Opportunities within Moog’s aerospace sector encompass a wide array of positions related to the design, manufacture, and support of precision control components and systems used in aircraft, spacecraft, and defense applications. These roles span various engineering disciplines, including mechanical, electrical, and software, as well as manufacturing, supply chain, and administrative functions. For example, a mechanical engineer might design hydraulic actuators for flight control systems, while a software engineer could develop embedded code for a satellite’s attitude control system.

The availability of roles in this domain is vital to maintaining and advancing technological capabilities within the aerospace industry. These positions provide skilled individuals with the chance to contribute to cutting-edge projects that impact air travel safety, space exploration, and national defense. Historically, advancements in aerospace technology have been driven by dedicated professionals in similar roles, leading to improvements in aircraft performance, fuel efficiency, and overall system reliability.

The following sections will delve into specific career paths within this field, required qualifications, typical responsibilities, and the long-term career prospects for individuals pursuing a profession focused on motion control solutions within the aerospace domain.

Guidance for Exploring Opportunities at Moog Aerospace

The following guidelines are intended to assist individuals in navigating the application process and increasing their chances of securing a position within Moog’s aerospace sector.

Tip 1: Research Moog’s Aerospace Technologies: A comprehensive understanding of the company’s product lines, including flight control systems, actuation technologies, and space-related components, is crucial. Review publicly available technical specifications and white papers to gain in-depth knowledge.

Tip 2: Tailor Resume to Specific Job Requirements: Generic resumes are less effective. Customize each application to highlight relevant skills and experience directly related to the posted requirements. Emphasize experience with specific software or hardware platforms used in the aerospace industry.

Tip 3: Highlight Relevant Certifications and Education: Certifications such as Six Sigma, project management (PMP), or industry-specific credentials like FAA airframe and powerplant licenses can significantly enhance candidacy. Showcase relevant coursework and projects completed during academic studies.

Tip 4: Demonstrate Problem-Solving Abilities: Provide concrete examples of how you have successfully addressed technical challenges in previous roles or academic projects. Quantify your accomplishments whenever possible, using metrics to illustrate the impact of your solutions.

Tip 5: Network Within the Aerospace Community: Attend industry conferences, join professional organizations (e.g., AIAA, IEEE), and connect with individuals working in similar roles on professional networking platforms. Building relationships can provide valuable insights and potential job leads.

Tip 6: Prepare for Technical Interviews: Expect rigorous technical assessments covering topics relevant to the specific position. Practice answering common engineering questions and be prepared to discuss design decisions and trade-offs.

Tip 7: Showcase Understanding of Aerospace Standards: Familiarize yourself with industry standards such as AS9100, DO-178B/C, and MIL-STD specifications. Demonstrating knowledge of these standards indicates a commitment to quality and compliance.

These guidelines should improve an applicant’s understanding of expectations and readiness for related positions. The consistent application of these suggestions can result in a more refined and competitive approach.

The subsequent section provides a summary of the material described, as well as ideas for future consideration.

1. Engineering Design

Engineering Design constitutes a core function within Moog Aerospace, directly influencing the capabilities and performance of its products. It encompasses the creation of detailed plans and specifications for components and systems that meet rigorous aerospace requirements. The direct impact of this process is observable in the functionality and efficacy of Moog’s motion control solutions used across various aerospace platforms. For instance, the design of hydraulic actuators for aircraft flight control demands precision and reliability, as these systems directly influence the pilot’s ability to control the aircraft. Similarly, the design of components for spacecraft requires careful consideration of environmental factors such as radiation and extreme temperatures, which demands sophisticated material selection and design strategies.

The design process frequently involves the application of advanced simulation tools and modeling techniques to predict performance and identify potential weaknesses prior to physical prototyping. This predictive capability allows engineers to optimize designs for weight, power consumption, and durability, critical factors in aerospace applications. An example can be seen in the design of servo valves for missile control systems, where engineers employ computational fluid dynamics (CFD) to analyze fluid flow and optimize valve geometry for rapid and accurate response. Furthermore, these designs must adhere to strict regulatory standards and certifications, ensuring that they meet established safety and performance criteria.

In summary, Engineering Design within Moog Aerospace is the foundational element that determines the functional and operational characteristics of its products. The importance of this process cannot be overstated, given its direct influence on the safety, efficiency, and reliability of aerospace systems. The consistent application of rigorous design principles and advanced simulation techniques allows for the creation of innovative and effective motion control solutions, contributing to the ongoing advancement of aerospace technology. Challenges remain in addressing the ever-increasing complexity of aerospace systems and the demand for lighter, more efficient components, underscoring the need for continuous improvement in design methodologies.

