The study and application of principles related to flight vehicle design, construction, and operation within the environment of the Earth’s atmosphere and beyond is a complex interdisciplinary field. This discipline draws heavily on mathematics, physics, and engineering principles to create aircraft, spacecraft, and related systems. Specific areas of focus include aerodynamics, propulsion, structures, control systems, and orbital mechanics.

Advancements in this field are critical for progress in aviation, space exploration, and national defense. Historically, developments in these areas have spurred technological innovation across numerous sectors, impacting transportation, communication, and scientific research. The development of lighter and stronger materials, more efficient engines, and advanced control systems are prime examples of how this discipline contributes to broader technological progress, leading to economic growth and improved quality of life.

The following discussion will delve into specific aspects of this field, exploring current research trends, educational pathways, and the evolving challenges and opportunities facing engineers and scientists working in this dynamic domain. Topics such as sustainable aviation, autonomous flight, and the exploration of deep space will be addressed.

Guidance for Pursuing Advanced Studies in Aerospace

Individuals considering specializing in the design, development, and analysis of aerospace systems should focus on several key areas to enhance their preparedness and maximize their potential for success. Strategic planning and diligent execution are essential.

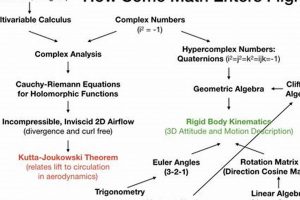

Tip 1: Strengthen Foundational Knowledge: A robust understanding of fundamental engineering principles, particularly mathematics, physics, and computer science, is paramount. Proficiency in calculus, differential equations, linear algebra, and programming languages such as Python or MATLAB is crucial.

Tip 2: Cultivate Analytical and Problem-Solving Skills: Aerospace challenges demand rigorous analytical thinking. Engage in projects, competitions, or research opportunities that necessitate the application of theoretical knowledge to practical problems. Develop the ability to identify, formulate, and solve complex engineering issues.

Tip 3: Develop Expertise in Relevant Software: Familiarity with industry-standard software packages for Computer-Aided Design (CAD), Computational Fluid Dynamics (CFD), and Finite Element Analysis (FEA) is essential. Hands-on experience with tools like ANSYS, SolidWorks, or similar programs will significantly enhance employability.

Tip 4: Engage in Research and Development: Participating in research projects, internships, or cooperative education programs provides invaluable practical experience. Seek opportunities to contribute to ongoing research efforts in areas such as aerodynamics, propulsion, or materials science.

Tip 5: Focus on Systems Engineering: Aerospace projects involve integrating multiple complex systems. Develop a comprehensive understanding of systems engineering principles, including requirements analysis, system architecture, integration, and testing.

Tip 6: Stay Abreast of Technological Advancements: The aerospace field is constantly evolving. Maintain awareness of emerging technologies, such as additive manufacturing, advanced materials, and autonomous systems, through publications, conferences, and online resources.

Tip 7: Develop Strong Communication Skills: The ability to effectively communicate technical information, both orally and in writing, is critical for success. Practice presenting research findings, writing technical reports, and collaborating with diverse teams.

These recommendations, when implemented with dedication, can significantly enhance an individual’s preparation for and success within this demanding yet rewarding discipline. A focus on fundamental knowledge, practical experience, and continuous learning is essential for navigating the complexities of the field.

The subsequent sections will provide deeper insight into specific technical domains within the discipline, illustrating how these principles are applied in real-world scenarios.

1. Aerodynamics

Aerodynamics, the study of air in motion, constitutes a foundational pillar within aerospace engineering. Its principles are intrinsically linked to the performance, stability, and overall efficiency of any airborne or spacefaring vehicle. Without a thorough understanding of aerodynamic phenomena, the design and operation of aircraft and spacecraft would be impossible.

- Lift Generation

Lift, the force that counteracts gravity and enables flight, is a direct consequence of aerodynamic principles. The shape of an airfoil, typically a wing, is designed to create a pressure difference between its upper and lower surfaces. This pressure differential generates the upward force necessary for sustained flight. The accurate prediction and manipulation of lift are critical aspects of aircraft design, dictating wing shape, size, and placement.

