Compensation for professionals in the field of aircraft and spacecraft technology working within the Kingdom of Saudi Arabia is a multifaceted subject, influenced by factors such as experience level, specific job role, educational qualifications, and the employing organization. This remuneration package typically comprises a base salary, complemented by benefits that may include housing allowances, transportation stipends, health insurance, and end-of-service bonuses.

Understanding the income potential for those specializing in the design, development, and testing of aerospace vehicles in this Middle Eastern nation is crucial for several reasons. It informs career planning for aspiring engineers, provides benchmarks for current professionals negotiating compensation, and offers valuable data for educational institutions tailoring their curricula to meet industry demands. Furthermore, this understanding contributes to the overall competitiveness and attractiveness of the Kingdom’s aerospace sector.

This analysis will delve into the typical salary ranges, explore the variables affecting earning potential, examine the benefits packages commonly offered, and compare compensation trends with global standards. By providing a comprehensive overview, this aims to offer a clearer picture of the financial rewards available within the aerospace engineering profession in Saudi Arabia.

Maximizing earning potential within the aerospace engineering field in Saudi Arabia requires a strategic approach, factoring in both personal qualifications and market realities. Careful consideration of the following points can aid in optimizing salary negotiations and career progression.

Tip 1: Invest in Advanced Education: Pursuing a Master’s or Doctoral degree can significantly increase earning potential. Specialized knowledge and research experience are highly valued, often leading to higher starting salaries and faster career advancement.

Tip 2: Acquire In-Demand Skills: Focus on developing expertise in areas with high demand within the Saudi aerospace sector. Examples include composite materials, avionics systems, and unmanned aerial vehicle (UAV) technology. Certifications and specialized training in these areas demonstrate competence and increase marketability.

Tip 3: Gain Relevant Experience: Internships and entry-level positions with reputable aerospace companies operating in Saudi Arabia provide invaluable experience. Demonstrating practical skills and a strong work ethic enhances prospects for higher compensation in subsequent roles.

Tip 4: Network Strategically: Attend industry conferences and workshops to connect with potential employers and gain insights into current salary trends. Building a professional network can provide access to unadvertised job opportunities and insider information regarding compensation packages.

Tip 5: Research Salary Benchmarks: Utilize online resources and industry reports to research average salaries for specific aerospace engineering roles in Saudi Arabia. This information provides a basis for negotiating a fair and competitive salary offer.

Tip 6: Highlight Accomplishments: When negotiating a salary, quantify achievements and demonstrate the value brought to previous employers. Use specific examples to illustrate how skills and experience have contributed to project success and cost savings.

Tip 7: Understand the Total Compensation Package: Consider the entire benefits package, including housing allowances, transportation stipends, health insurance, and end-of-service benefits. These perks can significantly impact the overall financial well-being and should be factored into the salary negotiation process.

By proactively managing skills development, networking effectively, and thoroughly researching compensation benchmarks, individuals can optimize their earning potential within the Saudi Arabian aerospace engineering sector. A well-informed and strategic approach to career management is paramount to maximizing financial rewards.

These strategies offer a framework for career advancement. The subsequent discussion will examine regional variations influencing compensation within the Kingdom.

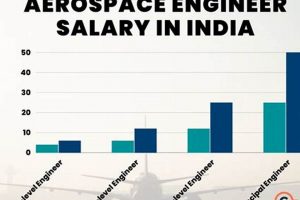

1. Experience Level

The correlation between experience level and compensation within the aerospace engineering sector in Saudi Arabia exhibits a direct and positive relationship. As professionals accumulate years of relevant experience, their earning potential demonstrably increases. This stems from the enhanced proficiency, problem-solving capabilities, and specialized knowledge gained through practical application and exposure to diverse project challenges.

For example, an entry-level aerospace engineer with 0-3 years of experience might focus on basic design tasks or assisting senior engineers, commanding a salary range significantly lower than that of a seasoned engineer with 10+ years of experience. The latter, having likely led complex projects, managed teams, and developed specialized expertise in areas such as aircraft maintenance or systems integration, would be positioned to negotiate a considerably higher salary. The practical significance of this understanding lies in its ability to guide career planning. Aspiring aerospace engineers should recognize the importance of continuous professional development and actively seeking opportunities to broaden their experience base. This can involve pursuing specialized training, taking on leadership roles within projects, and proactively seeking exposure to different facets of the aerospace industry.

