Employment opportunities within the aeronautics and astronautics sector located within the state of Vermont are the focus of this discussion. These positions encompass a range of roles, from engineering and design to manufacturing and maintenance, contributing to the broader aerospace industry. An example would be a mechanical engineer designing components for aircraft engines at a manufacturing facility in Vermont.

The significance of these career paths lies in their contribution to technological advancement, economic growth within the state, and the development of skilled labor. Historically, while not a major hub, Vermont has maintained a presence in this sector, offering specialized opportunities and supporting related industries through component manufacturing and technological innovation. The presence of these opportunities encourages specialized skill development and retention of talent within the state.

The following sections will delve into the specific types of roles available, the skills and qualifications typically required, leading companies operating in the field within Vermont, and resources for individuals seeking to pursue related career paths.

The following insights aim to guide individuals seeking professional roles in the aeronautics and astronautics sector within Vermont, providing actionable advice for career advancement.

Tip 1: Specialize Skillsets: The Aeronautics and Astronautics sector demands specialized knowledge. Focusing on areas like composite materials, avionics, or propulsion systems enhances employability. Example: Obtain certifications in CAD software relevant to aerospace design.

Tip 2: Targeted Education: Pursue academic degrees or vocational training programs tailored to Aeronautics and Astronautics. Consider institutions with established engineering programs or specialized technical schools. Example: A degree in Mechanical Engineering with a focus on fluid dynamics.

Tip 3: Networking Opportunities: Actively participate in industry events, conferences, and workshops. Building connections with professionals in the Aeronautics and Astronautics field provides valuable insights and potential opportunities. Example: Attend the annual Vermont Manufacturing Extension Center (VMEC) events.

Tip 4: Internship or Apprenticeship Programs: Seek practical experience through internships or apprenticeships with aerospace companies or related manufacturers. Hands-on experience is highly valued. Example: Apply for internships at companies that supply components to aerospace manufacturers.

Tip 5: Certifications and Licenses: Obtain relevant certifications and licenses that demonstrate expertise in specific areas. These credentials enhance credibility and marketability. Example: FAA Airframe and Powerplant (A&P) license for maintenance positions.

Tip 6: Research Companies: Thoroughly investigate companies in Vermont that are involved in the Aeronautics and Astronautics supply chain. Understanding their operations and requirements will aid in tailoring applications and interviews. Example: Investigate companies that specialize in precision machining for aerospace components.

Tip 7: Tailored Resume and Cover Letter: Customize the resume and cover letter to reflect the specific requirements of each position. Highlight relevant skills, experience, and accomplishments. Example: Emphasize experience with specific aerospace standards or regulations.

By implementing these strategies, individuals can increase their prospects for securing fulfilling and impactful roles within the Aeronautics and Astronautics industry within Vermont.

The subsequent sections will explore specific companies and resources to further guide the career search.

1. Engineering Design

Engineering design constitutes a crucial pillar within the Vermont aerospace employment landscape. The presence of aerospace-related enterprises within the state necessitates a cadre of skilled engineers capable of conceptualizing, developing, and refining aerospace components and systems. This demand creates a direct link: the more robust the aerospace industry in Vermont, the greater the need for competent engineering designers. Engineering design roles are not merely supplementary; they are foundational to the viability and competitiveness of related businesses. For instance, a Vermont-based company specializing in precision-machined parts for aircraft engines relies heavily on design engineers to ensure parts meet exacting specifications and performance criteria.

The significance of engineering design extends beyond the immediate creation of tangible products. It encompasses activities such as simulation and modeling, materials selection, and the optimization of manufacturing processes. Consider the development of a new composite material for aircraft wings: Engineering designers would be instrumental in determining the material’s suitability for specific applications, designing the wing structure to maximize its strength-to-weight ratio, and developing the manufacturing processes required for efficient production. This multifaceted role highlights the engineering design’s far-reaching impact on both product performance and cost-effectiveness. Companies benefit by improved product qualities, increased efficiency, and ability to generate increased revenue streams, leading to increased job security and job growth in Vermont.

In summary, the connection between engineering design and Vermont aerospace careers is strong and foundational. Effective engineering design is essential for the success of aerospace companies operating within the state. Investment in the engineering skills of the workforce and support for relevant training programs can contribute to the sustainable growth of Vermont’s aerospace industry and create more Vermont aerospace jobs. Understanding this relationship is therefore practically significant for individuals seeking careers in this field and for policymakers aiming to promote economic development within the state.

