A prominent figure in space exploration and technology innovation, he significantly impacted the aerospace sector through his entrepreneurial ventures. His companies have developed reusable rocket technology, advanced spacecraft, and satellite internet constellations. This individual’s approach integrates ambitious engineering goals with a focus on commercial viability, challenging conventional aerospace industry norms.

His work’s importance lies in its potential to drastically reduce the cost of space travel, making it more accessible for research, commercial endeavors, and eventual interplanetary colonization. The historical context involves a shift from government-led space programs to increasing private sector involvement, with his contributions playing a central role in this transition. His influence extends to inspiring a new generation of engineers and entrepreneurs focused on space-related technologies.

This overview serves as an introduction to understanding specific accomplishments in rocket design, the development of sustainable launch systems, and the overall impact on the future of space exploration and its terrestrial applications. Further exploration will delve into the details of these innovations and their broader societal and economic implications.

Guidance Derived from an Innovator in Aerospace Engineering

The following principles reflect an approach to problem-solving and innovation demonstrated through impactful contributions to the aerospace field. These guidelines emphasize ambitious goals, practical engineering solutions, and a disruptive approach to established industries.

Tip 1: Embrace First Principles Thinking: Dissect complex problems into their fundamental truths. Avoid assumptions and build solutions from the ground up. For example, consider the core components required for rocket propulsion rather than relying solely on existing rocket designs.

Tip 2: Pursue Ambitious, Seemingly Impossible Goals: Set targets that stretch capabilities and inspire innovation. The pursuit of Mars colonization, while challenging, drives advancements in related technologies applicable to Earth.

Tip 3: Integrate Vertical Integration: Control critical aspects of the supply chain to optimize cost and performance. Manufacturing key components in-house can lead to significant improvements in both areas.

Tip 4: Iterate Rapidly and Learn from Failures: Embrace a culture of experimentation and view failures as learning opportunities. Constant testing and refinement of designs are essential for rapid progress.

Tip 5: Prioritize Automation and Efficiency: Automate processes wherever possible to reduce costs and increase throughput. Robotics and artificial intelligence can optimize manufacturing and operational processes.

Tip 6: Foster a Culture of Innovation and Meritocracy: Empower talented individuals and reward performance. Create an environment where unconventional ideas are welcomed and rigorously tested.

Tip 7: Focus on Sustainable Solutions: Engineer systems with long-term viability in mind. Reusable rockets and efficient energy systems contribute to a more sustainable future in space and on Earth.

Adopting these principles encourages a mindset of continuous improvement, bold innovation, and a commitment to achieving ambitious goals. They can be applied across various engineering disciplines and organizational contexts to drive progress.

The application of these guidelines can facilitate the development of cutting-edge technologies and solutions in any challenging field.

1. Reusable Rocketry

The development and implementation of reusable rocket technology is a defining achievement associated with this individual and his aerospace endeavors. Prior to this innovation, rockets were largely expendable, with each launch requiring the construction of a new vehicle. This resulted in high costs and limited accessibility to space. The core principle of reusability focuses on recovering the primary stages of a rocket after launch, refurbishing them, and using them again for subsequent missions. This fundamentally alters the economics of spaceflight, reducing the cost per launch and enabling more frequent missions. The Falcon 9, a prominent example, demonstrates this concept with its ability to return the first stage to either land on a designated landing zone or on a drone ship at sea.

The practical significance of reusable rocketry extends beyond mere cost savings. It allows for a higher launch cadence, enabling faster deployment of satellite constellations, more frequent scientific missions, and increased opportunities for commercial activities in space. The development of this technology required overcoming significant engineering challenges, including precise landing maneuvers, thermal protection systems for reentry, and efficient refurbishment processes. Furthermore, the success of reusable rockets has encouraged other aerospace companies to pursue similar technologies, fostering competition and innovation within the industry. This shift towards reusability also necessitates a change in operational paradigms, including streamlined launch procedures and optimized logistics for rocket recovery and reuse.