The accrued knowledge and demonstrated ability to consistently deliver results are highly valued by employers in the Saudi Arabian aerospace industry. While educational qualifications and technical skills form a foundational base, practical experience serves as a crucial differentiator in determining compensation levels. Consequently, continuous accumulation of relevant experience remains a pivotal factor in maximizing earning potential in this field. A strategic focus on expanding experience, coupled with ongoing professional development, presents the most effective pathway to enhanced remuneration.

2. Educational Attainment

Educational attainment represents a significant determinant of compensation levels within the aerospace engineering sector in Saudi Arabia. Higher levels of education, particularly advanced degrees, often correlate with increased earning potential due to the specialized knowledge and skills acquired.

- Bachelor’s Degree as a Baseline

A bachelor’s degree in aerospace engineering or a related field serves as the fundamental entry requirement for most positions. While it establishes a foundation, it may result in a lower starting salary compared to candidates with advanced qualifications. Individuals with only a bachelor’s degree typically occupy entry-level roles, performing routine engineering tasks under supervision. The compensation reflects the basic skill set and limited independent decision-making involved.

- Master’s Degree: Specialization and Advancement

A Master’s degree signifies specialized knowledge within a particular area of aerospace engineering, such as aerodynamics, propulsion, or control systems. This level of education equips engineers with advanced analytical and problem-solving skills, making them more valuable to employers. Consequently, individuals holding a Master’s degree often command higher salaries and are considered for more complex and responsible roles, such as project engineers or design specialists. Their expertise allows them to contribute more effectively to research and development efforts, further justifying increased compensation.

- Doctorate (Ph.D.): Research and Leadership

A doctorate represents the highest level of formal education and signifies expertise in conducting original research and developing innovative solutions. Ph.D. holders are typically sought after for research and development positions in academia, government research institutions, and leading aerospace companies. Their advanced knowledge and research capabilities allow them to lead complex projects, develop new technologies, and contribute to the advancement of the aerospace field. As a result, individuals with a Ph.D. typically earn significantly higher salaries than those with lower levels of education.

- Certifications and Professional Development

Beyond formal degrees, certifications and ongoing professional development play a crucial role. Certifications demonstrate competency in specific areas (e.g., project management, specific software). Continuous learning keeps engineers abreast of technological advancements. These supplementary credentials enhance marketability and often translate to higher earning potential by demonstrating a commitment to professional growth and specialized expertise.

In conclusion, the level of educational attainment plays a vital role in determining compensation within the aerospace engineering sector in Saudi Arabia. Advanced degrees, particularly a Master’s or Ph.D., provide engineers with specialized knowledge and skills that are highly valued by employers, leading to increased earning potential. Continuous professional development and certifications further enhance an engineer’s marketability and contribute to higher salary levels, reflecting the dynamic and technologically advanced nature of the aerospace industry.

3. Job Role Specificity

The specific role an aerospace engineer holds within an organization operating in Saudi Arabia significantly influences the compensation received. Different roles demand varying levels of expertise, responsibility, and specialized skills, which are directly reflected in salary scales.

- Design Engineer

Design engineers are responsible for creating and developing technical designs for aircraft, spacecraft, and related components. Their duties involve utilizing computer-aided design (CAD) software, conducting simulations, and ensuring designs meet stringent performance and safety requirements. Within Saudi Arabia, a design engineer’s salary is influenced by experience with specific design tools, familiarity with regulatory standards such as those set by the Saudi Standards, Metrology and Quality Organization (SASO), and the complexity of the projects undertaken. For example, a design engineer working on commercial aircraft modifications may earn a different salary compared to one designing components for military aircraft due to variations in project scope and technical demands.

