The sector encompassing the design, development, manufacturing, and maintenance of aircraft and related components within the nations economic landscape is a complex and vital element. This encompasses activities ranging from the production of aircraft parts to the provision of maintenance, repair, and overhaul (MRO) services, contributing to both the domestic and global aviation supply chains. For instance, companies engaged in the creation of composite materials for aircraft wings or the provision of engine overhaul services fall under this broad definition.

This specialized area holds substantial significance for the nation, fostering technological advancement, generating high-skilled employment opportunities, and contributing significantly to export revenue. Historically, government initiatives and strategic partnerships with international players have been instrumental in nurturing its growth, positioning the nation as a key player in the Southeast Asian aviation market. The development of indigenous aerospace capabilities further enhances the nations economic competitiveness and technological independence.

The following sections will delve into specific aspects such as the current market landscape, key industry players, technological advancements, government policies, and future prospects. Examination of these areas will provide a detailed understanding of the opportunities and challenges within this dynamic segment of the national economy.

Strategic Considerations for the National Aviation Sector

This section outlines actionable recommendations designed to optimize the performance and growth trajectory of entities operating within the national aviation framework. These strategies are intended to provide a competitive advantage and contribute to the overall advancement of the sector.

Tip 1: Invest in Skilled Workforce Development: Prioritize the creation of specialized training programs in areas such as advanced composite materials, avionics systems, and aerospace engineering. This will ensure a pipeline of qualified personnel to meet the evolving demands of the industry. Example: Collaborate with technical universities to establish aerospace-focused curricula.

Tip 2: Foster Collaborative Partnerships: Actively seek strategic alliances with international aerospace manufacturers and technology providers. These partnerships can facilitate technology transfer, knowledge sharing, and access to global markets. Example: Joint ventures for manufacturing aircraft components or providing MRO services.

Tip 3: Enhance Research and Development Initiatives: Allocate resources to support research and development in key areas such as sustainable aviation technologies, unmanned aerial vehicles (UAVs), and advanced manufacturing processes. Innovation will be critical for maintaining competitiveness in the long term. Example: Government grants for research projects focused on reducing carbon emissions from aircraft.

Tip 4: Strengthen Regulatory Frameworks: Develop and implement clear and efficient regulatory frameworks that support the growth of the sector while ensuring safety and compliance with international standards. Streamlined certification processes can reduce bureaucratic hurdles and attract foreign investment. Example: Simplify the process for obtaining type certification for locally manufactured aircraft components.

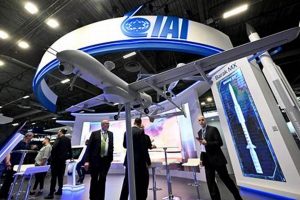

Tip 5: Promote Export-Oriented Strategies: Actively promote the capabilities of domestic aerospace companies in international markets. Participation in aerospace trade shows and targeted marketing campaigns can raise awareness and attract potential customers. Example: Support domestic companies in exhibiting at international airshows such as the Paris Air Show.

Tip 6: Focus on Niche Specialization: Identify areas of comparative advantage and focus on developing specialized capabilities within the aerospace value chain. This could include specializing in MRO services for specific aircraft types or manufacturing specific types of aircraft components. Example: Become a regional hub for the maintenance of turboprop engines.

These strategic considerations, when implemented effectively, can significantly enhance the national aviation sector’s competitiveness, innovation, and overall contribution to the economy.

The subsequent analysis will provide a concluding perspective on the prospects for continued expansion and the challenges that need to be addressed to ensure long-term success.

1. Manufacturing Capabilities

The capacity to produce aerospace components, systems, and complete aircraft within Malaysia is a fundamental pillar supporting the nation’s standing in the global aerospace market. These capabilities determine the extent to which the nation can participate in the aerospace value chain, influence technological advancement, and foster economic growth. Developing and expanding manufacturing capabilities is, therefore, a strategic imperative.

