This entity is a component of ST Engineering’s Aerospace sector, specifically located in Middle River, Maryland. It functions as a maintenance, repair, and overhaul (MRO) facility specializing in aircraft engine nacelle systems and composite structures. Its operations encompass a range of services, including structural repairs, modifications, and component manufacturing for various aircraft types.

The location’s strategic importance stems from its proximity to major aviation hubs and access to a skilled workforce. This facilitates efficient turnaround times for aircraft maintenance and supports the continued airworthiness of commercial and military fleets. The facility’s historical context involves continuous adaptation to evolving aviation technologies and regulatory requirements, solidifying its position as a key player in the aerospace MRO industry. This contributes significantly to the operational readiness and lifespan extension of aircraft worldwide.

The subsequent sections will elaborate on specific capabilities, services offered, technological advancements implemented, and the overall impact on the aerospace maintenance sector driven by this specialized MRO organization.

Operational Best Practices in Aerospace MRO

The following recommendations are drawn from the operational experience of specialized aerospace maintenance, repair, and overhaul (MRO) organizations. These practices aim to enhance efficiency, quality, and safety within the sector.

Tip 1: Prioritize advanced Non-Destructive Testing (NDT) methodologies. Implementing cutting-edge NDT techniques ensures early detection of structural anomalies, preventing potential in-service failures. For instance, phased array ultrasonics and computed tomography can identify subsurface defects not visible through traditional methods.

Tip 2: Emphasize rigorous adherence to Original Equipment Manufacturer (OEM) specifications. Strict compliance with OEM guidelines guarantees the maintenance operations align with the intended design parameters, mitigating the risk of compromising aircraft performance and safety. Deviations should only occur with documented engineering approvals.

Tip 3: Invest in continuous employee training and certification programs. Maintaining a highly skilled workforce necessitates ongoing professional development. Regular training on new technologies, regulatory changes, and specialized repair techniques is crucial for upholding industry standards and ensuring consistent quality.

Tip 4: Implement robust supply chain management practices. Establishing a reliable and efficient supply chain minimizes downtime and ensures the availability of necessary components. This includes developing strategic partnerships with approved vendors, maintaining adequate inventory levels, and implementing proactive obsolescence management.

Tip 5: Leverage data analytics for predictive maintenance. Utilizing data collected from maintenance operations enables the identification of trends and patterns, facilitating proactive maintenance interventions. This approach minimizes unscheduled maintenance events and optimizes resource allocation.

Tip 6: Foster a culture of safety and continuous improvement. Cultivating a safety-conscious environment and encouraging proactive identification and resolution of potential hazards is paramount. Implementing continuous improvement methodologies, such as Lean principles, further enhances operational efficiency and reduces waste.

These recommendations highlight the importance of meticulous planning, execution, and continuous improvement in aerospace MRO. Adherence to these practices contributes to enhanced aircraft reliability, safety, and operational efficiency.

The subsequent sections will delve into the specific applications of these practices within the context of aircraft nacelle and composite structure maintenance.

1. MRO Capabilities

The maintenance, repair, and overhaul (MRO) capabilities form the foundational core of operations at ST Engineering Aerospace Middle River. These capabilities define the scope of services offered and directly impact the facility’s contribution to the aerospace industry.

- Engine Nacelle Overhaul

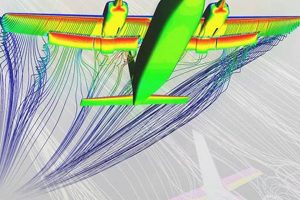

This facet involves the comprehensive inspection, repair, and refurbishment of engine nacelles the housings surrounding aircraft engines. ST Engineering Aerospace Middle River possesses specialized tooling and expertise for a wide array of nacelle types. This capability ensures the structural integrity and aerodynamic performance of the nacelle, crucial for engine efficiency and safety. Work performed includes composite repairs, structural modifications, and component replacements as needed per OEM standards.

- Composite Structure Repair

Modern aircraft increasingly utilize composite materials for their strength-to-weight ratio. The facility’s composite repair capability encompasses the identification, assessment, and repair of damage to these structures. Techniques employed include non-destructive testing, delamination repair, and replacement of damaged sections. This ensures continued structural integrity and extends the lifespan of composite components.

- Component Manufacturing and Modification

In addition to repair and overhaul, ST Engineering Aerospace Middle River undertakes the manufacturing of certain nacelle components and performs modifications to existing structures. This capability allows for customized solutions and addresses obsolescence issues by producing replacement parts according to stringent quality control standards. Modification work might include incorporating design changes or upgrades to enhance performance or extend service life.