- Project Manager

Project managers oversee the planning, execution, and completion of aerospace engineering projects. Responsibilities include managing budgets, coordinating teams, ensuring compliance with project timelines, and mitigating risks. In the Saudi context, a project manager’s salary is contingent upon factors such as the scale and complexity of the projects managed, the number of personnel supervised, and the proven ability to deliver projects successfully within established constraints. A project manager handling the development of a new air traffic control system, for instance, would likely command a higher salary than one managing smaller-scale maintenance projects due to the increased complexity and broader impact of the project.

- Avionics Engineer

Avionics engineers specialize in the design, development, and maintenance of electronic systems used in aircraft, including navigation, communication, and flight control systems. Their tasks include troubleshooting technical issues, conducting system testing, and ensuring compliance with aviation regulations. The compensation for avionics engineers in Saudi Arabia depends on their expertise in specific avionics systems, familiarity with relevant international standards (e.g., FAA, EASA), and their ability to integrate and maintain complex electronic equipment. Avionics engineers with specialized knowledge of military aircraft systems may earn a premium due to the sensitive nature of their work.

- Maintenance, Repair, and Overhaul (MRO) Engineer

MRO engineers are responsible for ensuring the airworthiness and safe operation of aircraft through regular maintenance, repairs, and overhauls. This involves conducting inspections, performing repairs, replacing defective components, and adhering to strict maintenance schedules. The salary of an MRO engineer in Saudi Arabia is influenced by their level of certification (e.g., FAA A&P license), experience with different types of aircraft, and familiarity with maintenance procedures mandated by aviation authorities. MRO engineers working on high-value commercial aircraft or specialized military platforms may receive higher compensation due to the criticality of their role in ensuring flight safety and operational readiness.

In summary, the specific job role undertaken by an aerospace engineer within the Saudi Arabian aerospace industry has a profound effect on the ultimate compensation received. Factors such as the level of expertise required, the scope of responsibilities, and the demand for specific skill sets within the industry all contribute to the variance in salary scales across different job functions.

4. Employer Type

The type of organization employing an aerospace engineer within Saudi Arabia exerts a substantial influence on the compensation structure. Variations in funding models, operational priorities, and strategic objectives among different employer categories directly impact salary ranges and benefits packages.

- Government Entities

Government-affiliated organizations, such as the Saudi Arabian Military Industries (SAMI) or governmental research institutions, often offer competitive salaries with comprehensive benefits packages. These packages may include housing allowances, transportation stipends, and generous end-of-service bonuses. While salaries may not always reach the peak levels offered by some private companies, the stability and long-term career prospects associated with government employment are often considered valuable advantages. Compensation structures are frequently standardized according to established government pay scales, which factor in experience, education, and job grade. Investment in national infrastructure and defense may drive increased demand, leading to competitive compensation packages to attract qualified engineers.

- International Aerospace Corporations

Multinational aerospace companies operating within Saudi Arabia typically offer salaries benchmarked against global standards to attract and retain top talent. These organizations may provide additional expatriate benefits, such as international schooling allowances and relocation assistance. While the base salary might be comparable to or slightly higher than that offered by local companies, the overall compensation package, including benefits and opportunities for international training and development, can be significantly more attractive. Furthermore, exposure to advanced technologies and international best practices enhances the long-term career prospects for engineers employed by these corporations. These corporations often engage in joint ventures or partnerships, influencing compensation norms.

- Private Saudi Companies

Privately-owned Saudi Arabian aerospace companies exhibit a wider range in compensation structures, influenced by factors such as company size, profitability, and strategic focus. Larger, more established private companies often offer competitive salaries and benefits packages comparable to those provided by government entities. However, smaller or newer companies may offer lower base salaries, potentially supplemented by performance-based bonuses or equity incentives. The compensation structures may be more flexible and tailored to individual skills and contributions compared to the standardized pay scales of government organizations. Privatization initiatives and growing investments in the aerospace sector may elevate compensation levels in such firms.

- Joint Ventures

Joint ventures between international and Saudi Arabian entities represent a unique employment landscape. Compensation structures in these organizations often blend aspects of both international and local pay scales and benefit practices. The level of international influence and the specific terms of the joint venture agreement significantly impact salary levels. Engineers working in these ventures may benefit from exposure to diverse operational methodologies and potentially receive compensation packages more competitive than those offered by purely local firms. Transfer of knowledge and technological expertise may lead to higher valuations of skilled engineers.