- Component Manufacturing

This involves the production of specific parts and sub-assemblies for aircraft, such as wings, fuselages, landing gear, and avionics systems. Companies like CTRM Aero Composites exemplify this, specializing in composite materials for aircraft structures. Expanding component manufacturing strengthens the supply chain, reduces reliance on foreign suppliers, and creates opportunities for export.

- Engine Manufacturing and Assembly

While complete engine manufacturing is a complex undertaking, the assembly and testing of engines represents a significant capability. This involves integrating various engine components and conducting rigorous testing to ensure performance and safety. Development in this area necessitates significant investments in infrastructure and skilled personnel but results in high-value-added activities.

- Aircraft Assembly and Integration

The assembly of complete aircraft, whether licensed production or indigenous designs, represents the highest level of manufacturing capability. This involves integrating all aircraft systems and components, conducting flight testing, and obtaining certification. A notable, though historical, example includes the assembly of light aircraft under license. Progressing toward aircraft assembly enhances technological expertise and creates a wider range of economic opportunities.

- Tooling and Fixture Design and Manufacturing

An often overlooked but essential aspect of manufacturing is the design and production of specialized tooling and fixtures used in aircraft manufacturing. This includes jigs, molds, and other equipment required to accurately and efficiently produce aircraft components. Developing this capability domestically reduces lead times, lowers costs, and promotes innovation in manufacturing processes.

Investment in and expansion of manufacturing capabilities directly bolsters participation in global aerospace supply chains, facilitates technology transfer, and creates high-skilled employment opportunities. Further development of these capabilities requires strategic investments in infrastructure, workforce training, and research and development, all aimed at enhancing the nation’s competitive position in the global aerospace industry.

2. MRO Specialization

Maintenance, Repair, and Overhaul (MRO) specialization constitutes a critical component of the nation’s broader aerospace sector. The ability to provide high-quality MRO services directly impacts the operational efficiency and safety of aircraft fleets, both domestic and international. The growth of MRO capabilities within the nation serves as a catalyst for attracting foreign investment, generating high-skilled employment, and establishing the nation as a regional aviation hub. For example, Sepang Aircraft Engineering (SAE), a subsidiary of Airbus, provides MRO services for Airbus aircraft, demonstrating the potential for attracting major aerospace players. This specialization directly supports the operational needs of airlines and other aircraft operators, ensuring the continued airworthiness of their fleets.

The practical significance of MRO specialization extends beyond simple aircraft maintenance. It involves advanced technical expertise, adherence to stringent regulatory standards, and the utilization of specialized equipment and facilities. This includes areas such as engine overhaul, avionics upgrades, structural repairs, and cabin refurbishment. Successful MRO operations require a highly skilled workforce of aircraft mechanics, engineers, and technicians, fostering the development of specialized training programs and educational institutions. The expansion of MRO capabilities also contributes to the growth of related industries, such as the manufacturing of spare parts and components. A concrete illustration can be found in the increasing number of local companies becoming certified suppliers for MRO providers, indicating a ripple effect across the supply chain.

In summary, MRO specialization is intrinsically linked to the health and competitiveness of the national aerospace sector. While challenges exist, such as the need for continuous investment in technology and workforce development, the potential benefits are substantial. By prioritizing the growth of MRO capabilities, the nation strengthens its position as a key player in the regional and global aviation landscape, fostering economic growth and enhancing its technological expertise. Future advancements in MRO technology, such as predictive maintenance and data-driven analysis, will further solidify the importance of this specialization within the aerospace domain.

3. Skilled Workforce

A highly skilled workforce is not merely an asset but a foundational necessity for the continued growth and global competitiveness of the national aerospace sector. The complexity and precision required in aerospace engineering, manufacturing, and maintenance demand a workforce proficient in advanced technologies and processes.

- Aerospace Engineers

These professionals are at the forefront of design, development, and testing of aircraft and aerospace systems. Their expertise spans aerodynamics, propulsion, structural analysis, and avionics. For instance, aerospace engineers contribute to the development of more fuel-efficient aircraft designs or innovative unmanned aerial vehicle (UAV) technologies. The availability of highly qualified aerospace engineers directly impacts the nation’s ability to innovate and compete in the global market.

