This entity functions as a private limited company specializing in the aerospace sector. The corporate structure indicates a specific type of business ownership with defined legal responsibilities and operational parameters within the aviation and space industries.

Such an organization plays a vital role in the advancement of aerospace technology through research, development, and potentially manufacturing. The benefits of its contributions can extend to improvements in aircraft efficiency, satellite technology, and overall aerospace innovation, influencing both commercial and defense applications, potentially having evolved from earlier technological initiatives or industry needs.

Subsequent sections will delve into specific aspects of its operations, exploring its role within the broader aerospace ecosystem and examining its impact on related markets.

Guidance for Aerospace System Development

The following points address critical considerations for entities involved in the creation and advancement of aerospace systems.

Tip 1: Prioritize Rigorous Testing Protocols: Comprehensive and multifaceted testing is paramount. This includes environmental testing, stress testing, and simulations that mirror real-world operating conditions, ensuring system resilience and safety.

Tip 2: Implement Stringent Quality Control Measures: Adherence to the highest quality standards throughout the manufacturing process is non-negotiable. This involves detailed inspections, material traceability, and process validation to minimize defects and ensure component reliability.

Tip 3: Foster Collaborative Partnerships: Strategic alliances with other organizations, research institutions, and suppliers can accelerate innovation and provide access to specialized expertise and resources. This fosters a robust ecosystem for system development.

Tip 4: Invest in Advanced Simulation and Modeling: Utilizing sophisticated simulation tools allows for the evaluation of system performance under various scenarios. This proactive approach helps identify potential design flaws and optimize system behavior before physical prototyping.

Tip 5: Maintain Continuous Monitoring and Data Analysis: Implementing systems for ongoing monitoring of system performance provides valuable data for identifying trends, predicting potential failures, and optimizing system operations throughout its lifecycle.

Tip 6: Focus on Regulatory Compliance: Strict adherence to all applicable regulatory standards and certifications is essential. This demonstrates a commitment to safety and ensures that the system meets the necessary legal and operational requirements.

Tip 7: Emphasize System Integration Expertise: Successfully integrating various components and subsystems into a cohesive whole is critical. This requires a deep understanding of system architecture and the ability to manage complex interdependencies.

Adherence to these guidelines can significantly contribute to the development of reliable, efficient, and safe aerospace systems, ensuring optimal performance and longevity.

Further exploration of specific applications and case studies will follow in subsequent sections.

1. Engineering Design

The engineering design process forms the bedrock of any successful aerospace endeavor, and its connection to this entity is pivotal. The effectiveness of its products and services is directly proportional to the robustness and ingenuity of its engineering design methodologies. Poor design choices can lead to catastrophic failures, whereas innovative designs contribute to improved performance, efficiency, and safety. For example, meticulously designed aircraft components can withstand extreme stress and temperature variations encountered during flight, thereby ensuring structural integrity.

Engineering design encompasses a broad spectrum of activities, including conceptualization, modeling, simulation, analysis, and prototyping. The practical application involves using advanced software tools to create detailed 3D models of aerospace components, followed by rigorous simulations to assess their performance under different operational conditions. These simulations can identify potential weaknesses or areas for optimization before physical prototypes are even constructed. Consider, for instance, the design of a new turbine blade for a jet engine. Engineers would use computational fluid dynamics (CFD) to simulate airflow around the blade and optimize its shape for maximum efficiency.

In summary, engineering design is not merely a component; it’s the driving force behind its ability to innovate and compete. Addressing the inherent challenges in aerospace design, such as weight reduction and enhanced durability, requires a continuous commitment to research, development, and the adoption of cutting-edge technologies. The success of this endeavor hinges on the effective integration of skilled engineers, advanced tools, and a rigorous design process.