- Engineering and Technical Support

Supporting the MRO activities is a team of engineers and technical specialists who provide expertise in areas such as structural analysis, repair design, and materials science. They ensure that all work performed adheres to regulatory requirements and OEM specifications. This engineering support is essential for developing customized repair solutions and addressing complex technical challenges that arise during the MRO process.

These MRO capabilities collectively position ST Engineering Aerospace Middle River as a comprehensive service provider for aircraft nacelles and composite structures. The facility’s commitment to quality, technical expertise, and adherence to industry standards ensures the safe and efficient operation of aircraft fleets worldwide. The integration of advanced technologies and continuous improvement initiatives further enhances these capabilities, solidifying its role as a critical player in the aerospace maintenance sector.

2. Nacelle Expertise

The specialized knowledge and skill related to aircraft engine nacelles constitute a core competency at ST Engineering Aerospace Middle River. This expertise directly influences the organization’s service offerings, technological investments, and overall standing within the aerospace maintenance, repair, and overhaul (MRO) sector.

- Comprehensive Nacelle Maintenance

This encompasses a full spectrum of services, including routine inspections, preventative maintenance, and major structural repairs of nacelles. Examples include addressing corrosion damage, repairing impact damage from foreign object debris (FOD), and performing modifications to improve aerodynamic efficiency. ST Engineering Aerospace Middle River’s capabilities ensure nacelles meet stringent airworthiness standards, contributing to safe and efficient flight operations.

- Advanced Composite Repair Techniques

Modern nacelles increasingly incorporate composite materials due to their lightweight and durable properties. ST Engineering Aerospace Middle River possesses specialized expertise in repairing these advanced composites, utilizing techniques such as vacuum bagging, hot bonding, and non-destructive testing to ensure structural integrity is restored. This expertise allows them to handle complex repairs on nacelles constructed from materials like carbon fiber reinforced polymers.

- Engine Build-Up Unit (EBU) Services

The EBU involves the assembly and testing of various components attached to the engine, including the nacelle, thrust reverser, and associated systems. ST Engineering Aerospace Middle River provides EBU services to ensure proper integration and functionality of these critical components. This includes verifying mechanical connections, electrical wiring, and hydraulic systems to ensure the engine operates reliably and efficiently.

- Engineering and Design Support for Nacelles

Complementing its maintenance and repair services, ST Engineering Aerospace Middle River offers engineering and design support for nacelle modifications and upgrades. This includes developing customized repair schemes, performing stress analysis, and creating engineering drawings to support the implementation of design changes. Such expertise ensures that all modifications comply with regulatory requirements and maintain the structural integrity of the nacelle.

These facets of nacelle expertise demonstrate the depth and breadth of capabilities at ST Engineering Aerospace Middle River. This specialized knowledge allows the facility to provide comprehensive support for aircraft operators, ensuring the safe and efficient operation of their fleets. The continued investment in training, technology, and engineering expertise further solidifies this position as a leading provider of nacelle MRO services.

3. Composite Structures

The relationship between composite structures and ST Engineering Aerospace Middle River is intrinsic to the latter’s operational capabilities and strategic importance. Modern aircraft increasingly rely on composite materials for their superior strength-to-weight ratios, enhancing fuel efficiency and performance. Consequently, the ability to effectively maintain, repair, and overhaul these structures becomes crucial. ST Engineering Aerospace Middle River has developed specialized expertise in this area, allowing it to service a wide range of aircraft utilizing advanced composite components. This expertise directly supports the continued airworthiness and operational lifespan of these aircraft.

A practical example of this connection is the repair of nacelles, which frequently incorporate composite materials such as carbon fiber reinforced polymers. When these nacelles sustain damage from foreign object debris (FOD) or experience structural degradation, ST Engineering Aerospace Middle River employs advanced repair techniques to restore their integrity. These techniques may include non-destructive testing to assess the extent of the damage, followed by the application of specialized repair procedures like resin infusion or prepreg lamination. Furthermore, the organization’s engineering team is involved in developing customized repair solutions that adhere to stringent OEM specifications and regulatory requirements. The presence of these composite repair capabilities allows airlines to minimize downtime and ensure the continued safe operation of their aircraft.

In summary, the ability to address the maintenance and repair needs of composite structures is a defining characteristic of ST Engineering Aerospace Middle River. This capability not only enables the organization to provide essential services to the aerospace industry but also ensures the continued safe and efficient operation of aircraft utilizing these advanced materials. The ongoing development and refinement of composite repair techniques remain a key focus, reflecting the growing importance of composite materials in modern aircraft design and construction.

