Opportunities within the aerospace sector related to a specific company, MB, encompass a wide range of roles crucial to the design, manufacturing, and maintenance of aircraft and spacecraft components. These positions can span engineering, manufacturing, quality control, and project management. As an example, a manufacturing engineer at MB might be responsible for optimizing the production processes for structural elements used in aircraft wings.

These career paths are vital for maintaining the competitive edge of the aerospace industry and contribute significantly to technological advancement. Historically, such roles have been pivotal in driving innovation in materials science, automation, and precision manufacturing. The benefits extend beyond the individual employee, impacting national economies and defense capabilities.

The following sections will delve into the specific types of opportunities available, the skills and qualifications generally required, and the overall outlook for those seeking to establish or advance their careers in this segment of the aerospace industry.

This section provides guidance for individuals seeking opportunities related to MB within the aerospace sector. Diligence and preparation are essential for a successful job search in this competitive field.

Tip 1: Research the Company. A thorough understanding of MB’s specific products, services, and market position within the aerospace industry is paramount. Examine the company’s website, recent press releases, and any available industry reports.

Tip 2: Tailor the Resume. Avoid generic applications. Customize the resume and cover letter to highlight skills and experiences that directly align with the requirements of the specific role. Quantifiable achievements should be emphasized.

Tip 3: Network Strategically. Attend industry events and connect with professionals on platforms like LinkedIn. Informational interviews can provide valuable insights into the company culture and potential opportunities.

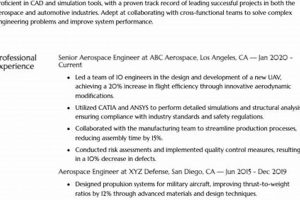

Tip 4: Emphasize Relevant Skills. Highlight proficiency in relevant software, tools, and techniques commonly used in aerospace engineering and manufacturing. Examples include CAD software, FEA analysis, and quality control methodologies.

Tip 5: Prepare for Technical Interviews. Expect rigorous technical questions during the interview process. Review fundamental engineering principles, relevant industry standards, and past projects. Be prepared to discuss problem-solving approaches.

Tip 6: Demonstrate Problem-Solving Abilities. Aerospace roles frequently require innovative solutions to complex challenges. Prepare examples of past projects where problem-solving skills were effectively applied to overcome obstacles.

Tip 7: Highlight Certifications and Training. Obtaining relevant certifications, such as those related to quality management or specific software packages, can enhance candidacy. Continuing professional development is viewed favorably.

By implementing these strategies, individuals can significantly increase their chances of securing a desirable position. Success in this field requires a combination of technical expertise, professional networking, and proactive job searching.

The following section will provide a concise summary of the information presented and offer concluding remarks.

1. Engineering Design

Engineering Design forms a cornerstone of activities pursued within MB Aerospace. It encompasses a range of specialized functions critical to the development and production of aerospace components and systems. Proficiency in these areas is essential for securing and excelling in related roles.

- CAD/CAM Proficiency

Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) skills are paramount. Engineers utilize CAD software (e.g., CATIA, NX) to create 3D models and technical drawings of components. CAM software is then employed to generate toolpaths for manufacturing processes. In MB Aerospace, this translates to designing turbine blades with intricate geometries or creating tooling fixtures for precise machining. A lack of proficiency hinders an engineer’s ability to contribute effectively to design and production cycles.

- Finite Element Analysis (FEA)

FEA is a crucial simulation technique used to assess the structural integrity and performance of aerospace components under various loading conditions. Engineers use FEA software (e.g., ANSYS, ABAQUS) to predict stress, strain, and deformation. For instance, FEA is used to analyze the impact of aerodynamic forces on aircraft wings or the thermal stresses on turbine disks. Expertise in FEA ensures that designs meet safety requirements and performance specifications.

- Materials Science Knowledge

A strong understanding of materials science is critical for selecting appropriate materials for aerospace applications. Engineers must consider factors such as strength, weight, corrosion resistance, and thermal properties. Examples include selecting nickel-based superalloys for high-temperature turbine components or utilizing composite materials for lightweight structural elements. Inadequate materials selection can lead to premature failure and compromise safety.

