Positions within the field blend the principles of mechanical engineering with the complexities of aerospace technology. These roles involve designing, developing, testing, and manufacturing aircraft, spacecraft, and related systems. Examples include propulsion system design, structural analysis of aircraft components, and development of satellite mechanisms.

This career path is crucial for advancements in air and space travel, defense systems, and exploration technologies. Contributions to these sectors drive innovation, enhance safety, and improve efficiency in these critical areas. Historically, demand for skilled professionals in this area has grown in tandem with advancements in aviation and space exploration programs.

The subsequent sections will delve into the specific responsibilities found in these roles, the necessary education and skills, and the outlook for individuals seeking to enter this challenging and rewarding profession.

Entering a career path integrating mechanical engineering with aerospace applications requires strategic preparation and consistent professional development.

Tip 1: Focus on Foundational Knowledge: A strong grounding in core mechanical engineering principles is essential. Coursework should include thermodynamics, fluid mechanics, heat transfer, and materials science.

Tip 2: Cultivate Aerospace-Specific Skills: Supplement core knowledge with specialized courses or projects focused on aerodynamics, propulsion systems, spacecraft design, and control systems.

Tip 3: Gain Practical Experience: Internships or research opportunities with aerospace companies or government agencies provide invaluable hands-on experience and exposure to real-world challenges.

Tip 4: Develop Modeling and Simulation Proficiency: Expertise in CAD software (e.g., SolidWorks, CATIA) and simulation tools (e.g., ANSYS, MATLAB) is crucial for design and analysis tasks.

Tip 5: Network Actively: Attend industry conferences, join professional organizations (e.g., AIAA, ASME), and connect with experienced engineers to expand professional contacts and learn about job opportunities.

Tip 6: Highlight Relevant Projects: When applying for positions, emphasize projects that demonstrate practical skills and relevant experience, such as designing a drone, developing a satellite component, or analyzing aircraft performance.

Tip 7: Consider Advanced Education: A master’s degree or doctorate can provide a competitive edge, particularly for roles involving research, development, or specialized design.

Preparation and continuous learning are crucial for success in this competitive field. A strategic approach to education, skill development, and networking can significantly increase the chances of securing rewarding career opportunities.

The following sections will explore the long-term career prospects, expected compensation, and potential pathways for advancement.

1. Design Expertise

Design expertise is a cornerstone of successful careers in this engineering discipline. The ability to conceptualize, model, and analyze complex systems is paramount. Deficiencies in design knowledge directly impact the efficiency, safety, and feasibility of aerospace projects. Consider, for example, the design of a new aircraft wing. Engineers must possess a thorough understanding of aerodynamics, materials science, and structural mechanics to create a wing that is both lightweight and capable of withstanding extreme stresses. A poorly designed wing could lead to catastrophic failure during flight.

The application of design expertise extends beyond the physical structure of aerospace vehicles. It also encompasses the development of propulsion systems, control systems, and onboard electronics. The design of a jet engine, for instance, requires expertise in thermodynamics, fluid dynamics, and combustion. Engineers must optimize the engine’s design to maximize thrust while minimizing fuel consumption and emissions. Similarly, the design of a satellite’s attitude control system demands precision and a deep understanding of orbital mechanics. These examples illustrate the breadth and depth of design challenges in the aerospace field. Furthermore, these examples showcase that those jobs require the ability to work in a collaborative environment, integrating the designs of multiple engineers to have it culminate into a final project.

In summary, design expertise is an indispensable attribute for professionals in this engineering domain. It is the foundation upon which safe, efficient, and innovative aerospace systems are built. The practical application of theoretical knowledge and an understanding of real-world constraints are crucial for success. Continuous learning and adaptation to new technologies are essential for maintaining a competitive edge in this dynamic field.

