Opportunities within the field encompass roles related to the design, development, testing, and production of aircraft, spacecraft, and related systems. These positions require a strong foundation in mathematics, physics, and engineering principles, often necessitating a bachelor’s or advanced degree. Examples include roles focusing on aerodynamics, propulsion systems, structural analysis, and control systems for both atmospheric and space vehicles.

Securing a position in this sector offers the potential to contribute to advancements in air travel, space exploration, and defense technology. Historically, government agencies, such as NASA, and private aerospace companies have driven innovation in this area, leading to significant technological breakthroughs. The benefits extend beyond technological progress, contributing to economic growth and national security. The demand for skilled professionals fluctuates with government funding, technological advancements, and overall economic conditions.

The following sections will delve into specific roles, required skill sets, educational pathways, and potential career trajectories available to individuals with relevant qualifications. Further discussion will address the impact of emerging technologies and industry trends on the future workforce needs of this dynamic field. The intention is to provide a thorough overview of career prospects and equip prospective applicants with the necessary information for informed decision-making.

This section provides actionable guidance to enhance prospects of obtaining a position within the specified field. Diligence in preparation and strategic planning are crucial for success.

Tip 1: Academic Excellence. A strong academic record, particularly in relevant coursework like fluid dynamics, thermodynamics, and control theory, is paramount. Focus on achieving high grades in core subjects and consider pursuing advanced degrees for specialized roles.

Tip 2: Internship Experience. Seek internship opportunities with aerospace companies or government agencies. Practical experience gained through internships provides invaluable insights into real-world applications and demonstrates commitment to the field.

Tip 3: Technical Proficiency. Develop proficiency in industry-standard software tools, such as CAD (Computer-Aided Design) software like CATIA or SolidWorks, and simulation software like ANSYS or MATLAB. Employers value candidates with hands-on experience using these tools.

Tip 4: Networking Opportunities. Attend industry conferences, career fairs, and workshops to network with professionals and learn about current trends and openings. Building connections can significantly improve opportunities.

Tip 5: Targeted Resume. Tailor the resume and cover letter to match the specific requirements of each target. Highlight relevant skills, experiences, and projects that demonstrate suitability for the role.

Tip 6: Professional Certifications. Pursue relevant professional certifications, such as those offered by the American Institute of Aeronautics and Astronautics (AIAA), to enhance credibility and demonstrate expertise.

Tip 7: Research and Development. Participate in research projects or design competitions to showcase technical abilities and problem-solving skills. Such activities demonstrate initiative and a passion for innovation.

These guidelines provide a foundation for strategic career planning. Implementing these suggestions can improve competitiveness and increase the likelihood of securing a desired position.

The subsequent section will explore emerging trends that could impact the future of the field, including areas for specialization and future learning.

1. Design

Design constitutes a foundational element within numerous roles. The process dictates the form and function of aerospace vehicles and their constituent components, directly influencing performance, safety, and efficiency. A deficiency in design can lead to catastrophic failures, highlighting the critical nature of this function. For example, flawed wing designs in early aircraft led to structural failures and loss of life. Modern designs leverage computational fluid dynamics and finite element analysis to mitigate these risks, ensuring designs meet stringent safety standards. Thus, proficiency in design principles and software tools is essential for roles relating to the development of aircraft and spacecraft.

Positions that heavily rely on design skills include, but are not limited to, Aerodynamic Design Engineers, Structural Design Engineers, and Propulsion System Designers. Aerodynamic Design Engineers focus on shaping the external surfaces of aircraft and spacecraft to optimize lift, reduce drag, and enhance stability. Structural Design Engineers ensure that the airframe can withstand the stresses encountered during flight, selecting appropriate materials and designing load-bearing structures. Propulsion System Designers create efficient and reliable engines and rocket motors, crucial for powering aerospace vehicles. Each design role requires a deep understanding of physics, mathematics, and material science.

In summary, design is inextricably linked to virtually all aspects of engineering. Competency in this area is not just advantageous, but mandatory. The continuous refinement of design methodologies and the adoption of advanced modeling techniques are driving improvements in the performance, reliability, and safety of aerospace systems. Therefore, a thorough understanding of design principles represents a key determinant in securing relevant opportunities and fostering career advancement.

2. Manufacturing

The manufacturing sector is a critical component of roles, representing the tangible realization of engineering designs and concepts. Precise and efficient manufacturing processes directly impact the performance, reliability, and cost-effectiveness of aerospace vehicles. Deficiencies in manufacturing can compromise structural integrity, leading to equipment failure or catastrophic events. For instance, inconsistencies in the manufacturing of composite materials used in aircraft wings can result in delamination and reduced strength, posing significant safety risks. Thus, meticulous attention to detail and adherence to strict quality control measures are paramount in manufacturing processes.

