The field encompasses the design, development, testing, and production of aircraft and spacecraft. It demands a multidisciplinary approach, integrating principles from aerodynamics, propulsion, structures, control systems, and materials science to create efficient, safe, and reliable vehicles. For example, an aerospace engineer might design a more fuel-efficient wing for a commercial airliner or develop the navigation system for a Mars rover.

This area of engineering is critical for advancements in air travel, space exploration, and national defense. Its benefits extend to economic growth through job creation and technological innovation. Historically, it has pushed the boundaries of human achievement, leading to inventions that have transformed society, from jet engines to satellite communication.

The following sections will delve into specific areas within this broad engineering discipline, including the design process, key technological challenges, and emerging trends shaping the future of flight and space exploration. These encompass topics from optimizing aircraft performance to developing sustainable space technologies.

The following insights offer a foundational understanding of the diverse elements central to the field. Adhering to these considerations can facilitate a more informed perspective on its complexities and opportunities.

Tip 1: Embrace Multidisciplinary Knowledge: Aerospace engineering necessitates a solid grasp of mathematics, physics, computer science, and engineering fundamentals. A holistic approach to these areas enables effective problem-solving and innovation.

Tip 2: Prioritize System-Level Thinking: Consider the interconnectedness of various systems within an aircraft or spacecraft. Optimizing one component in isolation may negatively impact overall performance. A systems-level perspective ensures harmonious integration.

Tip 3: Develop Strong Analytical Skills: The ability to analyze complex data, identify critical issues, and formulate effective solutions is paramount. Proficiency in computational analysis tools and experimental validation techniques is crucial.

Tip 4: Master Aerospace Design Principles: Familiarize oneself with established design methodologies, including requirements definition, conceptual design, detailed design, and testing. Understanding these principles is vital for creating safe and efficient aerospace vehicles.

Tip 5: Remain Current with Technological Advancements: The aerospace industry is characterized by rapid innovation. Staying abreast of emerging technologies, such as advanced materials, additive manufacturing, and artificial intelligence, is essential for maintaining a competitive edge.

Tip 6: Cultivate Effective Communication Skills: The ability to clearly and concisely communicate technical information to both technical and non-technical audiences is critical. Strong written and oral communication skills are essential for collaborative projects.

Tip 7: Understand Regulatory Requirements: Aerospace engineering is heavily regulated to ensure safety and compliance. Familiarity with industry standards and government regulations is crucial for responsible engineering practice.

These guidelines emphasize the importance of a broad skillset, rigorous analytical capabilities, and continuous learning. By embracing these principles, a more comprehensive understanding of aerospace engineering will be achieved.

The next section will consider the current challenges and future directions within the aerospace sector, providing a glimpse into the potential for future growth and innovation.

1. Aerodynamics

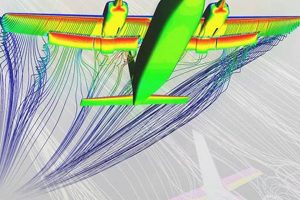

Aerodynamics is a foundational discipline within aerospace engineering, directly influencing the performance, stability, and control of aircraft and spacecraft. Understanding aerodynamic principles is crucial for designing efficient and safe vehicles capable of operating within Earth’s atmosphere and beyond.

- Lift Generation

Lift, the upward force that counteracts gravity, is a primary concern in aircraft design. Aerodynamicists manipulate wing shapes and angles of attack to create pressure differentials that generate lift. The study of lift is fundamental in determining aircraft performance characteristics such as stall speed and payload capacity. The shape of the wing, known as an airfoil, is carefully engineered to maximize lift while minimizing drag.

- Drag Reduction

Drag, the force that opposes motion through the air, significantly impacts fuel efficiency and speed. Aerodynamic engineers employ various techniques to reduce drag, including streamlining aircraft bodies, designing efficient wingtips, and utilizing laminar flow control. Minimizing drag translates directly to reduced fuel consumption and increased range for aircraft, critical factors in commercial aviation.

- Stability and Control

Aerodynamic forces play a key role in aircraft stability and control. Control surfaces such as ailerons, elevators, and rudders are used to manipulate airflow and generate moments that allow pilots to control the aircraft’s attitude. Careful aerodynamic design is essential to ensure that an aircraft is stable and responds predictably to control inputs, ensuring safe and reliable operation.