In summary, the link between reusable rocketry and this aerospace figure is pivotal to understanding the current state and future direction of space exploration. The achievement of reusable launch systems has demonstrably reduced the cost of access to space, increased launch frequency, and spurred further innovation across the industry. While challenges remain in optimizing reusability and ensuring the long-term reliability of reused components, the foundational work already accomplished has transformed the landscape of spaceflight and paved the way for more ambitious projects in the future.

2. Vertical Integration

Vertical integration is a core strategy employed by aerospace ventures associated with a specific entrepreneurial figure. This approach involves bringing multiple stages of the supply chain under the control of a single company, rather than outsourcing to external suppliers. This strategy affects production costs, quality control, and the pace of innovation.

- In-House Manufacturing of Rocket Components

Instead of purchasing engines, avionics, or other critical parts from external vendors, these components are manufactured internally. This reduces reliance on outside suppliers, potentially lowering costs and providing greater control over the design and specifications. The development of the Raptor engine is an example, as it was conceived and produced within the company, enabling specific performance targets to be met that may not have been available from existing suppliers.

- Control over Materials and Supply Chains

Securing direct access to raw materials and controlling the supply chain from end to end allows for greater predictability and reduced vulnerability to external market fluctuations. The acquisition of companies specializing in composite materials or metal processing can streamline the manufacturing process and ensure a consistent supply of high-quality materials. This control enables rapid response to design changes and mitigates the risk of supply chain disruptions.

- Software and Avionics Development

Beyond hardware, vertical integration extends to the development of proprietary software and avionics systems. Developing flight control software, guidance systems, and other critical software in-house provides a competitive advantage. It also allows for the creation of highly customized solutions tailored to the specific needs of the launch vehicles and spacecraft being developed. This integrated approach ensures seamless interaction between hardware and software components, optimizing performance and reliability.

- Launch Operations and Infrastructure

Owning and operating launch facilities and supporting infrastructure is an element of vertical integration. This reduces dependence on external launch providers and provides greater control over launch schedules and operations. Investment in private launch sites and ground support equipment ensures the ability to conduct frequent launches and rapidly iterate on launch procedures. The integration of launch operations with manufacturing and development activities accelerates the overall pace of innovation.

The implementation of vertical integration, as demonstrated in certain aerospace companies, necessitates a significant upfront investment in manufacturing capabilities, skilled personnel, and infrastructure. This strategy can, however, lead to long-term cost savings, improved quality control, and a faster rate of innovation compared to relying on external suppliers. The approach allows for better management of intellectual property and strengthens the company’s competitive position within the aerospace industry. The effectiveness of this strategy is linked to the ability to efficiently manage these integrated operations and maintain technological leadership across various disciplines.

3. Ambitious Goals

The relationship between aggressive objectives and specific aerospace endeavors is characterized by a synergistic effect wherein challenging targets function as a catalyst for technological advancement. These goals, such as Mars colonization, fundamentally alter the trajectory of engineering efforts. The pursuit of such a target necessitates breakthroughs in propulsion systems, life support mechanisms, and autonomous navigation capabilities, innovations that would likely not occur under less demanding circumstances. As an example, the development of reusable rocket technology was arguably accelerated by the long-term objective of establishing a permanent presence on another planet, driving the need for cost-effective space transportation. The practical significance lies in understanding that these aspirational visions are not merely aspirational; they serve as concrete drivers for technological innovation with direct applications to both space exploration and terrestrial technologies.

Further, the influence of these objectives extends beyond purely technical domains, shaping organizational structures, risk management strategies, and investment priorities. The implementation of an ambitious agenda necessitates a highly agile and adaptive organizational culture capable of rapidly prototyping, testing, and iterating on new designs. Risk assessment frameworks must accommodate a higher tolerance for failure, understanding that setbacks are inevitable in the pursuit of fundamentally novel solutions. Resource allocation decisions are guided by the overarching objective, with investment concentrated in areas critical for achieving the long-term vision. For instance, the aggressive timelines associated with developing fully self-landing rockets required significant investment in advanced sensor systems, control algorithms, and precision guidance systems.