Relevant positions within this domain encompass Manufacturing Engineers, Production Managers, and Quality Control Specialists. Manufacturing Engineers are responsible for optimizing production processes, selecting appropriate manufacturing techniques, and ensuring efficient resource utilization. Production Managers oversee the overall manufacturing process, coordinating various activities to meet production targets and deadlines. Quality Control Specialists are responsible for inspecting manufactured components and assemblies to ensure they meet specified standards and requirements. Each of these roles requires a thorough understanding of manufacturing processes, materials science, and quality control procedures. The adoption of advanced manufacturing technologies, such as additive manufacturing (3D printing), is increasingly prevalent, enabling the production of complex geometries and customized components.

In summary, the manufacturing sector plays a vital role in translating engineering designs into tangible products. A commitment to quality, efficiency, and innovation in manufacturing processes is essential for maintaining the competitiveness and safety of the aerospace industry. Understanding manufacturing principles and processes is critical for individuals seeking to secure relevant positions and contribute to the advancement of aerospace technology. Challenges such as maintaining high precision, managing material costs, and adapting to new manufacturing techniques drive continuous innovation in this field.

3. Research

Research forms an indispensable nexus within career paths, serving as the engine for innovation and advancement. The pursuit of knowledge, through experimentation, modeling, and analysis, fuels the development of new technologies and methodologies that shape the future of flight and space exploration. For example, research into advanced materials has led to the creation of lighter, stronger composites for aircraft structures, improving fuel efficiency and performance. Similarly, investigations into hypersonic propulsion systems are essential for enabling future high-speed flight and space access. The effectiveness and future viability of this professional sector depend heavily on continued, intensive investigation.

Positions directly involved in research include Research Scientists, Research Engineers, and Postdoctoral Researchers. These roles demand advanced degrees, often a Ph.D., and a demonstrated aptitude for conducting original research. Research Scientists typically lead research projects, develop research proposals, and publish findings in peer-reviewed journals. Research Engineers apply scientific principles to develop and test new technologies. Postdoctoral Researchers conduct research under the supervision of senior researchers, gaining experience and contributing to ongoing projects. A real-world application of this is the ongoing investigation into sustainable aviation fuels. Researching and developing alternative fuel sources aims to reduce the environmental impact of air travel, a vital goal in the industry.

In summary, research is not merely an auxiliary component, but a core driver of progression. It is critical for addressing the complex challenges facing the industry, from improving fuel efficiency and safety to developing new capabilities for space exploration. A thorough understanding of research methodologies and a passion for innovation are essential for individuals seeking success in this specialized area. Overcoming challenges such as securing research funding and translating research findings into practical applications requires perseverance and collaboration across disciplines. The ongoing pursuit of new knowledge will continue to shape the direction of the profession and its evolution.

4. Testing

Testing is an indispensable facet of positions within the specified sector, serving as the critical validation phase for designs, materials, and completed systems. The direct correlation between rigorous testing protocols and the assurance of safety, reliability, and performance cannot be overstated. Inadequate testing can lead to catastrophic failures, highlighting the cause-and-effect relationship between thorough evaluation and operational integrity. For example, extensive wind tunnel testing of aircraft designs identifies potential aerodynamic issues before they become airborne hazards. Similarly, stress testing of composite materials ensures their ability to withstand the extreme conditions encountered during flight and space missions. Without meticulous testing, the risks associated with aerospace operations would be unacceptably high.

The practical application of this understanding is evident in the various roles dedicated to testing and validation. Test Engineers design and execute test plans, analyze data, and identify potential design flaws or performance limitations. Flight Test Engineers evaluate the performance of aircraft during actual flight conditions, collecting data on handling characteristics, engine performance, and system functionality. Materials Testing Engineers assess the properties of materials under various stresses and environmental conditions, ensuring they meet stringent specifications. Non-Destructive Testing (NDT) Technicians utilize techniques such as radiography and ultrasonic testing to detect internal flaws without damaging the components. These positions demand a strong foundation in engineering principles, data analysis, and a commitment to meticulous evaluation.