- Drag Reduction

Drag, the force that opposes motion through the air, directly impacts fuel efficiency and overall performance. Aerospace engineers employ various techniques to minimize drag, including streamlining vehicle shapes, utilizing specialized surface coatings, and implementing boundary layer control strategies. Reducing drag is paramount for achieving higher speeds, longer ranges, and improved fuel economy.

- Stability and Control

Aerodynamic forces and moments govern the stability and control characteristics of aerospace vehicles. Aircraft must be designed to inherently resist unwanted changes in attitude or flight path. Control surfaces, such as ailerons, elevators, and rudders, manipulate aerodynamic forces to enable pilots to maneuver the aircraft effectively. Aerodynamic analysis is crucial for ensuring stable and controllable flight characteristics throughout the operational envelope.

- Supersonic and Hypersonic Flight

At supersonic and hypersonic speeds, the behavior of air becomes significantly more complex. Shock waves, expansion fans, and thermodynamic effects dominate the flow field. Aerospace engineers must account for these phenomena in the design of high-speed vehicles, ensuring structural integrity, efficient propulsion, and stable flight characteristics. Specialized wind tunnels and computational fluid dynamics (CFD) tools are essential for analyzing and optimizing aerodynamic performance at these extreme speeds.

In summary, aerodynamics is not merely a theoretical discipline but an applied science that profoundly influences every aspect of aerospace engineering. Its principles underpin the design of aircraft, spacecraft, and related systems, dictating their performance, stability, and efficiency. Continuous advancements in aerodynamic research and analysis are essential for pushing the boundaries of flight and space exploration.

2. Propulsion Systems

The design, analysis, and implementation of propulsion systems represent a core competency within aerospace engineering. These systems provide the necessary thrust to overcome drag and gravitational forces, enabling sustained flight and space travel. Efficient and reliable propulsion is paramount to the success of any aerospace mission, from commercial airliners to interplanetary spacecraft.

- Rocket Engines

Rocket engines generate thrust by expelling high-velocity exhaust gases produced from the combustion of propellant. These engines are essential for spacecraft launch and orbital maneuvers, operating independently of the atmosphere. Different types of rocket engines, such as solid-propellant, liquid-propellant, and hybrid engines, offer varying performance characteristics and are selected based on mission requirements. The Space Shuttle Main Engine (SSME) is a notable example of a high-performance liquid-propellant rocket engine.

- Gas Turbine Engines

Gas turbine engines, commonly found in commercial and military aircraft, utilize a rotating turbine to compress air, mix it with fuel, and ignite the mixture to produce thrust. These engines are characterized by their high thrust-to-weight ratio and efficiency at high speeds. Variations include turbojets, turbofans, and turboprops, each optimized for specific flight regimes. The General Electric GE90, powering the Boeing 777, exemplifies a high-bypass turbofan engine with exceptional thrust and fuel efficiency.

- Electric Propulsion

Electric propulsion systems generate thrust by accelerating ions or plasma using electric fields. These systems offer very high specific impulse, enabling long-duration missions with minimal propellant consumption. While providing relatively low thrust levels, electric propulsion is well-suited for deep-space exploration and satellite station-keeping. Ion thrusters used on the Deep Space 1 mission are an example of successful application of electric propulsion technology.

- Advanced Propulsion Concepts

Ongoing research explores advanced propulsion concepts to enable faster and more efficient space travel. These include nuclear propulsion, fusion propulsion, and advanced chemical propulsion systems. These technologies aim to achieve significantly higher exhaust velocities and thrust levels compared to conventional propulsion systems. Though currently under development, these concepts hold promise for future interstellar missions and faster interplanetary travel.

The selection and optimization of propulsion systems are critical decisions in aerospace engineering, directly influencing mission capabilities, payload capacity, and overall cost-effectiveness. Continuing advancements in propulsion technology are essential for expanding the reach of space exploration and improving the efficiency of air transportation.

