Opportunities at the El Cajon, California facility of a global aerospace engineering business encompass a diverse range of roles. These positions support the design, manufacture, and maintenance of advanced aerospace components and systems. These opportunities include engineering, manufacturing, quality assurance, supply chain management, and administrative functions.

The presence of an established aerospace company in El Cajon offers economic advantages to the region, providing skilled employment and fostering technological advancement. The availability of such positions contributes to the local economy, attracts talent, and strengthens the region’s position in the aerospace sector. The facility’s history in the area often reflects a commitment to long-term growth and investment in the community.

The following sections will delve into specific aspects of career possibilities at this facility, detailing potential roles, qualifications, and the overall employment landscape within the organization. Information regarding application procedures and employee benefits will also be presented.

The subsequent guidelines aim to assist prospective candidates in effectively pursuing and securing available positions within the specified organization and location.

Tip 1: Conduct Thorough Research: Prior to applying, examine the company’s website and industry publications to comprehend its core business, recent projects, and strategic direction. This will enable candidates to tailor their application materials to align with the organization’s specific needs.

Tip 2: Tailor Application Materials: Generic applications are less effective. Customize resumes and cover letters to specifically address the requirements outlined in each job description. Highlight relevant skills, experiences, and accomplishments that directly relate to the position.

Tip 3: Network Strategically: Utilize professional networking platforms to connect with current employees or individuals who have previously worked at the facility. Informational interviews can provide valuable insights into the company culture and hiring processes.

Tip 4: Prepare for Behavioral Interviews: Anticipate behavioral interview questions that assess past performance in specific situations. Use the STAR method (Situation, Task, Action, Result) to structure responses and demonstrate relevant competencies.

Tip 5: Emphasize Relevant Skills: Highlight technical proficiencies, problem-solving abilities, and collaborative experiences that are crucial for success in aerospace engineering and manufacturing environments. Quantify accomplishments whenever possible to showcase impact.

Tip 6: Showcase Continuous Learning: Demonstrate a commitment to professional development by highlighting relevant certifications, training courses, or participation in industry conferences. This indicates a proactive approach to staying current with industry advancements.

Tip 7: Follow Up Appropriately: After submitting an application or attending an interview, send a thank-you note to the hiring manager or interviewer. Reiterate interest in the position and briefly summarize key qualifications.

Adhering to these suggestions can significantly improve a candidate’s chances of successfully navigating the recruitment process and securing a position within the El Cajon aerospace facility.

The following section will present an overview of common roles and required qualifications.

1. Engineering Specialties

Engineering specialties represent a critical component of the El Cajon aerospace facility’s operations. These specialized roles directly contribute to the design, development, and manufacturing of advanced aerospace components, making them integral to the overall success of the organization.

- Design Engineering

Design engineers are responsible for creating and refining the blueprints and models for aerospace parts and systems. They utilize CAD software and engineering principles to ensure designs meet performance requirements and regulatory standards. At the El Cajon facility, this may involve designing turbine blades, structural components, or specialized hardware. Their work directly influences the efficiency, safety, and reliability of aircraft and aerospace vehicles.

- Stress Analysis Engineering

Stress analysis engineers evaluate the structural integrity of aerospace components under various loads and environmental conditions. They use finite element analysis (FEA) and other simulation techniques to identify potential weak points and ensure designs can withstand extreme stresses. This role is crucial for preventing failures and ensuring the safety of aircraft. This might involve analysis of composite materials or complex geometries specific to the facilitys products.

- Materials Engineering

Materials engineers focus on the selection, testing, and application of materials used in aerospace components. They possess expertise in metallurgy, polymers, and composite materials, ensuring that the right materials are chosen for specific applications to meet performance and durability requirements. This may include working with high-temperature alloys or advanced composites to improve the strength-to-weight ratio of aircraft components.