2. Systems Integration

Systems integration represents a critical function within mechanical aerospace engineering. It involves combining various subsystems or components into a cohesive and functional whole, ensuring they operate effectively together. Within these roles, engineers are frequently tasked with overseeing the seamless interaction of mechanical, electrical, and software components within aircraft or spacecraft. A failure to properly integrate these systems can result in performance degradation, safety hazards, or mission failure. For instance, integrating a new flight control system into an existing aircraft requires meticulous testing and validation to ensure compatibility with existing avionics and mechanical systems. The complexity of modern aerospace systems necessitates a deep understanding of interdependencies and potential points of failure.

The practical significance of systems integration is evident in numerous aerospace projects. Consider the development of a satellite. This requires integrating power systems, propulsion systems, communication systems, and payload instruments. Aerospace engineers are responsible for ensuring that these components function harmoniously within the constraints of weight, power, and environmental conditions. Similarly, the design of a new aircraft engine involves integrating mechanical components with electronic control systems to optimize performance and fuel efficiency. These activities illustrate the essential role that system integration plays in the successful operation of aerospace systems.

In summary, systems integration is an indispensable aspect of roles related to aerospace engineering. It demands a holistic understanding of system interactions, rigorous testing methodologies, and proactive problem-solving skills. The ability to effectively integrate complex systems directly contributes to the safety, reliability, and overall performance of aerospace vehicles and technologies. Challenges within this area underscore the need for skilled engineers capable of navigating the intricate complexities of modern aerospace design.

3. Material Innovation

Material innovation is inextricably linked to roles related to mechanical aerospace engineering. Advancements in materials science directly enable improvements in aircraft and spacecraft performance, efficiency, and safety. The development and application of novel materials are critical for overcoming the challenges posed by extreme environments and demanding operational requirements.

- Lightweight Composites

The development and implementation of lightweight composite materials, such as carbon fiber reinforced polymers, are essential for reducing aircraft weight, which directly improves fuel efficiency and payload capacity. Engineers in this field are responsible for designing and analyzing composite structures to ensure they meet stringent strength and durability requirements. For example, the Boeing 787 Dreamliner utilizes a significant amount of composite materials in its fuselage and wings, contributing to its improved fuel efficiency. Such applications demand expertise in composite material properties, manufacturing processes, and structural analysis techniques.

- High-Temperature Alloys

The development of high-temperature alloys, such as nickel-based superalloys, is critical for turbine engines and hypersonic vehicles. These materials must maintain their strength and resist oxidation at elevated temperatures. Mechanical aerospace engineers involved in material selection and design must understand the complex relationships between alloy composition, microstructure, and mechanical properties. The use of these alloys enables higher operating temperatures in jet engines, leading to improved performance and efficiency. Their application is crucial for the development of advanced propulsion systems and hypersonic flight capabilities.

- Additive Manufacturing

Additive manufacturing, or 3D printing, is revolutionizing the way aerospace components are designed and manufactured. This technology allows for the creation of complex geometries and customized parts, enabling weight reduction and improved performance. Mechanical aerospace engineers are involved in developing additive manufacturing processes for aerospace materials, optimizing part designs for additive manufacturing, and ensuring the quality and reliability of 3D-printed components. For instance, additively manufactured fuel nozzles are now used in some jet engines, demonstrating the potential of this technology to create lighter, more efficient, and more durable components.

- Smart Materials

The integration of smart materials, such as shape memory alloys and piezoelectric materials, into aerospace systems enables the development of adaptive structures and sensors. Shape memory alloys can be used to create morphing wings that optimize aircraft performance during different flight regimes. Piezoelectric materials can be used to create sensors that monitor the structural health of aircraft components. Mechanical aerospace engineers play a crucial role in designing and integrating these smart materials into aerospace systems, developing control algorithms, and analyzing their performance. Applications range from vibration damping systems to deployable structures in space.

The aforementioned facets underscore the critical role that material innovation plays in advancing aerospace technologies. From reducing weight and improving fuel efficiency to enabling new propulsion systems and adaptive structures, advancements in materials science are essential for meeting the increasing demands of modern aerospace engineering. Mechanical aerospace engineers are at the forefront of this innovation, translating fundamental research into practical applications that shape the future of flight and space exploration.