3. Structural Integrity

Structural integrity is a paramount concern within aerospace engineering. Its significance stems from the inherent need for aerospace vehicles to withstand extreme loads and environmental conditions without failure. Compromised structural integrity can have catastrophic consequences, leading to loss of life, mission failure, and substantial financial repercussions. The design and analysis of aerospace structures, therefore, demand rigorous attention to detail and adherence to stringent safety standards. The connection between structural integrity and the overarching goals of aerospace engineering is thus a causal one: compromised structural integrity directly causes failures, while maintained integrity enables successful operation.

The practical implications of structural integrity are exemplified in numerous scenarios. The Comet airliner disasters of the 1950s, caused by metal fatigue around the square windows, highlighted the critical importance of understanding material behavior under cyclic loading. Modern aircraft design incorporates fail-safe principles, meaning that even if a primary structural member fails, the remaining structure can still carry the load, preventing catastrophic collapse. Finite element analysis (FEA) is routinely employed to simulate stress distributions and identify potential weak points in aerospace structures before they are even built. Furthermore, regular inspections and non-destructive testing (NDT) techniques are essential for detecting cracks or other defects that could compromise structural integrity during service. For example, ultrasonic testing and eddy current testing are used to find hidden flaws in aircraft wings and fuselages.

Maintaining structural integrity in aerospace vehicles poses ongoing challenges. Weight optimization is a constant driver in aerospace design, but reducing weight must not come at the expense of structural strength. Novel materials, such as carbon fiber composites, offer significant weight savings but require careful consideration of their unique failure modes. The increasing use of additive manufacturing (3D printing) presents both opportunities and challenges for structural integrity, as the properties of additively manufactured parts can be highly dependent on the manufacturing process. In conclusion, structural integrity is not merely a sub-discipline within aerospace engineering but a fundamental principle that underpins all aspects of design, manufacturing, and maintenance. Overcoming the challenges associated with ensuring structural integrity is essential for advancing the capabilities and safety of aerospace vehicles.

4. Control Systems

Control systems are integral to aerospace engineering, enabling the stable and precise operation of aircraft, spacecraft, and unmanned aerial vehicles. These systems manage vehicle attitude, trajectory, and speed, compensating for disturbances and ensuring adherence to mission objectives. The reliability and performance of control systems directly affect the safety and effectiveness of aerospace platforms.

Consider the automatic flight control systems (AFCS) found in commercial airliners. These systems utilize sensors to monitor altitude, airspeed, and attitude, comparing these parameters to pilot-selected settings. If deviations occur due to turbulence or wind shear, the AFCS automatically adjusts control surfaces such as ailerons, elevators, and rudders to maintain the desired flight path. Similarly, spacecraft attitude control systems employ reaction wheels or thrusters to maintain proper orientation in space, crucial for tasks such as communication, navigation, and scientific observation. The Apollo missions relied heavily on sophisticated control systems for lunar orbit insertion, landing, and ascent.

Challenges in aerospace control engineering include dealing with uncertainty, nonlinearity, and time delays. Designing robust control systems that can function effectively in these conditions requires advanced control algorithms and sensor fusion techniques. Future advancements in areas such as adaptive control, artificial intelligence, and fault-tolerant control will further enhance the capabilities and reliability of aerospace systems. Understanding the principles of control systems is therefore crucial for aerospace engineers seeking to design and operate safe, efficient, and high-performing vehicles.

5. Materials Science

Materials science plays a foundational role in aerospace engineering, as the performance and reliability of aerospace vehicles are intrinsically linked to the properties of the materials used in their construction. The demanding operational environment, characterized by extreme temperatures, high stresses, and corrosive atmospheres, necessitates the use of advanced materials with exceptional characteristics. The relationship is causal: the selection and application of specific materials directly influence the vehicle’s weight, strength, durability, and overall performance. Without advancements in materials science, progress in aerospace engineering would be significantly constrained.

Practical examples underscore this connection. The development of high-temperature alloys, such as nickel-based superalloys, enabled the creation of efficient gas turbine engines capable of operating at elevated temperatures, thus improving fuel efficiency and thrust. The introduction of carbon fiber reinforced polymers (CFRP) revolutionized aircraft design by offering significant weight savings compared to traditional aluminum alloys, leading to reduced fuel consumption and increased payload capacity. Furthermore, the ongoing research into ceramic matrix composites (CMCs) aims to develop materials capable of withstanding the extreme heat experienced by hypersonic vehicles during atmospheric re-entry. The selection of appropriate materials for each application, informed by a deep understanding of their mechanical, thermal, and chemical properties, is a critical decision in the aerospace design process.

