Opportunities for employment within the aerospace sector, specifically with LISI Aerospace located in Torrance, California, constitute a segment of the broader Southern California job market. These positions span various disciplines, reflecting the diverse needs of an aerospace manufacturing company. Roles may include engineering, manufacturing, quality control, and administrative functions.

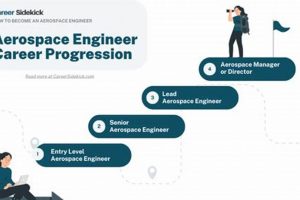

Securing a position at a company like LISI Aerospace offers potential benefits, including contribution to the aerospace industry, competitive compensation packages, and career growth opportunities. The aerospace sector in Southern California has a rich history, with numerous companies driving innovation and technological advancement. Employment in this sector can provide individuals with valuable experience and skills highly sought after in the manufacturing and engineering fields.

The following sections will delve into the specific types of roles commonly found at LISI Aerospace in Torrance, California, the qualifications typically required for these positions, and resources available for individuals seeking employment in this area.

This section provides guidance for individuals seeking employment opportunities within LISI Aerospace’s Torrance, California facility. Adhering to these tips may enhance the prospect of securing a desired position.

Tip 1: Research Company Operations: Prior to applying, thoroughly investigate LISI Aerospace’s specific activities at the Torrance location. Understanding their product lines, manufacturing processes, and target markets demonstrates genuine interest and preparedness.

Tip 2: Align Skills with Job Descriptions: Carefully scrutinize job descriptions and highlight skills and experiences that directly correlate with the specified requirements. Quantifiable achievements demonstrating relevant capabilities strengthen an application.

Tip 3: Tailor Resume and Cover Letter: Generic applications are less effective. Customize the resume and cover letter to address the specific requirements outlined in each job posting. Emphasize relevant experience within the aerospace industry or similar manufacturing environments.

Tip 4: Network Within the Industry: Attending industry events, connecting with professionals on platforms like LinkedIn, and engaging in informational interviews can provide valuable insights and potential leads within LISI Aerospace or related organizations.

Tip 5: Prepare for Technical Assessments: Depending on the role, anticipate technical assessments or aptitude tests. Review fundamental concepts related to engineering, manufacturing, or quality control relevant to the position.

Tip 6: Practice Behavioral Interview Questions: Behavioral interview questions assess past performance to predict future behavior. Prepare responses using the STAR method (Situation, Task, Action, Result) to clearly articulate accomplishments and problem-solving abilities.

Tip 7: Demonstrate a Commitment to Quality: The aerospace industry prioritizes quality and precision. Clearly articulate a dedication to meticulous work, adherence to standards, and continuous improvement in all aspects of the work process.

By implementing these strategies, candidates increase their potential for success in the application and interview process, enhancing their chances of securing a position at LISI Aerospace in Torrance, California.

The subsequent sections will explore the long-term career prospects and development opportunities available at LISI Aerospace.

1. Manufacturing Roles

Manufacturing roles constitute a critical component of employment opportunities at LISI Aerospace’s Torrance, California facility. These positions directly contribute to the production of aerospace fasteners and components, forming a fundamental aspect of the company’s operations.

- Precision Machining Operations

These roles involve operating and maintaining sophisticated machinery used in the creation of aerospace fasteners. Examples include CNC milling machines, lathes, and grinding equipment. Precision is paramount, requiring adherence to tight tolerances and rigorous quality control procedures. The implications for LISI Aerospace are significant, as the quality of the finished product directly impacts the safety and reliability of aerospace systems. Skilled machinists are thus essential to the company’s manufacturing process.

- Assembly and Fabrication

These positions focus on assembling individual components into finished fasteners and sub-assemblies. Responsibilities may include welding, riveting, and the application of specialized coatings. Attention to detail is crucial, as even minor errors can compromise the structural integrity of the final product. For LISI Aerospace, a competent assembly and fabrication team ensures that fasteners meet stringent industry specifications and performance requirements.

- Quality Control Inspection

Quality control inspectors are responsible for examining manufactured parts and assemblies to verify conformance to engineering drawings and quality standards. They utilize various inspection tools and techniques, including dimensional measurement, visual inspection, and non-destructive testing. Maintaining product quality is critical to LISI Aerospace’s reputation and its ability to supply fasteners for safety-critical applications.