- Supersonic and Hypersonic Aerodynamics

Aerodynamics extends beyond subsonic flight, encompassing the complex phenomena associated with supersonic and hypersonic speeds. Shock waves, wave drag, and thermal effects become significant factors at these speeds, requiring specialized aerodynamic analysis and design techniques. The design of supersonic aircraft like fighter jets and hypersonic vehicles like space shuttles necessitates a deep understanding of these advanced aerodynamic principles.

Aerodynamics is intrinsic to the design of any vehicle intended to operate within an atmosphere, from conventional airplanes to advanced spacecraft. The continuous refinement of aerodynamic principles and their application to vehicle design are central to the advancements witnessed in flight and space exploration.

2. Propulsion Systems

Propulsion systems represent a core element of aerospace engineering, dictating the ability of an aircraft or spacecraft to overcome gravity and aerodynamic drag, and to maneuver within its designated environment. The design, development, and implementation of these systems directly determine the operational capabilities of any aerospace vehicle, making their study and application critical to the broader field. The selection of a particular propulsion system be it a jet engine, rocket engine, or electric propulsion system is contingent upon mission requirements, performance objectives, and environmental constraints. For example, commercial airliners rely on turbofan engines for efficient atmospheric flight, while space launch vehicles utilize rocket engines for generating the thrust necessary to escape Earth’s gravity.

The impact of propulsion system advancements is evident in the evolution of air travel and space exploration. The development of more efficient jet engines has led to reduced fuel consumption and longer flight ranges for commercial aircraft. In the realm of space exploration, innovations in rocket engine technology, such as staged combustion cycles and high-performance propellants, have enabled more ambitious missions, including lunar landings and interplanetary probes. Furthermore, emerging technologies like electric propulsion are poised to revolutionize space travel by offering higher specific impulse and enabling longer-duration missions with reduced propellant requirements. These innovations directly influence the capabilities and limitations of aerospace vehicles.

In conclusion, propulsion systems are an indispensable component of aerospace engineering, shaping the performance, range, and operational capabilities of aircraft and spacecraft. Ongoing research and development efforts are focused on enhancing propulsion system efficiency, reducing emissions, and exploring novel propulsion concepts to enable future advancements in air travel and space exploration. These advancements face challenges related to materials science, thermodynamics, and control systems, but the potential rewardsin terms of increased efficiency, reduced environmental impact, and expanded access to spacedrive continued innovation in this vital area.

3. Structural Integrity

Structural integrity is a paramount concern within aerospace engineering, directly impacting the safety, reliability, and longevity of aircraft and spacecraft. It involves the ability of an aerospace vehicle to withstand the stresses and strains imposed during flight or space operation, maintaining its shape and functionality under a variety of conditions.

- Material Selection and Analysis

The choice of materials and their thorough analysis are crucial. Aerospace engineers must select materials that offer high strength-to-weight ratios, resistance to fatigue, corrosion, and extreme temperatures. Finite element analysis (FEA) is routinely employed to simulate stress distributions within structures, identifying potential weak points and optimizing material usage. For example, the wings of a commercial airliner are designed using advanced alloys and composite materials to withstand aerodynamic loads while minimizing weight, ensuring fuel efficiency and structural soundness.

- Load Bearing Capacity

Determining the load-bearing capacity of aircraft and spacecraft structures is essential. This involves calculating the maximum stresses and strains the structure can withstand before failure. Factors such as aerodynamic forces, internal pressure, and gravitational loads must be considered. Aircraft undergo rigorous testing, including static and fatigue tests, to validate their load-bearing capacity and ensure they meet safety standards. The fuselage of an aircraft, for instance, is designed to withstand the pressure differential between the cabin and the external environment at high altitudes.

- Damage Tolerance and Repair

Aerospace structures must be designed to tolerate damage and allow for repair. Even with careful design and material selection, cracks and other forms of damage can occur during operation. Damage tolerance design focuses on ensuring that a structure can continue to function safely even with a certain level of damage present. Non-destructive testing (NDT) methods, such as ultrasonic inspection and X-ray radiography, are used to detect and characterize damage, enabling timely repairs. The skin of an aircraft wing, for example, may be designed with crack arrestors to prevent cracks from propagating rapidly.

