Aerospace engineers design, develop, test, and supervise the manufacture of aircraft, spacecraft, satellites, and missiles. They also conduct research into aerodynamic characteristics, propulsion systems, structural integrity, and guidance and control mechanisms. These professionals apply principles of engineering, science, and mathematics to create innovative solutions within the aerospace field.

The work of these engineers is vital for advancements in air travel, space exploration, and national defense. Their contributions lead to safer, more efficient aircraft, advanced satellite technologies for communication and observation, and sophisticated defense systems. Historically, their efforts have driven significant technological leaps, transforming transportation and expanding our understanding of the universe.

Consequently, this field encompasses a broad range of specializations, including aerodynamics, propulsion, materials science, and control systems. The following sections will delve into these key areas, providing a more detailed examination of the diverse responsibilities and skills required in this demanding yet rewarding profession.

Guidance for Aspiring Professionals in the Field

Those pursuing a career designing and developing aircraft, spacecraft, and related systems should consider the following essential points for maximizing their potential.

Tip 1: Emphasize a Strong Foundation in Core Sciences: A thorough understanding of physics, mathematics (particularly calculus and differential equations), and computer science is paramount. These disciplines form the bedrock upon which advanced aerospace engineering principles are built. For instance, proficiency in fluid dynamics is essential for designing efficient airfoils.

Tip 2: Cultivate Proficiency in CAD/CAM Software: Expertise in Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) tools is crucial for creating detailed models and simulations of aerospace components and systems. Familiarity with industry-standard software such as CATIA, SolidWorks, or ANSYS is highly advantageous.

Tip 3: Seek Internship or Research Opportunities: Practical experience through internships or research projects provides invaluable insights into real-world engineering challenges and industry practices. Actively seek opportunities to work on projects related to aerodynamics, propulsion, or structural analysis to gain hands-on skills.

Tip 4: Develop Strong Analytical and Problem-Solving Skills: The ability to analyze complex problems, identify key factors, and develop effective solutions is essential for success in this field. Hone analytical skills by working on challenging projects and participating in engineering competitions.

Tip 5: Prioritize Effective Communication Skills: Aerospace engineers frequently collaborate with multidisciplinary teams and communicate technical information to diverse audiences. Cultivate strong written and oral communication skills to effectively convey design concepts, research findings, and project updates.

Tip 6: Stay Abreast of Technological Advancements: The aerospace industry is rapidly evolving. Continuous learning and staying informed about emerging technologies, such as advanced materials, additive manufacturing, and autonomous systems, are crucial for maintaining a competitive edge.

Tip 7: Consider Specializing in a Specific Area: Aerospace engineering encompasses a wide range of specializations. Focusing on a particular area, such as aerodynamics, propulsion, or control systems, can allow for the development of deep expertise and increased career opportunities.

By focusing on these key areas, individuals can enhance their prospects in this complex and dynamic industry. A solid academic foundation, practical experience, and a commitment to lifelong learning are vital for a successful career.

These insights provide a framework for embarking on a fulfilling career. The following discussion will present the overall conclusion on what it entails to engage on this career path.

1. Design

Design is a foundational element of the work performed by aerospace engineers. This aspect directly influences the performance, safety, and efficiency of aircraft, spacecraft, and related systems. The design process involves the application of scientific and mathematical principles to create detailed plans and specifications that guide the construction of aerospace vehicles and components. For instance, the initial design of a new commercial aircraft wing requires careful consideration of lift, drag, and structural integrity to ensure optimal performance and safety under various flight conditions. A deficient design in this phase can have cascading consequences, potentially leading to structural failures or reduced fuel efficiency. Therefore, the design phase is not merely a preliminary step but a critical determinant of the overall success of the final product.

The implementation of advanced computational tools and simulation techniques plays a crucial role in the design process. Engineers utilize Computer-Aided Design (CAD) software to create precise 3D models, which are then subjected to rigorous simulations to assess their behavior under different operational scenarios. For example, Computational Fluid Dynamics (CFD) simulations are used to analyze the airflow around an aircraft fuselage, allowing engineers to identify and mitigate potential aerodynamic inefficiencies. Similarly, Finite Element Analysis (FEA) is employed to evaluate the structural strength and stability of components, ensuring they can withstand the stresses and strains encountered during flight. These computational tools, therefore, provide insights into how the resulting designs meet operational requirements and safety standards.