2. Manufacturing Processes

The effectiveness of opportunities is intrinsically linked to the precision and efficiency of its manufacturing processes. These roles demand expertise in converting engineering designs into tangible products, requiring a deep understanding of material properties, machining techniques, and assembly procedures. The reliability of aerospace components hinges on adherence to stringent quality control measures throughout the manufacturing lifecycle. For instance, the fabrication of flight control actuators necessitates meticulous attention to detail in machining tolerances and surface finishes to ensure proper functionality and longevity under extreme operational conditions.

Roles associated with production involve optimizing workflows, implementing lean manufacturing principles, and leveraging automation technologies to enhance productivity and minimize waste. This could manifest as the utilization of Computer Numerical Control (CNC) machining to produce complex geometries with high accuracy, or the implementation of robotic systems for repetitive assembly tasks. Real-world examples include streamlining the production of hydraulic pumps used in aircraft landing gear, leading to reduced lead times and improved product quality. Furthermore, compliance with industry standards like AS9100 is paramount, requiring rigorous documentation and traceability of all manufacturing processes.

In summary, the success of individuals in this field is dependent on their proficiency in managing and improving manufacturing processes. Challenges such as the increasing complexity of aerospace components and the need for higher production volumes necessitate continuous innovation in manufacturing techniques and technologies. Understanding this connection is essential for both prospective employees seeking positions and for the continued growth and competitiveness of Moog Aerospace within the global aerospace market.

3. Systems Integration

Systems Integration, a critical element in aerospace operations, is inextricably linked to a diverse range of professional roles within the sector. This process involves ensuring that various components and subsystems function cohesively as a unified whole. Within the context of related positions, Systems Integration professionals are responsible for designing, implementing, and validating the interfaces and interactions between different hardware and software elements. For example, integrating a newly developed flight control computer into an existing aircraft platform requires meticulous planning and testing to guarantee seamless communication and compatibility with other onboard systems such as navigation, communication, and engine control units. The success of this integration is paramount to the overall performance and safety of the aircraft.

The importance of skilled Systems Integration professionals cannot be overstated. Failures in integration can lead to malfunctions, reduced performance, and even catastrophic incidents. Real-life examples highlight the practical significance of this area of expertise; consider the complexity of integrating a new radar system into a military aircraft. The radar must not only accurately detect and track targets but also seamlessly communicate its findings to the pilot and other onboard systems, while simultaneously avoiding interference with other electronic equipment. Systems Integration engineers are thus tasked with ensuring that all these elements work in concert, optimizing performance and mitigating potential risks.

Understanding the principles and practices of Systems Integration is essential for individuals pursuing roles that contribute to Moog’s aerospace operations. By focusing on the seamless and reliable interaction of complex systems, these professionals play a vital role in advancing the capabilities and safety of modern aerospace technology. Addressing challenges related to interoperability, cybersecurity, and evolving technology standards remains a core component, thereby securing continued growth and reliability.

4. Quality Assurance

Quality Assurance (QA) forms an integral component of opportunities within Moog Aerospace. These positions demand rigorous adherence to industry standards and regulatory requirements to ensure the safety, reliability, and performance of aerospace components and systems. The direct consequence of effective QA practices is a reduction in defects, enhanced product longevity, and increased customer confidence. For example, QA engineers are responsible for overseeing inspection processes, conducting audits, and implementing corrective actions to address non-conformances identified during manufacturing or testing phases. A failure in this area could lead to catastrophic consequences in flight or mission-critical scenarios.

The importance of QA is underscored by the stringent certification requirements imposed on aerospace manufacturers. Real-world examples include ensuring compliance with AS9100 standards, which govern quality management systems specific to the aerospace industry. QA professionals play a crucial role in developing and maintaining documentation, conducting internal audits, and facilitating external audits by regulatory bodies. Practical applications involve performing statistical process control (SPC) to monitor and improve manufacturing processes, conducting failure analysis to determine root causes of defects, and implementing robust change management processes to control modifications to designs and processes. Without the contribution from skilled QA experts, adherence to demanding requirements would not be possible.

In summary, competent QA personnel constitute a foundational aspect of related employment prospects. Challenges remain in adapting QA practices to accommodate increasingly complex aerospace systems and evolving regulatory landscapes. Sustained growth and viability in a competitive domain are significantly dependent on the commitment to superior product verification and the capacity to maintain standards.

5. Project Management

Project Management constitutes a fundamental discipline within Moog Aerospace’s operational framework. Its effective implementation directly correlates with the successful completion of aerospace projects, influencing factors such as schedule adherence, budget control, and the attainment of specified technical objectives. Within related job functions, project managers are responsible for overseeing the entire project lifecycle, from initial conceptualization and planning to execution, monitoring, and closure. The absence of proficient project management can lead to cost overruns, delays, and compromised product quality, directly impacting Moog’s reputation and competitive standing. For example, the development of a new flight control system necessitates meticulous project management to ensure that engineering, manufacturing, testing, and certification activities are synchronized and completed on time and within budget.

