Opportunities within the aerospace sector focusing on revitalizing and upgrading existing aircraft and systems represent a significant segment of the industry. These positions involve roles in maintenance, repair, and overhaul (MRO) services, component upgrades, and life extension programs for aircraft. A technician specializing in avionics upgrades on older aircraft models exemplifies such a role.

This facet of the aerospace industry offers considerable economic advantages by extending the operational lifespan of existing assets, thus reducing the need for immediate replacement with newer, more costly alternatives. This can be particularly beneficial in contexts where budgets are constrained or when proven technology remains reliable. Historically, such efforts have been crucial in maintaining air fleets during periods of rapid technological change or economic downturns.

The following discussion will delve into specific aspects related to securing employment in this area, encompassing required skill sets, potential career paths, and the overall outlook for this dynamic segment of the aerospace employment landscape.

Strategies for Pursuing Opportunities

The following guidelines provide a structured approach to identifying and securing employment focused on extending the life and enhancing the performance of existing aerospace assets.

Tip 1: Develop Specialized Expertise: Cultivate proficiency in areas such as avionics retrofitting, structural repair, or engine overhauls. Certification in specific aircraft types or systems provides a competitive advantage. For example, experience with Boeing 737 classic airframes is highly valuable.

Tip 2: Target MRO Organizations: Focus on companies specializing in Maintenance, Repair, and Overhaul (MRO) services. These organizations are actively involved in upgrade and refurbishment programs. Examples include ST Engineering Aerospace, and Lufthansa Technik.

Tip 3: Emphasize Experience with Legacy Systems: Highlight experience working with older aircraft models and their corresponding systems. Familiarity with analog instrumentation, older engine control systems, and structural repair techniques relevant to aging aircraft is highly sought after.

Tip 4: Obtain Relevant Certifications: Acquire certifications such as FAA Airframe and Powerplant (A&P) licenses or equivalent credentials. These certifications demonstrate a commitment to professional standards and compliance with industry regulations.

Tip 5: Network within the Industry: Attend industry conferences and trade shows to connect with professionals in the MRO sector. Networking can lead to valuable insights into current market demands and unadvertised employment opportunities.

Tip 6: Tailor Resumes and Cover Letters: Customize application materials to emphasize skills and experience relevant to the specific requirements of each role. Highlight accomplishments related to cost savings, efficiency improvements, and adherence to safety standards.

Adhering to these recommendations will significantly enhance an individual’s prospects in this specialized employment field. Emphasis on practical skills, relevant certifications, and targeted networking are crucial for success.

The subsequent sections will provide a detailed analysis of the long-term career prospects and evolving demands within this segment of the aerospace industry.

1. Skills Enhancement

Skills enhancement forms a foundational element for professionals engaged in extending the operational life and improving the performance of existing aerospace systems. The correlation stems from the continuous evolution of technology and the imperative to maintain the reliability and safety of aging aircraft. Without ongoing skills development, personnel are unable to effectively address the integration of modern avionics, updated structural components, or advanced engine management systems into legacy platforms. A technician, for instance, who receives training on the latest composite repair techniques is better equipped to address corrosion issues on older aircraft structures, thereby extending the aircraft’s lifespan and ensuring its continued airworthiness.

The practical significance of skills enhancement manifests in several ways. Firstly, it ensures compliance with evolving regulatory standards governing aircraft maintenance and operation. Secondly, it enables the implementation of cost-effective solutions for extending the operational life of aircraft, reducing the need for immediate fleet replacement. For example, an engineer proficient in reverse engineering techniques can develop replacement parts for obsolete systems, thereby avoiding costly redesign efforts. Thirdly, it enhances the efficiency and effectiveness of maintenance operations, minimizing downtime and maximizing aircraft availability. Maintenance personnel trained in advanced diagnostic techniques can quickly identify and resolve system malfunctions, preventing costly delays and improving operational efficiency.

In summary, continuous skills enhancement is not merely an option but a necessity for individuals involved in the revitalization and upgrade of existing aerospace assets. This commitment to lifelong learning addresses the challenges associated with maintaining aging fleets, ensuring compliance with regulatory requirements, and optimizing operational efficiency. Failure to invest in skills development can lead to decreased operational effectiveness, increased safety risks, and ultimately, a diminished ability to compete in the dynamic aerospace maintenance and upgrade market.

