Opportunities at the Torrance, California, location of LISI Aerospace encompass a range of positions within the aerospace manufacturing sector. These roles often involve the production, quality control, engineering, and administrative functions necessary to support the company’s operations. For example, individuals might find employment as machinists, quality inspectors, design engineers, or in supply chain management at this specific site.

Securing employment in this sector offers numerous advantages. The aerospace industry provides stable career paths, often with competitive compensation and benefits packages. Historically, it has been a driver of innovation and technological advancement, offering employees the chance to contribute to cutting-edge projects. Furthermore, the demand for skilled professionals in aerospace remains strong, particularly in regions with a significant manufacturing presence.

The following discussion will delve into the specific types of career opportunities typically available, the skills and qualifications often sought by employers, and the general environment and culture associated with working in this segment of the aerospace industry.

Strategies for Pursuing Opportunities at LISI Aerospace in Torrance

The following recommendations provide guidance for individuals seeking employment at the LISI Aerospace facility located in Torrance, California. Effective preparation and a targeted approach can significantly increase the likelihood of a successful application.

Tip 1: Thoroughly Research the Company. Candidates should demonstrate a comprehensive understanding of LISI Aerospace’s products, services, and market position. Reviewing the company’s website, press releases, and industry publications offers valuable insights. For example, understanding their specialization in aerospace fasteners and components is crucial.

Tip 2: Tailor the Application Materials. Generic resumes and cover letters are unlikely to succeed. Each application should be specifically tailored to the requirements of the posted position, highlighting relevant skills and experience. If a job description emphasizes precision machining, experience in that area must be prominently displayed.

Tip 3: Highlight Relevant Certifications and Training. Aerospace manufacturing often requires specific certifications and training. Examples include certifications in quality control (e.g., ASQ), machining (e.g., NIMS), or specific software proficiency (e.g., CAD/CAM). Actively showcasing these credentials enhances a candidate’s competitiveness.

Tip 4: Emphasize Problem-Solving Abilities. Aerospace environments demand individuals capable of identifying and resolving technical challenges. Applicants should provide concrete examples of how they have successfully addressed problems in previous roles, demonstrating their analytical and troubleshooting skills.

Tip 5: Demonstrate a Commitment to Quality and Safety. The aerospace industry operates under stringent quality and safety standards. Candidates must demonstrate a thorough understanding of these principles and a proven track record of adhering to them. Specific examples of implementing safety protocols or contributing to quality improvement initiatives are highly valuable.

Tip 6: Network Strategically. Connecting with current or former employees of LISI Aerospace can provide valuable insights into the company culture and hiring processes. Utilizing platforms like LinkedIn to identify and connect with relevant professionals can be a beneficial strategy.

Tip 7: Prepare for Technical Assessments. Many aerospace manufacturing roles require technical proficiency. Candidates should anticipate technical assessments, such as machining tests, blueprint reading exercises, or quality inspection simulations, and adequately prepare by reviewing relevant technical skills and knowledge.

Employing these strategies will increase the chances of securing a position within the LISI Aerospace Torrance facility. These steps focus on demonstrating relevant skills, understanding the industry, and proactively engaging with the company.

The subsequent sections will address common career paths, potential salary ranges, and expectations regarding career advancement within the organization.

1. Manufacturing opportunities

Manufacturing opportunities form a core element of the employment landscape at LISI Aerospace in Torrance. These positions are directly involved in the production and fabrication of aerospace components, which are essential to the company’s operations and the wider aerospace industry.

- Machining and Fabrication

This facet involves operating precision machinery, such as CNC mills and lathes, to manufacture parts according to strict engineering specifications. An example is the production of aerospace fasteners, requiring precise dimensions and material properties. The implications include the need for skilled machinists with experience in aerospace-grade materials and tight tolerances.