The practical significance of this understanding becomes evident when considering the complexity and scale of aerospace projects. Examples include the development and deployment of satellite propulsion systems, which require the coordination of numerous teams, suppliers, and regulatory agencies. Project managers utilize tools and techniques such as work breakdown structures, Gantt charts, and risk management plans to maintain control and ensure that all stakeholders are aligned. Effective communication and collaboration are paramount, as project managers must interact with engineers, technicians, customers, and executive leadership to address challenges and make informed decisions. Furthermore, adherence to project management methodologies such as Agile or Waterfall is often mandated to ensure consistency and predictability.

In summary, Project Management serves as a critical enabler for Moog Aerospace to achieve its strategic goals and deliver innovative aerospace solutions. Challenges persist in managing the increasing complexity of aerospace projects and adapting to evolving customer requirements. Sustained success requires a commitment to continuous improvement in project management practices and the development of highly skilled project management professionals. The connection between project management competence and the execution of advanced aerospace solutions remains fundamental to the organizations success.

Frequently Asked Questions Regarding Moog Aerospace Jobs

This section addresses common inquiries pertaining to opportunities within Moog’s aerospace division, providing clarity on eligibility, application procedures, and career development prospects.

Question 1: What are the minimum educational qualifications typically required for engineering positions at Moog Aerospace?

Generally, a Bachelor’s degree in a relevant engineering discipline, such as Mechanical, Electrical, Aerospace, or a closely related field, is the minimum requirement. Certain positions may necessitate advanced degrees (Master’s or Ph.D.) or specialized certifications depending on the role’s technical complexity and responsibilities.

Question 2: What type of experience is considered beneficial for applicants targeting a career at Moog Aerospace?

Experience in the aerospace industry, particularly with motion control systems, hydraulics, or avionics, is highly advantageous. Internships, co-op programs, or previous employment in related fields, coupled with demonstrated expertise in relevant software or hardware platforms, significantly enhance an applicant’s candidacy.

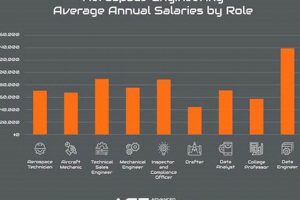

Question 3: What is the typical career progression path within the engineering department at Moog Aerospace?

Career progression typically begins with entry-level engineering roles and progresses through increasing levels of responsibility, such as Senior Engineer, Engineering Specialist, Engineering Manager, and potentially into leadership positions within the engineering organization. Advancement is contingent upon performance, technical expertise, and leadership capabilities.

Question 4: Does Moog Aerospace offer opportunities for professional development and continuing education?

Moog Aerospace recognizes the importance of ongoing professional development and offers various opportunities, including tuition reimbursement programs for advanced degrees, internal training programs focused on technical skills and leadership development, and participation in industry conferences and workshops.

Question 5: How does Moog Aerospace ensure compliance with industry-specific regulations and standards?

Moog Aerospace maintains a robust quality management system aligned with industry standards such as AS9100 and adheres to all applicable regulatory requirements mandated by organizations like the FAA and other relevant agencies. Compliance is ensured through rigorous internal audits, process controls, and ongoing training for employees.

Question 6: What is the company culture like at Moog Aerospace?

Moog Aerospace fosters a culture of innovation, collaboration, and technical excellence. The company emphasizes teamwork, continuous improvement, and a commitment to providing employees with opportunities to grow and develop their skills. Ethical conduct and adherence to high standards of integrity are also core values.

These FAQs provide a consolidated overview of essential aspects relevant to those interested in pursuing employment prospects. The details can be helpful in developing a clear idea of requirements.

The following section will summarize key points and suggestions for further reading.

Conclusion

The preceding analysis has detailed the diverse landscape of opportunities within Moog’s aerospace sector. Key aspects such as engineering design, manufacturing processes, systems integration, quality assurance, and project management were explored, each presenting distinct career paths and associated responsibilities. Understanding these areas is crucial for prospective employees seeking to contribute to Moog’s advancements in motion control solutions for aerospace applications. Frequently asked questions were also addressed, providing clarity on qualifications, professional development, and company culture.

The pursuit of roles related to moog aerospace jobs represents a commitment to technological progress and industry leadership. Continued exploration of specific job postings, engagement with industry professionals, and a dedication to continuous learning are essential for success in this demanding and rewarding field. The ongoing evolution of aerospace technology necessitates a proactive and informed approach to career development within this domain.