In summation, the employer type is a crucial determinant of aerospace engineering compensation within the Kingdom. Governmental organizations, international corporations, and private companies each offer distinct remuneration structures. These structures reflect variations in operational priorities, strategic objectives, and compensation philosophies. Job seekers should carefully consider these factors when evaluating employment opportunities to maximize financial benefits and align their career goals with organizational characteristics. Understanding the market position and operational dynamics of prospective employers empowers candidates to effectively negotiate favorable compensation packages.

5. Geographic Location

The geographical location within Saudi Arabia significantly influences the compensation packages offered to aerospace engineers. Variations in cost of living, industrial concentration, and regional development priorities contribute to discernible differences in salary levels across the Kingdom.

- Riyadh: Central Hub and Capital City

As the capital and a major economic center, Riyadh hosts numerous government entities, research institutions, and private aerospace companies. The concentration of these organizations drives demand for skilled engineers, leading to generally higher salary levels compared to other regions. The cost of living in Riyadh, particularly regarding housing, also contributes to elevated compensation packages. Furthermore, strategic government investments in aerospace initiatives within the capital region further bolster salary competitiveness.

- Jeddah: Coastal Commercial Center

Jeddah, a major port city and commercial hub on the Red Sea coast, presents a different employment landscape. While aerospace opportunities exist, they may be concentrated in areas related to aircraft maintenance, logistics, and support services for the aviation industry. While the cost of living can be significant, housing may be cheaper in the suburbs, influencing salary expectations compared to Riyadh. Salaries in Jeddah may reflect the city’s focus on commerce and tourism, potentially offering different benefits and career progression paths.

- Eastern Province: Industrial and Energy Sector

The Eastern Province, known for its concentration of oil and gas industries, may offer aerospace engineering opportunities related to specialized applications in those sectors, such as drone technology for pipeline inspection or advanced materials research. Salary levels could be competitive due to the overall high wages prevalent in the energy industry. However, opportunities directly related to traditional aerospace engineering might be less prevalent compared to Riyadh. The remote location of some facilities in the province might also influence compensation considerations. Specialized skills relevant to both the aerospace and energy sectors will likely command a premium.

- Emerging Economic Zones: NEOM and Other Projects

Large-scale development projects, such as NEOM and other new economic zones, present potential future opportunities for aerospace engineers. As these zones develop their infrastructure and attract aerospace-related businesses, demand for skilled professionals could increase significantly. Compensation packages in these emerging zones may be particularly attractive to incentivize relocation and participation in groundbreaking projects. Factors such as project funding, availability of amenities, and long-term growth prospects will influence salary expectations. These regions are likely to focus on innovative aerospace technologies, thereby rewarding specialists.

In conclusion, geographical location within Saudi Arabia is a key factor influencing the compensation of aerospace engineers. Riyadh, as the capital and economic hub, generally offers higher salaries due to the concentration of government entities and private companies. Jeddah’s focus on commerce and logistics presents different opportunities with potentially varying compensation levels. The Eastern Province’s energy sector may offer specialized aerospace applications with competitive wages. Emerging economic zones, such as NEOM, hold promise for future growth and attractive compensation packages. Therefore, individuals seeking employment in the Saudi aerospace industry should carefully consider regional variations in cost of living, industrial concentration, and development priorities when evaluating job offers.

6. Skill Specialization

Within the Saudi Arabian aerospace engineering sector, the degree of skill specialization significantly influences compensation. Focused expertise in specific, high-demand areas commands premium salaries, reflecting the value placed on specialized knowledge and capabilities within this technologically advanced industry.

- Aerodynamics and Fluid Dynamics

Expertise in aerodynamics and fluid dynamics is crucial for aircraft design and performance optimization. Engineers skilled in computational fluid dynamics (CFD) simulations and wind tunnel testing are highly sought after. The ability to improve aerodynamic efficiency, reduce drag, and enhance aircraft stability directly translates to fuel savings and improved performance, justifying higher salaries. For instance, engineers specializing in advanced wing design for commercial aircraft or optimizing the aerodynamics of unmanned aerial vehicles (UAVs) often command top-tier compensation due to the tangible impact of their work.