- Design Optimization

Engineering Design within MB Aerospace necessitates a focus on optimization. This involves refining designs to maximize performance, minimize weight, and reduce manufacturing costs. Techniques such as topological optimization and parametric studies are employed to achieve these goals. For example, optimizing the shape of a compressor blade to improve aerodynamic efficiency or minimizing the weight of a landing gear component while maintaining structural integrity. Efficient design optimization directly impacts product performance and profitability.

These facets of Engineering Design directly influence the types of positions available within MB Aerospace. From design engineers specializing in specific components to stress analysts ensuring structural integrity, these skills are vital for contributing to the company’s mission of producing high-quality aerospace solutions. Furthermore, these abilities are transferable across various roles, providing opportunities for career advancement and specialization within the field.

2. Manufacturing Processes

Manufacturing Processes are integral to MB Aerospace’s operational capabilities. This segment encompasses the methodologies and technologies employed to transform raw materials into finished aerospace components, directly influencing product quality, production efficiency, and cost-effectiveness. Competency in this area is highly valued for related opportunities.

- Precision Machining

Precision machining forms the backbone of many manufacturing operations within MB Aerospace. It involves the use of Computer Numerical Control (CNC) machines to precisely shape materials to meet exacting specifications. Examples include the creation of turbine blades, compressor disks, and structural components. Expertise in CNC programming, tooling selection, and process optimization is essential for maintaining dimensional accuracy and surface finish requirements, directly influencing the performance and lifespan of aerospace components.

- Specialized Welding

The fabrication of aerospace structures often requires specialized welding techniques to ensure structural integrity and joint strength. Processes such as electron beam welding, laser welding, and friction stir welding are employed to join dissimilar materials and create complex geometries. For instance, welding titanium alloys for aircraft frames or joining high-temperature alloys for engine components. Skilled welders and welding engineers are crucial for ensuring the reliability and safety of aerospace systems.

- Non-Destructive Testing (NDT)

Non-Destructive Testing methods are implemented throughout the manufacturing process to detect flaws or imperfections in materials and components without causing damage. Techniques such as ultrasonic testing, radiographic testing, and dye penetrant inspection are used to identify cracks, porosity, and other defects. In MB Aerospace, NDT is critical for ensuring that all components meet stringent quality standards and are free from potential failure points. NDT technicians and engineers play a pivotal role in maintaining the integrity and safety of aerospace products.

- Surface Treatments

Surface treatments are applied to aerospace components to enhance their properties and protect them from environmental degradation. Processes such as anodizing, plating, and coating are used to improve corrosion resistance, wear resistance, and thermal properties. Examples include applying chromium plating to landing gear components or coating turbine blades with thermal barrier coatings. Materials engineers and process technicians specializing in surface treatments are essential for extending the lifespan and improving the performance of aerospace components.

These facets of Manufacturing Processes underscore the critical need for skilled professionals within MB Aerospace. They range from machinists operating CNC equipment to materials engineers developing advanced surface treatments. These are key considerations for individuals seeking career paths within this sector.

3. Quality Assurance

Quality Assurance constitutes a critical function within MB Aerospace, ensuring that all products and processes adhere to stringent industry standards and customer requirements. Its implementation directly influences product safety, reliability, and overall company reputation, making it a central consideration for various positions.

- Inspection and Testing Protocols

Rigorous inspection and testing protocols are employed throughout the manufacturing process to verify conformance to design specifications and performance criteria. This encompasses dimensional inspections using coordinate measuring machines (CMMs), non-destructive testing (NDT) methods like ultrasonic and radiographic inspections, and functional testing of assembled components. Within MB Aerospace jobs, quality inspectors and test engineers are tasked with executing these protocols, identifying deviations, and initiating corrective actions to prevent defective products from reaching customers. Failure to adhere to these protocols can result in costly recalls and reputational damage.

- Process Control and Monitoring

Process control involves monitoring manufacturing processes to ensure stability and adherence to established parameters. Statistical process control (SPC) techniques are implemented to track key process variables, identify trends, and implement adjustments to prevent deviations from target values. Quality engineers and process engineers within MB Aerospace jobs are responsible for establishing process control plans, analyzing process data, and implementing improvements to enhance process capability and reduce variability. Effective process control minimizes defects, improves product consistency, and lowers manufacturing costs.