- Production Planning and Control

These roles involve planning and coordinating the flow of materials and work through the manufacturing process. Responsibilities include scheduling production, managing inventory levels, and ensuring timely delivery of finished goods. Efficient production planning is essential for optimizing resource utilization and meeting customer demand. At LISI Aerospace, effective production control minimizes lead times and maximizes manufacturing throughput.

The various manufacturing roles within LISI Aerospace’s Torrance facility are interconnected and contribute directly to the company’s overall success. These positions demand a combination of technical skills, attention to detail, and a commitment to quality. They represent a significant portion of the employment opportunities available and are vital for LISI Aerospace to maintain its position as a leading supplier of aerospace fasteners.

2. Engineering Positions

Engineering positions at LISI Aerospace’s Torrance, California location are integral to the company’s function as a manufacturer of aerospace fasteners and components. These roles encompass a range of disciplines critical for product design, development, and production.

- Design Engineering

Design engineers are responsible for the conceptualization and detailed design of aerospace fasteners. This involves utilizing CAD software, performing stress analysis, and ensuring that designs meet stringent aerospace specifications. Real-world examples include designing fasteners for aircraft structural components, engine assemblies, and landing gear systems. Within the context of LISI Aerospace, design engineering directly impacts product performance, safety, and manufacturability.

- Manufacturing Engineering

Manufacturing engineers focus on optimizing the manufacturing processes involved in producing aerospace fasteners. This includes selecting appropriate manufacturing equipment, developing process parameters, and implementing quality control procedures. Examples include designing tooling for CNC machining, optimizing heat treatment processes, and implementing statistical process control (SPC) to ensure consistent product quality. At LISI Aerospace, manufacturing engineering plays a vital role in improving efficiency, reducing costs, and maintaining product quality.

- Materials Engineering

Materials engineers are responsible for selecting and testing materials used in aerospace fasteners. This includes analyzing material properties, conducting failure analysis, and ensuring that materials meet the demanding requirements of aerospace applications. Examples include selecting high-strength alloys for critical structural fasteners, evaluating the corrosion resistance of protective coatings, and investigating material failures in service. For LISI Aerospace, materials engineering ensures that fasteners are durable, reliable, and capable of withstanding extreme operating conditions.

- Quality Engineering

Quality engineers are responsible for developing and implementing quality management systems to ensure that aerospace fasteners meet all applicable requirements. This includes developing inspection procedures, conducting audits, and analyzing data to identify areas for improvement. Examples include developing inspection plans for incoming materials, conducting internal audits to assess compliance with quality standards, and analyzing data to identify and resolve quality issues. Within the context of LISI Aerospace, quality engineering is essential for maintaining customer satisfaction and ensuring the safety and reliability of its products.

The engineering positions at LISI Aerospace’s Torrance facility, across the aforementioned disciplines, are critical for the company’s ability to design, manufacture, and deliver high-quality aerospace fasteners. These roles require a combination of technical expertise, problem-solving skills, and a commitment to excellence. The engineering department is therefore a fundamental component of LISI Aerospace’s operations and its continued success in the aerospace industry.

3. Quality Assurance

Quality assurance constitutes a vital component of operations at LISI Aerospace’s Torrance, California facility. Given the critical nature of aerospace fasteners and components, rigorous quality control measures are paramount to ensure product reliability and safety. Positions dedicated to quality assurance are therefore essential within the organizational structure.

- Inspection and Testing Protocols

Quality assurance personnel are responsible for implementing and executing comprehensive inspection and testing protocols throughout the manufacturing process. These protocols encompass dimensional measurements, material testing, and non-destructive examination techniques to verify conformance to stringent industry standards. The implications for LISI Aerospace are substantial, as deviations from established quality standards can compromise the structural integrity of finished products.

- Compliance with Industry Standards

Aerospace manufacturing is subject to strict regulatory oversight and industry-specific quality standards such as AS9100. Quality assurance specialists are tasked with ensuring that LISI Aerospace’s Torrance facility adheres to these requirements. This involves maintaining detailed documentation, conducting internal audits, and collaborating with external regulatory agencies. Failure to comply with industry standards can result in significant penalties and jeopardize the company’s operational licenses.

- Statistical Process Control (SPC) Implementation

SPC methodologies are employed to monitor and control manufacturing processes, minimizing variation and preventing defects. Quality assurance professionals are responsible for implementing and maintaining SPC charts, analyzing data, and identifying trends that may indicate potential quality issues. The utilization of SPC enables LISI Aerospace to proactively address manufacturing challenges, thereby enhancing product quality and reducing scrap rates.