- Structural Health Monitoring

Structural health monitoring (SHM) systems are increasingly being incorporated into aerospace vehicles to continuously monitor the condition of critical structural components. These systems use sensors to detect changes in strain, vibration, and temperature, providing early warnings of potential damage or degradation. SHM can enable proactive maintenance and prevent catastrophic failures. For example, sensors embedded in an aircraft wing can detect the growth of a crack and alert maintenance personnel before it reaches a critical size.

These considerations collectively highlight the central role of structural integrity in aerospace engineering. From material selection to ongoing monitoring, the ability to design and maintain robust and reliable structures is paramount for ensuring the safety and success of aerospace missions.

4. Control Systems

Control systems are an indispensable aspect of aerospace engineering, functioning as the central nervous system for aircraft and spacecraft. They govern the stability, maneuverability, and overall performance of these vehicles by managing and coordinating various subsystems. The design and implementation of control systems are therefore integral to the realization of safe, efficient, and effective aerospace operations. A malfunction or deficiency in the control system can have catastrophic consequences, underscoring its criticality within the broader engineering domain. For instance, the autopilot system in a commercial airliner autonomously maintains altitude, heading, and airspeed, allowing pilots to manage other aspects of flight. Similarly, satellite attitude control systems ensure proper orientation for communication and observation missions. Failures in these systems can lead to loss of control and mission failure.

The practical applications of control systems in aerospace engineering extend to diverse areas such as flight control surfaces, engine management, and robotic manipulation. Flight control surfaces, including ailerons, elevators, and rudders, are actuated by control systems to alter the aerodynamic forces acting on the vehicle, enabling pilots or automated systems to maneuver the aircraft. Engine management systems regulate fuel flow, air intake, and exhaust, optimizing engine performance and minimizing emissions. In the context of spacecraft, robotic manipulators used for satellite repair or construction in orbit rely on sophisticated control algorithms to achieve precise and coordinated movements. Advances in control theory, such as adaptive control and robust control, are continually being integrated into aerospace systems to enhance their performance and resilience in the face of uncertainties and disturbances.

In summation, control systems are a critical component within aerospace engineering, enabling the precise and reliable operation of aircraft and spacecraft. Their influence spans from basic stability augmentation to advanced autonomous navigation. Challenges in this field include the development of robust control strategies for complex and uncertain environments, the integration of artificial intelligence for enhanced decision-making, and the certification of safety-critical control systems. The ongoing evolution of control systems is essential for unlocking new possibilities in air travel, space exploration, and national defense, and is crucial in shaping what this branch of engineering involves now, and in the future.

5. Materials Science

Materials science is intrinsically linked to aerospace engineering, dictating the feasible designs, performance capabilities, and overall safety of aircraft and spacecraft. The selection and application of appropriate materials are not merely considerations but fundamental determinants of mission success or failure. The weight, strength, and durability of materials directly influence fuel efficiency, payload capacity, and structural integrity.

- High Strength-to-Weight Ratio Materials

Aerospace structures require materials that can withstand significant loads while minimizing weight. Alloys of aluminum, titanium, and magnesium, as well as composite materials like carbon fiber reinforced polymers (CFRP), are commonly employed. These materials offer exceptional strength-to-weight ratios, enabling the construction of lightweight aircraft and spacecraft. For instance, the Boeing 787 Dreamliner utilizes a significant amount of CFRP in its fuselage and wings, contributing to improved fuel efficiency and reduced emissions. The implications extend to increased payload capacity and improved maneuverability.

- High-Temperature Materials

Components exposed to extreme temperatures, such as engine parts and heat shields, necessitate the use of high-temperature materials. Nickel-based superalloys and ceramic matrix composites (CMCs) are capable of maintaining their strength and structural integrity at elevated temperatures. These materials are crucial for the operation of jet engines and hypersonic vehicles. The Space Shuttle’s thermal protection system, for example, relied on ceramic tiles to protect the vehicle from the intense heat generated during atmospheric reentry. Failure to utilize appropriate high-temperature materials can lead to catastrophic structural failure.

