This academic unit integrates the principles of mechanics and aerodynamics to design, analyze, and manufacture systems ranging from small components to large-scale vehicles. A typical setting for its operations includes laboratories equipped with advanced simulation software, wind tunnels, and materials testing equipment. Programs within this unit prepare students for careers in diverse fields, from automotive and energy industries to space exploration and national defense.

The value of such a unit lies in its contribution to technological advancement, innovation, and problem-solving in complex engineering challenges. Historically, its existence has been pivotal in driving progress in transportation, manufacturing, and energy sectors. Furthermore, it fosters interdisciplinary collaboration, enabling comprehensive solutions that address the multifaceted demands of modern engineering projects. It provides crucial education and research, ensuring a continuous supply of qualified engineers ready to address the future challenges in aerospace and mechanical systems.

The following sections will delve into the specifics of its curriculum, research opportunities, and potential career pathways for graduates. Examination of faculty expertise, available resources, and notable achievements will provide a comprehensive overview of its capabilities and impact.

Guidance for Aspiring Mechanical and Aerospace Engineers

The subsequent points provide essential guidance for individuals interested in pursuing a career in mechanical and aerospace engineering.

Tip 1: Strengthen Foundational Knowledge: A robust understanding of mathematics, physics, and chemistry is paramount. These subjects form the bedrock upon which advanced engineering concepts are built. Consistent practice and a focus on problem-solving are crucial.

Tip 2: Cultivate Technical Proficiency: Develop expertise in computer-aided design (CAD) software, simulation tools, and programming languages relevant to the field. Hands-on experience through projects and internships enhances practical skills.

Tip 3: Emphasize Analytical Skills: Engineering necessitates rigorous analysis and critical thinking. Practice analyzing complex systems, identifying potential problems, and devising effective solutions. Case studies and simulations can aid in skill development.

Tip 4: Foster Collaboration: Engineering projects often require teamwork and effective communication. Participate in group projects, learn to delegate tasks efficiently, and communicate ideas clearly and concisely. Strong interpersonal skills are invaluable.

Tip 5: Pursue Research Opportunities: Engage in research projects to gain exposure to cutting-edge technologies and contribute to the advancement of knowledge. This experience also helps to develop research methodologies and data analysis skills.

Tip 6: Seek Mentorship: Connect with experienced engineers or professors who can provide guidance and support. Mentors can offer valuable insights into career paths, industry trends, and professional development.

Tip 7: Stay Informed: Keep abreast of the latest developments in mechanical and aerospace engineering by reading industry publications, attending conferences, and participating in professional organizations. Continuous learning is essential for career advancement.

By consistently focusing on these areas, aspiring engineers can enhance their prospects for academic success and professional fulfillment. A dedication to fundamental principles, combined with a commitment to continuous learning, serves as the foundation for a successful career.

The concluding section will summarize key considerations for individuals embarking on a journey in mechanical and aerospace engineering.

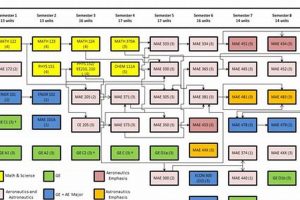

1. Curriculum Integration

Curriculum integration within a mechanical and aerospace engineering department denotes a strategic approach to course design, ensuring a coherent and progressive educational experience for students. This integration spans fundamental principles, specialized topics, and practical applications, fostering a holistic understanding of complex engineering systems. A poorly integrated curriculum can result in fragmented knowledge, hindering students’ ability to solve real-world problems. For example, a course on thermodynamics must seamlessly connect with fluid mechanics to enable the analysis of engine performance, a core component of aerospace design. The effectiveness of curriculum integration is a primary determinant of the graduates’ preparedness for professional practice.

The importance of curriculum integration is further exemplified in capstone design projects, where students apply knowledge acquired across various courses to develop comprehensive engineering solutions. These projects necessitate the synthesis of mechanical design principles, aerospace propulsion systems, and control engineering concepts. Successful capstone projects are direct outcomes of a well-integrated curriculum, enabling students to demonstrate mastery of engineering principles and problem-solving skills. Conversely, a fragmented curriculum can lead to students struggling to connect disparate concepts, resulting in suboptimal project outcomes. The accreditation bodies such as ABET often evaluate curriculum integration as a key metric of program quality.