In summary, testing provides the essential verification required to ensure the success and safety of systems. It is an inherent component, shaping its overall reliability and effectiveness. Challenges associated with increasingly complex designs and the need for more efficient testing methodologies drive ongoing innovation in this field. The continued emphasis on rigorous testing protocols is critical for maintaining the highest standards of safety and performance in the industry, contributing to both technological advancement and public confidence. Without testing, the foundation of the profession collapses.

5. Analysis

Analysis, in its various forms, constitutes a cornerstone of virtually all positions within the field. It is the systematic evaluation of data, designs, and systems, forming the basis for informed decision-making and continuous improvement. A deficiency in analytical capabilities can lead to inaccurate assessments, flawed designs, and ultimately, compromised safety and performance. It is the lens through which engineers interpret the world around them and make tangible improvements.

- Stress Analysis

Stress Analysis is the determination of stresses and strains in solid objects subjected to forces or thermal loads. In the field, this is critical for ensuring structural integrity and preventing failures of aircraft components. Finite Element Analysis (FEA) software is commonly used to simulate stress distributions in complex geometries. Accurate stress analysis prevents fatigue failures, extends service life, and improves safety. For example, stress analysis ensures the wings of an aircraft can withstand the immense forces during flight.

- Performance Analysis

Performance Analysis involves evaluating the operational characteristics of systems, such as fuel efficiency, speed, and range. It employs computational tools and flight data to identify areas for optimization. Performance analysis directly impacts the efficiency and cost-effectiveness of aircraft and spacecraft. For instance, analyzing flight data can reveal opportunities to reduce fuel consumption by adjusting flight profiles or optimizing engine performance.

- Data Analysis

Data Analysis is the process of inspecting, cleaning, transforming, and modeling data to discover useful information, draw conclusions, and support decision-making. Large volumes of data are generated during testing, flight operations, and manufacturing processes. Effective data analysis allows engineers to identify trends, detect anomalies, and improve processes. Examples include using flight data to diagnose engine problems or analyzing manufacturing data to improve production yields.

- Risk Analysis

Risk Analysis involves identifying and evaluating potential hazards and their associated probabilities and consequences. It is crucial for ensuring the safety of aerospace systems and mitigating potential risks. Risk analysis is applied throughout the lifecycle, from design to operations. For example, risk analysis is used to assess the likelihood of engine failures, component malfunctions, and other hazards. Mitigation strategies are then developed to reduce these risks to acceptable levels.

These analytical facets are intricately connected, forming a holistic approach to engineering problem-solving. Whether designing new aircraft, improving the performance of existing systems, or mitigating potential risks, analytical skills are indispensable. The ability to gather, interpret, and apply data is paramount for professionals seeking to excel and contribute to the advancement of the field. Therefore, expertise in analytical techniques is a fundamental requirement.

6. Management

The management function is inextricably linked to the success of any undertaking within the sector. Efficient project management, resource allocation, and team leadership are critical for navigating the complexities inherent in aerospace endeavors. Delays, cost overruns, and technical failures can often be traced back to deficiencies in management practices. Effective management ensures that projects remain on schedule, within budget, and meet stringent performance criteria. For example, the development of a new aircraft requires meticulous coordination across various engineering disciplines, manufacturing departments, and testing facilities, demanding strong management skills to maintain cohesion and achieve project milestones.

Various roles within the field require or benefit significantly from proficiency in management. Project Managers oversee the entire lifecycle of aerospace projects, from initial concept to final delivery, ensuring alignment with project goals and stakeholder expectations. Engineering Managers lead teams of engineers, providing technical guidance, mentoring, and ensuring effective collaboration. Program Managers manage multiple related projects, coordinating resources and ensuring consistency across programs. These positions demand a combination of technical expertise, leadership skills, and a thorough understanding of management principles. Moreover, quality management systems, such as AS9100, ensure consistent standards across the industry. Aerospace companies must rigorously adhere to these standards to maintain operational excellence and regulatory compliance. Quality Managers ensure that these standards are met, overseeing audits, implementing corrective actions, and driving continuous improvement.

In summary, effective management is not merely a supporting function, but a critical enabler of success. Inadequate management can lead to project failures, cost overruns, and safety risks, underscoring the need for skilled managers and robust management systems. Challenges associated with managing complex projects, diverse teams, and rapidly evolving technologies drive continuous innovation in management practices within the profession. Therefore, developing management skills and fostering a culture of effective management are essential for maintaining competitiveness and ensuring the future success within the aerospace industry.