2. Precision Manufacturing

Precision manufacturing is inextricably linked to opportunities within Vermont’s aerospace sector. The cause-and-effect relationship is straightforward: the stringent requirements of aerospace components necessitate highly precise manufacturing processes, thereby creating demand for skilled machinists, technicians, and engineers capable of operating and maintaining advanced manufacturing equipment. The importance of precision manufacturing is underscored by the fact that even minor deviations from specifications can compromise the safety and performance of aircraft and spacecraft. For example, the fabrication of turbine blades for jet engines demands tolerances measured in microns, requiring specialized machinery and expertise to ensure structural integrity and aerodynamic efficiency.

Consider the practical application: a Vermont-based machine shop that specializes in manufacturing aerospace fasteners. Their ability to consistently produce fasteners that meet or exceed industry standards, such as those established by the Society of Automotive Engineers (SAE) and the Aerospace Industries Association (AIA), directly translates into contracts from aerospace companies. These contracts, in turn, sustain existing jobs and potentially lead to the creation of new positions within the manufacturing facility. Furthermore, the presence of these precision manufacturing capabilities attracts aerospace businesses to the state, fostering economic growth and expanding the spectrum of aerospace-related roles available to Vermont residents.

In summary, precision manufacturing is not merely a component of “Vermont aerospace jobs”; it is a critical enabler. Challenges remain, including workforce development and the need to continually invest in advanced manufacturing technologies. However, by recognizing the vital role of precision manufacturing and supporting its growth, Vermont can further solidify its position as a contributor to the aerospace industry and expand the availability of related employment opportunities. Success here is directly linked to job creation and the state’s economic vitality.

3. Quality Assurance

Quality assurance is an indispensable function within the Vermont aerospace sector. Adherence to rigorous standards and regulations is paramount, given the critical nature of aerospace components and systems. Consequently, competent quality assurance professionals are in demand to ensure compliance and maintain the integrity of products.

- Inspection and Testing Protocols

Stringent inspection and testing protocols are essential to verify that aerospace parts and assemblies meet defined specifications. This encompasses non-destructive testing (NDT) methods, dimensional verification, and performance testing. For instance, a Vermont-based manufacturer of aircraft landing gear components must implement rigorous inspection procedures to detect any potential defects, such as microscopic cracks or inconsistencies in material properties, which could compromise the component’s structural integrity. The efficacy of these protocols directly impacts product reliability and safety.

- Regulatory Compliance (FAA, AS9100)

Compliance with stringent regulatory requirements, particularly those mandated by the Federal Aviation Administration (FAA) and the AS9100 aerospace quality management system standard, is non-negotiable. Quality assurance professionals must possess a thorough understanding of these regulations and ensure their consistent application across all aspects of the manufacturing process. This includes maintaining comprehensive documentation, conducting internal audits, and managing corrective actions. Failure to adhere to these standards can result in significant penalties and jeopardize a company’s ability to operate in the aerospace market.

- Process Control and Improvement

Quality assurance extends beyond mere inspection; it involves the implementation of robust process control measures to minimize variability and prevent defects from occurring in the first place. Statistical process control (SPC) techniques are often employed to monitor key process parameters and identify potential issues before they escalate. Continuous improvement initiatives, such as Lean Manufacturing and Six Sigma, are also integral to enhancing product quality and operational efficiency. For example, a quality assurance team might analyze data from a machining process to identify sources of variation and implement adjustments to reduce scrap rates and improve overall yield.

- Documentation and Traceability

Comprehensive documentation and traceability are essential for maintaining accountability and facilitating investigations in the event of a failure or discrepancy. Every component must be traceable back to its original raw materials, manufacturing processes, and inspection records. This requires meticulous record-keeping and the implementation of robust tracking systems. For example, a quality assurance professional might be responsible for ensuring that all documentation associated with a particular batch of aerospace fasteners is complete, accurate, and readily accessible for auditing purposes.

In summary, quality assurance is not simply a procedural formality within the Vermont aerospace industry; it is a critical function that safeguards product integrity, ensures regulatory compliance, and underpins the success of companies operating in this demanding sector. The employment of skilled quality assurance professionals is, therefore, essential to maintain and enhance the competitiveness of Vermont’s aerospace enterprises. The effective execution of these functions contributes directly to the availability and stability of “vermont aerospace jobs”.

