The fabrication of components and systems for flight vehicles and related technologies, encompassing everything from commercial airliners to spacecraft and defense systems, is a highly specialized industrial sector. It integrates precision engineering, advanced materials science, and stringent quality control processes to produce safe and reliable products. Examples of activities within this domain include the creation of airframes, engines, avionics, and interior elements for a diverse range of aircraft and space-bound vehicles.

The significance of this sector lies in its contribution to global transportation, national security, scientific advancement, and economic growth. Throughout history, advancements in aircraft and spacecraft design and production have revolutionized travel, facilitated exploration, and spurred technological innovation across numerous fields. Investment in and development of this area fosters high-skilled employment, drives research and development, and enhances a nation’s competitiveness on the world stage.

The following discussion will delve into critical aspects such as material selection, manufacturing techniques, supply chain management, and regulatory compliance within this complex and crucial field.

Considerations for Enhanced Operational Performance

The following are key recommendations directed toward optimizing processes, ensuring quality, and maintaining a competitive edge within the specified manufacturing sector.

Tip 1: Material Selection and Qualification: Emphasize rigorous testing and validation of materials used in production. Selecting the appropriate material, ensuring it meets required strength, weight, and environmental resistance specifications, is critical. For example, implementing a documented material certification program ensures traceability and compliance.

Tip 2: Advanced Manufacturing Techniques: Implement and refine additive manufacturing (3D printing), automated assembly, and robotic welding processes. These techniques offer improved precision, reduced material waste, and decreased production time. An investment in research and development to integrate these technologies is advisable.

Tip 3: Robust Quality Control Systems: Maintain stringent quality assurance protocols throughout the entire manufacturing lifecycle. Utilize non-destructive testing (NDT) methods, such as ultrasonic or radiographic inspection, to detect flaws and ensure structural integrity. Implementing statistical process control (SPC) will also monitor and improve process stability.

Tip 4: Optimized Supply Chain Management: Develop strong relationships with reliable suppliers to guarantee consistent material availability and quality. Utilize lean principles to minimize inventory and reduce lead times. Implement a supply chain risk management strategy to mitigate disruptions.

Tip 5: Regulatory Compliance Adherence: Maintain strict compliance with all applicable aviation and aerospace regulations (e.g., FAA, EASA, AS9100). Develop and maintain a comprehensive compliance management system to ensure ongoing adherence to industry standards and safety requirements.

Tip 6: Investment in Skilled Workforce Development: Implement training programs to enhance the skills of the workforce in advanced manufacturing techniques, quality control, and regulatory compliance. Supporting continuing education and professional certifications is essential for maintaining a highly qualified team.

Tip 7: Data-Driven Decision Making: Leverage data analytics to monitor manufacturing processes, identify areas for improvement, and optimize resource allocation. Implement a system for collecting and analyzing data from all stages of production to facilitate informed decision-making.

Implementing these recommendations will contribute to enhanced operational efficiency, improved product quality, and a strengthened competitive position within the aerospace manufacturing landscape.

The subsequent sections will further explore the challenges and opportunities present within the context of these considerations.

1. Material science innovations

Material science innovations are intrinsically linked to advancements within the aircraft and spacecraft manufacturing sector. Novel materials offering enhanced strength-to-weight ratios, thermal resistance, and corrosion protection directly enable the design and production of more efficient, durable, and safer aerospace vehicles. The development and implementation of these materials serve as a primary driver for progress in flight capabilities and extended operational lifecycles. For example, the introduction of carbon fiber reinforced polymers (CFRP) in modern aircraft structures has facilitated significant weight reduction compared to traditional aluminum alloys, leading to improved fuel efficiency and payload capacity.

The relationship extends beyond mere substitution of existing materials. Innovations frequently involve the creation of entirely new classes of substances tailored to specific aerospace applications. Ceramic matrix composites (CMCs), for example, are crucial in high-temperature engine components, permitting higher operating temperatures and increased engine thrust. Furthermore, self-healing materials are under development to address micro-cracking and extend the lifespan of aerospace structures, reducing maintenance costs and enhancing safety margins. These research and development efforts are often collaborative, involving partnerships between academic institutions, research laboratories, and manufacturing companies, fostering a continuous cycle of innovation and application.

In summary, progress in material science is not merely an adjunct to the aerospace manufacturing sector; it is a fundamental enabler. The ongoing pursuit of lighter, stronger, and more resilient materials represents a strategic imperative for achieving enhanced aircraft performance, extended service lives, and the realization of increasingly ambitious space exploration endeavors. Challenges remain in scaling up the production of these advanced materials and reducing their associated costs, but the potential benefits for both the aerospace industry and society at large are substantial, warranting continued investment and focused research efforts.