- Corrosion-Resistant Materials

Aerospace structures are susceptible to corrosion due to exposure to harsh environmental conditions, including moisture, salt spray, and atmospheric pollutants. Corrosion-resistant materials, such as stainless steel and specialized coatings, are employed to mitigate this risk. The selection of corrosion-resistant materials is crucial for ensuring the long-term durability and safety of aircraft and spacecraft. For example, the use of protective coatings on aluminum aircraft components helps to prevent corrosion-related failures that could compromise structural integrity. This is particularly important in marine environments.

- Radiation-Shielding Materials

Spacecraft operating in the harsh radiation environment of space require specialized materials to shield sensitive electronic components and protect astronauts from harmful radiation. High-density materials, such as lead and aluminum, are effective at attenuating radiation. The International Space Station (ISS) incorporates radiation shielding to protect its crew and equipment. The selection and placement of radiation-shielding materials are critical for ensuring the safety and reliability of spacecraft operating in deep space missions.

These examples illustrate the profound connection between materials science and aerospace engineering. Advancements in materials technology directly enable the development of more efficient, reliable, and capable aircraft and spacecraft. The ongoing research and development of new materials with enhanced properties is crucial for pushing the boundaries of aerospace exploration and innovation. This constant evolution of materials is inseparable from what aerospace engineering can accomplish.

6. Avionics

Avionics represents a critical intersection within aerospace engineering, encompassing the electronic systems that govern the operation and functionality of aircraft and spacecraft. Its integration is essential for modern aerospace vehicles to achieve the required levels of safety, performance, and autonomy. As such, its role profoundly influences what aerospace engineering entails.

- Navigation Systems

Navigation systems provide crucial positional data, enabling pilots and autonomous systems to determine their location, heading, and velocity. These systems integrate data from various sources, including GPS, inertial measurement units (IMUs), and radio navigation aids. For example, commercial airliners rely on sophisticated navigation systems to follow pre-programmed flight paths and maintain accurate positioning during all phases of flight. This facet directly influences flight safety and efficiency.

- Communication Systems

Communication systems facilitate the exchange of information between the aircraft or spacecraft and ground stations, air traffic control, or other vehicles. These systems employ various communication protocols and technologies, including radio, satellite, and data links. Effective communication is essential for coordinating air traffic, relaying critical data, and ensuring situational awareness. The use of satellite communication in transoceanic flights provides continuous contact even beyond the range of traditional radio systems. This is vital for safety and operational coordination.

- Flight Control Systems

Flight control systems manage the stability and maneuverability of aircraft and spacecraft, translating pilot inputs or autonomous commands into appropriate control surface deflections. These systems incorporate sensors, actuators, and control algorithms to maintain desired flight parameters. Modern fly-by-wire systems in aircraft like the F-35 fighter jet rely heavily on avionics to enhance performance and reduce pilot workload. These systems improve maneuverability and provide enhanced safety features.

- Electronic Warfare Systems

Electronic warfare systems, relevant primarily to military aircraft, are designed to detect, identify, and counter enemy electronic threats, such as radar and communication systems. These systems employ a range of techniques, including jamming, deception, and electronic surveillance. Effective electronic warfare capabilities are crucial for maintaining air superiority and protecting aircraft from hostile threats. The integration of electronic warfare systems represents a specialized area of avionics with significant implications for national security.

The described areas within avionics highlight the substantial role electronics play in the broader scope of aerospace engineering. The development, integration, and maintenance of these systems not only demand expertise in electronics but also a deep understanding of aerodynamics, propulsion, and structural mechanics. This interconnectedness solidifies avionics as an integral component in what aerospace engineering truly encompasses.

7. System Integration

System integration is a fundamental aspect of aerospace engineering, serving as the linchpin that connects the disparate elements of an aircraft or spacecraft into a cohesive, functional entity. Without effective system integration, even the most advanced individual components would fail to produce a viable aerospace vehicle. The process involves ensuring that all subsystems including avionics, propulsion, control systems, and structural components operate in concert, meeting performance requirements and adhering to stringent safety standards. A miscalculation or oversight in system integration can have cascading effects, potentially leading to catastrophic failure. For example, the integration of a new engine onto an existing aircraft platform requires careful consideration of aerodynamic effects, structural loads, and control system modifications to ensure stability and prevent unforeseen consequences.