4. Aerodynamics Knowledge

Aerodynamics knowledge is a fundamental and indispensable component of mechanical aerospace engineering roles. A thorough understanding of aerodynamics is critical for the design, analysis, and optimization of aircraft, spacecraft, and related systems. Deficiencies in this area can directly impact the performance, safety, and efficiency of these vehicles. The shape of an aircraft wing, for example, directly determines its lift and drag characteristics. Engineers must apply principles of aerodynamics to design wings that generate sufficient lift to enable flight while minimizing drag to reduce fuel consumption. An inadequate understanding of these principles can lead to designs that are inefficient or even unsafe.

The practical application of aerodynamics extends beyond the design of airfoils. It is essential for the analysis of flight stability, control systems, and propulsion systems. The stability of an aircraft, for instance, depends on its aerodynamic characteristics. Engineers must ensure that an aircraft is inherently stable or develop control systems to compensate for any instability. The design of jet engine inlets and nozzles requires a deep understanding of compressible flow and shock waves. These examples demonstrate the breadth and depth of aerodynamic considerations in mechanical aerospace engineering.

In summary, aerodynamics knowledge is a non-negotiable requirement for success in mechanical aerospace engineering. It is the bedrock upon which safe, efficient, and innovative aerospace systems are built. Continuous learning and adaptation to new aerodynamic concepts and technologies are essential for maintaining a competitive edge in this dynamic field. This area highlights why positions integrating mechanical engineering with aerospace applications require rigorous training and continuous professional development.

5. Propulsion Systems

Propulsion systems are integral to the field of mechanical aerospace engineering, directly influencing vehicle performance, range, and mission capabilities. Within the context of mechanical aerospace engineering jobs, professionals engage in the design, development, testing, and maintenance of these systems, which encompass a wide array of technologies, including gas turbines, rocket engines, and electric propulsion. A clear illustration of this connection is found in the design of a commercial aircraft engine. Aerospace engineers analyze thermodynamic cycles, optimize component geometry, and select appropriate materials to maximize thrust efficiency and minimize fuel consumption. The selection and design of these engines are heavily influenced by factors such as flight speed, altitude, and aircraft size, linking propulsion considerations directly to overall vehicle design and operational capabilities. In effect, proficiency in propulsion systems is a critical skill for those seeking to contribute meaningfully to aerospace advancements.

Practical applications of this expertise extend beyond commercial aviation. Space exploration, for instance, relies heavily on propulsion systems to achieve orbit, perform maneuvers, and travel to distant celestial bodies. Mechanical aerospace engineers working on rocket engines address challenges such as extreme temperatures, high pressures, and complex combustion processes. The development of ion thrusters and other advanced propulsion technologies represents a cutting-edge area where engineers strive to improve fuel efficiency and mission durations for long-duration space missions. Also, the advancements in drone technology rely on propulsion systems. They must be able to provide enough lift for the drone to leave the ground. Therefore, the study of propulsion system plays a very crucial role.

In summary, the understanding and application of propulsion system principles are fundamental components of mechanical aerospace engineering. The demand for engineers with expertise in this area is driven by the need for more efficient, reliable, and sustainable aerospace vehicles. While challenges remain in optimizing propulsion systems for diverse applications, continued research and development efforts promise significant advancements in air and space travel, underscoring the enduring importance of this field within the broader scope of aerospace engineering.

6. Testing Procedures

Rigorous testing procedures are inextricably linked to positions within mechanical aerospace engineering. These procedures serve as a critical validation step, ensuring that designs, materials, and systems meet stringent performance and safety requirements before deployment. Testing encompasses a diverse range of methods tailored to the specific components and operational environments encountered in aerospace applications.