- Assembly and Sub-Assembly

This includes the assembly of components into larger sub-assemblies, often requiring specialized tools and techniques. A real-world example is the assembly of locking mechanisms for aircraft doors. The need for careful attention to detail and adherence to safety protocols is crucial.

- Quality Control and Inspection

This involves the rigorous inspection of manufactured parts to ensure they meet quality standards and specifications. An example includes using coordinate measuring machines (CMMs) to verify dimensions and surface finishes. The role is critical in preventing defects and ensuring the reliability of aerospace components.

- Materials Handling and Logistics

This facet encompasses the movement and storage of raw materials, work-in-progress, and finished goods within the manufacturing facility. An example includes managing the inventory of specialized alloys used in aerospace applications. Efficient logistics are essential for maintaining production schedules and minimizing waste.

These manufacturing opportunities at the Torrance site represent a vital part of LISI Aerospace’s operations. They demand skilled workers, advanced equipment, and rigorous quality control processes to produce the high-precision components required by the aerospace industry. The integration of these facets directly impacts the company’s ability to fulfill contracts and maintain its position in the aerospace market.

2. Engineering roles

Engineering roles constitute a significant component of the professional landscape at LISI Aerospace’s Torrance location. These positions are crucial for the design, development, and improvement of manufacturing processes and aerospace components. The demand for qualified engineers directly influences the types of employment opportunities available at the Torrance facility. A practical example is the need for design engineers to create and refine specifications for aerospace fasteners, ensuring they meet stringent performance requirements. Therefore, the presence of a robust engineering team is essential for the facility’s operational success and its ability to innovate.

The types of engineering roles available often span various disciplines, including mechanical, materials, and manufacturing engineering. These engineers may be involved in tasks such as optimizing production processes to reduce waste, conducting failure analysis on components to improve reliability, or designing new tooling and fixtures to enhance manufacturing efficiency. For instance, manufacturing engineers might implement lean manufacturing principles to streamline production lines and improve throughput, directly impacting the facility’s overall productivity. These engineering efforts are not merely theoretical; they have direct and measurable effects on the quality and cost-effectiveness of the products manufactured in Torrance.

In conclusion, engineering roles are inextricably linked to the broader spectrum of career prospects within the LISI Aerospace Torrance jobs ecosystem. Their expertise is vital for driving innovation, ensuring product quality, and optimizing manufacturing processes. While challenges such as keeping pace with technological advancements and managing complex projects exist, the importance of engineering expertise cannot be overstated in maintaining LISI Aerospace’s competitive edge within the aerospace industry.

3. Quality assurance positions

Quality assurance positions constitute a critical element within the scope of LISI Aerospace Torrance employment opportunities. These roles are directly responsible for ensuring that manufactured components meet stringent aerospace industry standards. The correlation is causal: LISI Aerospace’s need to produce high-quality, reliable parts necessitates a dedicated quality assurance workforce. A real-world example is the inspection of fasteners, where quality assurance personnel verify dimensions, material properties, and surface treatments, often using advanced measurement tools. The practical significance lies in preventing defective components from reaching aircraft, thus minimizing safety risks and potential financial losses.

The specific responsibilities within quality assurance can vary, encompassing incoming material inspection, in-process inspection, final product inspection, and auditing of manufacturing processes. Furthermore, these positions may involve the implementation and maintenance of quality management systems, such as AS9100. The application of statistical process control (SPC) techniques is common, allowing quality professionals to monitor process variations and implement corrective actions. For instance, analyzing SPC charts might reveal a trend towards out-of-tolerance fasteners, prompting an investigation into the machining process. This proactive approach ensures continuous improvement and adherence to quality standards.

In summary, quality assurance positions are indispensable to LISI Aerospace Torrance. These roles directly contribute to the safety and reliability of aerospace components. The integration of robust quality assurance practices ensures adherence to industry standards, mitigates risk, and strengthens LISI Aerospace’s competitive position. The ongoing challenge is to adapt quality control methods to meet evolving industry requirements and technological advancements, ensuring the continued integrity of aerospace manufacturing.