2. MRO Specialization

Maintenance, Repair, and Overhaul (MRO) specialization forms a cornerstone of opportunities focused on extending the operational life of existing aerospace assets. MRO organizations are the primary employers for technicians, engineers, and managers engaged in upgrading, refurbishing, and maintaining aircraft fleets. Specialization within MRO, such as expertise in specific aircraft types, avionics systems, or structural repairs, directly correlates with enhanced career prospects. For instance, an MRO specializing in the maintenance of CFM56 engines, commonly used on Boeing 737 and Airbus A320 aircraft, creates a demand for technicians trained in this specific engine type. This targeted expertise elevates the technician’s value to the organization and increases job security.

The practical application of MRO specialization manifests in various areas. Technicians with specialized skills can command higher salaries and access more senior roles within MRO companies. Engineering expertise focused on component obsolescence mitigation within MRO settings is crucial for maintaining operational readiness of older aircraft. Specialized MRO services focusing on cabin refurbishment and passenger comfort upgrades enhance the value proposition of airlines operating older fleets. The economic impact of MRO specialization is significant, as it enables airlines and other aircraft operators to extend the lifespan of their assets, deferring the need for costly fleet replacements.

In summary, MRO specialization is inextricably linked to the continued viability and expansion of employment opportunities related to extending the life of aerospace assets. Concentrated expertise in specific MRO disciplines provides a competitive edge for both individuals and organizations. The ability of MRO organizations to adapt to changing technological landscapes and evolving customer demands dictates their long-term success and sustains employment opportunities within this crucial segment of the aerospace industry. Challenges remain in attracting and retaining skilled personnel within MRO fields, emphasizing the need for ongoing training and development initiatives.

3. Legacy Systems

The prevalence of legacy systems in aviation is a primary driver for many opportunities focused on upgrades and life extension. Legacy systems, in this context, refer to outdated or obsolete avionics, mechanical components, and software present in older aircraft models. The continued operation of these aircraft necessitates specialized knowledge and skills for maintenance, repair, and modernization. A significant portion of engineering and technician roles centers on adapting and integrating modern technology with these established systems, ensuring compliance with evolving safety regulations and operational efficiency standards. The obsolescence of specific components often requires innovative solutions such as reverse engineering, custom fabrication, and the development of alternative replacement parts. These activities generate employment in design, manufacturing, and testing, directly supporting the continued airworthiness of older aircraft. Airlines operating aging fleets allocate resources to upgrade programs designed to enhance reliability and extend the operational life of legacy systems, creating a demand for qualified professionals.

Understanding legacy systems is paramount for those seeking employment in this area. Expertise in troubleshooting, diagnostics, and repair of analog and early digital systems is highly valued. For example, an avionics technician capable of maintaining and calibrating inertial navigation systems (INS) found in older Boeing 727 or 737 models possesses a valuable skill set. Similarly, engineers with proficiency in retrofitting older aircraft with modern flight management systems (FMS) or enhanced ground proximity warning systems (EGPWS) are in high demand. The integration of modern communication and navigation equipment into older airframes requires a thorough understanding of both legacy and contemporary technologies. This creates opportunities for individuals with cross-disciplinary skills who can bridge the gap between outdated systems and modern requirements. Furthermore, the documentation associated with legacy systems, often in the form of paper manuals and schematics, necessitates expertise in interpreting and translating this information into digital formats for modern maintenance management systems.

In conclusion, the continued reliance on legacy systems within the aviation industry is a significant source of employment and drives the demand for specialized skills and knowledge. Proficiency in troubleshooting, repairing, and upgrading these systems is crucial for maintaining the airworthiness and operational efficiency of aging aircraft fleets. The challenge lies in attracting and training the next generation of aviation professionals to acquire the necessary expertise in legacy technologies. Addressing this skills gap is essential for ensuring the continued safe and efficient operation of aircraft equipped with these systems and sustaining the opportunities focused on extending their lifespan.

4. Certifications Crucial

The presence and type of professional certifications are inextricably linked to employment opportunities focused on extending the life and upgrading existing aerospace assets. These credentials serve as standardized validation of competence and adherence to industry regulations, significantly impacting hiring decisions and career advancement.