In conclusion, the correlation between these daring targets and progress within the aerospace sector is profound. These aims act as an impetus for technological innovation, influencing the allocation of resources, and fostering a culture conducive to rapid experimentation. While the challenges associated with such objectives are undeniable, the benefits in terms of technological advancement and long-term strategic positioning are significant. This understanding underscores the importance of maintaining a balance between realistic constraints and aspirational visions in guiding the future of aerospace engineering.

4. Rapid Iteration

Rapid iteration, a design and development methodology emphasizing frequent testing and revision cycles, is intrinsically linked to the approach of that engineer and his aerospace ventures. The implementation of this methodology involves generating successive versions of a design or product, subjecting each iteration to rigorous testing, and incorporating the resulting data to inform subsequent refinements. This cyclical process allows for the rapid identification and resolution of design flaws, optimization of performance, and adaptation to evolving requirements. A significant factor in the aerospace context involves the ability to accelerate the development of novel technologies and systems, as it mitigates the risks associated with relying on single, protracted design efforts. Consider the development of the Falcon 9 rocket, where iterative testing and design modifications led to substantial improvements in reliability and performance over time.

The application of rapid iteration extends beyond component-level design to encompass operational procedures and strategic decision-making. Launch sequences, for example, are continually refined based on data collected from previous missions, leading to improved efficiency and safety. Software updates for flight control systems are similarly deployed in an iterative manner, allowing for immediate response to anomalies or emerging threats. This approach also facilitates rapid adaptation to changing market conditions and competitive pressures. The development of Starlink, a satellite internet constellation, exemplifies this adaptability, as the design and deployment strategy have been iteratively adjusted in response to evolving customer needs and technological advancements. This iterative model requires a flexible organizational structure that encourages communication and collaboration across different engineering disciplines. Real-world applications also encompass the early and regular solicitation of feedback from customers and end-users, ensuring that products are closely aligned with market demand.

In summary, the integration of rapid iteration is a defining characteristic associated with that figure’s approach to aerospace engineering. This methodology fosters a culture of continuous improvement, accelerates the pace of innovation, and allows for effective adaptation to dynamic environments. The key challenges involve managing the complexity of iterative processes, maintaining rigorous testing protocols, and effectively integrating feedback into subsequent design cycles. By embracing rapid iteration, the barriers to entry in the aerospace industry are lowered, and innovative solutions are delivered to the market faster. This underscores the crucial role that this methodology plays in shaping the future of space exploration and commercialization.

5. Cost Reduction

The emphasis on reducing the cost of space access is a central tenet associated with this individuals aerospace engineering endeavors. This focus stems from the understanding that high launch costs have historically been a major impediment to widespread space exploration and commercialization. Reducing these costs is not merely an economic objective; it is a fundamental enabler for more ambitious projects, such as lunar bases and interplanetary travel. The pursuit of this objective has driven innovation in areas such as reusable rocket technology, streamlined manufacturing processes, and efficient operational procedures. The practical significance of this approach is evident in the reduced cost per kilogram to orbit achieved by Falcon rockets, which has significantly altered the competitive landscape of the launch services market.

Furthermore, the drive for cost reduction influences the engineering design process at every level. Components are selected and designed with a focus on minimizing both manufacturing costs and operational expenses. Materials are chosen not only for their performance characteristics but also for their availability and affordability. Manufacturing processes are optimized to reduce labor costs and improve production efficiency. For example, the use of additive manufacturing (3D printing) for certain rocket components has enabled the creation of complex geometries at lower costs than traditional manufacturing methods. The streamlining of launch operations, including automation and standardized procedures, further contributes to reducing overall costs. This comprehensive approach to cost management permeates all aspects of the organization, from engineering design to supply chain management.

In conclusion, cost reduction is an integral element associated with this aerospace figure’s approach. It functions not merely as a financial goal, but as a catalyst for innovation and a means of unlocking new possibilities in space exploration and commerce. While challenges remain in further optimizing efficiency and reducing costs, the progress made to date has already had a transformative impact on the aerospace industry, and the continued pursuit of this objective is likely to be a key driver of future advancements.