- Avionics and Control Systems

Specialization in avionics and control systems is vital for the safe and efficient operation of aircraft. Engineers proficient in designing, developing, and integrating electronic systems, navigation systems, and flight control systems are in high demand. Proficiency in areas such as radar systems, communication systems, and autopilot systems increases marketability and earning potential. In the Saudi Arabian context, expertise in integrating advanced avionics into military aircraft or developing sophisticated control systems for unmanned systems directly impacts national security, further increasing the value of these skills.

- Composite Materials and Structures

Expertise in composite materials and structures is increasingly important for designing lightweight and durable aircraft components. Engineers skilled in the selection, testing, and manufacturing of composite materials are highly valued. The ability to reduce aircraft weight while maintaining structural integrity leads to improved fuel efficiency and enhanced performance, justifying higher salaries. For example, engineers specializing in the design and analysis of composite wings or fuselages for commercial or military aircraft are typically well-compensated due to the critical role they play in aircraft performance and safety.

- Propulsion Systems

Specialization in propulsion systems, including gas turbine engines and rocket propulsion, is essential for the development and maintenance of aircraft and spacecraft. Engineers with expertise in engine design, performance analysis, and emissions reduction are in high demand. The ability to improve engine efficiency, reduce fuel consumption, and minimize environmental impact directly translates to cost savings and enhanced sustainability, justifying higher salaries. Engineers specializing in the design and testing of advanced jet engines or developing innovative rocket propulsion systems are highly sought after within the Saudi Arabian aerospace industry.

- UAV Technology and Integration

With growing interest in Unmanned Aerial Vehicle (UAV) or drone technology, engineers specializing in design, control, and integration of drone systems are in demand. Their work includes developing software algorithms for autonomous navigation, testing new propulsion systems, or refining aerodynamic designs for specific mission profiles. Expertise in drone-specific software or hardware can command a salary premium given growing civilian and military use cases. Experience with counter-drone technologies is increasingly relevant as well.

In summation, specialized skills significantly impact compensation levels within the Saudi Arabian aerospace engineering sector. Expertise in aerodynamics, avionics, composite materials, propulsion systems and UAV technology drives salary differentiation. Engineers possessing these in-demand skills command premium compensation packages, reflecting the value placed on specialized knowledge and capabilities in this technologically advanced industry.

7. Economic Conditions

The overall health and trajectory of the Saudi Arabian economy exert a palpable influence on compensation levels within the aerospace engineering sector. Macroeconomic indicators, such as gross domestic product (GDP) growth, government spending on infrastructure and defense, and fluctuations in oil prices, directly impact the demand for and valuation of skilled aerospace professionals. Periods of economic expansion, characterized by increased investment in aerospace-related projects and infrastructure development, typically lead to heightened demand for engineers, thereby driving salaries upward. Conversely, economic downturns or periods of fiscal austerity may result in hiring freezes, reduced salary growth, or even workforce reductions, negatively impacting compensation prospects. The Saudi Vision 2030 initiative, with its emphasis on diversifying the economy and developing a robust domestic defense industry, serves as a key driver of aerospace investment. Successful implementation of these initiatives is expected to create new opportunities and elevate the demand for skilled aerospace engineers, positively influencing salary levels. For example, increased government contracts awarded to domestic aerospace companies would stimulate hiring and potentially lead to bidding wars for qualified engineers, pushing salaries upward.

Furthermore, fluctuations in global oil prices, a significant contributor to the Saudi Arabian economy, can have indirect yet substantial effects. Lower oil prices may reduce government revenue, potentially leading to budget cuts in aerospace-related projects. This could result in decreased demand for engineers and downward pressure on salaries. Conversely, higher oil prices may bolster government revenue, allowing for increased investment in aerospace initiatives and a corresponding increase in compensation levels. The practical significance of understanding this relationship lies in the ability of aerospace engineers to anticipate potential shifts in the job market and adjust their career strategies accordingly. Engineers should monitor macroeconomic trends and government policies to identify emerging opportunities and potential risks, enabling them to make informed decisions regarding career advancement, salary negotiations, and skill development. Proactive monitoring of economic indicators will aid professionals in navigating the evolving landscape of the Saudi Arabian aerospace industry.