- Corrective and Preventive Action (CAPA) Systems

Effective CAPA systems are essential for addressing non-conformances and preventing future occurrences. Quality assurance personnel are responsible for investigating root causes of defects, implementing corrective actions, and validating the effectiveness of those actions. A robust CAPA system demonstrates LISI Aerospace’s commitment to continuous improvement and enhances its ability to consistently deliver high-quality products.

The facets of quality assurance outlined above are intrinsically linked to employment opportunities at LISI Aerospace in Torrance, California. Positions within this domain require a combination of technical expertise, analytical skills, and a meticulous attention to detail. The effective execution of quality assurance practices directly contributes to LISI Aerospace’s reputation as a reliable supplier of aerospace fasteners and components.

4. Competitive compensation

The attraction and retention of qualified personnel are directly influenced by compensation packages offered for positions at LISI Aerospace in Torrance, California. “Competitive compensation” serves as a primary motivator for individuals considering or accepting employment. Its significance stems from the specialized skill sets often required within the aerospace manufacturing sector. For example, a highly skilled CNC machinist familiar with aerospace tolerances can command a higher salary than a machinist with less specialized experience. Companies that offer competitive wages and benefits are more likely to attract and retain these individuals, ensuring a skilled workforce for the company.

The impact of “competitive compensation” extends beyond initial recruitment. Employee satisfaction and motivation are directly linked to perceived fairness in compensation. When employees feel adequately compensated for their skills and contributions, they are more likely to be engaged and productive. This, in turn, positively affects product quality, efficiency, and overall organizational performance. Moreover, compensation packages often include benefits such as health insurance, retirement plans, and paid time off, which contribute to employees’ overall well-being and further enhance retention rates. This is important as there is a constant need for skilled individuals in the LISI Aerospace industry.

Understanding the role of “competitive compensation” is crucial for both job seekers and LISI Aerospace itself. Potential employees should research industry standards and negotiate effectively to secure fair compensation for their skills and experience. LISI Aerospace must continuously evaluate its compensation strategies to remain competitive within the market, attracting top talent and maintaining a skilled workforce capable of meeting the demands of the aerospace industry. The alternative is losing talented members of the team and wasting time training new ones.

5. Aerospace sector

The aerospace sector serves as the foundational context for positions at LISI Aerospace’s Torrance, California facility. It represents the overarching industry that dictates the nature, scope, and demand for these employment opportunities. The company’s function as a manufacturer of aerospace fasteners is directly dependent on the health and activity within the broader aerospace ecosystem. For instance, increased aircraft production by Boeing and Airbus directly translates to higher demand for the fasteners LISI Aerospace produces, leading to potential growth in its workforce. Conversely, downturns in the aerospace sector, such as those experienced during periods of economic recession or geopolitical instability, can negatively impact LISI Aerospace’s hiring prospects and overall business operations.

Within this industry landscape, LISI Aerospace’s Torrance location is strategically significant. Southern California has historically been a hub for aerospace engineering, manufacturing, and research, fostering a concentration of talent, suppliers, and related businesses. This creates a synergistic environment wherein LISI Aerospace benefits from proximity to potential customers, skilled labor pools, and specialized service providers. The availability of experienced aerospace engineers and technicians in the region is a direct result of the area’s long-standing involvement in the sector, impacting the types of roles and the required qualifications for positions at LISI Aerospace.

Understanding the intrinsic link between the aerospace sector and the “LISI Aerospace Torrance CA jobs” is crucial for both prospective employees and the company itself. Job seekers must appreciate the cyclical nature of the industry and the specialized skills required to succeed within it. LISI Aerospace must continuously monitor industry trends, adapt its business strategies, and invest in its workforce to remain competitive in an evolving market. Challenges include navigating supply chain disruptions, managing fluctuating demand, and adapting to technological advancements in manufacturing processes. Ultimately, the long-term viability of LISI Aerospace’s Torrance operations is inextricably tied to the health and dynamism of the aerospace sector as a whole.