2. Manufacturing Precision

Manufacturing precision constitutes a fundamental element in the operation of aerospace organizations. The stringent demands of the aerospace industry necessitate the production of components with minimal tolerances and exceptional reliability. This requirement stems from the extreme operating conditions encountered by aircraft and spacecraft, where even minor defects can lead to catastrophic failures. Within this context, meticulous fabrication and assembly processes are not merely desirable, but essential for ensuring safety and operational integrity. For example, the precise machining of turbine blades in a jet engine is critical for maintaining optimal engine performance and preventing potentially hazardous mechanical failures. Similarly, the accuracy in manufacturing the fuselage of an aircraft directly impacts its aerodynamic properties and structural integrity.

The commitment to manufacturing precision translates into significant capital investment in advanced machinery, skilled personnel, and rigorous quality control protocols. Examples include the utilization of Computer Numerical Control (CNC) machining, advanced welding techniques, and non-destructive testing methods. Consider the production of a landing gear assembly: each component must be manufactured to exact specifications, assembled with precise torque settings, and inspected thoroughly to ensure it can withstand the immense forces experienced during landing. The efficacy of these processes hinges on the expertise of manufacturing engineers and technicians who possess a deep understanding of materials science, manufacturing techniques, and quality assurance principles.

In summary, manufacturing precision is not just a technical requirement; it is a core value. The ability to consistently produce high-quality components that meet or exceed industry standards is a key differentiator. Moreover, adherence to stringent manufacturing practices reduces the risk of defects, minimizes downtime, and ultimately enhances the safety and reliability of aerospace systems. Ongoing investment in advanced manufacturing technologies and workforce training remains critical for maintaining a competitive edge and upholding the highest standards of performance and safety within the aerospace sector.

3. System Integration

System integration constitutes a critical process within the aerospace domain, and its effectiveness directly influences the operational success of entities such as aerospace organizations. The capacity to seamlessly combine disparate components, software, and subsystems into a unified, functional entity is paramount for achieving desired performance metrics. In aerospace applications, this may involve integrating navigation systems with flight control software, or combining sensor data with automated piloting systems. The success of such integration efforts directly impacts factors such as flight safety, fuel efficiency, and overall mission effectiveness. A poorly integrated system can lead to communication failures between components, creating potentially hazardous situations or preventing the system from functioning as intended. For example, if the communication link between a satellite’s attitude control system and its propulsion system is unreliable, the satellite may not be able to maintain its designated orbit, thereby compromising its operational purpose.

Effective system integration necessitates a comprehensive understanding of each individual component and its interfaces, as well as the ability to manage complex dependencies between them. This often involves the use of specialized engineering tools and methodologies, such as model-based systems engineering (MBSE), which provides a structured approach to system design, analysis, and integration. Furthermore, rigorous testing and validation are essential to ensure that the integrated system performs as expected under various operating conditions. For instance, the integration of avionics systems in a modern aircraft requires extensive simulation and flight testing to verify their compatibility and reliability across a wide range of flight scenarios. This may involve simulating various weather conditions, engine failures, and other potential anomalies to ensure the system can respond appropriately.

In conclusion, system integration is not merely a technical process; it is a strategic imperative that directly impacts operational capabilities. Successful integration projects contribute to enhanced performance, improved safety, and reduced operational costs. Ongoing advancements in systems engineering methodologies and the continued development of skilled integration specialists are essential for ensuring the continued progress and reliability of aerospace technologies. The challenges associated with integrating increasingly complex aerospace systems necessitate a commitment to best practices and a focus on interdisciplinary collaboration.

4. Quality Assurance

Quality Assurance (QA) functions as a critical pillar for aerospace entities. Within this context, the implementation of robust QA protocols is not merely a procedural requirement but a fundamental necessity for ensuring product safety, reliability, and regulatory compliance. The integration of QA methodologies with operational processes directly affects its ability to meet the stringent demands of the aerospace sector.

- Material Inspection and Traceability

Material inspection and traceability encompass the systematic examination and documentation of raw materials and components used in manufacturing. This process involves verifying that materials meet specified requirements, such as tensile strength, chemical composition, and dimensional accuracy. Each material is assigned a unique identifier, allowing it to be tracked throughout the production process. In the context of this entity, rigorous material inspection and traceability ensure that only certified and compliant materials are used in the fabrication of aerospace components, thereby minimizing the risk of defects or premature failures. For example, titanium alloys used in aircraft structures undergo meticulous testing to confirm their resistance to fatigue and corrosion.