4. Location advantages

The geographical location of LISI Aerospace’s Torrance facility presents specific advantages that directly influence the availability and nature of employment opportunities. This location within a concentrated aerospace hub impacts talent acquisition, supply chain efficiency, and overall competitiveness.

- Proximity to Aerospace Industry Clusters

The Torrance location benefits from its proximity to a dense network of aerospace companies, suppliers, and research institutions in Southern California. An example is the presence of Boeing, SpaceX, and numerous smaller aerospace firms in the surrounding area. This concentration facilitates collaboration, knowledge sharing, and access to a skilled workforce familiar with aerospace manufacturing processes. The implication is a readily available pool of qualified candidates for LISI Aerospace Torrance jobs.

- Access to a Skilled Labor Pool

Southern California has a long history in aerospace, resulting in a large pool of experienced engineers, machinists, and technicians. Technical schools and universities in the region, such as Caltech and UCLA, produce graduates with the skills required for aerospace manufacturing. This access to a skilled labor pool reduces recruitment costs and ensures a workforce capable of meeting the demands of precision manufacturing. An example is the availability of graduates with degrees in aerospace engineering and materials science.

- Supply Chain Efficiencies

The location offers access to a well-established network of suppliers specializing in aerospace-grade materials, components, and services. This localized supply chain reduces lead times, transportation costs, and potential disruptions. An example is the proximity to suppliers of specialized alloys and surface treatments, essential for aerospace fasteners. The implication is a more efficient and responsive manufacturing process, contributing to LISI Aerospace’s competitiveness.

- Transportation Infrastructure

The Torrance area benefits from well-developed transportation infrastructure, including highways, ports, and airports. This facilitates the movement of raw materials, finished products, and personnel. For example, the proximity to Los Angeles International Airport (LAX) allows for efficient shipping of products worldwide and convenient travel for employees. The improved logistics translate to smoother operations and reduced operational expenses for LISI Aerospace.

These location advantages collectively contribute to the attractiveness and viability of LISI Aerospace’s Torrance facility, supporting a robust job market and fostering an environment conducive to innovation and growth. The strategic placement of the facility directly impacts its ability to attract talent, optimize operations, and maintain its competitive edge within the aerospace industry.

5. Skill requirements

The requisite skill sets for positions at LISI Aerospace in Torrance are directly shaped by the precision-demanding nature of aerospace manufacturing. These competencies are not merely desirable, but are fundamental prerequisites for successful job performance and adherence to industry standards. The following points outline specific skill facets crucial for prospective employees.

- Technical Proficiency in Manufacturing Processes

A comprehensive understanding of manufacturing techniques, such as CNC machining, precision grinding, and heat treating, is paramount. For instance, a machinist must be adept at interpreting complex blueprints and operating sophisticated machinery to fabricate components to exacting tolerances. Insufficient technical expertise can lead to production errors, material waste, and compromised product quality, directly impacting operational efficiency.

- Quality Control and Inspection Expertise

Competence in quality control procedures and inspection methodologies is essential for ensuring compliance with stringent aerospace standards. This includes proficiency in using measuring instruments like calipers, micrometers, and coordinate measuring machines (CMMs). A quality inspector, for example, must be able to accurately assess dimensional accuracy, surface finish, and material integrity. Failures in quality control can result in the acceptance of defective parts, jeopardizing safety and reliability.

- Knowledge of Aerospace Materials and Standards

Familiarity with the properties and characteristics of aerospace-grade materials, such as aluminum alloys, titanium, and composites, is a necessity. This knowledge extends to adherence to industry standards like AS9100 and specific customer requirements. An engineer, for example, must understand the effects of stress, temperature, and corrosion on different materials to design robust and reliable components. A lack of materials expertise can lead to premature failures and compromised structural integrity.

