Opportunities within the realm of aviation and defense technologies are the focus. These roles encompass a wide spectrum, from engineering and manufacturing to research and development, all centered around the design, production, and support of aircraft components and systems. For example, a mechanical engineer might be involved in designing landing gear, or a quality control specialist might ensure the precision of turbine blades.

These career paths are crucial for maintaining the safety, efficiency, and innovation within the aerospace sector. They provide individuals with the chance to contribute to advancements in flight technology and global connectivity. Historically, positions in this area have been associated with stable employment and opportunities for professional growth, driven by continuous technological advancements and evolving industry demands.

The subsequent sections will delve deeper into specific career paths, required qualifications, and the overall landscape of employment in this technological field. This exploration will provide a comprehensive overview of the possibilities available to those seeking to enter or advance within this dynamic industry.

This section provides focused guidance for individuals seeking roles in the design, manufacturing, and support of sophisticated aviation systems and components. Success in this field requires a strategic approach to career development and job searching.

Tip 1: Target Specific Skill Development: Identify areas where skills are in high demand, such as composite materials engineering, avionics systems integration, or advanced manufacturing techniques. Pursue certifications, advanced degrees, or specialized training programs to enhance expertise in these areas.

Tip 2: Leverage Online Professional Platforms: Actively engage on platforms like LinkedIn, showcasing relevant skills and experience. Connect with industry professionals, participate in relevant groups, and follow companies of interest to stay informed about emerging opportunities and industry trends.

Tip 3: Network at Industry Events: Attend industry conferences, trade shows, and career fairs to make connections with potential employers and learn about upcoming projects and hiring needs. Prepare a concise elevator pitch outlining qualifications and career goals.

Tip 4: Tailor Resumes and Cover Letters: Customize each application to align with the specific requirements of the position. Highlight relevant experience and skills using keywords from the job description. Quantify achievements whenever possible to demonstrate the impact of contributions.

Tip 5: Research Company Culture and Values: Before applying, thoroughly research the companys mission, values, and operating principles. Demonstrate an understanding of the companys culture and how the individual’s skills and values align with those of the organization.

Tip 6: Prepare Thoroughly for Interviews: Anticipate common interview questions related to technical skills, problem-solving abilities, and teamwork. Practice articulating past experiences and accomplishments using the STAR method (Situation, Task, Action, Result) to provide structured and compelling answers.

Tip 7: Consider Relocation Opportunities: Be open to opportunities in locations with a strong aerospace presence. This may require relocating to areas with specialized manufacturing facilities or research and development centers.

These strategic steps will increase the likelihood of securing a fulfilling and impactful role within this advanced technological sector. Proactive planning and targeted skill development are essential for long-term success.

The following sections will conclude by offering a final overview and perspective on the future of the aerospace sector and its demand for skilled professionals.

1. Engineering Design

Engineering design forms a foundational pillar for opportunities. This discipline provides the expertise necessary to conceive, develop, and refine aircraft components and systems. A strong command of engineering principles directly impacts product performance, safety, and efficiency. For example, the design of a more aerodynamically efficient wing, achieved through advanced computational fluid dynamics and materials science, directly reduces fuel consumption and enhances flight range. Consequently, individuals with specialized skills in areas such as structural analysis, aerodynamics, and control systems are highly sought after within this industry.

The design phase necessitates rigorous testing and validation procedures. Prototypes are subjected to simulated and real-world conditions to ensure compliance with stringent regulatory standards. This iterative process of design, testing, and refinement is crucial for identifying and mitigating potential design flaws before components enter mass production. Furthermore, a thorough understanding of manufacturing processes is essential for creating designs that are both functional and cost-effective. This integrated approach ensures that engineering design efforts contribute to the overall success and sustainability of the manufacturing company.

Ultimately, the effectiveness of engineering design directly impacts the competitiveness of the aerospace enterprise. Innovative designs can lead to the development of cutting-edge technologies, giving companies a competitive advantage in the global market. Therefore, investing in skilled engineering talent and fostering a culture of innovation are essential for maintaining a leadership position and capitalizing on opportunities within this highly specialized domain.

2. Manufacturing Processes

Manufacturing processes constitute the core operations that transform raw materials into finished aerospace components and systems. The efficiency and precision of these processes are directly linked to product quality, reliability, and cost-effectiveness. Individuals engaged in roles related to these processes are vital for maintaining operational standards and meeting the demands of the aerospace industry.