7. Maintenance

Maintenance constitutes a crucial segment of roles, ensuring the continued airworthiness, safety, and operational readiness of aerospace vehicles. Deficiencies in maintenance practices directly correlate with increased risks of mechanical failures, system malfunctions, and potentially catastrophic accidents. Consistent and thorough maintenance programs are therefore essential to mitigate these risks and uphold the stringent safety standards that govern the industry. The practical significance of maintenance is exemplified by scheduled inspections, component replacements, and system overhauls performed on aircraft after specific flight hour intervals or calendar periods. Properly maintained aircraft exhibit extended service lives, reduced downtime, and enhanced passenger safety.

The scope of maintenance operations encompasses a diverse array of specialized tasks performed by certified professionals. Aircraft Mechanics conduct routine inspections, troubleshoot mechanical issues, and perform repairs on airframes, engines, and other critical systems. Avionics Technicians maintain and repair electronic systems, including navigation, communication, and flight control equipment. Quality Assurance Inspectors ensure that all maintenance activities adhere to regulatory requirements and industry best practices. The demand for skilled maintenance personnel remains consistently high due to the increasing complexity of aerospace vehicles and the growing volume of air traffic. Maintenance personnel must possess in-depth knowledge of aircraft systems, proficiency in diagnostic techniques, and adherence to rigorous safety protocols.

In summary, maintenance is not merely an ancillary function, but an integral component of roles within the aerospace sector. It underpins the safety, reliability, and longevity of flight systems. Challenges such as adapting to new aircraft technologies and adhering to evolving regulatory requirements necessitate continuous training and professional development for maintenance personnel. Sustained investment in maintenance infrastructure and skilled workforce is critical for maintaining the operational efficiency and safety of air travel, thus supporting the broader goals of aerospace operations.

Frequently Asked Questions

The following addresses common inquiries regarding career prospects within the specified field. These are intended to provide concise and informative responses to frequently raised questions.

Question 1: What educational qualifications are typically required?

A bachelor’s degree in aerospace engineering or a closely related field (mechanical, electrical, etc.) is generally the minimum requirement. Advanced positions often necessitate a master’s degree or doctorate.

Question 2: Are internships essential for securing opportunities?

While not strictly mandatory, internships provide invaluable practical experience and significantly enhance employability. They allow candidates to apply theoretical knowledge in real-world settings and demonstrate a commitment to the field.

Question 3: What are the most in-demand skill sets currently?

Proficiency in CAD software (e.g., CATIA, SolidWorks), simulation tools (e.g., ANSYS, MATLAB), and a strong foundation in mathematics, physics, and engineering principles are highly valued. Specializations in areas such as aerodynamics, propulsion, and structural analysis are also sought after.

Question 4: How is government funding impacting availability?

Government funding for space exploration and defense programs directly influences the demand for engineers. Fluctuations in funding levels can lead to shifts in opportunities, with increased funding typically resulting in greater availability. The correlation between governmental support and industry growth is undeniable.

Question 5: What are some promising areas for specialization?

Emerging technologies such as additive manufacturing, advanced composites, autonomous systems, and sustainable aviation fuels offer promising areas for specialization. These fields are driving innovation and require skilled engineers to advance their development.

Question 6: How important is continuing education in maintaining competitiveness?

Continuous learning is essential due to the rapidly evolving nature of aerospace technology. Staying abreast of new developments through advanced coursework, professional certifications, and industry conferences is critical for maintaining competitiveness and advancing a career.

In summary, preparation, practical experience, and adaptability are key to navigating the job market. Staying informed on industry trends and continuously enhancing skills is essential for a successful and fulfilling career.

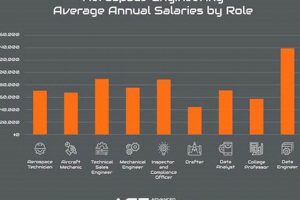

The following content will discuss salary expectations and typical benefits packages.

Conclusion

This exploration of career paths has revealed a multifaceted field characterized by diverse roles spanning design, manufacturing, research, testing, analysis, management, and maintenance. Each facet demands a unique blend of skills and expertise, contributing to the advancement of flight and space technology. The discussion has emphasized the importance of academic excellence, practical experience, and continuous learning in securing and advancing within this sector. Furthermore, government funding and technological advancements significantly influence career opportunities. It is clear that commitment, adaptability, and a thorough understanding of engineering principles are paramount for success in the field.

Therefore, those seeking a professional path should consider the information discussed and assess their aptitude and motivation to meet the demands of the profession. As aerospace technology continues to evolve, so too will the need for qualified individuals. The ongoing pursuit of knowledge and the development of specialized skills remain critical for capitalizing on these future opportunities and contributing to the continued growth and innovation.