The activities performed by a professional specializing in aerospace engineering encompass the design, development, testing, and production of aircraft, spacecraft, satellites, and missiles. This work involves applying principles of physics, mathematics, and engineering to create vehicles that operate within Earth’s atmosphere and in outer space. For example, an aerospace engineer might design a more fuel-efficient wing for a commercial airliner or develop a new propulsion system for a space exploration vehicle.

This field contributes significantly to advancements in air travel, space exploration, national defense, and scientific research. Historically, it has driven innovation in materials science, aerodynamics, and computational modeling. The benefits include improved transportation efficiency, enhanced communication capabilities through satellite technology, and a deeper understanding of the universe through space-based observation.

The specific tasks undertaken depend on the area of specialization, such as aerodynamics, propulsion, structures, or guidance and control systems. Further discussion will explore these different specializations and the typical responsibilities associated with each, providing a more detailed understanding of the profession.

Insights into Aerospace Engineering Tasks

Successfully navigating a career in aerospace engineering necessitates a combination of technical proficiency and strategic career planning. The following insights offer guidance for individuals considering or actively engaged in this demanding profession.

Tip 1: Cultivate a Strong Foundation in Fundamental Sciences: A deep understanding of physics, mathematics, and computer science is crucial. Continual learning in these areas will support the tackling of complex engineering problems.

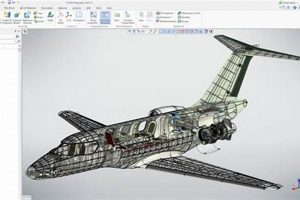

Tip 2: Develop Proficiency in Computer-Aided Design (CAD) and Simulation Software: Modern aerospace engineering relies heavily on digital tools. Mastering software such as CATIA, ANSYS, and MATLAB is essential for design, analysis, and simulation tasks.

Tip 3: Seek Internship Opportunities in Relevant Sectors: Practical experience is invaluable. Internships at aerospace companies, research institutions, or government agencies provide exposure to real-world projects and industry practices.

Tip 4: Specialize in a Specific Area of Aerospace Engineering: The field is broad. Focusing on a specialization such as aerodynamics, propulsion, structures, or avionics allows for the development of in-depth expertise.

Tip 5: Prioritize Effective Communication Skills: Aerospace engineers collaborate within multidisciplinary teams. The ability to clearly communicate technical information, both verbally and in writing, is critical for project success.

Tip 6: Maintain Awareness of Industry Trends and Technological Advancements: The aerospace industry is constantly evolving. Staying informed about new materials, technologies, and regulatory changes is crucial for career advancement.

Tip 7: Pursue Advanced Education or Certifications: A master’s degree or relevant professional certifications can enhance career prospects and provide opportunities for specialization and leadership roles.

By focusing on these areas, individuals can better position themselves for a successful and impactful career. These guidelines will be further expanded upon in the following sections.

1. Design Aircraft and Spacecraft

The design of aircraft and spacecraft represents a core function, directly embodying the capabilities and expertise of professionals in this field. This process demands a synthesis of theoretical knowledge and practical application, driving the creation of vehicles capable of functioning reliably in diverse and often extreme environments.

- Conceptualization and Requirements Definition

This initial stage involves establishing the operational parameters and performance objectives for the aircraft or spacecraft. Factors such as payload capacity, range, speed, altitude, and mission duration are defined. An aerospace engineer works to translate these abstract requirements into tangible design criteria. For example, the design of a long-range commercial airliner will prioritize fuel efficiency and passenger capacity, leading to specific airfoil designs and structural considerations.

- Aerodynamic and Structural Analysis

Engineers perform detailed analyses to ensure the vehicle’s aerodynamic efficiency and structural integrity. Computational Fluid Dynamics (CFD) simulations are used to optimize the shape of the aircraft for minimal drag. Finite Element Analysis (FEA) is employed to assess the structural stresses and strains under various load conditions. The Boeing 787 Dreamliner, for example, utilizes composite materials extensively to reduce weight and improve fuel efficiency, a decision that required extensive structural analysis.

