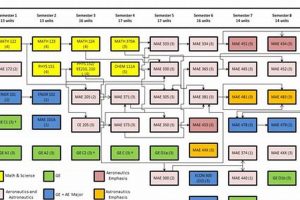

This area of specialization integrates principles from mechanics, materials science, and thermodynamics with the intricacies of flight and space vehicle design. Students pursuing this focused curriculum acquire a robust understanding of structural analysis, propulsion systems, aerodynamics, and control systems. A graduate, for instance, might possess expertise in designing lightweight components for aircraft or optimizing the performance of rocket engines.

The relevance of this expertise stems from the ever-present demand for innovation in aviation and space exploration. Historically, advancements in these fields have driven technological progress across multiple sectors. Today, professionals with this skillset are instrumental in developing more fuel-efficient aircraft, designing sustainable spacecraft, and advancing the frontiers of space travel. The benefits extend to national security, economic competitiveness, and scientific discovery.

The following sections will delve into the specific coursework that forms the foundation of this specialization, examine career paths available to graduates, and explore the current research landscape shaping the future of flight and space technology. These discussions will further highlight the vital contributions made by those skilled in this interdisciplinary field.

Guidance for Focused Study

Individuals pursuing this rigorous discipline should adopt proactive and structured study habits to maximize their learning potential.

Tip 1: Solidify Foundational Knowledge: A strong grasp of fundamental mechanical engineering principles is paramount. Review core concepts such as statics, dynamics, and thermodynamics frequently. Failure to do so will hinder comprehension of advanced aerospace-specific topics.

Tip 2: Prioritize Mathematical Proficiency: Advanced mathematics, particularly calculus, differential equations, and linear algebra, form the backbone of aerospace engineering analysis. Consistent practice and application of these mathematical tools are essential for problem-solving.

Tip 3: Engage with Simulation Software: Familiarize oneself with industry-standard simulation software, such as ANSYS or MATLAB. Practical experience in modeling and simulating aerodynamic behavior or structural integrity will greatly enhance employability.

Tip 4: Seek Out Relevant Projects: Participate in hands-on projects, such as designing and building model aircraft or developing control algorithms for autonomous vehicles. These experiences provide valuable practical skills and demonstrate commitment to the field.

Tip 5: Explore Interdisciplinary Connections: Cultivate an understanding of related disciplines, including electrical engineering, computer science, and materials science. Aerospace engineering is inherently interdisciplinary, and a broad knowledge base will foster innovation.

Tip 6: Attend Industry Events and Workshops: Actively engage with the aerospace community by attending conferences, workshops, and seminars. Networking with professionals and staying abreast of industry trends is crucial for career advancement.

Tip 7: Focus on Aerodynamics and Propulsion: dedicate a sufficient amount of time to gain a solid understanding of Aerodynamics and Propulsion system. These are the fundamentals on aerospace concentration and should be understand to progress.

By adhering to these recommendations, students can optimize their academic performance and prepare themselves for successful careers in the aerospace industry. A dedicated and focused approach is critical for mastering the complex and demanding subject matter.

The subsequent discussion will explore specific career paths and emerging research areas related to this highly specialized engineering discipline.

1. Aerodynamics

Aerodynamics, the study of air in motion, is a cornerstone within mechanical engineering with an aerospace concentration. Understanding aerodynamic principles is critical for designing efficient and stable aircraft and spacecraft. This field dictates how a vehicle interacts with the atmosphere, affecting lift, drag, and overall performance.

- Lift Generation

Lift, the force that counteracts gravity, is fundamentally rooted in aerodynamic principles. The shape of an airfoil, the cross-section of a wing, is carefully engineered to create pressure differences that generate lift. Understanding how to manipulate airflow over a wing surface, through the use of flaps or slats, directly impacts an aircraft’s ability to take off, maintain altitude, and land safely. This knowledge is critical for mechanical engineers specializing in aerospace.

- Drag Reduction

Drag, the force that opposes motion through the air, is a primary concern in aerospace design. Minimizing drag is essential for improving fuel efficiency and increasing speed. This involves optimizing the shape of the aircraft to reduce air resistance and understanding the different types of drag, such as skin friction and pressure drag. Techniques like streamlining and the use of laminar flow control are applied to minimize these effects. A mechanical engineer with an aerospace focus must possess a deep understanding of these drag reduction methods.

- Stability and Control

Aerodynamic stability refers to an aircraft’s ability to return to its equilibrium state after a disturbance. Control surfaces, such as ailerons, elevators, and rudders, are used to manipulate airflow and control the aircraft’s orientation. Aerodynamic principles govern the effectiveness of these control surfaces, and engineers must design them to provide adequate control without compromising stability. Furthermore, this domain is applicable to missile control and other aerospace designs.