4. Strategic Location

The geographical placement of ST Engineering Aerospace Middle River is a deliberate strategic decision with cascading effects on operational efficiency and market access. Its presence in Middle River, Maryland, facilitates proximity to key aviation hubs on the eastern seaboard of the United States. This positioning enables expedited turnaround times for aircraft maintenance, repair, and overhaul (MRO) services, a critical factor for airlines seeking to minimize downtime and maximize aircraft utilization. The location also provides ready access to a skilled labor pool, contributing to the quality and consistency of MRO operations. This is a considerable advantage, as the aerospace industry demands a workforce adept in specialized technical skills.

The presence of major airports and air cargo facilities within a relatively short radius of Middle River streamlines the logistics of component transportation. This reduces shipping costs and transit times for critical aircraft parts, further enhancing operational responsiveness. Furthermore, the location benefits from a well-developed transportation infrastructure, including road and rail networks, facilitating efficient movement of equipment and personnel. For example, proximity to Baltimore/Washington International Thurgood Marshall Airport (BWI) allows for swift delivery of engines and nacelles requiring urgent maintenance. These logistical advantages translate directly into competitive pricing and service delivery for ST Engineering Aerospace Middle River.

In conclusion, the strategic location of ST Engineering Aerospace Middle River is not merely coincidental; it is a calculated element that underpins its operational efficiency, market accessibility, and competitive advantage. The convergence of logistical advantages, skilled workforce availability, and proximity to aviation hubs creates a synergistic environment that supports the organization’s role as a key player in the aerospace MRO sector. Any potential disruption to these locational advantages, such as infrastructure limitations or workforce shortages, could pose a significant challenge to the organization’s sustained success.

5. Technical Innovation

Technical innovation serves as a critical driver of efficiency, safety, and competitive advantage at ST Engineering Aerospace Middle River. Its incorporation across various facets of the organizations operations stems from the need to adapt to the evolving demands of the aerospace maintenance, repair, and overhaul (MRO) sector. Technical advancements directly impact the organization’s ability to perform complex repairs on modern aircraft, particularly those utilizing advanced composite materials and sophisticated engine technologies. For instance, the implementation of advanced non-destructive testing (NDT) methods, such as phased array ultrasonics and computed tomography, enables the detection of subtle structural defects that would otherwise go unnoticed, preventing potential in-service failures. This proactive approach to quality control directly enhances aircraft safety and extends component lifespan.

Further, the adoption of digital technologies, such as augmented reality (AR) for training and remote assistance, streamlines maintenance processes and improves technician efficiency. AR applications can overlay digital information onto physical components, guiding technicians through complex repair procedures and reducing the likelihood of errors. This leads to reduced turnaround times and enhanced customer satisfaction. Likewise, the integration of data analytics for predictive maintenance allows ST Engineering Aerospace Middle River to anticipate potential equipment failures and schedule maintenance proactively, minimizing unscheduled downtime and optimizing resource allocation. This data-driven approach improves operational efficiency and reduces costs for both the organization and its customers.

In conclusion, technical innovation is not merely an aspirational goal but a fundamental requirement for sustained success at ST Engineering Aerospace Middle River. It directly influences the organization’s ability to deliver high-quality MRO services, enhance aircraft safety, and maintain a competitive edge in the dynamic aerospace industry. Continuous investment in research and development, as well as the active pursuit of emerging technologies, are essential for ensuring the organization’s continued relevance and leadership in the sector. The commitment to technical innovation is therefore integral to the ongoing evolution and success of ST Engineering Aerospace Middle River.

6. Quality Assurance

Quality assurance is paramount to the operational integrity and regulatory compliance of ST Engineering Aerospace Middle River. It serves as the framework through which all maintenance, repair, and overhaul (MRO) activities are governed, ensuring adherence to stringent industry standards and Original Equipment Manufacturer (OEM) specifications.

- Adherence to Regulatory Standards

Compliance with aviation regulations, such as those set forth by the Federal Aviation Administration (FAA) and other international bodies, forms the cornerstone of quality assurance. ST Engineering Aerospace Middle River meticulously documents and monitors all processes to meet these requirements. For instance, documented procedures for nacelle repairs are regularly audited to ensure adherence to FAA directives, thereby minimizing the risk of non-compliance and maintaining airworthiness standards.