- Problem-Solving and Analytical Abilities

The ability to identify and resolve technical challenges is crucial in the dynamic aerospace manufacturing environment. This entails applying analytical skills to diagnose process deviations, troubleshoot equipment malfunctions, and implement corrective actions. For example, a manufacturing engineer must be able to analyze production data to identify bottlenecks and optimize workflow. Inadequate problem-solving skills can result in prolonged downtime, increased costs, and reduced productivity.

These skill requirements are integral to all positions at LISI Aerospace Torrance. Proficiency in these areas directly impacts the facility’s ability to produce high-quality, reliable aerospace components, maintain compliance with industry standards, and remain competitive in the global market. The continuous development and enhancement of these skills are therefore critical for both individual career advancement and the overall success of the organization.

6. Career development

The availability of career development opportunities is intrinsically linked to the attractiveness and retention of personnel at LISI Aerospace’s Torrance location. The presence of clearly defined career paths and professional growth programs directly affects employee morale, productivity, and long-term commitment to the organization. For example, the implementation of a mentorship program, pairing experienced engineers with junior staff, can accelerate skill development and knowledge transfer. Consequently, employees are more likely to remain with the company, reducing turnover costs and fostering a more experienced and capable workforce. The absence of such opportunities, conversely, can lead to employee dissatisfaction and attrition.

Furthermore, career development initiatives can take various forms, including technical training, leadership development programs, and tuition reimbursement for advanced education. An example is providing employees with access to specialized training in advanced manufacturing techniques or quality control methodologies. The direct result is an improvement in technical skills, enhanced job performance, and increased adaptability to evolving industry demands. Internal promotion opportunities, based on merit and skill development, also serve as a powerful incentive for employees to strive for excellence and contribute to the organization’s success. The practical application of these programs is demonstrated through increased employee engagement scores and a higher percentage of internal promotions filling senior positions.

In summary, career development is an integral component of the employment value proposition at LISI Aerospace Torrance. A commitment to employee growth fosters a more skilled, engaged, and loyal workforce. While challenges such as resource allocation and program implementation exist, the long-term benefits of investing in career development significantly outweigh the costs. This investment contributes to a sustainable and competitive workforce, essential for maintaining LISI Aerospace’s position in the aerospace industry.

7. Company reputation

The reputation of LISI Aerospace directly influences the attractiveness and accessibility of positions at its Torrance location. A strong corporate image enhances talent acquisition, customer relationships, and overall business stability. Consequently, understanding the facets of reputation is crucial in assessing the value and prospects associated with opportunities there.

- Attracting Top Talent

A positive reputation acts as a magnet for skilled professionals. Individuals are more inclined to apply for positions at companies known for ethical practices, innovation, and employee satisfaction. For example, a candidate evaluating multiple job offers in the aerospace sector might favor LISI Aerospace if it has a reputation for providing opportunities for professional development and a positive work environment. A negative reputation, conversely, can deter qualified applicants, leading to recruitment challenges.

- Customer Confidence and Order Book

A reputable company is more likely to secure contracts with major aerospace manufacturers. Customers prioritize suppliers with a proven track record of delivering high-quality products and adhering to stringent industry standards. For instance, if LISI Aerospace is known for its reliable fasteners and adherence to AS9100 standards, it is more likely to be awarded contracts, thereby creating a stable demand for manufacturing and engineering personnel at the Torrance facility.

- Investor Relations and Financial Stability

A positive reputation enhances investor confidence, leading to improved financial stability. Investors are more willing to support companies with a strong brand image and a history of ethical conduct. This financial stability translates to greater job security and opportunities for growth within the organization. A company facing reputational challenges may struggle to attract investment, potentially leading to workforce reductions or facility closures.

- Brand Equity and Market Position

A strong reputation contributes to brand equity and a favorable market position. This allows the company to command premium pricing for its products and services, increasing profitability and providing resources for investment in innovation and employee development. For example, if LISI Aerospace is recognized as a leader in aerospace fastener technology, it can justify higher prices and attract customers willing to pay for superior quality and reliability, further supporting job creation and stability at the Torrance location.