- Supersonic and Hypersonic Flow

As aircraft and spacecraft reach supersonic and hypersonic speeds, the behavior of air becomes significantly more complex. Shock waves form, and aerodynamic heating becomes a major challenge. Designing vehicles that can withstand these extreme conditions requires a specialized understanding of compressible flow, shock wave theory, and heat transfer. These considerations are crucial for the design of high-speed aircraft and re-entry vehicles, showcasing their significance in mechanical engineering with an aerospace concentration.

The interplay between lift, drag, stability, and the complexities of supersonic flow highlights the central role of aerodynamics. Each facet is essential in the training of mechanical engineers specializing in aerospace, informing the design, analysis, and optimization of aircraft and spacecraft. The mastery of these aerodynamic principles enables advancements in flight efficiency, safety, and performance, underscoring its fundamental position in the field.

2. Propulsion Systems

Propulsion systems are integral to mechanical engineering with an aerospace concentration, providing the thrust necessary for aircraft and spacecraft to overcome gravity and atmospheric resistance. The design, analysis, and optimization of these systems require a deep understanding of thermodynamics, fluid mechanics, and combustion, directly impacting the performance and efficiency of aerospace vehicles.

- Jet Engines

Jet engines, widely used in commercial and military aircraft, rely on the principles of Brayton cycle thermodynamics. Air is compressed, mixed with fuel, ignited, and expanded through a turbine to produce thrust. Mechanical engineers focusing on aerospace contribute to the design of more efficient compressors, turbines, and combustors, aiming to reduce fuel consumption and emissions. Innovations in materials and cooling techniques also play a vital role in enhancing jet engine performance. The design of these engines and their components are crucial to advancing the aviation industry.

- Rocket Engines

Rocket engines, essential for space travel, operate on the principle of Newton’s third law. Propellants are burned in a combustion chamber, and the resulting hot gases are expelled through a nozzle, generating thrust. Mechanical engineers with an aerospace concentration are involved in optimizing rocket engine designs for higher thrust-to-weight ratios and improved specific impulse. This includes research into new propellant combinations, advanced nozzle designs, and cooling methods to withstand the extreme temperatures and pressures within the engine.

- Electric Propulsion

Electric propulsion systems, utilized primarily for spacecraft, use electrical energy to accelerate propellant, creating thrust. These systems, such as ion thrusters and Hall effect thrusters, offer high specific impulse, enabling long-duration space missions. Mechanical engineers contribute to the design of the thruster components, including the ionization chambers, acceleration grids, and magnetic fields. This also includes integrating the power source and control system. Research into more efficient and powerful electric propulsion systems is crucial for enabling future deep-space exploration missions.

- Propeller Systems

Propeller systems, used in smaller aircraft and drones, generate thrust by accelerating air rearward. Mechanical engineers focusing on aerospace are involved in designing propellers with optimized blade shapes for maximum efficiency and minimum noise. This includes studying the aerodynamic forces acting on the propeller blades and developing control systems to adjust the blade pitch for different flight conditions. Advancements in propeller materials and design contribute to improved performance and reduced fuel consumption for light aircraft.

The diversity of propulsion systems, from jet engines powering commercial airliners to electric thrusters enabling deep-space probes, underscores the importance of this field within mechanical engineering aerospace concentration. The continuous pursuit of more efficient, reliable, and powerful propulsion systems drives innovation in aviation and space exploration, highlighting the critical role of mechanical engineers in advancing these technologies.

3. Structural Analysis

Structural analysis, a fundamental aspect of mechanical engineering with an aerospace concentration, is the process of assessing the integrity and stability of aerospace structures under various loading conditions. This discipline ensures that aircraft and spacecraft can withstand the forces exerted during flight, launch, and operation, thereby maintaining safety and performance. The application of structural analysis methodologies is crucial for preventing catastrophic failures and optimizing the weight and efficiency of aerospace designs.

- Finite Element Analysis (FEA)

Finite Element Analysis (FEA) is a computational method used to predict how a structure will react to real-world forces, vibration, heat, fluid flow, and other physical effects. In aerospace, FEA is employed to simulate stress distributions in aircraft wings, fuselage sections, and engine components. For example, FEA can model the effects of aerodynamic loads on a wing during flight, identifying areas of high stress concentration that require reinforcement. This technique is invaluable for optimizing the structural design and ensuring it can withstand operational stresses.