- Precision Machining

Precision machining involves the use of computer-controlled machines to fabricate parts with extremely tight tolerances. Examples include the creation of turbine blades for jet engines or structural components for aircraft fuselages. In manufacturing roles, machinists, programmers, and quality control inspectors work together to ensure that components meet exacting specifications. Any deviation can compromise aircraft performance and safety.

- Composite Fabrication

Composite fabrication encompasses the layering and curing of carbon fiber and other advanced materials to create lightweight and strong aircraft structures. This process requires specialized equipment and expertise in material science and engineering. Operators, technicians, and engineers in composite fabrication roles contribute to enhancing fuel efficiency and structural integrity. Quality control measures are crucial in detecting delamination or other defects that could weaken the structure.

- Assembly and Integration

Assembly and integration involve the joining of individual components into larger systems, such as landing gear assemblies or flight control surfaces. This requires a skilled workforce capable of following detailed assembly instructions and using specialized tooling. Assemblers, technicians, and engineers collaborate to ensure proper alignment, functionality, and safety. Thorough testing and inspection are essential to verify that all systems operate as designed.

- Specialized Coatings and Treatments

Specialized coatings and treatments are applied to aerospace components to enhance their resistance to corrosion, wear, and extreme temperatures. Examples include thermal barrier coatings for turbine blades and anti-corrosion coatings for airframe structures. Coating specialists, technicians, and engineers are essential for ensuring that these coatings meet stringent performance requirements. Quality control processes monitor coating thickness, adhesion, and uniformity to guarantee long-term durability.

These facets of manufacturing processes collectively shape the landscape of opportunities. Skilled professionals in these areas are fundamental to the production of reliable, high-performance aerospace systems. Ongoing advancements in manufacturing technologies, such as additive manufacturing and automation, are creating new opportunities and demanding specialized expertise. The commitment to quality and precision in manufacturing processes remains paramount for those seeking roles within this sector.

3. Quality Assurance

Quality Assurance constitutes a critical function within organizations focused on aviation systems and components. This discipline ensures that products and services consistently meet specified requirements and industry standards, directly impacting operational safety and reliability. Individuals involved in these roles are essential for upholding the integrity and performance of aerospace products.

- Inspection and Testing Protocols

Rigorous inspection and testing protocols are implemented throughout the manufacturing process to detect defects and ensure compliance with engineering specifications. These protocols encompass non-destructive testing (NDT) methods such as ultrasonic testing, radiographic testing, and dye penetrant inspection, among others. Inspectors and technicians apply these techniques to identify flaws that may compromise structural integrity or performance. For example, inspecting turbine blades for microscopic cracks or evaluating composite panels for delamination are standard practices.

- Compliance with Regulatory Standards

Adherence to regulatory standards set by agencies such as the Federal Aviation Administration (FAA) is paramount. These standards dictate design, manufacturing, testing, and maintenance practices to ensure airworthiness and passenger safety. Quality Assurance specialists are responsible for interpreting and implementing these regulations, as well as conducting audits to verify compliance. Failure to adhere to these standards can result in significant penalties and reputational damage.

- Process Control and Improvement

Process control methodologies, such as Statistical Process Control (SPC), are employed to monitor and optimize manufacturing processes. By collecting and analyzing data on key process parameters, quality assurance engineers can identify trends, detect anomalies, and implement corrective actions. Continuous improvement initiatives, such as Lean Manufacturing and Six Sigma, are also utilized to streamline operations, reduce waste, and enhance product quality. For example, SPC could be used to monitor the consistency of weld bead dimensions in fuselage assembly.

- Documentation and Traceability

Comprehensive documentation and traceability systems are essential for maintaining accountability and verifying the history of aerospace components. These systems track materials, processes, and inspections performed throughout the manufacturing lifecycle. Auditors and investigators can use this documentation to trace defects back to their root causes and identify opportunities for improvement. For instance, each aircraft engine component may have a unique serial number that links it to specific material certifications, manufacturing records, and inspection reports.

The aforementioned facets collectively underscore the critical role that quality assurance plays in maintaining standards and ensuring the reliability of aerospace products. Professionals in this field are entrusted with safeguarding the safety and performance of aircraft and related systems. This commitment contributes to the overall success of organizations that are the source of such roles.

4. Systems Integration

Systems integration is a critical element for individuals in aviation-related technical roles. It concerns the process of assembling disparate hardware and software components into a unified, functioning system. This integration is essential in aircraft manufacturing, where numerous specialized systems (avionics, hydraulics, electrical, etc.) must operate seamlessly together. A systems integration engineer might be tasked with ensuring compatibility between a newly developed navigation system and the aircraft’s existing flight control systems. Failure in integration can lead to system malfunctions or failures, impacting safety and operational efficiency.

