Positions within the aerospace sector at Ferco offer opportunities for individuals with various skill sets and experience levels. These roles encompass a broad spectrum, ranging from engineering and design to manufacturing, quality control, and management, all contributing to the development and production of aerospace components and systems. An example includes a stress engineer responsible for ensuring the structural integrity of aircraft parts.

The availability of such employment is crucial for both individual career advancement and the overall growth of the aerospace industry. These jobs foster technological innovation, contribute to economic development through job creation, and support the continued advancement of air and space travel. Historically, the demand for skilled professionals in this field has fluctuated with advancements in technology and shifts in global market dynamics, constantly requiring adaptation and specialization.

The subsequent sections will delve into specific aspects related to career paths, required qualifications, the application process, and the overall industry outlook in the context of Fercos operations.

This section provides guidance for individuals seeking employment within the aerospace sector at Ferco. The information is intended to enhance the applicant’s understanding and improve their prospects.

Tip 1: Research Ferco’s Specializations: Prior to applying, conduct thorough research into Ferco’s specific areas of expertise. Knowing whether the company primarily focuses on aircraft interiors, engine components, or other aerospace systems allows for a more targeted application.

Tip 2: Tailor Rsums to Specific Positions: Generic applications are unlikely to succeed. Modify the rsum to highlight skills and experiences directly relevant to the specific job description. If the position requires CAD experience, emphasize proficiency in relevant software.

Tip 3: Emphasize Relevant Technical Skills: The aerospace industry demands specific technical capabilities. Clearly articulate proficiency in areas such as materials science, aerodynamics, or software programming relevant to aerospace engineering.

Tip 4: Highlight Compliance and Regulatory Knowledge: Familiarity with aerospace industry regulations, such as FAA or EASA standards, is highly valued. Explicitly state any experience with quality assurance, safety protocols, or regulatory compliance.

Tip 5: Demonstrate Problem-Solving Abilities: Aerospace engineering often involves complex challenges. Provide examples of how critical-thinking skills were employed to resolve technical issues effectively.

Tip 6: Showcase Teamwork and Communication Skills: Aerospace projects typically involve multidisciplinary teams. Articulate the ability to collaborate effectively with engineers, technicians, and other stakeholders.

Adhering to these recommendations will enhance application materials and demonstrate a strong understanding of Ferco’s operational needs and the broader aerospace industry.

The subsequent section will explore the application process and what to anticipate during the interview phase.

1. Engineering Design

Engineering design forms a cornerstone of operations at Ferco and constitutes a significant portion of available positions. These positions involve the creation, analysis, and refinement of aerospace components and systems. A deficiency in engineering design capabilities directly impedes Ferco’s ability to innovate and produce competitive products. For instance, engineers at Ferco might be responsible for designing lighter, more fuel-efficient aircraft interiors, directly impacting the operational costs and environmental footprint of airlines.

The impact extends beyond individual products. Robust engineering design processes ensure the reliability and safety of aerospace systems. A design flaw in a critical component can have catastrophic consequences. Therefore, Ferco seeks engineers with a strong understanding of aerospace principles, materials science, and computer-aided design (CAD) software. Practical application of these skills is evident in the iterative design process, involving prototype development, testing, and refinement based on performance data. The demand for engineers proficient in finite element analysis (FEA) and computational fluid dynamics (CFD) is consistently high due to their role in simulating and optimizing designs.

In summary, effective engineering design is inextricably linked to Ferco’s success. The quality of the design dictates the performance, safety, and market viability of its aerospace products. Recognizing the critical nature of this function underscores the value placed on engineering design positions and the stringent qualifications expected of applicants. Without continuous advancement in this sphere, it cannot remain competitive within the aerospace industry.

2. Manufacturing Processes

Manufacturing processes form a critical link in the value chain associated with Ferco’s operations. Available positions at Ferco directly hinge upon the efficiency and effectiveness of its manufacturing infrastructure. Inadequate manufacturing capability acts as a bottleneck, limiting production output and reducing the overall profitability. Conversely, optimized processes translate directly into increased efficiency, higher product quality, and improved competitiveness. For instance, Ferco might employ advanced techniques such as additive manufacturing for creating lightweight components, enabling faster production cycles and reducing material waste.