- Material Selection and Testing

The selection of appropriate materials is integral to structural analysis. Aerospace engineers must consider factors such as strength-to-weight ratio, corrosion resistance, and fatigue properties. Testing of materials, including tensile testing, fatigue testing, and non-destructive testing, provides data to validate the accuracy of structural models and ensure that materials meet required specifications. For instance, composite materials are often used in aircraft structures due to their high strength-to-weight ratio, but their performance must be thoroughly characterized through testing and analysis.

- Buckling Analysis

Buckling analysis focuses on predicting the critical load at which a structure will undergo sudden and catastrophic failure due to instability. This is particularly important for thin-walled structures commonly found in aircraft fuselages and rocket bodies. Engineers employ buckling analysis techniques to determine the maximum load that a structure can withstand before buckling occurs, ensuring that designs are sufficiently robust to prevent collapse under operational conditions. Understanding the effects of high pressure is necessary for preventing failures and maintaining safety.

- Vibration Analysis

Vibration analysis assesses the dynamic response of aerospace structures to external vibrations and internal excitations. This is essential for preventing resonance, which can lead to structural fatigue and failure. Vibration analysis techniques are used to identify natural frequencies and mode shapes of structures, enabling engineers to design damping systems and modify structural characteristics to mitigate the effects of vibration. The design of helicopter rotor blades, for instance, requires careful consideration of vibration characteristics to ensure stability and prevent premature failure.

These facets of structural analysis are interconnected and essential for ensuring the safety and reliability of aerospace vehicles. By employing advanced analytical techniques, selecting appropriate materials, and conducting rigorous testing, mechanical engineers with an aerospace concentration contribute to the design of structures that can withstand the harsh conditions of flight and space travel. The ongoing development of new materials, analytical methods, and computational tools further enhances the capabilities of structural analysis in aerospace engineering.

4. Control Systems

Control systems are fundamental to the successful operation of aerospace vehicles and form a critical area of study within mechanical engineering aerospace concentration. These systems ensure that aircraft, spacecraft, and related technologies perform as intended by maintaining stability, directing movement, and responding to changing conditions. Effective control systems are vital for safety, efficiency, and mission success in aerospace applications.

- Flight Control Systems

Flight control systems manage an aircraft’s attitude, altitude, and trajectory. These systems employ sensors to measure parameters such as airspeed, altitude, and orientation, and use actuators to adjust control surfaces like ailerons, elevators, and rudders. For example, an autopilot system uses feedback control loops to maintain a pre-set course and altitude, reducing pilot workload and improving flight precision. The design and implementation of these systems require a deep understanding of aerodynamics, dynamics, and control theory.

- Guidance and Navigation Systems

Guidance and navigation systems determine the position and velocity of an aerospace vehicle and guide it along a desired path. These systems rely on various technologies, including inertial navigation systems (INS), global positioning systems (GPS), and star trackers. For instance, a spacecraft uses a combination of INS and star trackers to navigate through space, correcting its trajectory based on celestial observations. Accurate guidance and navigation are essential for achieving mission objectives and avoiding collisions.

- Engine Control Systems

Engine control systems regulate the operation of aircraft and spacecraft engines, optimizing performance and ensuring safe operation. These systems monitor parameters such as fuel flow, air intake, and exhaust temperature, and adjust engine settings to maintain desired thrust levels and prevent overheating or stalling. For example, a full authority digital engine control (FADEC) system automatically manages all aspects of engine operation, improving fuel efficiency and reducing emissions. The design of engine control systems requires expertise in thermodynamics, combustion, and control engineering.

- Attitude Control Systems

Attitude control systems maintain the orientation of a spacecraft in space. These systems use sensors, such as gyroscopes and star trackers, to determine the spacecraft’s attitude, and actuators, such as reaction wheels and thrusters, to adjust its orientation. For example, a satellite uses reaction wheels to maintain a stable orientation for communication or observation purposes, counteracting external torques caused by solar radiation or gravity gradients. Precise attitude control is critical for pointing instruments accurately and maintaining communication links.

The integration of these control systems demonstrates the multidisciplinary nature of mechanical engineering aerospace concentration. Expertise in control theory, sensor technology, and actuator design is essential for developing advanced aerospace vehicles. As aerospace technology continues to evolve, the demand for skilled engineers capable of designing and implementing sophisticated control systems will only increase, reinforcing the significance of this area of study.