- Systems Integration and Component Selection

Aerospace engineers must integrate various systems, including propulsion, avionics, and environmental control, into a cohesive design. This involves selecting appropriate components that meet performance and reliability requirements. The selection of a specific engine type for an aircraft, such as a turbofan or turboprop, directly impacts its speed, range, and fuel consumption. Similarly, the selection of avionics systems determines the aircraft’s navigation and communication capabilities.

- Prototyping and Testing

Before full-scale production, prototypes are often built and subjected to rigorous testing. This may involve wind tunnel tests, flight tests, or simulated space environments. Data from these tests are used to validate the design and identify any necessary modifications. The development of a new spacecraft, for example, involves thermal vacuum testing to simulate the extreme temperature variations encountered in space, ensuring that the spacecraft’s components can withstand these conditions.

These activities collectively exemplify the pivotal role aerospace engineers play in shaping the future of air and space travel. Through rigorous design processes, advanced analytical techniques, and comprehensive testing, these professionals contribute to the creation of safer, more efficient, and more capable aircraft and spacecraft, directly addressing the fundamental question of professional responsibilities in the aerospace domain.

2. Analyze Aerodynamic Performance

Aerodynamic performance analysis forms a crucial element of the responsibilities. It directly impacts the efficiency, stability, and control of flight vehicles. This analysis involves applying fundamental principles of fluid dynamics to evaluate and optimize the flow of air around an aircraft or spacecraft, significantly shaping design decisions.

- Computational Fluid Dynamics (CFD) Simulations

Aerospace engineers utilize CFD software to model airflow patterns around a vehicle. These simulations provide detailed insights into pressure distribution, drag, and lift characteristics. For instance, in the design of a supersonic aircraft, CFD analysis helps optimize the shape to minimize wave drag and ensure stable flight at high speeds. These insights inform modifications to the aircraft’s geometry, leading to improved aerodynamic characteristics and fuel efficiency.

- Wind Tunnel Testing

Physical wind tunnel tests complement CFD simulations by providing empirical data on aerodynamic performance. Scale models of aircraft are subjected to controlled airflow conditions, and sensors measure forces and pressures acting on the model. This data is used to validate CFD results and identify potential design flaws. During the development of a new aircraft wing, wind tunnel testing helps determine the optimal airfoil shape for maximizing lift and minimizing drag under various flight conditions.

- Stability and Control Analysis

Aerodynamic performance analysis extends to evaluating the stability and control characteristics of the aircraft. This involves assessing how the aircraft responds to disturbances and how effectively it can be controlled by the pilot or flight control system. Understanding these characteristics is critical for ensuring flight safety and maneuverability. For example, analyzing the aerodynamic forces acting on the control surfaces (ailerons, elevators, and rudder) helps determine their effectiveness in controlling the aircraft’s attitude and direction.

- Performance Optimization

The ultimate goal of aerodynamic performance analysis is to optimize the aircraft’s overall performance. This involves iteratively refining the design based on CFD simulations, wind tunnel tests, and stability analysis. The design is continuously improved to achieve desired objectives, such as increased range, reduced fuel consumption, or improved maneuverability. This continuous optimization process results in aircraft that are both efficient and capable.

These facets underscore the central role in ensuring that flight vehicles meet performance requirements while adhering to safety standards. Through precise analysis and iterative design improvements, these professionals contribute significantly to the advancement of air and space transportation technologies.

3. Develop Propulsion Systems

The development of propulsion systems is an integral component of what professionals in aerospace engineering do. It encompasses the design, analysis, and testing of engines and related systems that provide the thrust necessary for aircraft and spacecraft to operate. A direct causal relationship exists: effective propulsion systems enable the sustained flight and maneuverability essential to these vehicles. Without functional propulsion, the aircraft is grounded, and the spacecraft remains earthbound.

The importance of propulsion development is amplified by its direct impact on vehicle performance metrics. For example, the design of the Space Shuttle’s Solid Rocket Boosters (SRBs) was a critical element that allowed the shuttle to achieve orbit. The SRBs provided the necessary initial thrust to overcome Earth’s gravity. Similarly, the development of turbofan engines with high bypass ratios has significantly improved the fuel efficiency of commercial airliners. These improvements directly reduce operating costs and environmental impact, demonstrating the practical applications and significant benefits of propulsion system innovation.