In conclusion, effective curriculum integration is paramount to the success of a mechanical and aerospace engineering department. It fosters a deeper understanding of core engineering principles, enhances problem-solving capabilities, and prepares students for the demands of the engineering profession. Challenges in achieving integration, such as maintaining relevance in a rapidly evolving technological landscape, necessitate continuous assessment and refinement of course content and pedagogical approaches, aligning with the broader goals of the department and the ever-changing needs of the industry.

2. Research Innovation

Within a mechanical and aerospace engineering department, research innovation serves as a critical engine for progress, driving advancements in fundamental knowledge and applied technologies. It fosters an environment where faculty and students engage in cutting-edge investigations, leading to breakthroughs that benefit both the department and the broader engineering community.

- Advanced Materials Development

This facet encompasses the design, synthesis, and characterization of novel materials with enhanced properties suitable for aerospace and mechanical applications. For instance, research into lightweight composites for aircraft structures can improve fuel efficiency and reduce emissions. The implications extend to the development of stronger, more durable components for engines, turbines, and other critical systems.

- Propulsion System Optimization

This area focuses on improving the efficiency, performance, and environmental impact of propulsion systems used in aircraft, spacecraft, and other vehicles. Research may involve exploring alternative fuels, developing advanced combustion techniques, or designing more efficient turbine engines. Such innovations are crucial for reducing carbon emissions and enabling future space exploration missions.

- Robotics and Automation

The integration of robotics and automation technologies in manufacturing, inspection, and maintenance processes is a significant area of research. Developing autonomous systems for aircraft inspection or robotic assembly lines for complex mechanical components can increase efficiency, reduce costs, and improve safety. This research contributes to the advancement of smart manufacturing practices and the creation of more reliable and efficient engineering systems.

- Computational Modeling and Simulation

This facet entails the development and application of advanced computational tools to simulate and analyze complex engineering phenomena. Researchers use computational fluid dynamics (CFD) to study airflow around aircraft, finite element analysis (FEA) to predict the structural behavior of components, and multi-physics simulations to optimize system performance. These tools enable engineers to design and test new concepts virtually, reducing the need for expensive physical prototypes and accelerating the innovation process.

These facets of research innovation are deeply intertwined within a mechanical and aerospace engineering department, contributing to the generation of new knowledge, the training of skilled engineers, and the development of cutting-edge technologies. The collective impact of these endeavors is a department that is at the forefront of engineering progress, capable of addressing the most pressing challenges facing the aerospace and mechanical industries.

3. Industry Collaboration

Effective industry collaboration represents a cornerstone of a thriving mechanical and aerospace engineering department. These partnerships provide essential resources, real-world insights, and practical learning opportunities that are critical for the success of students and faculty, and the advancement of engineering knowledge.

- Internship and Co-op Programs

These programs allow students to gain hands-on experience in industry settings, working alongside experienced engineers on real-world projects. For example, a student might intern at a company designing aircraft engines, contributing to performance analysis and optimization efforts. These experiences provide invaluable practical skills, enhance their understanding of engineering principles, and increase their employability upon graduation.

- Sponsored Research Projects

Companies often sponsor research projects within a department, providing funding and expertise to address specific challenges or develop new technologies. This collaboration can lead to breakthroughs in areas such as advanced materials, propulsion systems, or autonomous vehicle design. It allows faculty and students to work on cutting-edge problems with direct relevance to industry needs, fostering innovation and knowledge transfer.

- Industry Advisory Boards

These boards consist of industry professionals who provide guidance and feedback on the department’s curriculum, research directions, and strategic planning. They ensure that the department’s activities are aligned with industry needs and that graduates are equipped with the skills and knowledge required to succeed in the workforce. Their input is crucial for maintaining the relevance and quality of the department’s programs.

- Joint Research and Development Centers

Collaborative research centers, jointly operated by universities and industry partners, provide a platform for conducting large-scale, interdisciplinary research projects. These centers facilitate the sharing of resources, expertise, and infrastructure, enabling the development of advanced technologies with significant commercial potential. For example, a joint center might focus on developing sustainable aviation technologies, bringing together researchers from academia and industry to address a pressing global challenge.