5. Materials Science

The intersection of materials science and mechanical engineering, particularly within the aerospace concentration, is characterized by a critical interdependence. The performance, safety, and longevity of aerospace vehicles are fundamentally constrained by the properties of the materials from which they are constructed. A mechanical engineer specializing in aerospace requires a comprehensive understanding of material behavior under extreme conditions, encompassing factors such as high and low temperatures, intense stress, corrosive environments, and radiation exposure. This knowledge directly informs material selection, influencing design decisions from initial concept to final product. For example, the development of high-temperature alloys capable of withstanding the extreme heat generated within a jet engine necessitates a profound understanding of materials science principles to achieve both performance and durability.

Practical application of materials science principles in aerospace extends to the development of lightweight, high-strength composites, vital for reducing vehicle weight and improving fuel efficiency. The design of carbon fiber reinforced polymer (CFRP) structures, commonly used in modern aircraft, requires a thorough grasp of composite material mechanics, including lamination theory, failure modes, and environmental degradation. Additionally, the implementation of advanced manufacturing techniques, such as additive manufacturing, is contingent on a solid foundation in materials science to ensure the production of components with controlled microstructures and desired mechanical properties. The correct application of materials science also is important to reduce weight, reduce corrosion, and extend the life cycle of different aerospace systems.

In summary, materials science is not merely a supplementary field, but an integral component of mechanical engineering with an aerospace concentration. Challenges in this domain include the ongoing search for materials with enhanced performance characteristics, as well as the development of sustainable and environmentally friendly alternatives. The effective integration of materials science principles into aerospace design and manufacturing processes is crucial for advancing the capabilities of aerospace vehicles and ensuring continued progress in the field. The successful implementation of mechanical design and materials science are important and should be prioritized.

6. Thermodynamics

Thermodynamics plays a pivotal role in mechanical engineering with an aerospace concentration, serving as the scientific foundation for understanding and optimizing energy conversion and transfer processes within aerospace systems. The behavior of fluids and gases, energy management in propulsion systems, thermal control of spacecraft, and the analysis of aerodynamic phenomena are all rooted in thermodynamic principles. For instance, the design of efficient jet engines necessitates a deep understanding of thermodynamic cycles, such as the Brayton cycle, to maximize thrust output and minimize fuel consumption. Similarly, the analysis of heat transfer within a rocket nozzle requires detailed knowledge of thermodynamics to prevent overheating and structural failure. These aspects highlight the cause-and-effect relationship wherein thermodynamic analysis directly impacts system performance and reliability. Therefore, mechanical engineers specializing in aerospace must possess a strong grasp of thermodynamic principles to effectively design, analyze, and optimize aerospace systems.

The practical applications of thermodynamics in aerospace are extensive. The design of spacecraft thermal control systems, which maintain optimal operating temperatures for onboard electronics and life support, relies heavily on thermodynamic analysis. These systems utilize various techniques, such as radiative heat transfer, conductive heat transfer, and convective heat transfer, to manage heat dissipation and prevent overheating or freezing. Moreover, the development of hypersonic vehicles requires a thorough understanding of high-temperature gas dynamics and chemical kinetics, which are governed by thermodynamic principles. The design of these vehicles must account for aerodynamic heating caused by friction with the atmosphere, necessitating the use of advanced materials and thermal protection systems. These applications exemplify the practical significance of thermodynamics in addressing real-world aerospace challenges.

In summary, thermodynamics is an indispensable component of mechanical engineering with an aerospace concentration. Its principles underpin the design, analysis, and optimization of critical aerospace systems, including propulsion systems, thermal control systems, and hypersonic vehicles. Addressing future challenges, such as developing more efficient and sustainable aerospace technologies, will require continued advancements in thermodynamic modeling, analysis, and experimentation. The effective application of thermodynamic principles is crucial for ensuring the continued progress and success of the aerospace industry. The effective implementation of mechanical design and thermodynamics are important and should be prioritized.

7. Vehicle Design

Vehicle design, within the context of a mechanical engineering aerospace concentration, represents the culmination of various engineering disciplines. This process synthesizes aerodynamics, propulsion, structural analysis, control systems, and materials science to create functional aircraft and spacecraft. The aerodynamic characteristics influence the external shape, directly impacting lift, drag, and stability. Propulsion system requirements dictate the integration of engines or thrusters, affecting overall weight distribution and performance parameters. Structural integrity considerations determine the vehicle’s framework and material composition. Control system placement influences maneuverability, and materials science informs the selection of optimal materials for weight reduction and durability. A failure to adequately integrate these factors during design directly compromises the vehicle’s operational capabilities and safety.