The challenges in aerospace materials science are multifaceted. There exists a constant drive to develop lighter, stronger, and more durable materials. This requires not only the discovery of new materials but also the development of advanced manufacturing techniques to produce them cost-effectively. The need to withstand increasingly harsh environments, such as prolonged exposure to radiation in space or extreme temperatures in hypersonic flight, further complicates the material selection process. In summary, materials science is not merely a supporting discipline within aerospace engineering but a critical enabler of progress, driving innovation and shaping the future of flight and space exploration.

6. Orbital Mechanics

Orbital mechanics, a specialized branch of astrodynamics, is inextricably linked to aerospace engineering. It governs the motion of spacecraft and other artificial satellites around celestial bodies, defining their trajectories, predicting their positions, and enabling controlled maneuvers. Understanding orbital mechanics is not merely beneficial, but fundamentally necessary for aerospace engineers involved in the design, development, and operation of space missions. The principles of orbital mechanics dictate the feasibility of mission objectives, influence spacecraft design, and directly impact mission success. For instance, without precise orbital calculations, placing a communications satellite into geostationary orbit or navigating a spacecraft to Mars would be impossible.

The connection between orbital mechanics and aerospace engineering manifests in several critical areas. Trajectory design, a central aspect of mission planning, relies heavily on orbital mechanics to determine the most efficient paths for spacecraft to reach their destinations, minimizing propellant consumption and transit time. Orbital maneuvers, such as orbit insertion, station-keeping, and rendezvous, require precise calculations based on Keplerian orbital elements and perturbation effects. Furthermore, the design of spacecraft propulsion systems, navigation systems, and attitude control systems is directly influenced by the requirements imposed by orbital mechanics. The Global Positioning System (GPS), for example, depends on the accurate prediction of satellite orbits to provide precise positioning information to users on Earth. Similarly, space debris mitigation efforts rely on orbital mechanics to predict the trajectories of defunct satellites and prevent collisions.

In conclusion, orbital mechanics forms an indispensable pillar of aerospace engineering, underpinning the design, planning, and execution of space missions. The continued advancement of space exploration and utilization hinges on the ability of aerospace engineers to apply and refine the principles of orbital mechanics. Challenges remain in modeling complex orbital environments and developing robust algorithms for autonomous navigation and control, but these are essential steps towards realizing ambitious future space endeavors.

7. Systems Integration

In aerospace engineering, systems integration represents the holistic process of combining individual components and subsystems into a unified, functional aerospace vehicle or system. It is a critical phase, demanding a comprehensive understanding of each element’s functionality and their interactions to achieve optimal overall performance and mission success. Failure to effectively integrate systems can lead to inefficiencies, malfunctions, and even catastrophic failures.

- Requirements Management and Traceability

Aerospace projects are characterized by stringent and complex requirements, often mandated by regulatory bodies and mission objectives. Systems integration necessitates a robust requirements management process to ensure that each component and subsystem meets specified performance criteria. Traceability matrices are employed to link requirements to design elements, verification activities, and test results, providing a clear audit trail and facilitating the identification of potential inconsistencies or gaps.

- Interface Management

Aerospace systems involve numerous interfaces between different subsystems, including mechanical, electrical, and communication interfaces. Effective systems integration requires meticulous interface management to ensure seamless interaction and compatibility. Interface control documents (ICDs) are used to define interface parameters, data protocols, and physical connections, mitigating the risk of integration issues and ensuring interoperability. For example, the interface between a spacecraft’s power system and its communication payload must be carefully managed to ensure that the payload receives adequate power without causing interference.

- Testing and Verification

A rigorous testing and verification program is essential for validating the performance and reliability of integrated aerospace systems. This involves a series of tests at the component, subsystem, and system levels, designed to simulate operational conditions and identify potential vulnerabilities. Integration testing focuses on verifying the proper interaction of subsystems and validating system-level requirements. Flight testing of aircraft and spacecraft provides the ultimate validation of the integrated system’s performance in its intended environment.