The symbiotic relationship between a mechanical and aerospace engineering department and industry is fundamental to the department’s success. These collaborations ensure that the education and research conducted are relevant, impactful, and aligned with the evolving needs of the engineering profession, ultimately leading to the advancement of technology and the training of highly skilled engineers who can drive innovation and address complex challenges.

4. Faculty Expertise

The strength of a mechanical and aerospace engineering department is fundamentally rooted in the expertise of its faculty. Their collective knowledge, research accomplishments, and pedagogical skills define the quality of education and the scope of innovation within the department. This expertise directly shapes the curriculum, research directions, and overall impact of the department on the engineering profession.

- Specialized Knowledge Domains

Faculty members possess specialized knowledge in diverse domains such as fluid dynamics, thermodynamics, structural mechanics, control systems, and materials science. This depth of knowledge enables the department to offer a comprehensive curriculum covering both fundamental principles and advanced topics. For instance, a professor specializing in computational fluid dynamics may lead research on turbulence modeling, contributing to the design of more efficient aircraft wings. The presence of diverse expertise ensures students are exposed to a wide range of engineering disciplines.

- Research Accomplishments and Publications

A faculty’s research output, measured by publications in peer-reviewed journals and presentations at international conferences, reflects the department’s commitment to advancing engineering knowledge. These publications disseminate new findings, inspire further research, and elevate the department’s reputation within the academic community. For example, a professor’s groundbreaking research on advanced composite materials could lead to their adoption in the aerospace industry, improving the performance and safety of aircraft structures. The visibility of faculty research attracts talented students and funding opportunities.

- Industry Experience and Collaboration

Faculty members with prior industry experience bring practical insights and real-world perspectives to the classroom. Their involvement in industry collaborations, such as consulting projects and joint research ventures, fosters a connection between academia and practice. A professor who previously worked as a design engineer at an aerospace company can provide valuable guidance to students working on capstone design projects. These collaborations ensure that the curriculum remains relevant to industry needs.

- Teaching and Mentoring Skills

Effective teaching and mentoring are essential components of faculty expertise. Professors who are skilled at conveying complex concepts, engaging students in active learning, and providing personalized guidance play a crucial role in shaping the next generation of engineers. A professor who dedicates time to mentoring undergraduate students in research projects can inspire them to pursue careers in engineering. These skills ensure that students receive a high-quality education and develop the necessary skills to succeed in their future careers.

In summation, faculty expertise is the most valuable asset of any mechanical and aerospace engineering department. The integration of specialized knowledge, research accomplishments, industry experience, and teaching skills ensures a vibrant learning environment, promotes innovation, and prepares students for successful careers in the engineering profession. A continuous investment in faculty development and recruitment is therefore paramount to the long-term success and impact of the department.

5. Accreditation Standards

Accreditation standards serve as a crucial benchmark for evaluating the quality and rigor of academic programs within a mechanical and aerospace engineering department. These standards, typically established by recognized accrediting bodies, ensure that programs meet specific criteria related to curriculum, faculty, resources, and student outcomes, thereby guaranteeing a certain level of competency among graduates.

- Curriculum Content and Structure

Accreditation standards mandate that the curriculum covers a broad range of topics essential to mechanical and aerospace engineering, including thermodynamics, fluid mechanics, structural analysis, control systems, and aerospace propulsion. The curriculum must also include sufficient depth to enable students to apply these principles to real-world problems. For instance, accreditation might require that students complete a capstone design project that integrates multiple areas of engineering knowledge, demonstrating their ability to design and analyze complex systems. Failure to meet these standards could result in a program being denied accreditation, impacting its reputation and the career prospects of its graduates.

- Faculty Qualifications and Expertise

Accreditation standards stipulate that faculty members possess the necessary qualifications and expertise to effectively teach and conduct research in their respective fields. This typically includes holding advanced degrees (e.g., Ph.D.) and having relevant professional experience. Accrediting bodies may also assess the faculty’s research productivity, teaching effectiveness, and contributions to the engineering profession. For example, a department might be required to demonstrate that a certain percentage of its faculty members are actively engaged in funded research projects. Insufficient faculty qualifications can jeopardize a program’s accreditation status.