In summary, the design phase is integral to the functionality of an aerospace engineer’s tasks. It not only requires a comprehensive understanding of theoretical principles but also a proficiency in utilizing advanced computational tools for analysis and optimization. The ability to create innovative and reliable designs is paramount to advancing the field of aerospace engineering, directly impacting the safety, performance, and sustainability of air and space travel. The challenges lie in adapting to evolving technologies and adhering to stringent regulatory requirements, thereby making the design phase a perpetually evolving aspect of an aerospace engineers responsibility.

2. Development

Development constitutes a crucial phase in aerospace engineering, bridging the gap between theoretical design and practical implementation. It involves the iterative refinement and optimization of aerospace systems and components to meet specified performance criteria and regulatory standards.

- Prototype Construction and Testing

Aerospace engineers oversee the construction of prototypes based on initial designs. These prototypes undergo rigorous testing to evaluate their performance under simulated and real-world conditions. For example, an engineer developing a new aircraft engine would construct a prototype and subject it to extensive tests to measure thrust, fuel consumption, and emissions. The results of these tests inform design modifications and improvements.

- System Integration

Development involves integrating various subsystems and components into a cohesive and functional aerospace system. This requires careful coordination and management of interfaces to ensure compatibility and seamless operation. In the development of a satellite, for instance, engineers must integrate the communication, power, propulsion, and control systems to achieve the desired mission objectives.

- Software and Algorithm Development

Many aerospace systems rely heavily on software and algorithms for control, navigation, and data processing. Engineers develop and refine these software components to optimize system performance and reliability. For example, the development of autonomous flight control algorithms for unmanned aerial vehicles (UAVs) requires extensive testing and validation to ensure safe and efficient operation.

- Materials and Manufacturing Process Optimization

Aerospace engineers work to optimize the materials and manufacturing processes used in the construction of aerospace components. This includes selecting materials with desirable properties, such as high strength-to-weight ratio, and developing efficient manufacturing techniques to reduce costs and improve production rates. The development of new composite materials and additive manufacturing processes has significantly impacted the aerospace industry.

The development phase is characterized by iterative experimentation and refinement, playing a pivotal role in achieving performance and safety objectives. Integrating design, testing, and manufacturing expertise, it ensures that designs meet the stringent demands of aerospace applications.

3. Testing

Testing forms an indispensable function in the array of responsibilities. Rigorous evaluation of designs, prototypes, and final products is essential to ensure they meet stringent performance, safety, and regulatory requirements. This phase verifies that aerospace systems can withstand the extreme conditions encountered during operation, such as high altitudes, extreme temperatures, and significant mechanical stresses. For instance, before a new commercial aircraft enters service, it undergoes extensive flight testing to validate its aerodynamic performance, structural integrity, and systems functionality. The results of these tests are crucial for identifying potential design flaws or operational limitations.

Effective testing employs a combination of simulation, ground-based experiments, and flight trials. Simulations utilize advanced computational models to predict the behavior of aerospace systems under various conditions, allowing engineers to identify potential weaknesses early in the development process. Ground-based experiments, such as wind tunnel tests and structural load tests, provide empirical data to validate simulation results and assess the performance of physical prototypes. Flight trials involve operating aircraft or spacecraft in real-world conditions to evaluate their performance and identify any unforeseen issues. For example, the development of a new rocket engine requires numerous static firing tests to evaluate its thrust, stability, and combustion efficiency. These tests provide valuable data for refining the engine design and ensuring its reliability for future space missions.

In summary, testing constitutes an integral function. It provides critical feedback throughout the design and development process, ensuring that aerospace systems meet the highest standards of performance, safety, and reliability. The ability to design and implement effective test programs is essential for mitigating risks and ensuring the success of aerospace projects. As aerospace technology continues to advance, the role of testing will become increasingly important in addressing the complex challenges of designing and operating advanced air and space vehicles.