6. Torrance location

The “Torrance location” is not merely a geographical detail; it is an integral component influencing the nature of “lisi aerospace torrance ca jobs.” Its presence within Southern California’s aerospace cluster affects the talent pool, operational logistics, and business opportunities available to LISI Aerospace. The proximity to major aerospace manufacturers, suppliers, and research institutions creates a competitive environment for skilled labor. For example, the presence of companies like SpaceX and Northrop Grumman in the region generates a demand for engineering and manufacturing talent, impacting the compensation levels and specific skill sets required for positions at LISI Aerospace in Torrance. Real-world examples include local colleges and universities tailoring their engineering programs to meet the needs of these aerospace companies, providing a readily available source of qualified candidates.

The “Torrance location” also offers practical advantages in terms of logistics and supply chain management. Access to major transportation networks, including the Ports of Los Angeles and Long Beach, facilitates the import of raw materials and the export of finished products. This logistical efficiency translates to reduced operational costs and improved delivery times for LISI Aerospace, impacting its competitiveness in the global market. Furthermore, the concentration of aerospace suppliers in Southern California allows for closer collaboration and reduced lead times for specialized components, further optimizing the manufacturing process. These efficiencies result in a more dynamic and responsive operational environment for those involved in “lisi aerospace torrance ca jobs”.

In summary, the “Torrance location” is a critical factor shaping the landscape of employment at LISI Aerospace. The location’s influence extends from the availability of skilled labor and logistical advantages to its role in fostering a competitive and innovative business environment. Understanding this connection is vital for both potential employees seeking opportunities and LISI Aerospace strategizing for sustained growth and success within the aerospace sector. Overcoming challenges related to talent acquisition and managing supply chains within this specific geographic context are essential for realizing the full potential of “lisi aerospace torrance ca jobs.”

Frequently Asked Questions Regarding Opportunities at LISI Aerospace in Torrance, CA

This section addresses common inquiries concerning employment prospects within LISI Aerospace’s Torrance, California facility. The information presented aims to provide clarity and guidance to potential applicants.

Question 1: What types of positions are typically available at LISI Aerospace in Torrance?

Positions commonly span manufacturing, engineering (including design, materials, and quality), quality assurance, and administrative roles. Specific openings vary depending on the company’s current needs and project demands.

Question 2: What qualifications are generally required for engineering roles at LISI Aerospace?

Engineering positions typically require a bachelor’s degree in a relevant engineering discipline (e.g., mechanical, aerospace, materials). Experience within the aerospace industry or a related manufacturing environment is often preferred. Specific requirements vary based on the position’s responsibilities.

Question 3: Does LISI Aerospace offer internships or entry-level programs for recent graduates?

LISI Aerospace may offer internships or entry-level positions depending on the company’s current recruitment needs. Prospective applicants are advised to consult the company’s careers website or job boards for available opportunities.

Question 4: What is the typical compensation range for positions at LISI Aerospace in Torrance?

Compensation ranges are contingent upon the specific role, level of experience, and prevailing market conditions. Information regarding salary expectations is typically discussed during the interview process.

Question 5: How does LISI Aerospace ensure product quality and adherence to industry standards?

LISI Aerospace implements comprehensive quality assurance programs, including rigorous inspection protocols, statistical process control (SPC), and adherence to industry standards such as AS9100. Quality engineers and inspectors play a critical role in maintaining product quality and compliance.

Question 6: What is the work environment like at LISI Aerospace’s Torrance facility?

The work environment is typically characterized by a focus on precision manufacturing, teamwork, and adherence to safety protocols. Specific aspects of the work environment may vary depending on the department and role.

This FAQ section has provided essential details on job opportunities at LISI Aerospace in Torrance. Knowing the available positions, necessary qualifications, compensation, product quality, and the work environment could help you with your career choice.

The subsequent sections will explore the benefits of working within the aerospace industry and within Southern California.

Conclusion

The preceding discussion has explored facets associated with employment opportunities at LISI Aerospace in Torrance, California. Key areas of consideration included the types of positions typically available (manufacturing, engineering, quality assurance), the qualifications generally required, aspects of compensation, and the influence of both the aerospace sector and the Torrance location on available positions. Emphasis was placed on the significance of quality assurance, competitive compensation, and the strategic importance of the Torrance location within the Southern California aerospace ecosystem.

Understanding the factors outlined herein is critical for individuals considering pursuing “lisi aerospace torrance ca jobs”. The aerospace industry demands a highly skilled and dedicated workforce, and companies like LISI Aerospace play a vital role in providing these opportunities. Continual assessment of market trends, technological advancements, and workforce development initiatives will be essential for sustained success in this competitive field.