These facets underscore the critical role of reputation in shaping the overall employment landscape at LISI Aerospace Torrance. A positive reputation not only attracts top talent and secures customer contracts but also enhances financial stability and market position, creating a more secure and rewarding environment for its workforce.

Frequently Asked Questions Regarding Career Opportunities at LISI Aerospace Torrance

The following addresses common inquiries concerning employment opportunities at LISI Aerospace’s Torrance, California facility. These answers are intended to provide clarity and guidance for prospective applicants.

Question 1: What types of positions are typically available at the LISI Aerospace Torrance location?

The facility generally offers positions in manufacturing, quality assurance, engineering, and administrative support. Specific roles include machinists, quality inspectors, design engineers, and supply chain specialists. The availability of specific roles fluctuates based on business needs and current contracts.

Question 2: What are the minimum qualifications required for manufacturing positions?

Minimum qualifications typically include a high school diploma or equivalent, along with relevant experience in a manufacturing environment. Specific positions may require vocational training, certifications (e.g., NIMS), or experience operating specific types of machinery (e.g., CNC mills, lathes).

Question 3: What educational background is preferred for engineering positions?

Engineering positions generally require a bachelor’s degree in a relevant engineering discipline, such as mechanical, aerospace, or materials engineering. Advanced degrees or certifications may be preferred for specialized roles.

Question 4: How does LISI Aerospace support employee development and career advancement?

LISI Aerospace may offer internal training programs, tuition reimbursement for relevant coursework, and opportunities for advancement within the organization. Specific opportunities vary depending on the employee’s role, performance, and company needs.

Question 5: What is the typical work environment like at the Torrance facility?

The work environment is typically characterized by a focus on precision manufacturing, adherence to strict quality standards, and a commitment to safety. Employees are expected to collaborate effectively within teams and to contribute to continuous improvement initiatives.

Question 6: Where can prospective applicants find information on current job openings?

Information on current job openings is typically available on the LISI Aerospace corporate website, as well as on job boards such as Indeed, LinkedIn, and industry-specific websites. Applicants are encouraged to regularly check these sources for updates.

In summary, prospective employees should thoroughly research available positions, understand the required qualifications, and be prepared to demonstrate their skills and experience in a competitive application process.

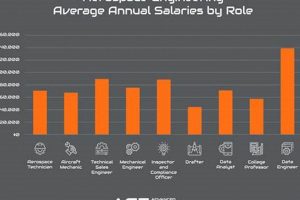

The subsequent section will provide insights into potential salary expectations and benefits packages associated with employment at the Torrance facility.

Concluding Remarks on LISI Aerospace Torrance Jobs

This exploration of LISI Aerospace Torrance Jobs has highlighted the diverse range of employment opportunities available, spanning manufacturing, engineering, and quality assurance. The importance of specific skills, certifications, and the company’s strategic location within a prominent aerospace hub have been underscored. Furthermore, the significance of career development and the company’s overall reputation in attracting and retaining talent were examined.

The information presented serves as a foundation for prospective employees and industry observers seeking a comprehensive understanding of the employment landscape at LISI Aerospace’s Torrance facility. Continued monitoring of job postings and industry trends is essential for those pursuing career opportunities in this sector. The aerospace industry’s demand for skilled professionals suggests a promising outlook for those prepared to meet its exacting standards.

![Find Top Aerospace Jobs in Phoenix, AZ - [Your Company Name] Innovating the Future of Flight with Reliable Aviation Solutions Find Top Aerospace Jobs in Phoenix, AZ - [Your Company Name] | Innovating the Future of Flight with Reliable Aviation Solutions](https://mixaerospace.com/wp-content/uploads/2026/01/th-729-300x200.jpg)