In summary, the development of propulsion systems is a key aspect of the role. Challenges in this area include designing for extreme conditions, optimizing for fuel efficiency, and ensuring system reliability. Continuous advancements in propulsion technology are essential for progress in both air and space travel. This work is intrinsically linked to the goals of advancing the capabilities of flight and space exploration.

4. Oversee Testing and Production

The oversight of testing and production constitutes a critical, later-stage function. It bridges the design and analysis phases with the realization of tangible flight vehicles. This activity is paramount in verifying design integrity and ensuring the adherence to stringent quality standards, a non-negotiable aspect of aerospace endeavors.

- Test Planning and Execution

Aerospace engineers develop and execute comprehensive test plans to validate the performance and reliability of aircraft components and systems. This includes defining test objectives, selecting appropriate test methods, and ensuring that tests are conducted in accordance with industry standards and regulatory requirements. For example, engineers overseeing the testing of a new aircraft engine would design tests to evaluate its thrust output, fuel consumption, and emissions under various operating conditions. The results of these tests inform design modifications and ensure that the engine meets specified performance criteria.

- Manufacturing Process Supervision

These professionals supervise manufacturing processes to ensure that aircraft and spacecraft are built according to design specifications and quality standards. This involves monitoring production lines, inspecting components, and resolving manufacturing issues. During the construction of an aircraft wing, an engineer might oversee the composite layup process to ensure that the materials are properly aligned and cured, preventing structural defects that could compromise the wing’s integrity.

- Quality Assurance and Control

Engineers implement quality assurance and control procedures to maintain the highest levels of product reliability and safety. This includes conducting audits, inspecting finished products, and implementing corrective actions to address any quality defects. For instance, an aerospace engineer might conduct a final inspection of a completed aircraft to verify that all systems are functioning correctly and that the aircraft meets all regulatory requirements before it is delivered to the customer.

- Production Optimization and Improvement

Another responsibility involves identifying opportunities to improve production efficiency and reduce manufacturing costs. This can involve streamlining production processes, implementing new technologies, and optimizing resource utilization. By analyzing production data and identifying bottlenecks, engineers can implement changes that improve the overall efficiency of the manufacturing operation. This is often seen in the implementation of automated assembly processes to reduce labor costs and improve product consistency.

Collectively, these facets of overseeing testing and production are pivotal in ensuring the safety, reliability, and performance of aerospace products. These activities are essential for translating designs into fully functional and reliable aircraft and spacecraft. They highlight the practical, hands-on aspects of “what do you do as an aerospace engineer,” demonstrating the profession’s commitment to excellence in manufacturing and quality control.

5. Ensure System Safety

Ensuring system safety is a paramount responsibility for aerospace engineers. It permeates every aspect of design, development, testing, and production, inextricably linking it to their core functions. System safety is not a standalone task but rather an integrated principle guiding decisions and actions throughout the engineering lifecycle.

- Hazard Analysis and Risk Assessment

Aerospace engineers conduct thorough hazard analyses to identify potential failure modes and assess the associated risks. This involves evaluating the likelihood and severity of potential accidents or incidents. For instance, in the design of an aircraft’s hydraulic system, engineers analyze the potential for hydraulic line ruptures, pump failures, and control surface malfunctions. The resulting risk assessments inform design decisions, such as the incorporation of redundant systems or the implementation of safety interlocks to mitigate identified hazards. This proactive approach to safety ensures that potential risks are addressed early in the design process.

- Redundancy and Fault Tolerance

Redundancy and fault tolerance are critical design strategies for ensuring system safety. Aerospace engineers incorporate redundant components and systems to provide backup capabilities in the event of failures. Fault-tolerant designs allow systems to continue functioning safely even in the presence of component failures. A prime example is the use of multiple independent flight control computers in commercial aircraft. If one computer fails, the others can seamlessly take over, ensuring continued control of the aircraft. This reliance on redundancy and fault tolerance exemplifies a commitment to minimizing the impact of potential failures.