The demand for personnel skilled in process optimization, lean manufacturing principles, and quality control within the manufacturing domain is consistently high. A failure in any stage of the production line, such as improper material handling or inadequate quality checks, directly impacts the reliability and safety of the final aerospace products. Ferco therefore emphasizes adherence to stringent industry standards, such as AS9100, which governs quality management systems within the aerospace industry. Employees are required to demonstrate proficiency in operating and maintaining advanced manufacturing equipment, troubleshooting production issues, and implementing corrective actions to prevent recurring defects. The practical significance of this understanding is evident in the reduced risk of product recalls, improved customer satisfaction, and sustained regulatory compliance.

The connection between manufacturing processes and career opportunities at Ferco reflects the essential role that manufacturing plays in delivering high-quality aerospace components. Efficient production workflows are foundational to meeting market demands. As such, individuals with expertise in areas such as precision machining, composite manufacturing, and automated assembly are highly sought after, making knowledge of manufacturing processes a pivotal aspect of “Ferco aerospace jobs”.

3. Quality Assurance

Quality assurance is a critical function within Ferco’s aerospace operations. Positions related to this discipline are instrumental in maintaining product integrity and regulatory compliance, directly influencing the safety and reliability of aircraft components and systems.

- Inspection and Testing Procedures

Inspection and testing positions ensure all materials, components, and finished products meet specified requirements and industry standards. Examples include non-destructive testing (NDT) of structural components and functional testing of electronic systems. These activities are integral to validating product conformance and are essential for “ferco aerospace jobs” as they prevent defective parts from entering the supply chain.

- Regulatory Compliance Audits

Audits are conducted to verify adherence to industry regulations such as AS9100 or FAA guidelines. Quality assurance personnel may conduct internal audits or participate in external audits by regulatory agencies. These procedures are paramount for “ferco aerospace jobs” as they ensure operational practices align with legal and safety requirements.

- Corrective and Preventive Actions (CAPA)

The implementation of CAPA systems addresses identified non-conformities and prevents their recurrence. Quality assurance roles involve analyzing defects, identifying root causes, and implementing corrective measures. This proactive approach enhances process efficiency and minimizes risks, forming an integral part of ferco aerospace jobs by safeguarding the products integrity through continuous improvements.

- Documentation and Reporting

Accurate documentation of inspection results, audit findings, and CAPA activities is crucial for maintaining traceability and demonstrating compliance. Quality assurance personnel are responsible for creating and maintaining quality records, ensuring all processes are adequately documented and auditable. Proper documentation serves as evidence of quality control and risk management practices, ensuring traceability in “ferco aerospace jobs”.

The emphasis on quality assurance in “ferco aerospace jobs” underscores the company’s commitment to excellence and safety within the aerospace sector. The above facets exemplify the comprehensive approach adopted to guarantee product reliability and adherence to industry standards. These measures not only safeguard operational integrity, but also bolster Fercos reputation within the competitive aerospace market.

4. Project Management

Effective project management is integral to the successful completion of aerospace projects at Ferco. Positions within this field are crucial for coordinating resources, managing timelines, and ensuring projects adhere to budget constraints. A lack of proficient project management directly causes project delays, cost overruns, and reduced product quality. Conversely, competent project management facilitates the timely delivery of high-quality aerospace components, thereby enhancing customer satisfaction and bolstering Ferco’s reputation.

The application of project management principles involves several key processes, including project planning, risk management, and stakeholder communication. Ineffective project planning leads to poorly defined objectives and unachievable timelines, resulting in resource misallocation and ultimately project failure. Risk management requires identifying and mitigating potential threats to project success, such as supply chain disruptions or technical challenges. Proactive risk mitigation ensures minimal impact on project timelines and budgets. Regular communication with stakeholders, including engineers, manufacturing personnel, and customers, is vital for maintaining alignment and addressing concerns promptly. A well-managed project, for instance, the development of a new aircraft interior, ensures that the design, manufacturing, and installation phases are synchronized, minimizing disruptions and ensuring on-time delivery.

Positions in project management are foundational to “ferco aerospace jobs” due to their influence on the overall efficiency and effectiveness of operations. Proficiency in these disciplines is paramount to meeting industry demands. Recognizing the interconnectedness between effective processes and career advancement is crucial, underscoring project managements essential role within Ferco’s aerospace ventures. Failure to incorporate sufficient project management can undermine Fercos competitive position within the aerospace sector.

5. Regulatory Compliance

Regulatory compliance represents a non-negotiable aspect of operations within the aerospace industry and significantly shapes the landscape of available positions at Ferco. Strict adherence to regulations, such as those stipulated by the FAA (Federal Aviation Administration) or EASA (European Union Aviation Safety Agency), is mandatory for ensuring the safety and airworthiness of aerospace products. Failure to comply with these regulations can result in severe penalties, including fines, production shutdowns, and reputational damage. Consequently, Ferco invests heavily in compliance-related roles, underscoring the practical significance of this function. For example, a regulatory compliance specialist might be responsible for ensuring that all aircraft interior components meet flammability standards defined by the FAA, thereby preventing the use of non-compliant materials that could pose a safety risk.