4. Systems Integration

Systems integration is a vital, yet often unseen, aspect of many “vermont aerospace jobs”. The causal link is direct: the complexity of modern aerospace systems necessitates a skilled workforce capable of integrating diverse components and software into cohesive, functional units. Its importance lies in ensuring that individual subsystems, often sourced from different manufacturers or developed independently, operate seamlessly together to meet overall system performance requirements. Without effective systems integration, even the most advanced individual components are rendered useless. A practical example is integrating a new flight control system with an existing aircraft’s avionics suite. This requires expertise in hardware interfacing, software compatibility, and rigorous testing to ensure proper functionality and prevent malfunctions during flight. The presence of systems integration expertise fosters a more robust and capable aerospace sector, indirectly supporting and generating associated employment opportunities.

The practical application extends across various disciplines within the aerospace domain. In the development of unmanned aerial vehicles (UAVs), systems integration professionals are crucial for combining navigation systems, sensor payloads, communication links, and control algorithms into a unified platform. Similarly, in the manufacturing of satellite components, experts are needed to integrate power systems, communication modules, and scientific instruments into a functional satellite payload. Furthermore, with the increasing reliance on software-defined systems, systems integration also involves the implementation of secure and reliable software architectures that ensure the integrity and confidentiality of critical data. The integration of disparate systems such as radar with defense systems is another example of how the demand for competent professionals can lead to the expansion of job opportunities in defense and aerospace industries.

In summary, systems integration is an essential, often understated, element in Vermont’s aerospace landscape. Addressing the challenges of increasing system complexity and the need for skilled professionals is essential to securing the future of Vermont aerospace jobs. Recognizing the integral role of systems integration can guide educational initiatives and workforce development programs, ensuring Vermont companies maintain a competitive edge in this sector.

5. Maintenance Repair

Maintenance repair services form a crucial and continuous component supporting “vermont aerospace jobs.” The direct connection arises from the ongoing need to maintain and repair aircraft and associated systems. The reliability and safety of aerospace operations necessitate rigorous maintenance schedules and prompt attention to any malfunctions or damages. The availability of skilled maintenance repair technicians directly impacts the operational readiness of aircraft, and consequently, the economic viability of businesses that rely on air transport. For instance, a regional airline operating out of a Vermont airport requires a team of certified mechanics to perform routine inspections, diagnose mechanical issues, and execute necessary repairs to keep its fleet operational and compliant with safety regulations.

The practical application of maintenance repair expertise extends beyond routine tasks. It includes troubleshooting complex system failures, performing engine overhauls, and implementing upgrades to avionics systems. Consider a scenario where an aircraft experiences a sudden hydraulic system malfunction. Skilled maintenance technicians must be able to rapidly diagnose the cause of the failure, identify the faulty components, and perform the necessary repairs to restore the system to proper working order. This requires a combination of technical knowledge, diagnostic skills, and practical experience. Furthermore, adherence to strict safety protocols and regulatory requirements is paramount in all maintenance repair activities. The availability of well-trained and certified maintenance personnel in Vermont is therefore a key factor in attracting and retaining aerospace-related businesses within the state.

In summary, maintenance repair is an integral and ongoing function that is essential to maintaining the viability and safety of the aerospace sector within Vermont. Supporting the growth of a skilled workforce capable of performing these critical tasks is vital to the long-term sustainability of “vermont aerospace jobs.” Investments in training programs, apprenticeships, and certification programs can help ensure that Vermont possesses the necessary expertise to meet the evolving maintenance repair needs of the aerospace industry and provide economic stability for those employed in that sector.

6. Research Development

Research and development (R&D) serves as a catalyst for growth within the Vermont aerospace job market. The cause-and-effect relationship is straightforward: investment in aerospace-related R&D fuels innovation, which, in turn, creates demand for skilled scientists, engineers, and technicians. The presence of active R&D programs elevates the technical capabilities of Vermont companies, making them more competitive in the global aerospace market. For instance, a Vermont-based company engaged in developing advanced composite materials for aircraft structures requires a team of researchers to conduct experiments, analyze data, and refine manufacturing processes. This demand generates opportunities for materials scientists, chemical engineers, and laboratory technicians.