In conclusion, economic conditions serve as a fundamental determinant of aerospace engineering salaries in Saudi Arabia. Government spending, oil price fluctuations, and the success of economic diversification initiatives like Vision 2030 all contribute to the overall demand for and valuation of skilled engineers. By closely monitoring these economic indicators and understanding their potential impact on the aerospace sector, professionals can proactively manage their careers and maximize their earning potential. However, uncertainties in global markets and the evolving nature of government policies pose ongoing challenges, necessitating continuous adaptation and strategic planning to navigate the dynamic landscape of the Saudi Arabian aerospace industry.

Frequently Asked Questions

This section addresses common queries regarding the financial aspects of pursuing a career in aerospace engineering within the Kingdom of Saudi Arabia. The information presented aims to provide clarity and informed guidance to prospective and current professionals in this field.

Question 1: What is the typical starting salary for an aerospace engineer in Saudi Arabia?

Entry-level salaries for aerospace engineers in Saudi Arabia vary depending on factors such as the employer, educational qualifications, and specific job responsibilities. However, a reasonable estimate for a recent graduate with a Bachelor’s degree falls within a specific range, which is influenced by prevailing market conditions.

Question 2: How does experience impact the earning potential of aerospace engineers in Saudi Arabia?

Experience plays a crucial role in determining compensation. As aerospace engineers accumulate practical experience, their salaries typically increase to reflect their enhanced skills, problem-solving abilities, and project management capabilities. Engineers with several years of experience often command significantly higher salaries compared to entry-level professionals.

Question 3: What are the most valuable skills for maximizing earning potential as an aerospace engineer in Saudi Arabia?

Certain specialized skills are highly sought after within the Saudi aerospace industry. Expertise in areas such as avionics, composite materials, propulsion systems, and unmanned aerial vehicle (UAV) technology can significantly enhance earning potential. Acquiring certifications and pursuing professional development opportunities in these areas is advisable.

Question 4: Do salaries for aerospace engineers vary significantly across different regions within Saudi Arabia?

Geographic location does influence compensation. Salaries in major metropolitan areas, such as Riyadh and Jeddah, may be higher to reflect the higher cost of living and the concentration of aerospace-related organizations. Opportunities and salary ranges may vary in other regions of the Kingdom.

Question 5: What benefits are typically included in the compensation packages offered to aerospace engineers in Saudi Arabia?

In addition to base salary, compensation packages often include benefits such as housing allowances, transportation stipends, health insurance, and end-of-service bonuses. The specific benefits offered can vary depending on the employer and the terms of the employment contract. These benefits add substantial value to the overall compensation package.

Question 6: How does the compensation of aerospace engineers in Saudi Arabia compare to global averages?

Compensation levels for aerospace engineers in Saudi Arabia can be competitive compared to global averages, particularly for experienced professionals with specialized skills. However, variations may exist depending on factors such as the specific job role, the size and type of the employing organization, and the prevailing economic conditions.

In summary, compensation for aerospace engineers in Saudi Arabia is influenced by a complex interplay of factors, including experience, skills, location, and employer type. Careful consideration of these factors is essential for individuals seeking to maximize their earning potential in this dynamic field.

The following section will explore resources for staying informed about industry trends and salary benchmarks.

Aerospace Engineering Salary in Saudi Arabia

The preceding analysis has illuminated the multifaceted nature of aerospace engineering salary in Saudi Arabia. Key determinants such as experience, education, job role, employer type, geographic location, skill specialization, and prevailing economic conditions exert considerable influence on compensation levels. Understanding these factors is paramount for individuals seeking to enter or advance within the Saudi aerospace sector.

Navigating the landscape of aerospace engineering compensation in Saudi Arabia requires diligence in acquiring in-demand skills, strategic career planning, and continuous monitoring of industry trends. While external factors, such as economic fluctuations and government policies, introduce elements of uncertainty, a proactive and informed approach will empower professionals to optimize their earning potential and contribute to the Kingdom’s growing aerospace industry. Continued investment in education and specialized training remains crucial for long-term career success.