- Aircraft Maintenance Technicians

These technicians are responsible for the inspection, maintenance, and repair of aircraft, ensuring the safety and airworthiness of fleets. Their expertise covers a wide range of systems, including engines, hydraulics, electrical systems, and avionics. A shortage of skilled aircraft maintenance technicians can lead to delays in aircraft maintenance, increased operational costs, and potential safety risks. Growing MRO capabilities hinge on an adequate supply of skilled technicians.

- Manufacturing Technicians and Specialists

These individuals are involved in the production of aircraft components and systems. They operate and maintain advanced manufacturing equipment, such as CNC machines, composite lay-up equipment, and welding systems. Their skills are critical for ensuring the quality, precision, and efficiency of manufacturing processes. As the nation seeks to expand its manufacturing capabilities, the demand for skilled manufacturing technicians and specialists will continue to grow.

- Avionics Technicians

These technicians specialize in the maintenance, repair, and installation of avionics systems, which include navigation, communication, and flight control systems. Their expertise is crucial for ensuring the safe and reliable operation of modern aircraft. The increasing complexity of avionics systems requires technicians to possess a deep understanding of electronics, software, and data communication protocols. Without skilled avionics technicians, the nation cannot effectively maintain and upgrade its aircraft fleets.

The synergistic effect of these specialized roles creates a thriving ecosystem within the national aerospace sector. Investment in training programs, technical education, and continuous professional development is paramount to ensure a readily available pool of qualified personnel. The sector’s growth is inextricably linked to the availability and expertise of its workforce, highlighting the need for ongoing initiatives to develop and retain skilled professionals within the nation.

4. Government Support

Government support functions as a critical catalyst for the development and sustained growth of the nation’s aerospace sector. Policies, funding initiatives, and strategic partnerships enacted by the government directly influence the competitiveness and innovation capacity of the industry. The provision of financial incentives, tax breaks, and research grants encourages investment in advanced technologies and infrastructure, crucial for competing in the global market. Examples include the establishment of aerospace-focused industrial parks and the provision of subsidized loans for aerospace companies, incentivizing expansion and modernization efforts. A direct correlation exists between effective government support and the ability of domestic aerospace companies to secure international contracts and expand their export markets. The significance lies in creating a conducive environment for businesses to thrive and contribute to the national economy.

Further government support manifests through the establishment and enforcement of regulatory frameworks that foster safety, quality, and adherence to international standards. These frameworks facilitate streamlined certification processes, enabling quicker market access for domestically produced aerospace components and services. Moreover, government-led initiatives to promote workforce development, such as funding for vocational training programs and partnerships with educational institutions, address the critical need for skilled personnel within the sector. The National Aerospace Industry Coordinating Office (NAICO), for example, plays a vital role in coordinating government efforts and aligning industry development with national economic goals. This integrated approach ensures that resources are directed effectively and that the industry operates within a stable and predictable regulatory environment.

In conclusion, government support acts as a cornerstone for the sustained development of the national aerospace sector. While challenges remain, such as ensuring efficient allocation of resources and adapting to evolving global market dynamics, the proactive engagement of the government remains essential. A continued commitment to fostering a supportive policy environment, incentivizing investment, and developing a skilled workforce is paramount for ensuring the long-term viability and competitiveness of the industry, contributing significantly to the nation’s economic prosperity.

5. Regional Hub

The aspiration to position the nation as a prominent regional hub within the aerospace industry represents a strategic objective aimed at maximizing economic benefits and technological advancement. This positioning leverages the nations geographical location, skilled workforce, and supportive government policies to attract foreign investment and promote the growth of domestic aerospace companies.

- MRO Center of Excellence

Establishing the nation as a center of excellence for Maintenance, Repair, and Overhaul (MRO) services is a core component of the regional hub strategy. This involves attracting airlines and aircraft operators from the region to utilize domestic MRO facilities, generating revenue and creating high-skilled jobs. For example, the presence of Airbus and Boeing maintenance facilities within the nation contributes significantly to its MRO capabilities. This positions the nation as a preferred destination for aircraft maintenance services within Southeast Asia.