- Structural Testing

Structural testing involves subjecting aerospace components and systems to simulated operational loads and environmental conditions to verify their structural integrity and identify potential failure points. For example, aircraft wings undergo extensive fatigue testing to simulate the stresses experienced during repeated flight cycles. This testing is crucial for ensuring that the wings can withstand the cumulative effects of these stresses over the aircraft’s service life. Results inform design modifications and material selection, contributing to overall airworthiness. These jobs ensure that structural testing and its results provide essential validation data for mechanical aerospace engineers.

- Wind Tunnel Testing

Wind tunnel testing simulates aerodynamic conditions to assess the performance of aircraft and spacecraft designs. Scale models are placed in wind tunnels and subjected to controlled airflows to measure lift, drag, and stability characteristics. This data is crucial for optimizing aerodynamic designs and predicting flight performance. For instance, wind tunnel testing is used to evaluate the effectiveness of wing designs and control surfaces, influencing decisions regarding aircraft shape and flight control systems. It provides key insights for engineers and the final results.

- Non-Destructive Testing (NDT)

NDT methods are used to inspect aerospace components for defects without causing damage. Techniques such as ultrasonic testing, radiography, and eddy current testing are employed to detect cracks, voids, and other imperfections that could compromise structural integrity. NDT is essential for ensuring the safety and reliability of critical components, such as engine turbines and landing gear. Regular NDT inspections are performed during aircraft maintenance to identify potential issues before they lead to catastrophic failures. Because of these non destructive testings it can save so much in both production costs and overall safety.

- Environmental Testing

Environmental testing simulates the extreme conditions encountered during aerospace missions, including temperature variations, vacuum, radiation, and vibration. This testing verifies that components and systems can withstand these harsh environments without degradation in performance or reliability. For example, satellites undergo extensive thermal vacuum testing to simulate the temperature extremes of space and ensure that their electronics and mechanical systems function properly. Environmental testing jobs and simulations of an aircraft is also cheaper overall to manufacture a product. The engineers must be able to test the products multiple times before producing the product. Because environmental testing will determine how the product react in the real world.

These facets highlight the diverse and essential role that testing procedures play in mechanical aerospace engineering. From validating structural integrity to optimizing aerodynamic performance and ensuring reliability in extreme environments, rigorous testing is paramount for ensuring the safety and success of aerospace endeavors. The effectiveness of these testing regimens directly impacts the airworthiness, mission capabilities, and overall advancement of aerospace technologies.

7. Regulatory Compliance

Adherence to regulatory compliance is a non-negotiable aspect of roles within mechanical aerospace engineering. Stringent regulations govern the design, manufacture, operation, and maintenance of aircraft and spacecraft, impacting every stage of the product lifecycle. These regulations are in place to ensure safety, security, and environmental responsibility.

- FAA Certification

Federal Aviation Administration (FAA) certification is a critical requirement for aircraft and aircraft components operating in the United States. Mechanical aerospace engineers must demonstrate compliance with FAA regulations related to airworthiness, safety, and performance. This involves rigorous testing, documentation, and analysis to prove that designs meet FAA standards. For example, engineers working on a new aircraft engine must demonstrate that it meets FAA noise and emissions requirements, as well as safety standards related to engine failure and containment. Non-compliance can lead to significant delays, fines, and even the grounding of aircraft.

- EASA Regulations

The European Union Aviation Safety Agency (EASA) sets similar standards for aviation safety in Europe. Mechanical aerospace engineers working on aircraft or components intended for use in Europe must comply with EASA regulations. These regulations cover a wide range of areas, including aircraft design, manufacturing, and maintenance. Compliance often involves demonstrating that designs meet specific performance and safety targets, as well as undergoing audits and inspections by EASA officials. Compliance with these regulations is essential for accessing the European aviation market.

- ITAR Compliance

The International Traffic in Arms Regulations (ITAR) govern the export and import of defense-related articles and services. Mechanical aerospace engineers working on projects with military applications must comply with ITAR regulations to prevent the unauthorized transfer of sensitive technology. This involves obtaining export licenses, implementing security measures to protect controlled technology, and adhering to strict reporting requirements. Violation of ITAR regulations can result in severe penalties, including fines, imprisonment, and the loss of export privileges.