- FAA Airframe and Powerplant (A&P) License

This certification, issued by the Federal Aviation Administration (FAA), is a fundamental requirement for technicians performing maintenance, repairs, and alterations on aircraft. An A&P license signifies a technician’s understanding of aircraft systems, airworthiness standards, and regulatory requirements. For roles involving hands-on maintenance or modification of aircraft structures or engines, possession of an A&P license is often non-negotiable. MRO facilities commonly stipulate A&P certification as a minimum qualification for technician positions.

- Avionics Certifications (e.g., FCC General Radiotelephone Operator License)

Avionics certifications validate expertise in the installation, maintenance, and repair of aircraft electronic systems, including communication, navigation, and flight control equipment. The FCC General Radiotelephone Operator License, for example, authorizes individuals to work on radio communication equipment aboard aircraft. These certifications demonstrate specialized knowledge and skills necessary for maintaining the complex electronic systems found in both legacy and modern aircraft. Opportunities focused on avionics upgrades and retrofits frequently require specific avionics certifications relevant to the equipment being installed or maintained.

- NDT (Non-Destructive Testing) Certifications (e.g., ASNT Level II or III)

Non-destructive testing (NDT) certifications demonstrate proficiency in inspecting aircraft components and structures for defects without causing damage. Methods such as ultrasonic testing, radiographic inspection, and dye penetrant inspection are commonly used to identify cracks, corrosion, and other flaws. ASNT (American Society for Nondestructive Testing) Level II or III certifications signify a high level of competence in performing and interpreting NDT inspections. Given the age of many aircraft undergoing life extension programs, NDT certifications are critical for ensuring structural integrity and identifying potential safety hazards.

- Manufacturer-Specific Training and Certifications

Aircraft and component manufacturers often provide specialized training courses and certifications related to their specific products. Completion of these programs demonstrates in-depth knowledge of particular aircraft models, engines, or avionics systems. For example, Boeing offers training courses on the maintenance of its aircraft, while Pratt & Whitney provides certifications for technicians working on its engines. Possessing manufacturer-specific certifications can significantly enhance an individual’s competitiveness for positions involving maintenance or upgrades on aircraft using that manufacturer’s equipment.

The acquisition and maintenance of relevant certifications are essential for professionals seeking to establish or advance their careers focused on sustaining and improving existing aerospace assets. These credentials not only validate technical competence but also demonstrate a commitment to professional development and adherence to industry best practices. Employers prioritize candidates with recognized certifications as a means of mitigating risk and ensuring the quality and safety of their operations.

5. Industry Networking

Industry networking represents a critical element for professionals seeking or holding employment within the field of upgrading and extending the life of existing aerospace assets. This proactive engagement facilitates access to information, opportunities, and collaborative partnerships that are often inaccessible through conventional channels. The value lies in building relationships and exchanging knowledge within the specialized ecosystem of aerospace maintenance, repair, and overhaul (MRO) and related services.

- Access to Unadvertised Opportunities

Many positions within the aerospace industry, particularly those requiring specialized expertise in legacy systems or emerging upgrade technologies, are filled through referrals and personal connections. Industry events, conferences, and workshops provide a platform for direct interaction with hiring managers and technical leaders. For example, a maintenance technician attending an industry trade show might learn of an upcoming avionics retrofit project at a regional airline, leading to a direct introduction and potential employment. The implicit understanding of industry needs and the demonstration of active engagement significantly enhance candidacy.

- Knowledge Acquisition and Skill Development

Networking events serve as forums for disseminating technical knowledge, sharing best practices, and discussing emerging trends. Attendance at industry conferences and technical seminars provides opportunities to learn about new technologies, maintenance procedures, and regulatory changes. A structural engineer, for instance, might attend a presentation on advanced composite repair techniques, gaining insights that can be directly applied to life extension programs for aging aircraft. This continuous learning is essential for maintaining relevance and competitiveness in a rapidly evolving technical field.

- Partnership Development and Collaboration

Collaboration among aerospace companies, research institutions, and regulatory agencies is crucial for driving innovation and addressing challenges in the maintenance and upgrade of existing aircraft. Industry networking facilitates the formation of strategic partnerships and collaborative projects. For example, an MRO facility might partner with a university research group to develop more efficient corrosion prevention methods for aging aircraft structures. These collaborations can lead to the development of new technologies, improved maintenance procedures, and ultimately, enhanced employment opportunities within the sector.