- Configuration Management

Aerospace projects involve numerous revisions and modifications throughout the design and development lifecycle. Systems integration necessitates a robust configuration management process to track changes, manage baselines, and ensure that all components are compatible and consistent. Configuration control boards (CCBs) review proposed changes and assess their impact on the integrated system, preventing unintended consequences and maintaining system integrity. This is particularly critical for long-duration projects with multiple stakeholders and suppliers.

These facets of systems integration are central to realizing functional and reliable aerospace vehicles and systems. From initial design stages to final deployment and operation, the integrated approach ensures each component works cohesively to meet mission objectives, while adhering to stringent safety and performance standards.

Frequently Asked Questions Related to Advanced Aerospace Studies

The following addresses common inquiries and misconceptions regarding specialized education and career paths within the domain of flight vehicle engineering. It is intended to provide concise and authoritative answers for prospective students and professionals.

Question 1: What foundational knowledge is crucial for entering this field?

A strong grounding in mathematics (calculus, differential equations, linear algebra), physics (mechanics, thermodynamics, electromagnetism), and computer science (programming, data structures, algorithms) is essential. Proficiency in these areas provides the necessary analytical framework for advanced studies.

Question 2: Which programming languages are most relevant?

Python and MATLAB are widely used for numerical analysis, simulation, and data processing. C++ is often employed for real-time embedded systems development. Familiarity with at least one of these languages is highly recommended.

Question 3: What are the key technical specializations within this discipline?

Aerodynamics, propulsion, structures, control systems, materials science, and orbital mechanics represent core areas of specialization. Individuals should select a focus area based on their interests and career aspirations.

Question 4: What software tools are commonly used in industry?

Industry-standard software packages include ANSYS (for finite element analysis), SolidWorks (for computer-aided design), and various computational fluid dynamics (CFD) solvers. Practical experience with these tools is advantageous.

Question 5: What distinguishes it from other engineering disciplines?

It focuses specifically on the design, development, and operation of vehicles and systems that operate within or beyond the Earth’s atmosphere. This entails a unique set of challenges related to aerodynamics, propulsion, and structural integrity under extreme conditions.

Question 6: How does one stay abreast of advancements in the field?

Active participation in professional organizations (e.g., AIAA), attendance at conferences, and regular review of technical publications are crucial for staying informed about emerging technologies and research trends.

In summary, preparation for and success within this domain require a strong academic foundation, practical experience, and a commitment to continuous learning. Strategic planning and dedicated effort are essential for navigating the complexities of this field.

The following sections will explore resources for further learning and development within the field.

Conclusion

This exploration has illuminated the multifaceted nature of aerospace engineering, underscoring its dependence on a robust foundation in mathematics, physics, and computational skills. Further discussion has revealed the criticality of specialized knowledge in areas such as aerodynamics, propulsion, structural integrity, control systems, materials science, orbital mechanics, and systems integration. The discussion emphasized the importance of practical experience, familiarity with industry-standard software, and continuous professional development to navigate its complexities.

The domain continues to evolve, presenting ongoing challenges and opportunities for innovation. Further progress will necessitate a commitment to research, development, and the application of advanced technologies. The pursuit of sustainable aviation, exploration of deep space, and development of autonomous flight systems represent key areas of focus for future generations of engineers and scientists. A dedicated approach to foundational knowledge, practical skills, and lifelong learning remains crucial for those seeking to contribute to this dynamic and impactful field.

![Best Alabama Aerospace Engineering Ranking [2024 Guide] Innovating the Future of Flight with Reliable Aviation Solutions Best Alabama Aerospace Engineering Ranking [2024 Guide] | Innovating the Future of Flight with Reliable Aviation Solutions](https://mixaerospace.com/wp-content/uploads/2026/03/th-111-300x200.jpg)

![Top Aerospace Engineering Programs in Canada [Rankings] Innovating the Future of Flight with Reliable Aviation Solutions Top Aerospace Engineering Programs in Canada [Rankings] | Innovating the Future of Flight with Reliable Aviation Solutions](https://mixaerospace.com/wp-content/uploads/2026/03/th-99-300x200.jpg)