- Environmental Regulations

Environmental regulations are increasingly important in the aerospace industry. Mechanical aerospace engineers must design aircraft and spacecraft that minimize their environmental impact. This includes reducing noise pollution, emissions, and waste. Compliance with environmental regulations may involve developing more fuel-efficient engines, using sustainable materials, and implementing recycling programs. For example, engineers working on a new aircraft may need to demonstrate that it meets stringent noise and emissions standards set by international organizations and government agencies.

The preceding examples demonstrate the pervasive influence of regulatory compliance on mechanical aerospace engineering. Engineers working in this field must possess a thorough understanding of applicable regulations and adhere to them diligently to ensure the safety, security, and environmental sustainability of aerospace products. Non-compliance can have severe consequences, underscoring the critical importance of regulatory expertise in this field.

Frequently Asked Questions Regarding Mechanical Aerospace Engineering Positions

The following addresses common inquiries and clarifies prevailing misconceptions about careers integrating mechanical engineering with aerospace technology.

Question 1: What are the primary responsibilities assumed within typical roles of this profession?

Responsibilities generally encompass the design, development, testing, and manufacturing of aircraft, spacecraft, and associated systems. Specific tasks may include structural analysis, propulsion system design, and the development of control systems.

Question 2: What educational background is considered essential for entry into this field?

A bachelor’s degree in mechanical engineering, aerospace engineering, or a closely related field is generally required. Advanced degrees, such as a Master’s or Ph.D., may be advantageous for specialized roles and research positions.

Question 3: What specific skills are deemed most valuable by employers seeking to fill mechanical aerospace engineering positions?

Proficiency in CAD software, simulation tools, and data analysis is highly valued. A strong understanding of thermodynamics, fluid mechanics, materials science, and control systems is also crucial.

Question 4: What is the anticipated career trajectory for individuals pursuing a path within this engineering discipline?

Career progression typically involves advancement from entry-level positions to roles with increasing responsibility, such as project management, team leadership, and technical specialization. Opportunities for advancement may also exist within research and development.

Question 5: What is the approximate compensation range for professionals employed in mechanical aerospace engineering positions?

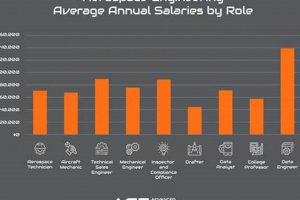

Compensation varies based on experience, education, location, and specific job responsibilities. Entry-level salaries generally fall within a competitive range, with potential for significant increases as experience and expertise grow.

Question 6: What are the key challenges currently confronting professionals within this engineering domain?

Challenges often include balancing performance demands with cost constraints, adapting to rapidly evolving technologies, and ensuring compliance with increasingly stringent safety and environmental regulations.

Understanding the responsibilities, required qualifications, career trajectory, and challenges can aid individuals considering careers in this field.

The following section will provide resources for individuals seeking to learn more about and pursue related career paths.

Concluding Remarks on Mechanical Aerospace Engineering Positions

This examination has outlined the critical facets of positions incorporating mechanical engineering with aerospace applications. It underscored the importance of design expertise, systems integration, material innovation, aerodynamics knowledge, propulsion systems, rigorous testing procedures, and stringent regulatory compliance. Furthermore, it addressed common inquiries related to educational prerequisites, essential skills, career advancement, and compensation expectations.

The sector continues to evolve, driven by ongoing advancements in technology and increasing demands for safety, efficiency, and sustainability. Aspiring professionals are encouraged to cultivate a strong foundation in core engineering principles, pursue specialized knowledge in aerospace-specific domains, and remain abreast of emerging trends. The future demands skilled individuals capable of addressing complex engineering challenges and driving innovation in air and space travel.