- Student Outcomes Assessment

Accreditation standards require programs to demonstrate that their graduates have achieved specific learning outcomes, such as the ability to apply engineering principles, design solutions to complex problems, communicate effectively, and function in multidisciplinary teams. Programs must implement assessment methods to measure student achievement of these outcomes, such as exams, projects, and surveys. For example, a department might track the employment rates and career progression of its graduates to assess the program’s effectiveness in preparing them for professional practice. Failure to demonstrate adequate student outcomes can lead to a program being placed on probation or losing its accreditation.

- Continuous Improvement Processes

Accreditation standards emphasize the importance of continuous improvement and require programs to establish processes for regularly evaluating their effectiveness and making necessary changes. This includes soliciting feedback from students, faculty, and industry stakeholders, analyzing assessment data, and implementing action plans to address identified weaknesses. For example, a department might conduct an annual survey of alumni to gather feedback on the curriculum and make adjustments based on their responses. A commitment to continuous improvement is essential for maintaining accreditation and ensuring that the program remains relevant and effective.

The adherence to accreditation standards is vital for any mechanical and aerospace engineering department seeking to provide a high-quality education and prepare its graduates for success in the engineering profession. Accreditation not only assures students and employers of the program’s quality but also drives continuous improvement and innovation within the department. Furthermore, graduates from accredited programs are often given preference by employers and may be eligible for professional licensure, underscoring the importance of accreditation in shaping the career trajectories of mechanical and aerospace engineers.

Frequently Asked Questions

The following addresses common inquiries regarding academic programs and research activities.

Question 1: What is the typical duration required to complete an undergraduate degree?

The standard timeframe for completing a Bachelor of Science degree is four years, assuming full-time enrollment and satisfactory academic progress. Individual circumstances, such as transfer credits or course load variations, may influence the actual duration.

Question 2: What are the primary areas of research emphasis?

Research efforts are concentrated in areas including advanced materials, propulsion systems, robotics, and computational modeling. Specific research projects are often interdisciplinary, reflecting the complex nature of modern engineering challenges.

Question 3: Are there opportunities for undergraduate research involvement?

Undergraduate students are encouraged to participate in research projects under the guidance of faculty mentors. These opportunities provide valuable hands-on experience and contribute to the advancement of knowledge in the field.

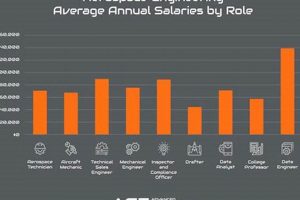

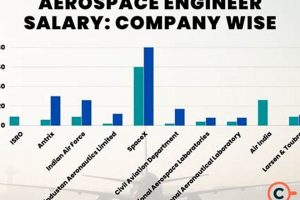

Question 4: What career paths are typically pursued by graduates?

Graduates pursue careers in a wide range of industries, including aerospace, automotive, energy, and manufacturing. Common roles include design engineer, research scientist, and project manager.

Question 5: What resources and facilities are available to students?

Students have access to a variety of resources, including state-of-the-art laboratories, computer facilities, and specialized software. These resources support both coursework and research activities.

Question 6: How does the curriculum address current industry trends?

The curriculum is regularly updated to reflect the latest advancements in engineering technology and industry practices. This ensures that graduates are well-prepared for the challenges of the modern workforce.

These answers provide a concise overview of key aspects. Further details can be obtained from department resources and faculty advisors.

The following content will transition to discussions on future trends and opportunities within the field.

Concluding Remarks

This exploration of the mechanical and aerospace engineering department has illuminated its multifaceted role in education, research, and industry collaboration. The significance of curriculum integration, research innovation, faculty expertise, and adherence to accreditation standards has been emphasized. The department’s commitment to these areas is fundamental to its ability to produce qualified engineers and contribute to technological advancement.

The future of engineering demands a continuous pursuit of knowledge, innovation, and adaptation to emerging challenges. Stakeholders are encouraged to support and engage with these academic units to foster progress and ensure the ongoing relevance of mechanical and aerospace engineering in addressing global needs and driving technological progress. Continued investment and collaboration are essential for sustaining excellence in engineering education and research.