- Manufacturing Engineering

Manufacturing engineers bridge the gap between design and production. They develop and optimize manufacturing processes, ensuring that components can be produced efficiently and cost-effectively while meeting quality standards. This role involves process planning, tooling design, and troubleshooting manufacturing issues. Within the El Cajon facility, they work to improve production workflows, reduce waste, and implement lean manufacturing principles.

These engineering specialties are interconnected and vital to the success of the El Cajon aerospace facility. Each role contributes unique expertise to the development and manufacturing of high-quality aerospace components, ultimately impacting the performance, safety, and reliability of aircraft and spacecraft. The demand for skilled engineers in these areas contributes to the prominence of this location for professional aerospace employment.

2. Manufacturing Roles

The range of manufacturing roles within the El Cajon facility forms a critical component of the organization’s operational capabilities. These roles directly contribute to the physical realization of aerospace components and systems, transforming engineering designs into tangible products. The effectiveness of manufacturing processes directly impacts product quality, production efficiency, and overall cost-effectiveness. For example, skilled machinists, fabricators, and assembly technicians are essential for producing high-precision parts that meet stringent aerospace standards. The availability of these roles underscores the facility’s position as a significant manufacturing hub within the aerospace sector.

These positions are not merely about physical labor; they often require a deep understanding of complex manufacturing processes, adherence to strict quality control protocols, and the ability to operate and maintain sophisticated machinery. Consider a CNC machinist responsible for creating intricate turbine blades. Their expertise in programming and operating computer-controlled machines ensures the blades are manufactured to exact specifications, contributing to the overall performance and efficiency of aircraft engines. Similarly, composite technicians play a vital role in fabricating lightweight yet durable structural components. These examples highlight the crucial role of manufacturing roles in translating designs into reliable and functional aerospace products.

In summary, manufacturing roles are intrinsically linked to the El Cajon facility’s success. Their ability to produce high-quality aerospace components directly affects the organization’s competitiveness and reputation. While challenges such as maintaining a skilled workforce and adapting to evolving manufacturing technologies exist, the practical significance of these roles cannot be overstated. Understanding the importance of manufacturing roles is essential for appreciating the overall value proposition of the El Cajon facility as a significant player in the aerospace industry.

3. Quality Assurance Positions

Quality Assurance (QA) positions within the El Cajon aerospace facility represent a critical function ensuring adherence to stringent industry standards and regulatory requirements. These roles directly impact the safety, reliability, and performance of aerospace components and systems manufactured at the facility. The presence of robust QA procedures is essential for maintaining customer confidence and complying with international aviation regulations, such as those enforced by the Federal Aviation Administration (FAA) and other governing bodies. For instance, a QA inspector might meticulously examine turbine blades for microscopic imperfections or verify that composite materials meet specified strength and weight criteria. These actions directly influence the integrity of the final product.

The practical significance of QA positions extends beyond mere inspection. QA professionals are actively involved in developing and implementing quality control processes, identifying potential risks, and implementing corrective actions. This involves collaborating with engineering and manufacturing teams to optimize production methods and prevent defects before they occur. Consider a scenario where a QA engineer analyzes manufacturing data to identify a trend of increasing surface roughness on machined components. By implementing process adjustments and refining tooling parameters, the engineer can proactively address the issue, preventing non-conforming parts from reaching downstream operations. Such proactive measures highlight the importance of QA in maintaining a culture of continuous improvement.

In summary, QA roles are indispensable to the success of the El Cajon aerospace facility. These professionals are responsible for upholding the highest standards of quality and safety, contributing to the overall reliability of aircraft and spacecraft. While maintaining rigorous quality control procedures can be challenging due to the complexity of aerospace manufacturing and the constant evolution of industry standards, the value of these roles in ensuring customer satisfaction and regulatory compliance cannot be overstated. The strength of the organization depends heavily on the competence and vigilance of its QA personnel.