- Stringent Material Control

The integrity of repairs and overhauls hinges on the quality of materials used. ST Engineering Aerospace Middle River employs rigorous material control processes, including verification of material certifications, storage protocols, and traceability systems. For example, the receipt and inspection of composite materials for nacelle repairs involve detailed checks against OEM specifications, preventing the use of substandard or counterfeit components.

- Comprehensive Inspection Procedures

Multi-tiered inspection processes are integral to quality assurance. ST Engineering Aerospace Middle River utilizes various inspection techniques, including non-destructive testing (NDT) methods, to detect hidden defects and ensure structural integrity. For instance, phased array ultrasonics is employed to inspect composite repairs, revealing any delamination or voids that could compromise the nacelle’s performance.

- Continuous Improvement Programs

Quality assurance is not a static function but an ongoing process of improvement. ST Engineering Aerospace Middle River implements continuous improvement programs, such as Lean methodologies and Six Sigma, to identify and eliminate inefficiencies and errors. For example, data analytics are used to track repair metrics, identifying areas where process enhancements can reduce turnaround times and improve the quality of completed work.

These interconnected facets of quality assurance are indispensable to ST Engineering Aerospace Middle River’s operations. They ensure that all MRO activities meet the highest standards of safety, reliability, and regulatory compliance, reinforcing the organization’s reputation as a trusted provider of aerospace services. The effectiveness of the quality assurance program directly impacts the airworthiness of serviced aircraft and the overall safety of air travel.

Frequently Asked Questions

This section addresses common inquiries regarding operations and service offerings. The information provided aims to offer clarity and a deeper understanding of its role within the aerospace industry.

Question 1: What specific aircraft types does ST Engineering Aerospace Middle River service?

The facility supports a diverse range of commercial and military aircraft platforms. Specific models depend on current contracts and service agreements, encompassing both narrow-body and wide-body aircraft. Detailed inquiries regarding specific aircraft models should be directed to the organization’s customer service department.

Question 2: What certifications and approvals does ST Engineering Aerospace Middle River hold?

The organization maintains a comprehensive suite of certifications, including those from the Federal Aviation Administration (FAA) and other relevant international aviation authorities. These certifications validate adherence to stringent safety and quality standards. A complete list of certifications is available upon request and verification.

Question 3: Does ST Engineering Aerospace Middle River offer on-site maintenance services?

While the primary focus is on providing MRO services within its facility, limited on-site support may be available depending on the scope of the project and contractual agreements. On-site services typically involve minor repairs and inspections. Extensive maintenance procedures are generally conducted within the controlled environment of the Middle River facility.

Question 4: How does ST Engineering Aerospace Middle River ensure the quality of its repairs?

Quality assurance is integral to all operations. This involves stringent adherence to OEM specifications, implementation of advanced non-destructive testing (NDT) methods, and a comprehensive quality management system. Regular audits and continuous improvement initiatives further reinforce the commitment to maintaining the highest standards of repair quality.

Question 5: What is the typical turnaround time for nacelle overhaul services?

Turnaround time varies depending on the extent of the required repairs, the availability of parts, and contractual obligations. A detailed assessment is conducted upon receipt of the nacelle to provide an accurate estimate of the completion time. Expedited services may be available under specific circumstances and subject to additional fees.

Question 6: How can one request a quote for MRO services?

Requests for quotes can be submitted through the organization’s official website or by contacting the sales department directly. Detailed technical specifications, including aircraft type, component details, and desired service scope, are required for accurate quote preparation.

These frequently asked questions provide a snapshot of key aspects regarding ST Engineering Aerospace Middle River. For more detailed information, direct contact with the organization is recommended.

The following section will provide contact information and additional resources for further inquiries.

Conclusion

This exploration has detailed the multifaceted operations of ST Engineering Aerospace Middle River, emphasizing its core competencies in MRO services, nacelle expertise, composite structure repair, strategic location advantages, dedication to technical innovation, and unwavering commitment to quality assurance. These interconnected elements contribute to the organization’s standing as a key player within the global aerospace maintenance sector. Its specialized capabilities directly support the airworthiness and operational efficiency of numerous aircraft fleets.

The continued success of ST Engineering Aerospace Middle River hinges on its ability to adapt to evolving industry demands, particularly in the areas of advanced materials, digital technologies, and sustainable practices. Stakeholders are encouraged to engage with the organization directly to explore potential collaborations and address specific maintenance requirements, thereby fostering mutual growth and contributing to the continued advancement of aerospace safety and reliability.