- Documentation and Traceability

Comprehensive documentation and traceability systems are essential for maintaining accountability and compliance with regulatory requirements. This includes maintaining detailed records of manufacturing processes, inspection results, material certifications, and equipment calibrations. Quality assurance specialists and documentation specialists within MB Aerospace jobs are responsible for creating and maintaining these records, ensuring that all products are fully traceable throughout their lifecycle. This traceability is crucial for investigating failures, implementing corrective actions, and demonstrating compliance to regulatory agencies such as the FAA.

- Corrective and Preventive Actions (CAPA)

The CAPA system is a formalized process for addressing non-conformances, investigating root causes, and implementing corrective and preventive actions to prevent recurrence. This involves identifying the underlying causes of defects, implementing solutions to address those causes, and verifying the effectiveness of those solutions. Quality managers and CAPA specialists within MB Aerospace jobs are responsible for managing the CAPA system, facilitating investigations, and ensuring that effective corrective actions are implemented and validated. A robust CAPA system is critical for continuous improvement and preventing future defects.

The diverse roles associated with Quality Assurance within MB Aerospace, from inspectors on the shop floor to quality managers overseeing the entire system, are fundamental to maintaining the highest standards of product excellence. The effectiveness of the Quality Assurance program directly impacts the company’s ability to compete in the demanding aerospace market.

4. Supply Chain

Supply Chain management is a critical function that significantly influences the success of MB Aerospace and the nature of associated job roles. Effective supply chain operations ensure the timely and cost-efficient procurement of materials, components, and services necessary for aerospace manufacturing and maintenance activities. A robust supply chain directly impacts production schedules, product quality, and overall profitability, making it a key area of focus for many positions within the company.

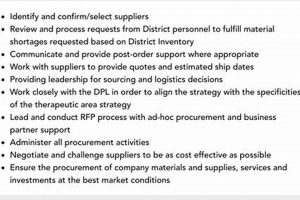

- Procurement and Sourcing

This facet involves the strategic acquisition of raw materials, parts, and services from external suppliers. Procurement specialists within MB Aerospace are responsible for identifying and evaluating potential suppliers, negotiating contracts, and managing supplier relationships. For instance, sourcing high-strength alloys for turbine blades or procuring electronic components for avionics systems requires a deep understanding of material properties, industry standards, and supplier capabilities. Efficient procurement minimizes costs, ensures quality, and mitigates supply chain risks. Procurement positions are vital for overall organizational efficiency.

- Logistics and Transportation

Logistics and transportation encompass the movement of materials and components from suppliers to MB Aerospace facilities, as well as the distribution of finished products to customers. Logistics managers and transportation specialists are responsible for optimizing transportation routes, coordinating shipments, and managing inventory levels. Examples include transporting large aircraft structures by sea or air, or managing the flow of components between manufacturing plants. Effective logistics minimizes transportation costs, reduces lead times, and ensures timely delivery of products. Careers within logistics ensure production runs without delays.

- Inventory Management

Inventory management involves controlling the flow of materials within MB Aerospace facilities to minimize storage costs and prevent stockouts. Inventory planners and analysts are responsible for forecasting demand, setting inventory levels, and implementing inventory control systems. For instance, managing the stock of fasteners, seals, and other consumable items used in aircraft assembly or maintaining an adequate supply of spare parts for maintenance and repair operations. Effective inventory management optimizes working capital, reduces obsolescence, and ensures that materials are available when needed. This directly contributes to the fiscal health of MB Aerospace.

- Supplier Quality Management

Supplier quality management ensures that suppliers consistently meet MB Aerospace’s quality standards and specifications. Supplier quality engineers and auditors are responsible for conducting supplier audits, monitoring supplier performance, and implementing corrective actions to address quality issues. For example, auditing a supplier’s manufacturing processes to ensure compliance with aerospace standards or investigating the root cause of defective components. Effective supplier quality management reduces the risk of receiving non-conforming materials, improves product quality, and strengthens supplier relationships.

These facets of Supply Chain management highlight the importance of skilled professionals within MB Aerospace. Those holding supply chain positions are pivotal for streamlining operations, reducing costs, and improving overall competitiveness. From strategic sourcing to efficient logistics and robust quality control, these functions contribute to the success of the organization and the fulfillment of its commitments to customers.