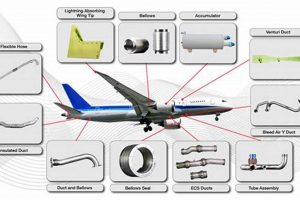

2. Precision component fabrication

The ability to manufacture parts with extremely tight tolerances and exacting specifications is paramount within the aerospace sector. This capability underpins the performance, reliability, and safety of flight vehicles and associated systems, contributing directly to mission success and operational efficiency.

- Advanced Machining Techniques

The fabrication of complex aerospace components relies heavily on Computer Numerical Control (CNC) machining, Electrical Discharge Machining (EDM), and other advanced methods. These techniques allow for the creation of intricate geometries and surface finishes required for parts such as turbine blades, fuel injectors, and structural elements. Achieving micron-level accuracy is often necessary to ensure proper fit, function, and longevity of these critical items. For example, the precise shaping of airfoil surfaces on a turbine blade directly affects engine efficiency and thrust output.

- Specialized Materials Processing

Many aerospace components are fabricated from high-performance alloys, composites, and ceramics that demand specialized processing techniques. These materials often require controlled environments and precise parameter control during manufacturing to avoid defects and ensure desired material properties. Examples include vacuum heat treatment for hardening alloys and autoclave curing for composite laminates. Ensuring consistent and repeatable material processing is crucial for maintaining component integrity under extreme operating conditions.

- Non-Destructive Testing and Inspection

Precision component fabrication is inseparable from rigorous inspection and testing protocols. Non-Destructive Testing (NDT) methods such as ultrasonic testing, radiographic inspection, and dye penetrant inspection are employed to detect minute flaws or imperfections that could compromise component performance. These techniques are essential for verifying that parts meet stringent quality standards and ensuring structural integrity. The detection and mitigation of even microscopic cracks or voids can prevent catastrophic failures during flight.

- Assembly and Integration

The precise fabrication of individual components is only one aspect of the overall process. Equally important is the accurate assembly and integration of these parts into larger systems. This requires precise alignment, fastening, and bonding techniques to ensure proper functionality and structural integrity. Examples include the assembly of aircraft wings, engine modules, and control surfaces. Achieving seamless integration of components, even those manufactured by different suppliers, is critical for maintaining the overall performance and safety of the aerospace vehicle.

The multifaceted nature of precision component fabrication highlights its significance within the broader aerospace manufacturing landscape. Meeting the stringent requirements for accuracy, material quality, and assembly integrity is paramount for producing safe, reliable, and high-performance aircraft and spacecraft. Continuous advancements in manufacturing technologies, materials processing techniques, and inspection methods are essential for maintaining a competitive edge and enabling the development of next-generation aerospace vehicles.

3. Rigorous quality assurance

Stringent quality assurance is not merely a procedural step but an indispensable element within the aircraft and spacecraft manufacturing environment. The nature of flight, with its inherent risks and operational demands, necessitates unwavering commitment to identifying, mitigating, and preventing potential failures across all stages of design, production, and maintenance. The consequences of lapses in quality can be catastrophic, making rigorous assurance practices an ethical and operational imperative.

- Non-Destructive Testing (NDT) Implementation

The utilization of NDT techniques, such as ultrasonic testing, radiography, and eddy current inspection, forms a cornerstone of aerospace quality assurance. These methods enable the detection of internal flaws, cracks, and inconsistencies within materials and components without causing damage. For example, NDT is routinely employed to inspect welds in aircraft fuselages and turbine blades for microscopic defects that could compromise structural integrity. The findings from NDT inform decisions regarding component acceptance, repair, or rejection, ensuring only parts meeting stringent standards are incorporated into flight vehicles.

- Statistical Process Control (SPC) Application

SPC methodologies are applied to monitor and control manufacturing processes, aiming to minimize variability and maintain consistent product quality. By tracking key process parameters, such as temperature, pressure, and dimensional accuracy, SPC charts provide early warnings of potential deviations from established norms. For instance, in the machining of aircraft landing gear components, SPC is used to monitor the dimensions of critical features, ensuring they remain within specified tolerances. This proactive approach prevents defects from occurring in the first place, reducing scrap rates and improving overall process efficiency.