- Process Control and Validation

Process control and validation involve the monitoring and verification of manufacturing processes to ensure they consistently produce components that meet predetermined specifications. Statistical process control (SPC) techniques are employed to track key process variables, such as temperature, pressure, and machining parameters. Validation procedures are implemented to confirm that the manufacturing process is capable of consistently producing acceptable results. In its setting, robust process control and validation protocols contribute to the repeatability and reliability of manufacturing operations. For example, the welding processes used to join aircraft fuselage sections are carefully monitored and validated to ensure the integrity of the weld joints.

- Non-Destructive Testing (NDT)

Non-destructive testing encompasses a range of techniques used to evaluate the integrity of materials and components without causing damage. Common NDT methods include ultrasonic testing, radiographic testing, and dye penetrant inspection. These techniques can detect internal flaws, surface cracks, and other defects that may compromise structural integrity. Application of NDT methodologies is crucial for verifying the quality and reliability of critical aerospace components, such as turbine blades, landing gear components, and composite structures. For example, radiographic testing is used to inspect weld joints in rocket engine nozzles to ensure they are free from porosity and other defects.

- Compliance and Certification

Compliance and certification refer to the adherence to industry standards, regulatory requirements, and customer specifications. Aerospace organizations are typically required to obtain certifications from regulatory agencies, such as the Federal Aviation Administration (FAA) or the European Aviation Safety Agency (EASA). These certifications demonstrate that the organization has implemented robust quality management systems and that its products meet the required safety and performance standards. By adhering to compliance and certification requirements, aerospace businesses can demonstrate their commitment to quality and safety. This might include ensuring that the manufacturing facility meets the requirements of AS9100, the aerospace quality management standard.

The interplay of these elements ensures that operations conform to the elevated benchmarks of performance and safety required in the aerospace domain. Continuous enhancement of quality assurance protocols is paramount for upholding and augmenting operational benchmarks, thereby bolstering overall competitiveness and safeguarding against potential operational hazards.

5. Regulatory Compliance

Regulatory compliance constitutes a non-negotiable aspect of operations within the aerospace sector. For an entity operating within this sphere, adherence to established regulations is paramount to ensuring safety, maintaining operational integrity, and mitigating potential legal liabilities. This compliance landscape encompasses a diverse array of national and international standards, certifications, and oversight mechanisms.

- Airworthiness Standards

Airworthiness standards dictate the design, manufacture, and maintenance requirements for aircraft to ensure safe operation. These standards are promulgated by regulatory bodies such as the Federal Aviation Administration (FAA) in the United States and the European Aviation Safety Agency (EASA) in Europe. An entity engaged in the design or manufacturing of aircraft components must demonstrate compliance with these airworthiness standards through rigorous testing and certification processes. Non-compliance can result in grounding of aircraft, substantial fines, and reputational damage. As an illustrative example, consider the certification process for a new aircraft engine. The engine manufacturer must demonstrate that the engine meets stringent performance and safety criteria, including tests simulating extreme operating conditions, before the engine can be certified for use in commercial aircraft.

- Export Control Regulations

Export control regulations govern the transfer of sensitive technologies and goods to foreign countries. These regulations are designed to prevent the proliferation of weapons and maintain national security. Organizations operating in the aerospace sector are subject to strict export control requirements, particularly when dealing with technologies related to missile guidance systems, satellite components, or advanced materials. Failure to comply with export control regulations can result in severe penalties, including fines, imprisonment, and the revocation of export privileges. An example of export control in action is the need to obtain licenses before shipping certain types of satellite technology to specific countries that are considered national security risks.

- Environmental Regulations

Environmental regulations aim to minimize the environmental impact of aerospace activities. These regulations address a range of issues, including air and noise pollution, greenhouse gas emissions, and the disposal of hazardous waste. Entities operating in the aerospace industry must comply with environmental regulations related to aircraft engine emissions, noise levels around airports, and the handling of materials like jet fuel and de-icing fluids. Failure to adhere to these regulations can lead to fines, legal action, and reputational harm. An example is the ongoing effort to develop more fuel-efficient aircraft engines to reduce carbon emissions and comply with international climate agreements.