6. Commercialization

The intersection of commercialization and this individual’s endeavors represents a fundamental shift in the aerospace industry. Historically, space exploration was largely driven by government initiatives. His companies have actively pursued commercial applications of space technology. This is evident in the development of reusable launch systems and satellite internet services, both aimed at generating revenue and creating a sustainable business model. The commercialization of space, therefore, is not merely a byproduct but rather a central tenet of this approach, influencing engineering decisions and business strategies. The availability of more affordable launch services has opened opportunities for private companies and research institutions to access space, fostering innovation and economic growth.

The practical applications of this commercial focus extend to several areas. Satellite internet constellations aim to provide global internet access, particularly to underserved areas. Commercial crew programs enable private companies to transport astronauts to the International Space Station, reducing reliance on government-funded missions. The development of privately owned launch facilities supports both commercial and government launches, creating a more competitive market. The pursuit of Mars colonization, while a long-term goal, also involves commercial considerations, such as developing technologies that can be marketed and sold in the near term. These activities demonstrate a commitment to creating a self-sustaining space economy.

In summary, commercialization is an indispensable element associated with this aerospace figure’s approach. It has driven innovation in launch technology, satellite services, and other areas, ultimately lowering the cost of space access and expanding opportunities for commercial entities. This focus, however, is not without its challenges, including the need to balance commercial interests with safety and regulatory concerns. Nonetheless, the commercialization of space represents a paradigm shift, and this figure has been a significant factor in this transformation, contributing to the growth of a vibrant space economy.

Frequently Asked Questions

This section addresses common inquiries regarding the aerospace-related activities and their impact on the industry.

Question 1: What is the significance of reusable rocket technology?

Reusable rocket technology drastically reduces the cost of space access by allowing the primary stages of rockets to be recovered and reused multiple times. This innovation lowers the economic barrier to space exploration and commercialization.

Question 2: How does vertical integration contribute to success in aerospace?

Vertical integration allows for greater control over the supply chain, leading to improved quality control, reduced costs, and a faster pace of innovation by bringing component manufacturing and other critical processes in-house.

Question 3: What role do ambitious goals play in driving technological advancement?

Ambitious goals, such as Mars colonization, serve as catalysts for technological innovation by requiring breakthroughs in areas such as propulsion, life support, and autonomous navigation.

Question 4: How does rapid iteration contribute to the development process?

Rapid iteration accelerates the development process by allowing for frequent testing and refinement of designs, leading to faster identification and resolution of design flaws.

Question 5: Why is cost reduction considered a crucial aspect of aerospace engineering?

Cost reduction is crucial for enabling wider access to space, fostering commercial opportunities, and facilitating more ambitious exploration endeavors.

Question 6: What is the importance of commercialization in space exploration?

Commercialization helps create a sustainable space economy by generating revenue through services such as satellite internet and commercial crew programs, which reduces reliance on government funding.

In conclusion, understanding these core principles provides insight into the dynamics shaping the future of space exploration.

The subsequent section will explore specific technological advancements and their broader impact.

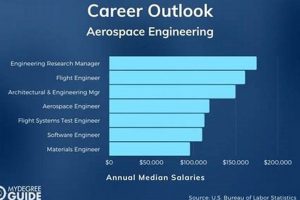

Aerospace Engineering

The preceding analysis has explored key aspects of the aerospace engineer’s influence, including reusable rocketry, vertical integration, ambitious goals, rapid iteration, cost reduction, and commercialization. These elements collectively represent a paradigm shift in how space exploration and exploitation are approached. The confluence of technical innovation and entrepreneurial strategy has redefined the industry’s trajectory.

Sustained progress in aerospace hinges upon continued focus on these core principles. The future of space exploration, commercialization, and, ultimately, humanity’s reach beyond Earth, depends on a commitment to innovation, efficiency, and a willingness to challenge conventional boundaries. The advancements discussed provide a foundation for further development, and their implications will continue to shape the aerospace landscape for decades to come.