- Traceability and Documentation Management

Maintaining complete traceability of materials, components, and manufacturing processes is crucial for ensuring accountability and facilitating root cause analysis in the event of failures. A comprehensive documentation system captures all relevant information, including material certifications, inspection reports, and process parameters. For example, the serial number of each aircraft engine component is linked to its manufacturing history, allowing investigators to trace back to the source of any defects. Effective documentation management ensures that quality records are readily available for auditing and regulatory compliance.

- Supplier Quality Management

Given the complexity of aerospace supply chains, managing the quality performance of suppliers is essential. Aerospace manufacturers implement rigorous supplier qualification programs, requiring suppliers to meet stringent quality standards and undergo regular audits. For instance, a manufacturer of aircraft avionics systems may require its suppliers of electronic components to demonstrate compliance with specific industry standards for reliability and performance. Effective supplier quality management ensures that all components incorporated into aerospace vehicles meet the required quality levels, regardless of their origin.

The discussed facets of stringent quality assurance are interwoven into the fabric of aircraft and spacecraft manufacturing. From the initial selection of materials to the final assembly and testing of finished products, quality control measures are applied at every stage. The ongoing pursuit of improved quality control technologies and methodologies is vital for maintaining the safety, reliability, and performance of aerospace vehicles, ensuring the continued advancement of flight capabilities and space exploration endeavors.

4. Supply chain integration

Effective supply chain integration is critical to the operation and success of aerospace manufacturing. The sector necessitates a highly complex and coordinated network of suppliers, manufacturers, and distributors to deliver finished products. A failure in this integration can have significant consequences, ranging from production delays and cost overruns to compromised product quality and safety.

The aerospace industry relies on a tiered supply chain, where original equipment manufacturers (OEMs) are at the top, followed by tier 1, tier 2, and tier 3 suppliers. These suppliers provide a wide range of materials, components, and services, from raw materials like aluminum and titanium to complex avionics systems and engine components. Successful integration requires seamless communication, data sharing, and collaboration across all tiers. For instance, consider the production of a commercial airliner. The OEM relies on numerous tier 1 suppliers to provide the wings, fuselage sections, engines, and avionics. These tier 1 suppliers, in turn, rely on their own network of tier 2 and tier 3 suppliers for raw materials, components, and sub-assemblies. Any disruption in this chain, such as a shortage of a critical component or a delay in delivery, can cascade through the entire system, affecting the final assembly and delivery of the aircraft.

The aerospace industry faces unique supply chain challenges, including long lead times, high quality requirements, and stringent regulatory oversight. Supply chains must be resilient, agile, and capable of adapting to changing market conditions and unforeseen disruptions. The integration of digital technologies, such as cloud computing, data analytics, and blockchain, can enhance supply chain visibility, improve communication, and enable more efficient coordination. Ultimately, strong supply chain integration is paramount for the efficient production of safe, reliable, and high-performance aircraft and spacecraft. Successfully managing the entire value stream is a significant differentiator in this competitive market.

5. Regulatory standard compliance

Adherence to regulatory standards constitutes a foundational pillar within aircraft and spacecraft manufacturing. This compliance is non-negotiable, given the safety-critical nature of the industry and the potential for catastrophic consequences stemming from non-conformance. Regulatory bodies, such as the Federal Aviation Administration (FAA) in the United States and the European Aviation Safety Agency (EASA) in Europe, establish and enforce stringent requirements governing the design, production, operation, and maintenance of aerospace vehicles.

- Design Certification and Airworthiness

Regulatory authorities mandate a rigorous design certification process for all aircraft and spacecraft. Manufacturers must demonstrate that their designs meet specific safety standards and performance requirements. Airworthiness certificates are issued only after thorough evaluation and testing, signifying that an aircraft is safe for flight. For instance, the FAA’s Part 25 regulations outline the airworthiness standards for transport category airplanes, covering aspects such as structural integrity, flight controls, and engine performance. Non-compliance with these regulations can lead to the grounding of aircraft and significant financial penalties.

- Production Quality Systems

Regulatory standards dictate the implementation of robust quality management systems throughout the manufacturing process. Aerospace manufacturers must establish and maintain documented procedures for controlling materials, processes, and inspections. Compliance with standards such as AS9100, a widely adopted quality management system for the aerospace industry, is often a prerequisite for regulatory approval. For example, manufacturers must demonstrate that they have effective procedures for preventing foreign object debris (FOD) from entering aircraft systems, as FOD can cause significant damage and compromise safety.