The importance of R&D extends beyond the immediate creation of new products and technologies. It fosters a culture of innovation and problem-solving, which benefits the entire organization. Consider a scenario where a Vermont company is tasked with developing a lighter and stronger alternative to traditional aluminum alloys for aircraft wings. The R&D team would not only be responsible for conducting experiments with different materials and manufacturing techniques, but also for collaborating with other departments, such as engineering and manufacturing, to ensure that the new material can be integrated seamlessly into existing production processes. This collaborative effort promotes cross-functional learning and knowledge sharing, leading to improved overall organizational performance and securing “vermont aerospace jobs” within the organization.

In summary, the relationship between aerospace R&D and “vermont aerospace jobs” is synergistic and critical for the sustained growth of the sector within Vermont. By fostering a supportive environment for innovation, Vermont can attract and retain aerospace companies, creating a virtuous cycle of R&D investment, job creation, and economic prosperity. Addressing the challenges of funding limitations and the need for specialized talent will be crucial in maximizing the benefits of aerospace R&D for Vermont and its workforce. The link to the broader theme of ensuring Vermont’s competitiveness in high-technology industries is clear: strategic investment in R&D is an essential component of long-term economic success.

Frequently Asked Questions Regarding Vermont Aerospace Employment

The following aims to address common inquiries concerning professional opportunities within Vermont’s aeronautics and astronautics sector.

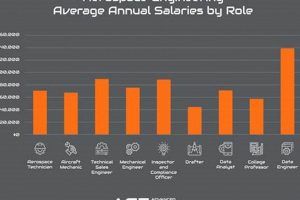

Question 1: What types of educational backgrounds are most conducive to securing “vermont aerospace jobs”?

Degrees in engineering (aerospace, mechanical, electrical), materials science, and physics are highly relevant. Vocational training in precision manufacturing, avionics, or aircraft maintenance is also valuable.

Question 2: What are the primary skills employers seek when hiring for “vermont aerospace jobs”?

Technical proficiency in areas such as CAD/CAM software, composite materials, or aerospace standards (e.g., AS9100) is critical. Strong problem-solving, analytical, and communication skills are also highly valued.

Question 3: Are there specific certifications or licenses that enhance employability in “vermont aerospace jobs”?

FAA Airframe and Powerplant (A&P) licenses, certifications in non-destructive testing (NDT), and credentials related to quality assurance (e.g., Certified Quality Engineer) can significantly improve career prospects.

Question 4: How does the size of Vermont’s aerospace sector impact the availability of “vermont aerospace jobs”?

While Vermont’s aerospace sector is not as large as those in states like California or Washington, it offers specialized opportunities in areas such as precision manufacturing, component supply, and research and development. The sector’s relatively small size can foster closer collaboration and networking opportunities.

Question 5: What are the typical career advancement paths within “vermont aerospace jobs”?

Progression depends on the specific role. Engineers may advance to project management or technical leadership positions. Technicians may specialize in specific areas and pursue supervisory roles. Continual professional development is essential for career advancement.

Question 6: What resources are available to individuals seeking “vermont aerospace jobs”?

Online job boards, professional networking platforms (e.g., LinkedIn), Vermont-based trade organizations, and career services at local colleges and universities can provide valuable resources and connections.

A realistic understanding of the required qualifications and available resources is crucial for those seeking professional involvement in Vermont’s aeronautics and astronautics activities.

The subsequent sections explore considerations for individuals entering this field.

Conclusion

This analysis has provided a detailed overview of the Vermont aerospace employment landscape, encompassing its critical components, skill requirements, and available resources. The discussions on engineering design, precision manufacturing, quality assurance, systems integration, maintenance repair, and research development illustrate the breadth and depth of career opportunities within the state. It is understood that pursuing “vermont aerospace jobs” necessitates specialized education, targeted skill development, and proactive networking.

The information outlined herein should serve as a practical guide for individuals seeking to enter or advance within the Vermont aerospace sector. Recognizing the sector’s significance to the state’s economy, ongoing investment in workforce development and technological innovation remains paramount. The future vitality of “vermont aerospace jobs” hinges on a continued commitment to excellence, strategic partnerships, and a proactive approach to addressing the evolving demands of the global aerospace industry.