4. Research

Research constitutes a foundational pillar within the broader scope of aerospace engineering. It drives innovation, enabling the development of advanced technologies and methodologies that define the future of air and space travel. This investigative pursuit encompasses a wide array of activities, ranging from theoretical studies to experimental investigations, all aimed at expanding the boundaries of current knowledge and capabilities.

- Aerodynamics and Fluid Dynamics Research

This area focuses on understanding and manipulating the flow of air around aircraft and spacecraft. Research in this domain leads to the design of more efficient airfoils, reduced drag, and improved aerodynamic stability. For example, ongoing research into boundary layer control techniques aims to minimize turbulence and enhance fuel efficiency in commercial aircraft. Implications extend to decreased fuel consumption, reduced emissions, and enhanced flight performance.

- Propulsion Systems Research

Propulsion research centers on developing advanced engines and propulsion systems for aircraft and spacecraft. This includes investigations into alternative fuels, advanced combustion techniques, and novel engine designs. For example, research on scramjet engines aims to enable hypersonic flight capabilities for future aircraft and space launch vehicles. The potential benefits include faster air travel, more efficient space access, and new possibilities for space exploration.

- Materials Science and Structural Research

This area focuses on the development of advanced materials and structures capable of withstanding the extreme conditions encountered in aerospace applications. Research includes investigations into lightweight composites, high-temperature alloys, and advanced manufacturing techniques. For example, ongoing research on carbon fiber-reinforced polymers aims to create lighter and stronger aircraft structures, leading to improved fuel efficiency and payload capacity. Implications extend to enhanced aircraft performance, reduced structural weight, and improved safety.

- Autonomous Systems and Control Research

This research area focuses on developing autonomous systems and control algorithms for aircraft, spacecraft, and unmanned aerial vehicles (UAVs). This includes investigations into sensor fusion, artificial intelligence, and machine learning techniques. For example, research on autonomous flight control systems aims to enable safer and more efficient air traffic management, as well as the development of autonomous spacecraft for deep-space exploration. Potential benefits include reduced pilot workload, improved safety, and new capabilities for autonomous missions.

In essence, research serves as the engine driving progress in aerospace engineering. By continuously pushing the boundaries of knowledge and technology, it enables the creation of safer, more efficient, and more capable air and space vehicles. These facets contribute to advancing aerospace engineering, enhancing the overall efficacy and sustainability of flight and space exploration, thereby impacting society.

5. Supervision

Supervision in aerospace engineering is a critical function that ensures designs, processes, and manufactured products adhere to specified standards, regulations, and safety protocols. It entails overseeing projects from inception to completion, maintaining quality control, and ensuring that all team members perform their tasks effectively and safely.

- Oversight of Design and Development Processes

Aerospace engineers in supervisory roles oversee the design and development of aircraft, spacecraft, and related systems. This includes reviewing design specifications, monitoring progress, and ensuring that designs meet performance and safety requirements. For instance, a supervisory engineer might oversee the development of a new composite wing structure, ensuring that it meets stringent strength and weight requirements. Implications of failing to adequately supervise this process can result in structural failures during operation.

- Management of Manufacturing and Production Activities

Supervision extends to managing manufacturing and production activities, ensuring that aerospace components and systems are built to precise specifications. This involves overseeing production lines, monitoring quality control processes, and resolving any manufacturing-related issues. An example includes supervising the assembly of a jet engine, where precise tolerances and meticulous quality control are essential to ensure safe and efficient operation. Improper supervision could lead to defective components and potentially catastrophic engine failures.

- Ensuring Regulatory Compliance and Safety Standards

Aerospace engineers are responsible for ensuring that all projects comply with relevant regulatory requirements and safety standards. This involves staying up-to-date with industry regulations, implementing safety protocols, and conducting regular audits to identify and address potential hazards. For example, supervising the maintenance and inspection of commercial aircraft involves ensuring adherence to Federal Aviation Administration (FAA) regulations to guarantee passenger safety. Failure to enforce these standards can lead to severe legal and financial repercussions, as well as compromise safety.