- Data Security and Privacy Regulations

Data security and privacy regulations safeguard sensitive information, including technical data, customer data, and employee records. These regulations are becoming increasingly important in the aerospace sector due to the reliance on digital technologies and the potential for cyberattacks. Organizations must implement robust cybersecurity measures to protect sensitive data from unauthorized access, disclosure, or modification. Non-compliance with data security and privacy regulations can result in fines, legal liabilities, and damage to reputation. An example of data security concern is the protection of sensitive aircraft design data from cyber espionage.

Navigating this complex regulatory landscape requires dedicated expertise and a proactive approach to compliance. The ability to effectively manage regulatory compliance is not merely a legal obligation but a strategic advantage that enhances operational efficiency, mitigates risks, and fosters trust with customers and stakeholders. Proactive engagement with regulatory bodies and continuous monitoring of regulatory changes are essential for maintaining a robust compliance posture and ensuring long-term sustainability. A failure in regulatory compliance undermines the integrity of operations and potentially exposes it to significant legal and financial repercussions.

Frequently Asked Questions

The following addresses prevalent inquiries concerning the functions and impact of aerospace-related business entities. It seeks to clarify operational aspects and dispel potential misconceptions.

Question 1: What fundamental purpose do aerospace systems entities serve?

These entities are primarily engaged in the design, development, manufacturing, and integration of aerospace technologies and systems. Their activities contribute to advancements in aviation, space exploration, and defense capabilities.

Question 2: What are the primary challenges facing entities within the aerospace systems sector?

Significant challenges include managing complex technological integrations, adhering to stringent regulatory requirements, maintaining high levels of quality and reliability, and adapting to rapidly evolving technological landscapes.

Question 3: How does quality assurance impact the operations of aerospace systems companies?

Quality assurance is paramount, ensuring that all components and systems meet rigorous safety and performance standards. Robust quality control processes are essential to mitigate the risk of failures and ensure operational integrity.

Question 4: In what ways does regulatory compliance affect the aerospace industry?

Regulatory compliance imposes stringent requirements on the design, manufacturing, and operation of aerospace systems. Adherence to these regulations is critical for ensuring safety, environmental protection, and adherence to international standards.

Question 5: How do engineering design principles contribute to the success of aerospace systems projects?

Engineering design forms the foundation for innovation and performance in aerospace systems. Advanced design methodologies, simulation tools, and materials science are employed to optimize system performance, reduce weight, and enhance reliability.

Question 6: What role does manufacturing precision play in the production of aerospace components?

Manufacturing precision is crucial for ensuring the dimensional accuracy, material integrity, and overall performance of aerospace components. Tight tolerances and advanced manufacturing techniques are employed to meet demanding specifications.

In summary, the aerospace sector operates under stringent constraints and demands, requiring a multifaceted approach to engineering, manufacturing, quality assurance, and regulatory compliance. These FAQs provide insight into the core considerations that define successful operations in this industry.

The subsequent section will explore case studies to illustrate the practical application of these principles in real-world scenarios.

Conclusion

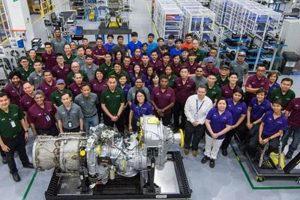

This exploration has illuminated critical facets of operations within the aerospace sector, exemplified by the activities of throttle aerospace systems pvt ltd. Core competencies in engineering design, manufacturing precision, system integration, quality assurance, and regulatory compliance have been delineated. The importance of each area has been underscored through examination of practical implications and industry standards.

Moving forward, continued commitment to excellence across these domains remains essential for sustained success and contribution to the advancement of aerospace technology. Further analysis of specific case studies and technological innovations will undoubtedly provide additional insights into the evolving landscape of this critical industry.