- Aerospace Manufacturing Cluster

Developing a cohesive aerospace manufacturing cluster strengthens the nation’s supply chain and attracts foreign direct investment (FDI) in manufacturing activities. This involves attracting companies to establish manufacturing facilities within the nation, producing aircraft components, systems, and potentially complete aircraft. The creation of aerospace-focused industrial parks, with incentives for foreign companies, is a key strategy. Successful implementation would result in the nation becoming a significant exporter of aerospace products.

- Training and Education Hub

Elevating the nation as a regional hub for aerospace training and education addresses the critical need for a skilled workforce. This involves attracting students from neighboring countries to pursue aerospace-related education and training within the nation. Investment in aerospace engineering programs, aviation academies, and vocational training centers strengthens the skills base. A skilled workforce is a key competitive advantage in attracting aerospace companies and facilitating industry growth.

- Aerospace Technology Development Center

Establishing the nation as a regional center for aerospace technology development requires investment in research and development (R&D) capabilities. This involves fostering collaboration between universities, research institutions, and aerospace companies to develop innovative technologies. Examples include the development of advanced composite materials, unmanned aerial vehicle (UAV) technologies, and sustainable aviation solutions. Successful R&D initiatives enhance the nation’s technological capabilities and attract international partnerships.

The realization of the regional hub ambition hinges on a coordinated approach involving government support, private sector investment, and international collaboration. While challenges such as competition from other regional players exist, the potential economic and technological benefits are substantial, solidifying the nation’s standing in the global aerospace landscape.

Frequently Asked Questions

This section addresses common inquiries regarding the sector’s current state, opportunities, and challenges. It provides concise answers based on factual information and industry trends.

Question 1: What are the primary sub-sectors within the Malaysia Aerospace Industry?

The primary sub-sectors include aircraft component manufacturing, maintenance, repair, and overhaul (MRO) services, engineering design, systems integration, and aerospace training.

Question 2: What role does the government play in the development of the Malaysia Aerospace Industry?

The government provides support through policy formulation, financial incentives, investment promotion, infrastructure development, and the establishment of regulatory frameworks to ensure safety and compliance.

Question 3: What are the key challenges facing the Malaysia Aerospace Industry?

Key challenges include a shortage of skilled labor, competition from established global players, the need for continuous technological upgrades, and navigating complex regulatory requirements.

Question 4: What opportunities exist for foreign investment in the Malaysia Aerospace Industry?

Opportunities exist in areas such as MRO services, component manufacturing, technology transfer, and joint ventures with local companies to access the regional market.

Question 5: How does the Malaysia Aerospace Industry contribute to the national economy?

The sector contributes through export revenue, high-skilled job creation, technology transfer, and the development of a high-value manufacturing base.

Question 6: What are the future prospects for the Malaysia Aerospace Industry?

Future prospects are positive, driven by increasing air travel demand in the region, the growth of the MRO sector, and government initiatives to promote aerospace manufacturing and technology development.

The answers provided offer a glimpse into the complexities of the sector and highlight its significance within the national economic landscape.

The subsequent analysis will present concluding remarks summarizing the strengths, weaknesses, opportunities, and threats (SWOT) facing the Malaysia Aerospace Industry.

Conclusion

The examination of the sector within the national economy reveals a multifaceted landscape characterized by both significant opportunities and persistent challenges. Sustained growth hinges upon strategic investments in workforce development, technological advancement, and the fostering of collaborative partnerships. While the nation has made strides in establishing manufacturing capabilities and MRO expertise, maintaining competitiveness requires a proactive approach to innovation and adaptation to evolving global market dynamics.

Continued commitment to strengthening government support mechanisms, attracting foreign investment, and cultivating a skilled workforce is paramount for securing the long-term viability of this important segment. The future trajectory will depend on the ability to address existing shortcomings and effectively capitalize on emerging opportunities within the regional and global aerospace ecosystem, solidifying its role as a key contributor to economic prosperity and technological advancement.