced Operational Efficiency

Virtual representations facilitate the optimization of system performance in real-time. By continuously monitoring system parameters and adjusting operational settings, organizations can improve efficiency and reduce energy consumption. For instance, a virtual representation of a power plant can be used to optimize boiler operation, reducing fuel consumption and minimizing emissions. Increased efficiency directly reduces operational costs and contributes to environmental sustainability.

- Mitigation of Failure Consequences

Unforeseen system failures can result in significant financial losses, including repair costs, downtime, and potential safety incidents. Virtual representations enable the simulation of failure scenarios and the development of mitigation strategies. By identifying potential vulnerabilities and implementing preventative measures, organizations can minimize the impact of failures and reduce associated costs. For example, simulating a hydraulic system failure in a virtual aircraft model can inform the design of redundant systems and emergency procedures, preventing catastrophic events and minimizing financial losses.

The cost reductions achievable through virtual representations extend across the entire system lifecycle, from design and development to operation and maintenance. By enabling proactive problem-solving, optimized resource allocation, and enhanced operational efficiency, this technology provides a compelling return on investment for mechanical and aerospace engineering organizations. The economic benefits, combined with improved system performance and enhanced safety, are driving the increasing adoption of virtual representations in these industries.

Frequently Asked Questions

The following section addresses common inquiries regarding the application of virtual representations within mechanical and aerospace engineering, providing concise and informative responses. These answers aim to clarify misconceptions and highlight the key aspects of this technology.

Question 1: What distinguishes a virtual representation from a traditional simulation?

A virtual representation is a dynamic digital replica of a physical asset or system that continually learns and updates from real-time data, unlike a traditional simulation which typically operates on static inputs and pre-defined scenarios. The continuous feedback loop and ability to adapt to changing conditions are key differentiators.

Question 2: How is data security addressed when implementing a virtual representation?

Robust cybersecurity protocols are essential. These include encryption of data transmission, strict access controls, regular security audits, and compliance with relevant industry standards. Protecting sensitive design data and operational information is paramount to maintaining system integrity.

Question 3: What level of expertise is required to effectively utilize a virtual representation?

Effective utilization requires a multidisciplinary team with expertise in mechanical and/or aerospace engineering, data science, software development, and domain-specific knowledge relevant to the system being modeled. Continuous training and knowledge sharing are crucial for maximizing value.

Question 4: How does a virtual representation contribute to sustainability efforts?

By optimizing system performance, reducing energy consumption, minimizing waste, and enabling predictive maintenance, virtual representations contribute to increased resource efficiency and reduced environmental impact. They facilitate informed decision-making in support of sustainable practices.

Question 5: What are the limitations of virtual representations?

The accuracy of a virtual representation is limited by the quality and availability of data, the fidelity of the underlying models, and the computational resources available. Over-reliance on a poorly validated virtual representation can lead to inaccurate predictions and suboptimal decisions.

Question 6: What is the future outlook for virtual representations in mechanical and aerospace engineering?

The future involves increased integration with artificial intelligence, machine learning, and augmented reality. This will enable more autonomous operation, improved predictive capabilities, and enhanced visualization for complex systems. Widespread adoption is expected across various engineering domains.

These FAQs provide a foundational understanding of virtual representations, highlighting both their potential benefits and associated challenges. Careful consideration of these aspects is essential for successful implementation and effective utilization.

The following section will explore the potential future trends influencing the evolution of this technology within engineering practice.

Conclusion

The preceding discussion has illuminated the multifaceted nature of virtual representations within mechanical and aerospace engineering. From design optimization and predictive maintenance to lifecycle management and cost reduction, the potential benefits are substantial. Effective implementation, however, demands a commitment to data integrity, model validation, and interdisciplinary collaboration. Real-time monitoring and robust cybersecurity protocols are essential components of a successful strategy.

The evolution of this technology will likely be shaped by advancements in artificial intelligence, machine learning, and augmented reality. As virtual representations become more sophisticated and accessible, their impact on engineering practice will continue to grow. A commitment to continuous learning and innovation is paramount to harnessing the full potential of this transformative technology and shaping the future of mechanical and aerospace engineering.