The design of a commercial airliner illustrates this integration. The wing design must generate sufficient lift at various speeds while minimizing drag to maximize fuel efficiency. Engine placement must consider thrust vectoring and aerodynamic interference. The fuselage must withstand pressurization and aerodynamic loads. Control surfaces must provide precise maneuverability. Materials must be lightweight yet strong enough to ensure structural integrity. Each component is interdependent, requiring a holistic approach. Consider, for example, the Boeing 787 Dreamliner, where the integration of composite materials significantly reduced weight, improving fuel efficiency and range. This exemplifies the practical application of advanced materials science in vehicle design.

In summary, vehicle design is not merely an isolated engineering activity but the synthesis of knowledge and skills acquired within a mechanical engineering aerospace concentration. The process necessitates a comprehensive understanding of aerodynamic principles, propulsion systems, structural analysis, control system implementation, and materials science. The effective integration of these elements is crucial for creating safe, efficient, and functional aerospace vehicles. The challenges facing vehicle design include achieving greater fuel efficiency, improving passenger comfort, reducing environmental impact, and enhancing safety. These challenges continue to drive innovation and define the future of aerospace engineering.

Frequently Asked Questions About Mechanical Engineering Aerospace Concentration

The following questions and answers address common inquiries and misconceptions regarding a concentration in aerospace within a mechanical engineering program. This information aims to provide clarity for prospective students and those seeking to understand the scope of this specialized field.

Question 1: What distinguishes a mechanical engineering aerospace concentration from a dedicated aerospace engineering degree?

A mechanical engineering aerospace concentration provides a strong foundation in core mechanical engineering principles, followed by specialized coursework in aerospace topics. A dedicated aerospace engineering degree often focuses exclusively on aerospace subjects from the outset. The concentration offers broader career flexibility, while the degree provides more in-depth knowledge of aerospace-specific areas.

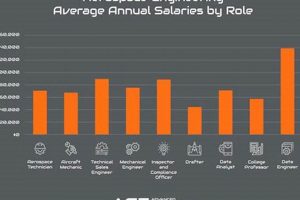

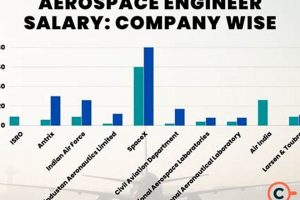

Question 2: What are the primary career paths available to graduates with this concentration?

Graduates can pursue careers in aircraft design, spacecraft development, propulsion systems, aerodynamics research, and related fields within the aerospace industry. Opportunities also exist in government agencies, such as NASA, and in defense-related industries. Some may pursue graduate studies for advanced specialization.

Question 3: Is advanced mathematics crucial for success in this concentration?

A strong foundation in advanced mathematics, including calculus, differential equations, and linear algebra, is essential. These mathematical tools are fundamental to understanding and analyzing complex engineering problems related to fluid mechanics, structural analysis, and control systems.

Question 4: What role does computer-aided design (CAD) and simulation software play in the curriculum?

CAD and simulation software are integral to the design process and are widely used throughout the curriculum. Students gain proficiency in industry-standard software to model, analyze, and simulate the performance of aerospace components and systems. This practical experience is highly valued by employers.

Question 5: What are the key differences in skill sets learned for mechanical engineering and mechanical engineering with aerospace concentration?

Mechanical engineers learn core mechanical engineering skill such as thermodynamics, heat transfer, manufacturing, design, and mechanics of material. Mechanical engineers with aerospace concentration learns a variety of additional skill that includes aerodynamics, propulsion, flight dynamics, and aerospace vehicle design. Mechanical engineers design various mechanical products while mechanical engineers with aerospace concentration design aerospace vehicle and its component.

Question 6: Are there opportunities for hands-on experience during the course of study?

Many programs offer opportunities for hands-on experience through laboratory work, design projects, and internships. These experiences allow students to apply theoretical knowledge to practical problems and develop valuable skills that are highly sought after by employers.

A mechanical engineering aerospace concentration provides a robust foundation for a career in the aerospace industry. A focused approach to learning, coupled with practical experience, is critical for success in this challenging and rewarding field.

The following section explores emerging trends and future directions within this field of specialization.

Conclusion

This exploration of mechanical engineering aerospace concentration has highlighted the depth and breadth of knowledge required for success in this field. The integration of fundamental mechanical engineering principles with specialized aerospace concepts creates a demanding yet rewarding curriculum. Mastery of aerodynamics, propulsion systems, structural analysis, control systems, and materials science is essential for designing and analyzing aircraft and spacecraft.

The ongoing advancements in aerospace technology necessitate a continuous pursuit of knowledge and innovation. Those entering this field must be prepared to engage with complex challenges, contribute to cutting-edge research, and uphold the highest standards of engineering practice. The future of air and space travel depends on the dedication and expertise of engineers skilled in this critical area.