- Market Intelligence and Competitive Advantage

Active engagement within industry networks provides access to valuable market intelligence, including information about competitor activities, emerging market trends, and customer needs. This knowledge enables organizations and individuals to make informed decisions and maintain a competitive advantage. For example, a business development manager at an MRO company might attend an industry conference to gather insights on airlines’ fleet modernization plans, allowing the company to proactively tailor its service offerings to meet evolving customer demands. This strategic awareness is critical for sustaining growth and securing long-term employment opportunities.

These facets of industry networking collectively contribute to a dynamic ecosystem that fosters innovation, facilitates knowledge exchange, and drives career advancement within the context of upgrading and extending the life of aerospace assets. The cultivation of relationships and the proactive pursuit of information are essential for navigating the complexities of this specialized sector and capitalizing on emerging opportunities.

Frequently Asked Questions Regarding Opportunities Focused on Extending the Life and Upgrading Existing Aerospace Assets

The following section addresses common inquiries related to pursuing employment focused on upgrading and maintaining existing aircraft and systems. These answers aim to provide clarity and guidance for prospective candidates.

Question 1: What specific skills are most valuable for securing positions in this sector?

Proficiency in avionics retrofitting, structural repair, engine overhauls, and knowledge of legacy systems are highly valued. Certification on specific aircraft types or systems provides a competitive advantage. Practical experience is favored over theoretical knowledge.

Question 2: Which organizations are most likely to offer relevant employment?

Maintenance, Repair, and Overhaul (MRO) facilities are primary sources of employment. Aerospace companies involved in component manufacturing, aircraft modifications, and life extension programs also offer opportunities.

Question 3: How important is prior experience with older aircraft models?

Experience working with older aircraft models and their associated systems is highly advantageous. Familiarity with analog instrumentation, older engine control systems, and relevant structural repair techniques is essential.

Question 4: What certifications are considered essential for advancement?

FAA Airframe and Powerplant (A&P) licenses, avionics certifications, and Non-Destructive Testing (NDT) certifications are highly regarded. Manufacturer-specific training and certifications related to specific aircraft models are also beneficial.

Question 5: How can networking contribute to securing employment in this field?

Attending industry conferences, trade shows, and workshops provides opportunities to connect with professionals and learn about unadvertised opportunities. Building relationships with individuals working in MRO facilities and aerospace companies is crucial.

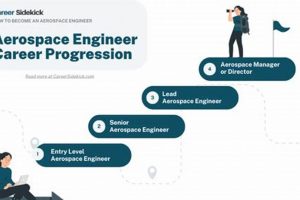

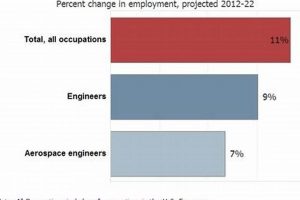

Question 6: What are the long-term career prospects within this segment of the aerospace industry?

Long-term prospects are generally positive, given the increasing need to maintain and upgrade aging aircraft fleets. Continuous technological advancements and evolving regulatory requirements necessitate ongoing investment in skills development and training.

In summary, a combination of specialized skills, relevant certifications, targeted networking, and a commitment to continuous learning are crucial for success. Opportunities exist for individuals with the expertise to maintain and upgrade existing aerospace assets.

The subsequent section will present a concluding perspective, underscoring the continuing relevance and significance of the aviation sector.

Concluding Perspective

This discussion has illuminated crucial facets related to employment focused on revitalizing existing aerospace assets. Key takeaways include the necessity for specialized skills, the importance of recognized certifications, and the value of industry engagement. Sustained emphasis on legacy systems knowledge and adaptability to evolving technological landscapes remains paramount for professionals seeking advancement in this domain.

The enduring relevance of extending the operational life of aerospace assets warrants continued investment in training, technology development, and strategic partnerships. Opportunities within this sphere will persist, demanding a highly skilled workforce prepared to address the challenges of maintaining and upgrading existing aircraft fleets while ensuring safety and operational efficiency. Proactive preparation and targeted skill development are essential for success in this continuously evolving field.