- Maintenance, Repair, and Overhaul (MRO) Requirements

Regulatory standards extend beyond the initial manufacturing phase to encompass the maintenance, repair, and overhaul of aircraft. MRO providers must adhere to strict guidelines for performing maintenance activities, using approved parts, and documenting all work performed. For instance, the FAA’s Part 145 regulations outline the requirements for repair stations, specifying the qualifications of personnel, the adequacy of facilities, and the control of maintenance processes. Non-compliance with MRO regulations can lead to the improper repair of aircraft and the potential for safety hazards.

- Environmental Compliance

Increasingly, regulatory standards address the environmental impact of aerospace manufacturing and operations. These standards aim to reduce emissions, noise pollution, and waste generation. For example, the International Civil Aviation Organization (ICAO) has established standards for aircraft engine emissions, limiting the levels of pollutants such as nitrogen oxides and particulate matter. Manufacturers are also required to implement sustainable manufacturing practices, such as reducing energy consumption and recycling materials. Compliance with environmental regulations is essential for mitigating the environmental footprint of the aerospace industry and promoting sustainable growth.

The discussed facets underscore the criticality of regulatory standard compliance within the aircraft and spacecraft manufacturing domain. Adhering to these stringent requirements is not simply a legal obligation but an ethical imperative, contributing directly to the safety, reliability, and sustainability of aerospace operations. Continuous improvement in compliance practices and a proactive approach to regulatory changes are essential for maintaining a competitive edge and ensuring long-term success in this highly regulated industry.

Frequently Asked Questions Regarding Aerospace Manufacturing

This section addresses common inquiries and clarifies pertinent details related to the complex industrial processes involved in creating aircraft and spacecraft.

Question 1: What distinguishes aerospace manufacturing from other manufacturing sectors?

Aerospace manufacturing is characterized by its stringent safety requirements, tight tolerances, use of specialized materials, and complex assembly processes. Unlike many other manufacturing sectors, aerospace necessitates unwavering adherence to regulatory standards and a high degree of precision in every stage of production.

Question 2: What are the primary materials employed in aerospace manufacturing?

Commonly used materials encompass aluminum alloys, titanium alloys, steel alloys, composites (such as carbon fiber reinforced polymers), and specialized ceramics. The selection of a particular material is dictated by factors such as strength-to-weight ratio, thermal resistance, corrosion resistance, and cost.

Question 3: How is quality assured in the manufacture of aircraft components?

Quality assurance relies on a multi-layered approach, incorporating non-destructive testing (NDT), statistical process control (SPC), comprehensive documentation, and rigorous supplier management. NDT methods, such as ultrasonic and radiographic inspection, are employed to detect internal flaws, ensuring structural integrity.

Question 4: What role does automation play in aerospace manufacturing?

Automation is increasingly prevalent, with robots and automated systems used for tasks such as drilling, riveting, welding, and painting. Automation improves efficiency, reduces human error, and enhances precision, particularly in repetitive or hazardous operations.

Question 5: How does the supply chain function within the aerospace industry?

The aerospace supply chain is a complex network involving multiple tiers of suppliers providing materials, components, and services. Effective supply chain management requires close collaboration, data sharing, and adherence to stringent quality standards to ensure timely delivery and minimize disruptions.

Question 6: What are the key regulatory standards governing aerospace manufacturing?

Key regulatory standards include those promulgated by the Federal Aviation Administration (FAA) in the United States, the European Aviation Safety Agency (EASA) in Europe, and other national aviation authorities. These regulations cover design certification, production quality systems, maintenance requirements, and environmental compliance.

This FAQ section provides a concise overview of key aspects of aerospace manufacturing. Further research is recommended for a more in-depth understanding of specific topics.

The subsequent section will address the future trends and challenges within this dynamic industrial landscape.

Concluding Remarks on Aerospace Fabrication

This exploration of aerospace fabrication has underscored the sector’s inherent complexity, emphasizing the critical importance of material innovation, precision engineering, rigorous quality control, and efficient supply chain management. Compliance with stringent regulatory standards remains paramount, ensuring the safety and reliability of all flight vehicles and related systems. The integration of these elements is not merely a desirable outcome but an absolute necessity for sustained success.

The continued advancement of flight capabilities and space exploration hinges upon a steadfast commitment to excellence within this manufacturing domain. A proactive approach to embracing technological innovation, fostering a skilled workforce, and prioritizing safety will be decisive in shaping the future of aerospace. The ongoing pursuit of improvement remains a fundamental imperative for all stakeholders in this dynamic and vital field.