4. Supply Chain Management

Effective supply chain management is a critical component supporting operations at the El Cajon aerospace facility. This encompasses the strategic oversight and coordination of all activities related to the sourcing, procurement, and delivery of materials and components necessary for manufacturing aerospace products. A robust supply chain ensures the timely availability of high-quality materials, minimizing production delays and maintaining operational efficiency. For instance, a reliable supplier network for specialized alloys or composite materials is essential for meeting production schedules and adhering to stringent aerospace quality standards. Disruptions in the supply chain, such as material shortages or transportation delays, can directly impact production output and delivery timelines, ultimately affecting the organization’s ability to meet customer demands.

The integration of advanced technologies, such as enterprise resource planning (ERP) systems and real-time tracking, plays a crucial role in optimizing supply chain performance at the El Cajon facility. These technologies enable proactive monitoring of inventory levels, streamlined communication with suppliers, and efficient management of logistics and transportation. For example, implementing a predictive analytics system can anticipate potential material shortages based on historical data and market trends, allowing procurement teams to proactively secure alternative sources and mitigate supply chain risks. Furthermore, effective supplier relationship management fosters collaboration and open communication, enabling the organization to negotiate favorable terms, ensure quality compliance, and build long-term partnerships.

In conclusion, supply chain management is an indispensable function that underpins the El Cajon aerospace facility’s ability to operate efficiently and competitively. By focusing on optimizing material flow, managing supplier relationships, and leveraging technology, the organization can minimize disruptions, reduce costs, and maintain a reliable supply of high-quality materials. The effectiveness of supply chain management directly influences the organization’s ability to meet customer demands, maintain its reputation, and sustain its position in the aerospace industry. Challenges associated with global logistics, geopolitical risks, and fluctuating material costs require a proactive and adaptable approach to supply chain management to ensure long-term success.

5. Skill Requirements

Proficiency in specific skill sets constitutes a fundamental determinant in securing and performing roles at the El Cajon aerospace facility. The technical demands of aerospace engineering and manufacturing necessitate a highly skilled workforce capable of meeting rigorous industry standards. A candidate’s skills directly influence their suitability for open positions and their subsequent contributions to the organization’s objectives.

- Technical Proficiency

Technical proficiency encompasses expertise in areas directly related to aerospace engineering and manufacturing processes. For example, engineers must possess strong knowledge of CAD software, finite element analysis, and materials science. Manufacturing personnel require proficiency in operating CNC machines, welding techniques, and composite layup procedures. These skills enable employees to design, analyze, and produce high-quality aerospace components. A deficiency in technical skills can hinder an employee’s ability to perform assigned tasks effectively, leading to reduced productivity and potential quality issues. An example of this skill in practice could be a mechanical engineer who uses CAD and FEA to validate designs for airplane wings. Aerospace quality assurance personnel use coordinate measuring machines and/or blue light scanners to validate the dimensional accuracy of production part.

- Problem-Solving Abilities

Problem-solving abilities are crucial for addressing challenges that arise during the design, manufacturing, and testing of aerospace components. Employees must be able to identify root causes of issues, develop effective solutions, and implement corrective actions. For instance, a manufacturing engineer might troubleshoot a recurring defect in a production process by analyzing data, identifying the source of the problem, and implementing process improvements. Strong problem-solving skills are essential for maintaining production efficiency, minimizing downtime, and ensuring product quality.

- Communication Skills

Effective communication skills are essential for collaboration and coordination across different teams and departments within the El Cajon aerospace facility. Engineers must be able to clearly communicate technical information to colleagues, suppliers, and customers. Manufacturing personnel must be able to follow instructions, provide feedback, and report issues effectively. Strong communication skills facilitate seamless teamwork, prevent misunderstandings, and ensure that projects are completed successfully. Strong communication skills with internal teams and outside customer teams in important in these “gkn aerospace el cajon jobs.”