The practical significance of systems integration extends to problem-solving and troubleshooting. Engineers regularly address issues arising from interactions between different systems. Consider the scenario where installing a new communications system disrupts radar performance. A deep understanding of systems integration is necessary to identify the root cause, propose solutions, and implement changes without creating further issues. Often, systems integration engineers use modeling and simulation tools to predict system behavior and optimize integration strategies before physical implementation. Furthermore, real-world examples are easily found in the development and deployment of automatic pilot. This type of technology requires that aircraft control systems are synced up with navigation systems and sensor-reading tools. The effective integration of these devices greatly enhances safety and allows the aircraft to maintain course even in challenging weather conditions. The success of this integration heavily relies on the efforts of engineers who specialize in this field.

In summary, systems integration represents a core competency in many technical professions. Challenges in this area are often complex, requiring not only technical expertise but also effective communication and collaboration across different engineering disciplines. A robust understanding of this concept is indispensable for aerospace engineering experts and is crucial for maintaining operational integrity and pushing the boundaries of innovation in aviation.

5. Research & Development

Research & Development (R&D) forms a critical link to opportunities. It fuels innovation, drives technological advancement, and shapes the future of the aerospace industry. These activities are foundational to the design, manufacturing, and improvement of aircraft systems and components, creating a constant demand for specialized expertise.

- Advanced Materials Innovation

The exploration of novel materials with enhanced strength-to-weight ratios, temperature resistance, and durability is a primary focus of R&D. Examples include the development of advanced composites, alloys, and coatings that improve aircraft performance and extend service life. A materials scientist might be responsible for synthesizing new polymers with exceptional thermal stability for use in engine components. These roles involve experimentation, analysis, and collaboration with engineering teams to integrate these new materials into practical applications. This drives competitive advantages in the aerospace market.

- Aerodynamic Efficiency and Performance

R&D activities focused on aerodynamics aim to optimize aircraft design to reduce drag, increase lift, and improve fuel efficiency. Computational fluid dynamics (CFD) simulations and wind tunnel testing are employed to analyze airflow patterns and evaluate the effectiveness of different wing configurations, control surfaces, and engine nacelle designs. An aeronautical engineer could conduct CFD analysis to refine the shape of a winglet to minimize induced drag. This work enhances the aircraft’s overall performance and fuel economy, directly benefiting airline operations and lowering emissions.

- Autonomous Systems and Robotics

Research into autonomous systems and robotics is revolutionizing manufacturing processes and aircraft operations. Automated inspection systems, robotic assembly lines, and unmanned aerial vehicles (UAVs) are increasingly utilized to improve efficiency, reduce costs, and enhance safety. A robotics engineer might design and program a robot to perform precise drilling operations on aircraft fuselage panels. The integration of automation requires collaboration between robotics specialists, manufacturing engineers, and software developers to ensure seamless operation and quality control.

- Sustainable Aviation Technologies

With increasing environmental concerns, R&D efforts are focusing on the development of sustainable aviation technologies, such as alternative fuels, electric propulsion systems, and hybrid-electric aircraft. Research chemists might be involved in developing biofuels derived from renewable resources, while electrical engineers are designing high-power electric motors and battery systems for aircraft propulsion. These initiatives aim to reduce the carbon footprint of aviation and contribute to a more sustainable future.

These facets of R&D collectively drive innovation within the aviation and aerospace sector. The insights gained from fundamental research and experimental development directly translate into opportunities for scientists, engineers, and technicians. These roles require a strong foundation in scientific principles, analytical skills, and a passion for pushing the boundaries of technology. A commitment to R&D is essential for maintaining competitiveness and achieving continued success in this dynamic and demanding field.

6. Project Management

Project Management serves as a pivotal function for roles related to aircraft components. Effective project management ensures the timely and cost-effective completion of projects ranging from new product development to upgrades of existing systems. The aerospace industry operates under stringent safety regulations and complex technical specifications, thus necessitating meticulous project planning, execution, and monitoring. Without skilled project managers, projects can easily exceed budgets, fall behind schedule, or fail to meet performance requirements, jeopardizing both financial stability and operational integrity. For instance, the development of a new aircraft wing requires coordinating engineers, manufacturing specialists, and supply chain partners, all within a defined timeframe and budget. A project managers expertise is crucial in orchestrating these diverse activities to achieve project goals.