The importance of system integration extends beyond the initial design phase, encompassing manufacturing, testing, and ongoing maintenance. During manufacturing, precise alignment and interconnection of components are essential to ensure proper functionality and prevent interference. Testing involves subjecting the integrated system to simulated operational conditions to verify its performance and identify potential vulnerabilities. Furthermore, system integration considerations are paramount throughout the vehicle’s lifespan, influencing maintenance procedures and upgrade strategies. A change to one subsystem may necessitate modifications to others, requiring careful analysis and coordination. Consider the integration of a new communication satellite into an existing ground network; the satellite’s communication protocols, data formats, and orbital parameters must be seamlessly integrated with the ground station’s hardware and software to ensure reliable data transmission and control.

In conclusion, system integration is an essential component that fundamentally defines aerospace engineering. It’s not merely a procedural step, but rather a holistic process that permeates all stages of an aerospace project, from initial concept to ongoing operation. Challenges arise from the increasing complexity of aerospace systems, requiring advanced modeling and simulation tools, rigorous testing methodologies, and robust communication protocols to ensure successful integration. Understanding the principles and practices of system integration is therefore crucial for any aerospace engineer seeking to contribute to the design, development, and deployment of safe, reliable, and high-performance aerospace vehicles. The effective management of these integrations directly dictates the success and advancement of all endeavors.

Frequently Asked Questions

This section addresses common inquiries regarding the scope and nature of aerospace engineering, offering clarifications and insights into this complex field.

Question 1: Is aerospace engineering solely focused on the design of aircraft and spacecraft?

While design is a significant aspect, the field encompasses a broader spectrum of activities, including research, development, testing, manufacturing, and maintenance of aerospace vehicles and related systems. Furthermore, it involves the application of fundamental engineering principles to solve challenges related to flight within and beyond Earth’s atmosphere.

Question 2: What are the primary disciplines that constitute aerospace engineering?

The core disciplines include aerodynamics, propulsion, structures, control systems, materials science, and avionics. Expertise in these areas is essential for developing efficient, safe, and reliable aerospace vehicles. System integration, which ensures that these elements function harmoniously, is also a critical discipline.

Question 3: How does aerospace engineering contribute to fields beyond aviation and space exploration?

Aerospace engineering principles and technologies find applications in various sectors, including automotive engineering, wind energy, and biomedical engineering. For instance, computational fluid dynamics (CFD) techniques, initially developed for aircraft design, are now used to optimize vehicle aerodynamics and improve the performance of wind turbines. Furthermore, lightweight materials developed for aerospace applications are utilized in prosthetics and other medical devices.

Question 4: What is the role of computer-aided design (CAD) and simulation in aerospace engineering?

CAD software and simulation tools are indispensable for designing and analyzing complex aerospace systems. These tools enable engineers to create detailed 3D models, simulate flight dynamics, and assess structural integrity before physical prototypes are built. This reduces development time and cost while improving design accuracy and reliability.

Question 5: Are there specific ethical considerations within aerospace engineering?

Ethical considerations are paramount due to the potential impact of aerospace systems on public safety and the environment. Aerospace engineers must adhere to professional codes of ethics, prioritizing safety, reliability, and environmental sustainability. This includes responsible use of resources and careful assessment of potential risks associated with aerospace technologies.

Question 6: What are some of the emerging trends in aerospace engineering?

Emerging trends include the development of sustainable aviation technologies, such as electric and hybrid-electric propulsion systems, as well as the exploration of hypersonic flight, space tourism, and the utilization of advanced materials like metamaterials and self-healing composites. These trends are driven by the need for more efficient, environmentally friendly, and capable aerospace vehicles.

This FAQ section highlights the breadth and depth of aerospace engineering. The field’s importance to both technological advancement and societal well-being cannot be overstated.

The subsequent discussion will focus on career opportunities and educational pathways within aerospace engineering.

Conclusion

The preceding exploration has elucidated the multifaceted nature of aerospace engineering. From aerodynamics and propulsion to structural integrity, control systems, materials science, avionics, and system integration, this engineering discipline requires a comprehensive understanding of numerous interconnected principles. Its domain extends beyond mere design, encompassing the full lifecycle of aerospace vehicles from conception to decommissioning.

Given the continuous advancements in technology and the increasing demand for efficient, sustainable, and safe aerospace systems, the challenges and opportunities within this field remain considerable. The continued application of rigorous engineering principles and a commitment to innovation are essential for addressing these challenges and shaping the future of flight and space exploration.