- Adherence to Standards and Regulations

Aerospace manufacturing is subject to strict regulatory requirements and industry standards. Employees must demonstrate a thorough understanding of these requirements and adhere to them diligently. This includes following established procedures, documenting processes accurately, and ensuring that all products meet specified quality standards. Non-compliance with regulatory requirements can lead to serious consequences, including fines, production delays, and damage to the organization’s reputation.

These skill requirements are fundamental to the success of both individual employees and the El Cajon aerospace facility as a whole. By prioritizing the development and acquisition of these skills, prospective candidates can enhance their employment prospects and contribute to the organization’s continued growth and success. The El Cajon aerospace facility offers “gkn aerospace el cajon jobs” that rely on the specific skill mentioned above.

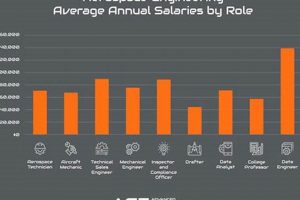

6. Competitive Compensation

The provision of competitive compensation packages serves as a crucial element in attracting and retaining qualified personnel for positions at the El Cajon aerospace facility. This facet directly influences the organization’s ability to secure skilled engineers, manufacturing technicians, and other professionals essential for maintaining operational efficiency and driving innovation. In instances where compensation lags behind industry standards, the organization may face difficulties in recruiting top talent, resulting in increased turnover rates and potential skill gaps. For example, if a design engineer receives a significantly higher salary offer from a competitor in a comparable location, the likelihood of employee attrition increases. Conversely, offering attractive salaries, benefits, and incentive programs can enhance employee morale, increase productivity, and foster a more engaged workforce. The presence of “gkn aerospace el cajon jobs” with competitive pay is often the initial attractant for prospective applications.

Moreover, the structure of compensation packages can significantly impact employee behavior and performance. Implementing performance-based bonuses or stock options can incentivize employees to achieve organizational goals and contribute to the company’s overall success. For example, awarding bonuses based on the successful completion of a major project or the achievement of specific quality targets can motivate teams to strive for excellence. Additionally, offering comprehensive benefits packages, including health insurance, retirement plans, and paid time off, can enhance employee well-being and reduce financial stress, leading to improved job satisfaction and increased retention rates. Therefore, the organization’s approach to compensation should align with its strategic objectives and reflect the value it places on its employees. The provision of “gkn aerospace el cajon jobs” is strongly related to appropriate compensation.

In summary, competitive compensation is intrinsically linked to the success of the El Cajon aerospace facility. By offering attractive and equitable compensation packages, the organization can attract and retain top talent, motivate employees to perform at their best, and foster a culture of excellence. Challenges associated with balancing compensation costs and maintaining profitability require a strategic and data-driven approach to compensation management. Ultimately, the organization’s ability to provide competitive compensation is a key factor in its ability to compete effectively in the aerospace industry and sustain long-term growth with “gkn aerospace el cajon jobs”.

7. Career Advancement

Opportunities for professional growth and development within the El Cajon aerospace facility are crucial considerations for prospective candidates. The availability of career advancement prospects directly influences employee satisfaction, retention rates, and the long-term success of both the individual and the organization.

- Internal Promotion Pathways

Clear pathways for internal promotion offer employees the opportunity to advance within the organization based on performance, experience, and demonstrated leadership potential. These pathways may involve transitioning from entry-level positions to supervisory roles, or from technical specializations to project management responsibilities. For example, a skilled manufacturing technician could progress to a team lead position, overseeing a group of technicians and ensuring production targets are met. The existence of well-defined internal promotion pathways provides employees with a tangible incentive to excel in their roles and contribute to the organization’s growth. Opportunities such as these are examples of “gkn aerospace el cajon jobs” benefits.

- Training and Development Programs

Access to comprehensive training and development programs equips employees with the skills and knowledge necessary to advance their careers. These programs may include technical training, leadership development courses, and opportunities for professional certifications. For instance, an engineer might participate in a specialized training program focused on advanced materials or finite element analysis, enhancing their expertise and enabling them to take on more complex projects. Investment in employee training and development demonstrates the organization’s commitment to fostering a skilled and adaptable workforce. By participating in these programs, applicants can enhance their chances of future “gkn aerospace el cajon jobs”.