5. Project Management

Project Management serves as a crucial framework for organizing and executing initiatives within MB Aerospace. Its importance stems from the intricate nature of aerospace projects, characterized by stringent timelines, demanding technical specifications, and substantial financial investments. Effective project management ensures that projects are completed on time, within budget, and according to established quality standards. A failure in project management can result in significant delays, cost overruns, and compromised product performance, impacting the company’s competitive standing and customer satisfaction. A real-life example includes the development of a new aircraft engine component: project managers coordinate design, manufacturing, testing, and certification phases, assigning tasks, managing resources, and mitigating risks to meet the delivery deadline and technical objectives.

Practical applications of project management principles within MB Aerospace extend across various functional areas. In engineering, project managers oversee the design and development of new products, ensuring adherence to technical requirements and regulatory standards. In manufacturing, project managers coordinate the production of aerospace components, optimizing production processes, managing inventory levels, and ensuring quality control. In supply chain, project managers manage the procurement of materials, the transportation of goods, and the coordination of suppliers. Project management methodologies, such as Agile or Waterfall, are adapted to suit the specific needs of each project, allowing for flexibility and adaptability in the face of changing circumstances. For example, implementing a new Enterprise Resource Planning (ERP) system requires careful planning, resource allocation, and stakeholder coordination to minimize disruption to ongoing operations.

In summary, Project Management is an indispensable element of MB Aerospace’s operational success. It provides the structure and processes necessary to manage complex projects effectively, mitigate risks, and deliver high-quality products on time and within budget. Challenges within the aerospace industry, such as increasing regulatory scrutiny and intensifying global competition, underscore the importance of robust project management capabilities for maintaining a competitive edge and achieving long-term sustainability. The effective integration of project management principles across all functional areas is critical for MB Aerospace to meet its strategic goals and uphold its reputation for excellence.

Frequently Asked Questions

This section addresses common inquiries regarding employment opportunities within MB Aerospace, providing clarity on qualifications, application processes, and career prospects.

Question 1: What are the most frequently advertised positions within MB Aerospace?

Commonly advertised positions include design engineers, manufacturing engineers, quality assurance specialists, supply chain analysts, and project managers. The specific roles vary depending on the company’s current projects and business needs.

Question 2: What qualifications are generally required to secure employment with MB Aerospace?

Typically, a bachelor’s degree in a relevant engineering discipline (e.g., aerospace, mechanical, materials) is required for engineering roles. Other positions may require degrees in business administration, supply chain management, or related fields. Experience, certifications, and specialized skills are also considered.

Question 3: Does MB Aerospace offer internships or entry-level programs?

MB Aerospace may offer internships or entry-level programs for recent graduates. The availability of these opportunities can vary and is typically advertised on the company’s website or through university career services.

Question 4: What is the typical career progression path within MB Aerospace?

Career progression depends on the specific role and an individual’s performance. Generally, employees can advance from entry-level positions to senior roles through experience, training, and demonstrated leadership capabilities.

Question 5: How does MB Aerospace support employee development and training?

MB Aerospace may offer various training and development programs to enhance employee skills and knowledge. These programs may include technical training, leadership development, and opportunities for professional certifications.

Question 6: What is the application process for MB Aerospace jobs?

The application process typically involves submitting a resume and cover letter through the company’s online career portal. Selected candidates are then invited for interviews, which may include technical assessments or behavioral interviews.

In summary, securing employment with MB Aerospace requires appropriate qualifications, relevant experience, and a demonstrated commitment to the aerospace industry. Prospective candidates are encouraged to research the company thoroughly and tailor their applications to specific job requirements.

The following section will delve into resources for additional information.

Conclusion

This exploration of opportunities at MB Aerospace has illuminated the breadth of roles available, the necessary qualifications, and the critical functions each position serves. From engineering design and manufacturing processes to quality assurance, supply chain management, and project oversight, this analysis provides insight into the interconnected nature of various career paths within the organization. Understanding these key components enables prospective candidates to make informed decisions about their career aspirations and the necessary steps to pursue them.

The information presented serves as a guide for those seeking to contribute to the aerospace industry through MB Aerospace. Continued diligence in skill development, strategic networking, and focused application efforts will be essential for navigating this competitive landscape. The ongoing evolution of aerospace technology suggests a continued need for qualified professionals, emphasizing the significance of proactive career planning and lifelong learning within this sector.