The demand for professionals skilled in navigating the complex regulatory environment is consistently high across various departments, from engineering and manufacturing to quality assurance and supply chain management. Consider the role of a quality assurance manager who must implement and oversee a quality management system compliant with AS9100 standards, which are designed to ensure aerospace products meet stringent safety and reliability requirements. Furthermore, regulatory compliance extends to documentation and traceability. Accurate record-keeping is crucial for demonstrating adherence to regulations and providing evidence of due diligence in the event of an incident or audit. This entails maintaining detailed records of materials used, manufacturing processes followed, and testing results conducted.

Positions related to regulatory compliance are fundamental to “ferco aerospace jobs” because they safeguard operational integrity and mitigate risks associated with non-compliance. The competencies required include a comprehensive understanding of aerospace regulations, meticulous attention to detail, and strong communication skills. Neglecting compliance exposes Ferco to legal liabilities, financial losses, and reputational harm, whereas robust compliance processes foster a culture of safety and reliability, solidifying Ferco’s position within the competitive aerospace market. Therefore, compliance expertise is not merely an advantage but a prerequisite for many positions, emphasizing its intrinsic value and importance in “ferco aerospace jobs”.

Frequently Asked Questions

The following addresses common inquiries regarding job opportunities within Ferco’s aerospace division. The information provided aims to clarify expectations and assist potential candidates in their application process.

Question 1: What types of positions are typically available at Ferco Aerospace?

Positions encompass a broad range of disciplines, including engineering (mechanical, aerospace, electrical), manufacturing, quality assurance, project management, and supply chain management. Specific openings vary depending on Ferco’s current project needs and market demands.

Question 2: What qualifications are generally required for engineering roles?

Engineering positions commonly necessitate a bachelor’s or master’s degree in a relevant engineering field. Experience with CAD/CAM software, finite element analysis, and a solid understanding of aerospace materials and manufacturing processes are often prerequisites.

Question 3: Does Ferco offer internships or entry-level programs?

Ferco may offer internship and entry-level programs to provide opportunities for recent graduates or students to gain practical experience within the aerospace sector. Availability varies, and interested candidates are advised to check the careers section of Ferco’s website for current offerings.

Question 4: What are the key attributes Ferco seeks in prospective employees?

Ferco values candidates who demonstrate strong technical skills, problem-solving abilities, teamwork, and a commitment to quality and safety. Experience with aerospace regulations (e.g., FAA, EASA) is also highly regarded.

Question 5: How should I prepare for an interview at Ferco?

Candidates should thoroughly research Ferco’s specific areas of expertise and be prepared to discuss their skills and experience in relation to the job requirements. Technical questions related to aerospace engineering principles and industry standards are commonly included in the interview process.

Question 6: Does Ferco offer opportunities for professional development and advancement?

Ferco typically provides opportunities for professional development through training programs, mentorship initiatives, and tuition reimbursement. Career advancement is often based on performance, skills development, and the company’s growth trajectory.

These FAQs are designed to offer clarity for those considering “ferco aerospace jobs”. Further details and specific requirements can be found on Ferco’s official website or through direct contact with their human resources department.

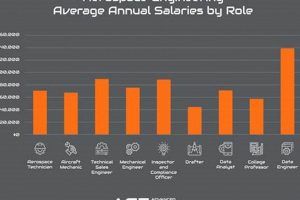

The next section will delve into the benefits and compensations.

In Conclusion

This exposition has provided a detailed overview of the landscape surrounding “ferco aerospace jobs,” elucidating the types of positions available, required qualifications, essential skills, and the critical role of regulatory compliance. It underscored the importance of aligning individual skills with Ferco’s specific needs to enhance application success and long-term career prospects within the organization. Emphasis was placed on the significance of quality assurance, efficient manufacturing processes, effective project management, and adherence to industry standards.

Understanding these multifaceted dimensions is paramount for individuals aspiring to secure and excel in positions at Ferco. A proactive approach that involves continuous skill development, industry awareness, and a commitment to safety and quality will position candidates favorably for future opportunities within the dynamic aerospace sector. The information presented serves as a foundational resource for navigating the complexities of “ferco aerospace jobs” and underscores the critical interplay between individual aspirations and organizational requirements.