- Mentorship Opportunities

Mentorship programs connect less experienced employees with seasoned professionals who can provide guidance, support, and career advice. Mentors can share their knowledge, insights, and experiences, helping mentees navigate career challenges and develop essential leadership skills. For example, a junior engineer might be paired with a senior engineer who can provide guidance on project management, technical problem-solving, and career planning. Mentorship programs foster a culture of learning and collaboration, accelerating employee growth and development.

- Cross-Functional Opportunities

Opportunities to work on cross-functional projects or rotate through different departments can broaden employees’ skill sets and provide them with a more comprehensive understanding of the organization’s operations. This exposure can be invaluable for employees seeking to advance into leadership roles or take on new challenges. For instance, an engineer might have the opportunity to work on a project that involves collaboration with manufacturing, quality assurance, and supply chain teams, providing them with a holistic perspective on the product development process.

The presence of robust career advancement opportunities is a key factor in attracting and retaining talent at the El Cajon aerospace facility. Employees who perceive a clear path for professional growth and development are more likely to be engaged, motivated, and committed to the organization’s success. Therefore, prioritizing career advancement initiatives is essential for fostering a high-performing workforce and ensuring the long-term viability of the organization and the ability to fulfill requirements of all “gkn aerospace el cajon jobs”.

Frequently Asked Questions Regarding Employment Opportunities at the El Cajon Facility

The following addresses common inquiries from prospective candidates regarding career possibilities at the specified aerospace manufacturing location. This information aims to clarify key aspects of employment and application procedures.

Question 1: What types of roles are typically available at the El Cajon facility?

The facility generally offers positions spanning engineering, manufacturing, quality assurance, supply chain management, and administrative functions. Specific openings vary depending on business needs and current projects.

Question 2: What are the minimum qualifications for engineering positions?

Engineering roles generally require a bachelor’s degree in a relevant field, such as aerospace, mechanical, or materials engineering. Specific positions may necessitate advanced degrees or specialized certifications. A strong understanding of CAD software and engineering principles is typically expected.

Question 3: What kind of experience is required for manufacturing roles?

Experience requirements for manufacturing positions vary depending on the specific role. Entry-level positions may require a high school diploma or equivalent, while more specialized roles may necessitate technical certifications or prior experience in aerospace manufacturing.

Question 4: How does one apply for a position at the El Cajon facility?

Interested candidates are advised to visit the company’s career website to view current job openings and submit applications online. Application materials typically include a resume and cover letter.

Question 5: What is the company’s policy on employee benefits?

The company generally offers a comprehensive benefits package, including health insurance, retirement plans, paid time off, and other employee perks. Specific benefits may vary depending on the position and employment status.

Question 6: Does the company offer opportunities for career advancement?

The company is committed to providing opportunities for employee growth and development. This may include internal promotion pathways, training programs, mentorship opportunities, and cross-functional project assignments.

This FAQ section has addressed key areas of concern for potential candidates. Further information can be obtained by visiting the company website or contacting the human resources department directly. These “gkn aerospace el cajon jobs” can bring great success.

The following section will provide a brief summary of this overview.

Conclusion

This overview has explored diverse facets related to career opportunities. Key areas examined include engineering specialties, manufacturing roles, quality assurance positions, and supply chain management, each presenting unique skill requirements and pathways for advancement. The importance of competitive compensation packages and robust training programs to attract and retain qualified personnel has also been emphasized.

The potential for skilled individuals to contribute to the aerospace sector within the El Cajon facility is substantial. Prospective candidates are encouraged to thoroughly research current openings and tailor their applications to align with the specific needs of this organization. The sustained growth and innovation within the aerospace industry suggest continued demand for qualified professionals at this location.