- Team Leadership and Project Management

Supervision includes leading and managing teams of engineers, technicians, and other personnel. This involves assigning tasks, providing guidance and support, and ensuring that projects are completed on time and within budget. An example of this is an engineer supervising the development of a new satellite, coordinating the efforts of engineers specializing in communication systems, power systems, and control systems to ensure the satellite meets its mission objectives. Effective team leadership is essential for fostering collaboration and innovation, which is vital for the success of aerospace projects.

In essence, supervision plays a vital role by ensuring adherence to safety standards, regulatory compliance, and efficient project management throughout all stages of design, development, manufacturing, and operation. The effectiveness of supervision directly impacts the reliability, performance, and safety. Therefore, it is an indispensable aspect.

Frequently Asked Questions Regarding Responsibilities

The following addresses commonly encountered questions regarding the scope and nature of duties performed by professionals.

Question 1: Is mathematical ability crucially important?

Yes, a strong foundation in mathematics is essential. Calculus, differential equations, and linear algebra are frequently applied in modeling aerodynamic forces, simulating structural behavior, and designing control systems. A deficiency in mathematical understanding can significantly impede an engineer’s ability to analyze and solve complex problems.

Question 2: What role do computer skills play?

Proficiency in computer-aided design (CAD), computer-aided manufacturing (CAM), and simulation software is integral to the profession. Engineers utilize these tools to create detailed models, conduct simulations, and optimize designs. Familiarity with programming languages may also be necessary for developing custom software solutions. Lack of such skills can limit the efficiency and effectiveness of design and analysis processes.

Question 3: What are the main areas of specialization within the field?

Specializations include aerodynamics, propulsion, materials science, structural engineering, and control systems. Each area requires specialized knowledge and expertise. Focusing on a particular specialization can lead to deeper expertise and greater career opportunities. The choice of specialization significantly impacts the type of projects an engineer will work on.

Question 4: How important is practical experience through internships or research?

Practical experience gained through internships or research projects is highly valuable. These opportunities provide insights into real-world engineering challenges and industry practices, allowing aspiring engineers to apply theoretical knowledge to practical problems. Participation in such experiences can significantly enhance career prospects.

Question 5: Does the profession require strong communication skills?

Effective communication is essential for engineers, who frequently collaborate with multidisciplinary teams and communicate technical information to diverse audiences. Clear written and oral communication skills are necessary for conveying design concepts, research findings, and project updates. Communication deficiencies can hinder collaboration and project success.

Question 6: How significant is the impact of regulatory compliance?

Adherence to stringent regulatory requirements and safety standards is paramount. The aerospace industry is heavily regulated to ensure the safety and reliability of aircraft and spacecraft. Engineers must be knowledgeable about relevant regulations and ensure that designs and processes comply with these requirements. Non-compliance can lead to legal repercussions and compromise safety.

These FAQs provide a concise overview of critical aspects for anyone considering this profession, offering insight into the skills, knowledge, and responsibilities inherent in this field.

The subsequent section presents a detailed conclusion summarizing the main aspects of the subject.

What Does Aerospace Engineers Do

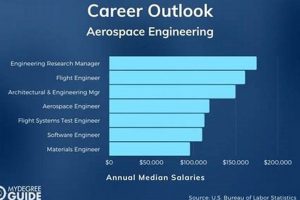

This exploration has elucidated the multifaceted nature of the work, extending from conceptual design to final product supervision. The detailed phases of design, development, testing, research, and supervision reveal a profession demanding rigorous scientific knowledge, technical proficiency, and adherence to stringent safety standards. Mathematical acumen, computer skills, and effective communication are indispensable for success in this field. The outlined responsibilities underscore the critical role these professionals play in advancing air and space travel.

The continued evolution of aerospace technology necessitates ongoing education and adaptation. As society faces challenges related to sustainable transportation and space exploration, the expertise and innovation of these engineers become increasingly vital. Continued investment in research and development, coupled with a commitment to ethical and safe practices, will ensure that future generations can benefit from advancements in air and space technologies.

![Top UC Berkeley Aerospace Engineering Masters Programs [Rankings] Innovating the Future of Flight with Reliable Aviation Solutions Top UC Berkeley Aerospace Engineering Masters Programs [Rankings] | Innovating the Future of Flight with Reliable Aviation Solutions](https://mixaerospace.com/wp-content/uploads/2026/02/th-647-300x200.jpg)