The practical significance of project management is evident in various aspects of the aviation industry. Consider a scenario where a modification to an existing aircraft engine is necessary to comply with new environmental regulations. Project managers would lead this initiative, coordinating engineers in redesigning engine components, overseeing manufacturing changes, and managing certification processes with regulatory agencies. Alternatively, project managers might oversee the implementation of new manufacturing technologies, such as additive manufacturing for producing lightweight aircraft parts. This requires coordinating equipment procurement, training personnel, and establishing quality control procedures. These examples illustrate how project management competencies drive efficiency, innovation, and compliance throughout the life cycle of aviation products.

In summary, project management skills are indispensable for individuals in this profession, impacting cost control, regulatory compliance, and technological advancement. Challenges include navigating complex project requirements, managing stakeholder expectations, and mitigating risks associated with technical and operational uncertainties. A thorough understanding of project management principles is therefore vital for aspiring aviation professionals.

Frequently Asked Questions About Opportunities in Advanced Aviation Technologies

This section addresses common inquiries concerning roles within the field. The intent is to clarify misconceptions and provide guidance to individuals interested in pursuing career paths in advanced aviation technologies.

Question 1: What educational background is most suitable for positions?

A bachelor’s degree in a relevant engineering field (e.g., aerospace, mechanical, electrical, materials science) is typically required. Advanced degrees (master’s or doctorate) may be necessary for specialized roles or research-oriented positions. Certification in project management, quality assurance, or specific technical areas can also enhance employability.

Question 2: What specific skills are highly valued by employers?

Employers often seek candidates with a blend of technical proficiency and soft skills. Technical skills include proficiency in CAD software, knowledge of aerospace materials, and experience with manufacturing processes. Soft skills include communication, problem-solving, teamwork, and leadership abilities.

Question 3: What career paths are available within this field?

A range of career paths exists, spanning design engineering, manufacturing, quality assurance, systems integration, and research and development. Individuals may specialize in specific areas, such as avionics, propulsion systems, or composite structures. Advancement opportunities often lead to project management or engineering leadership positions.

Question 4: How can one gain relevant experience for these roles?

Internships, co-op programs, and entry-level positions are effective means of gaining practical experience. Participating in relevant projects during academic studies, such as designing a model aircraft or conducting materials testing, can also provide valuable skills. Professional certifications and online courses can further demonstrate knowledge and commitment.

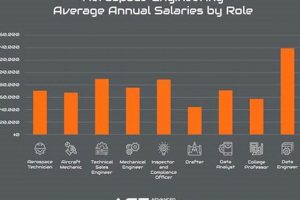

Question 5: What is the typical salary range for positions?

Salary ranges vary based on experience, education, and location. Entry-level positions may offer starting salaries competitive with other engineering fields. More experienced professionals with specialized skills and advanced degrees can command higher salaries. Geographic location and company size also influence compensation levels.

Question 6: What is the future outlook for careers?

The outlook is generally positive, driven by increasing demand for air travel, advancements in aerospace technology, and the need for sustainable aviation solutions. The sector is expected to continue to evolve, creating new opportunities in areas such as electric propulsion, autonomous aircraft, and advanced manufacturing techniques. Continuous learning and adaptation are essential for long-term career success.

Key takeaways from this FAQ section emphasize the importance of a solid technical education, targeted skill development, and a commitment to continuous learning. These factors contribute to a successful and rewarding career in advanced aviation technologies.

The following sections conclude with a final summary and overarching perspective on the future prospects and continuing need for skilled professionals in the aerospace field.

Conclusion

This examination of positions within advanced aviation technologies underscores the crucial intersection of technical expertise, rigorous standards, and continuous innovation. These opportunities demand a comprehensive understanding of engineering principles, manufacturing processes, and quality assurance protocols. Success in these roles necessitates a commitment to precision, safety, and the advancement of aerospace systems. The explored domains, encompassing engineering design, manufacturing, quality assurance, systems integration, research and development, and project management, reflect the diverse skill sets essential for contributing to this critical industry.

As the aerospace sector continues to evolve, driven by technological advancements and global demands, the need for qualified professionals will persist. Individuals pursuing careers in advanced aviation technologies are encouraged to cultivate expertise, seek continuous learning opportunities, and engage with industry developments. The future of aviation relies on their dedication to excellence and innovation, ensuring the continued safety, efficiency, and sustainability of air travel.

![Aerospace Engineering Job Description Guide | [Prefix] [Job Title] [Suffix] Innovating the Future of Flight with Reliable Aviation Solutions Aerospace Engineering Job Description Guide | [Prefix] [Job Title] [Suffix] | Innovating the Future of Flight with Reliable Aviation Solutions](https://mixaerospace.com/wp-content/uploads/2026/01/th-689-300x200.jpg)