- System Verification and Validation

Rigorous verification and validation processes are essential for confirming that aerospace systems meet safety requirements. Verification involves ensuring that the system is designed and built correctly, while validation confirms that the system meets its intended operational needs. This often involves extensive testing, simulation, and analysis. Before a new aircraft enters service, it undergoes extensive flight testing to validate its performance and safety characteristics under various operating conditions. This meticulous approach to system verification and validation provides assurance that the aircraft can be operated safely.

- Regulatory Compliance and Certification

Aerospace engineers must ensure that their designs comply with applicable regulatory requirements and industry standards. This involves working with regulatory agencies, such as the Federal Aviation Administration (FAA) in the United States or the European Aviation Safety Agency (EASA) in Europe, to obtain certification for aircraft and spacecraft. Compliance with these regulations ensures that the system meets minimum safety standards. The certification process involves thorough reviews of design documentation, testing data, and manufacturing processes. Meeting these regulatory standards is a key component of ensuring system safety in the aerospace field.

These facets illustrate the pervasive nature of system safety within the profession. From initial design concepts to final production and certification, aerospace engineers prioritize safety to protect passengers, crew, and the public. The commitment to safety shapes decisions, drives innovation, and defines the ethical responsibilities of these professionals. The question is not merely “what do you do” but “how do you do it safely,” underscoring the core principle that guides their work.

Frequently Asked Questions

The following questions address common inquiries regarding the tasks, responsibilities, and scope of aerospace engineering.

Question 1: What is the primary objective of an aerospace engineer?

The main goal is to design, develop, test, and supervise the manufacture of aircraft, spacecraft, satellites, and missiles. This includes applying engineering principles to create efficient, safe, and reliable vehicles for atmospheric and space environments.

Question 2: What specific types of analysis are commonly performed?

Aerodynamic analysis using Computational Fluid Dynamics (CFD) is crucial for optimizing vehicle shapes to minimize drag and maximize lift. Structural analysis with Finite Element Analysis (FEA) ensures structural integrity under various loads. Propulsion analysis evaluates engine performance and efficiency.

Question 3: How important is computer proficiency to a professional in this field?

Proficiency in computer-aided design (CAD), simulation software, and programming languages is essential. Modern aerospace engineering relies heavily on digital tools for design, analysis, and simulation, enabling the creation of complex and optimized solutions.

Question 4: What role does testing play in the development process?

Testing is vital for validating designs and ensuring that aerospace systems meet performance and safety requirements. This includes wind tunnel testing, flight testing, and simulated space environment testing. Test data is used to identify design flaws and make necessary modifications.

Question 5: How does this field contribute to broader technological advancements?

Aerospace engineering drives innovation in materials science, aerodynamics, propulsion systems, and computational modeling. This field has led to improvements in air transportation, space exploration, satellite technology, and national defense.

Question 6: What are the ethical considerations for a working in this profession?

The commitment to safety is paramount. Adherence to regulatory requirements, rigorous testing protocols, and ethical design practices are crucial for protecting passengers, crew, and the public. These professionals are also responsible for contributing to sustainable practices in the aerospace sector.

In summary, it’s a multi-faceted profession requiring a strong foundation in science and engineering principles and a commitment to safety and innovation. This profession is integral to pushing the boundaries of air and space travel.

The next section will elaborate on educational pathways and career opportunities.

What Do You Do as an Aerospace Engineer

The preceding discussion has outlined the breadth of responsibilities associated with the profession. From the initial conceptual design of aircraft and spacecraft to the rigorous testing and oversight of production, the activities are diverse and demanding. Aerodynamic performance analysis, propulsion system development, and, crucially, the assurance of system safety are fundamental tasks. These activities require a combination of technical expertise, analytical skills, and a commitment to precision.

The future of air and space travel relies on the ongoing contributions. Technological advancements and a dedication to innovation will be necessary to meet the challenges of efficiency, sustainability, and safety. Further study of specific specializations is crucial for any individual considering a career in this domain to fully grasp its impact and significance.